Coronavirus Technology Solutions

May 7, 2020

Bassaire Provides Containment Rooms and Fan

Filter Units

Avantor in Unique Position To

Supply Products to Mitigate the Coronavirus

Upscale KN95 Masks Available

10,000 COVID Cases in the

Meat Packing Industry

FDA Withdraws Approval of

Sixty Chinese Mask Designs

Poor

Ventilation Rather Than Momentary Contact is the

Bigger Threat

McIlvaine Provides a Coronavirus Solution Bridge

Between Suppliers and the Food Processing

Industry

_____________________________________________________________________________

Bassaire Provides Containment Rooms and Fan

Filter Units

Bassaire is the oldest cleanroom company in the

UK and has been awarded ISO9001 accreditation.

The company has considerable experience in

building pharmaceutical cleanrooms. It also

supplies fan filter units and will be a resource

for coronavirus mitigation.

http://www.bassaire.co.uk/

Avantor in Unique

Position To Supply Products to Mitigate the

Coronavirus

In 2018 Avantor acquired VWR for approximately

$6.4 billion cash, in a deal the companies said

would create a combined global provider

of consumables-focused solutions and services to

life sciences and advanced technologies

businesses, as well as education, government,

and research institutions.

The deal was designed to enable the combined

company to serve customers from research through

production by joining Avantor’s strengths in

cGMP manufacturing processes and significant

exposure to emerging markets with VWR’s focus on

providing product and service solutions to

laboratory and production customers in the

Americas and Europe.

VWR supplies masks, gowns, gloves and other

consumables.

It also supplies hardware from various

manufacturers such as clean benches from

Bassaire (covered in the previous article).

VWR® Advanced Protection Face Masks offer

excellent bacteria and particulate protection

and are available in multiple styles to provide

security and comfort throughout extended use.

-

Guards against bacteria and

particulates

-

Highly breathable and fluid

resistant

-

Malleable noseband ensures

custom, secure seal

-

Soft and hypoallergenic

Masks feature three-ply construction for

excellent particle and bacterial filtration

efficiency. Available in two styles, with

spandex ear loops or polypropylene ties

ultrasonically welded to maintain softness and

protect against particulates. An encased, 12cm

(43/4") malleable steel

nose-band creates a secure facial seal and

improves wearer comfort. Latex-free. Masks are

rigorously tested and manufactured in an ISO

Certified facility under stringent process

controls to ensure that each product meets

exacting quality standards. Products are

validated through independent lab testing.

|

Description |

Color |

VWR Catalog Number |

Unit |

Price |

|

Mask with Ear Loops |

Green |

414004-663 |

Case of 500 |

$236.78 |

|

Pallet of 30000 |

$14,164.42 |

|||

|

Mask with Ear Loops |

Blue |

414004-662 |

Case of 500 |

$236.78 |

|

Pallet of 20000 |

$9,442.94 |

|||

|

Mask with Ear Loops |

Yellow |

414004-665 |

Case of 500 |

$231.95 |

|

Pallet of 25000 |

$11,593.12 |

|||

|

Mask with Ear Loops |

Pink |

414004-664 |

Case of 500 |

$232.13 |

|

Mask with Ties |

Blue |

414004-666 |

Case of 500 |

$235.62 |

|

Pallet of 18000 |

$8,472.51 |

Upscale KN95 Masks Available

We have previously written about Vogmask with

designer type high efficiency washable masks

selling for $33. Here is mask which sells for

around $5 from 22 Mask.

The mask complies

with national standard GB2626-2006.

Filtration efficiency is not less than 95%.

Effective Protection: 5 layers of protection,

disposable dust mask, activated carbon layer,

non-woven fabric layer, double electrostatic

absorption cotton and soft non-woven fabric

layer. Can filter tiny dust, pollen, particulate

matter and almost 95% of particles in the air.

https://22mask.com/masks-sale/kn95-mask-protection-efficency-95-anti-particle-mask-10-pcs/

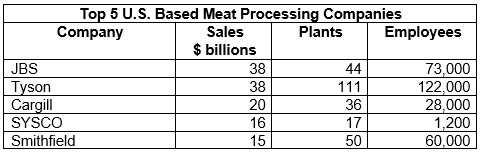

10,000 COVID Cases

in the Meat Packing Industry

The meatpacking industry hit a grim milestone

this week when the number of coronavirus cases

tied to outbreaks at its plants passed 10,000,

according to USA TODAY and Midwest Center for

Investigative Reporting tracking.

At least 170 plants in 29 states have had one or

more workers test positive for the coronavirus.

Some of those workers also have infected others,

which is included in the count. At least 45

workers have died.

The outbreaks have prompted at least 40 meat

slaughtering and processing plant closures –

lasting anywhere from one day to several weeks –

since the start of the pandemic.

The shutdowns sparked meat shortages in some

parts of the country and triggered an executive

order by President Donald Trump to keep plants

open. But more than a week after Trump’s order,

closures have continued unabated, the media

outlets found.

Many companies said they have implemented social

distancing measures for workers, but Smithfield

Foods, one of the largest meatpacking companies

in the U.S., said doing so would be difficult.

"There are inescapable realities about our

industry," a statement on its website reads.

"Meat processing facilities, which are

characterized by labor-intensive assembly-line

style production, are not designed for social

distancing."

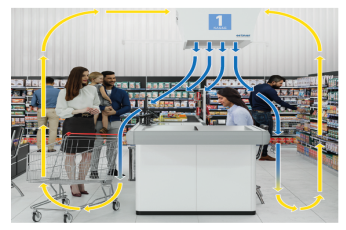

In this poultry processing plant it will be very

difficult to install partitions. These would

also be ineffective as explained in previous

alerts. The solution will be laminar downward

flow from HEPA filters about 8 feet above the

floor and air returns

which allow air to flow at floor level

behind the workstations.

The flow above the poultry workers would be

similar to the flow above the cashier and

customer at a checkout counter.

There would be a series of fan filter units on

the poultry processing line just as there would

be a series of fan filter units at checkout

counters.

FDA Withdraws

Approval of Sixty Chinese Mask Designs

Federal officials withdrew approval for more

than 60 manufacturers in China to export

N95-style masks to the U.S. after finding what

they said were a large number of low-quality

products from those companies.

The Food and Drug Administration said Thursday

that it had cut the number of

mask makers in

China approved

to make N95-style masks for use in the U.S. to

14, from around 80. That reversed an April 3

decision to allow imports from manufacturers

whose masks hadn’t been tested by U.S.

authorities but had been reviewed by an

independent laboratory.

The shift illustrates the challenge to federal

officials who are trying to help meet huge

demand for masks from front-line workers

battling the coronavirus pandemic, while also

ensuring that medical gear works effectively.

“We’ve been using all of our authorities to

increase availability,” an FDA official said in

an interview. “There were a growing number of

respirators that failed to meet the expedited

performance standards.”

Poor Ventilation

Rather Than Momentary Contact is the Bigger

Threat

Scientists agree that the virus primarily

spreads between people

via droplets

that fly through the air when an infected person

coughs, sneezes, or speaks. Evidence also

increasingly shows that the risk of infection is

much higher in poorly ventilated, crowded

areas.

So while it can be jarring to have a runner

invade your 6-foot bubble, that fleeting moment

is

far less risky

than, say, working in an office with hundreds of

colleagues.

A recent study about an outbreak in a call

center in Seoul, South Korea, revealed that

almost

half the employees

on one floor

got infected. Nearly all of them sat in the same

section.

That makes the prospect of returning to offices

risky.

The more time you spend near someone who has

COVID-19, the higher the chance their infectious

droplets make it over to your face.

"I would not worry about walking by someone,"

Dr. Amesh Adalja, an infectious-disease

specialist at Johns Hopkins University, told

Slate.

"Even in a healthcare setting, contact is

defined by being near someone for a certain

amount of time. I would not worry about these

fleeting encounters."

Airflow matters, too. "In such a tightly

enclosed space without vigorous air movement for

a short period of time, I'm afraid you might be

exposed," Schaffner

previously told

Business Insider.

The same goes for hospitals.

A study

published last week in the journal Nature found

that virus particles were most highly

concentrated in the air within the 9-square-foot

toilet areas in patients' rooms in two hospitals

in Wuhan, China. These toilets were not

ventilated.

In ventilated ward areas, however, the amount of

virus was very low, a difference the authors

attributed to proper air circulation.

McIlvaine Provides a Coronavirus Solution Bridge

Between Suppliers and the Food Processing

Industry

Food processors around the world employ millions

of workers and generate trillions of dollars in

annual sales. The U.S meat packing industry has

reported over 10,000 coronavirus cases.

At least 170 plants in 29 states have had one or

more workers test positive for the coronavirus.

Social distancing is not an option as

shown by this poultry processing plant.

The initiative to install partitions and to

choose masks less efficient than N95 will not be

a solution.

Instead a whole suite of control

technologies with foot sanitizers, fan filter

units, laminar air flow, N95 masks and other PPE

will be the answer

McIlvaine is acting as a bridge between

suppliers and food processors to help them

understand their options and make the best

decisions for their plants. Daily Alerts,

interviews and webinars are part of the

McIlvaine program. The daily Alerts have details

on specific plant problems and solutions which

are cost effective.

They can be searched as per the example

for “pork” below

Search results for: pork

10 results found.

Sorted by relevance / Sort

by date

1. McIlvaine

Coronavirus Market Ale

... April

16, 2020 Ventilation and Filtration Important in

Buildings to Mitigate the Virus Impact Pork Processing

Plant in South Dakota Tries to Cope with 600

COVID Cases Meat Processing Plants ...

2. McIlvaine

Coronavirus Market Ale

... for

JBS, the American subsidiary of the world's

largest processor of fresh beef and pork.

This week there probably will be around 500,000

head processed at U.S ...

4. McIlvaine

Coronavirus Market Ale

... scanner

purchases. So far, the scanners have been

installed in four facilities; pork plants

in Iowa and Indiana and poultry plants in

Arkansas and Georgia. The company ...

5. McIlvaine

Coronavirus Market Ale

... Workers

Return to Wisconsin Meat Plant with 85 Positive

Cases 116 COVID Cases at Oklahoma Pork Plant

UNMC Provides a Draft Guidance on HVAC and Masks

for Meat Processors ____ ...

6. McIlvaine

Coronavirus Market Ale

... That

has a big implication for Hong Kong, which

imported all of its fresh pork and

94 per cent of its fresh beef from mainland

China. Billion Dollar Meat ...

7. McIlvaine

Coronavirus Market Ale

... which

are federally inspected. In March, the country

saw meat, beef and pork production

reach record highs, according to the US

Agriculture Department (USDA) . ...

8. McIlvaine

Coronavirus Market Ale

... improve

product quality. Studies have shown that cleaner

environments can result in extension of pork shelf

life by 12 days. Here are some of the mitigation

technologies which can ...

9. McIlvaine

Coronavirus Market Ale

... been

investigated and deemed unfounded. In Buchanan

County, Missouri, a Triumph Foods pork plant

in St. Joseph is the only cluster of virus

outbreaks, said Mary ...

10. McIlvaine

Coronavirus Market Ale

... .

These facilities represent more than 1 in 3 of

the nation's biggest beef, pork and

poultry processing plants. Rates of infection

around these plants are higher than those ...

html

McIlvaine assists suppliers reaching those with

needs as per the following example.

|

First Name |

Last Name |

Company |

City |

State |

Title |

email |

Phone |

|

Rudy |

X |

Creekstone Farms

Premium Beef |

Arkansas City |

KS |

General Manager |

X |

X |

|

Stephen

|

X |

CTI Foods |

Dallas |

TX |

Maintenance Mgr |

X |

X |

|

Michael (Mike) |

X |

Allen Harim

Foods |

Dover |

DE |

Plant Operation |

X |

X |

|

Brian

|

X |

Golden State

Foods |

Irvine |

CA |

Chief Operating

Officer |

X |

X |

|

Eric |

X |

Chicago |

IL |

Plant Manager |

X |

X |

|

|

Daniel |

X |

Bell & Evans |

Annville |

PA |

Chief Operating

Officer |

X |

X |

|

Daniel

|

X |

Golden State

Foods |

Jefferson |

GA |

Director/

Quality & Food

Safety |

X |

X |

|

Tracy |

X |

Allen Harim

Foods |

Millsboro |

DE |

Sr.

Director/Operations

& Environmental |

X |

X |

|

Kyle |

X |

Tyson Foods |

Fayetteville |

AR |

Engineer III PM

Prep Food

Division |

X |

X |

|

Matthew |

X |

SugarCreek |

West Chester |

OH |

Packaging

Engineer |

X |

X |

|

Nathan |

X |

Eddy Packing Co.

Inc. |

Salt Lake City |

UT |

Chief Operating

Officer |

X |

X |

|

Jerry |

X |

Strauss Brands,

Inc |

Milwaukee |

WI |

President |

X |

X |

|

Greg |

X |

Strauss Brands,

Inc |

Milwaukee |

WI |

Chief Operating

Officer |

X |

X |

|

Mark

|

X |

Strauss Brands,

Inc |

Milwaukee |

WI |

Creative

Director |

X |

X |

Over 500,000 people work in the animal

slaughtering and processing industry in the

U.S. 331,000 are in production. The top 100 U.S.

based meat processing companies employ more than

500,000 people but many are not in the plants.

Nevertheless office workers will need to be

protected as well.

Food processing is just one of the applications

covered in this worldwide service.

Coronavirus Technology Solutions

Click here for more information

Bob McIlvaine can answer your questions at

rmcilvaine@mcilvainecompany.com

or by cell at 847 226 2391