Coronavirus Technology Solutions

April 29, 2020

Sterilucent has Authorization from FDA for H2O2

Sterilization of Masks

Viruses Released to the Air While Doffing PPE

Minimum Dose and Viral Load are Crucial Factors

Reverse Engineer a Semiconductor Cleanroom

Masks with Valves have Advantages but Design and

Maintenance are a Challenge

Coronavirus Detected on Air Pollution Particles

Trump

Orders Meat Processing Plants to Stay

Open

Leprino Foods Shuts Dairy Food Plant Due to

Virus

Air Showers are a Way to Reduce Virus in Locker

Room Areas

Converting Patient Rooms to Negative Pressure

Isolation

Mecart Providing Modular Isolation Rooms to

Hospitals

Puracore COVID -19 Containment Modules

Immediately Available

What Level of Filtration is Necessary?

______________________________________________________________________________

Sterilucent has Authorization from FDA for H2O2

Sterilization of Masks

The U.S. Food and Drug

Administration has granted Sterilucent, Inc.

(Minneapolis, MN), an Emergency Use

Authorization to allow the emergency use of the

Sterilucent™ HC 80TT Vaporized Hydrogen Peroxide

Sterilizer for decontaminating single-use

compatible N95 and N95-equivalent respirators.

Test results have

demonstrated that filtering facepiece

respirators may be reprocessed for use during

the COVID-19 pandemic in the HC 80TT Flexible

Cycle up to 10 times without a detrimental

impact on filtration performance or a

significant reduction in respirator fit. The

system can reprocess up to 12 respirators at a

time.

“We are glad to be able to

help extend the safe use of PPE for healthcare

staff during this time of overburdened supply

chains,” said Chief Operating Officer Stephen

Loes. “The HC 80TT sterilizer can provide timely

internal turnaround of PPE that helps extend a

facility’s inventory and better manage supply

disruption or unavailability. Unlike other

systems that deliver fixed amounts of

chemistries for all load sizes for the selected

cycle, the HC 80TT Cycle Guardian™ technology

dynamically adjusts delivery of the sterilant

needed based on the load in the chamber. The N95

load is light and, therefore, the HC 80TT

sterilizer delivers less chemistry, resulting in

less degradation of the respirator and lowering

the cost per cycle for the facility.”

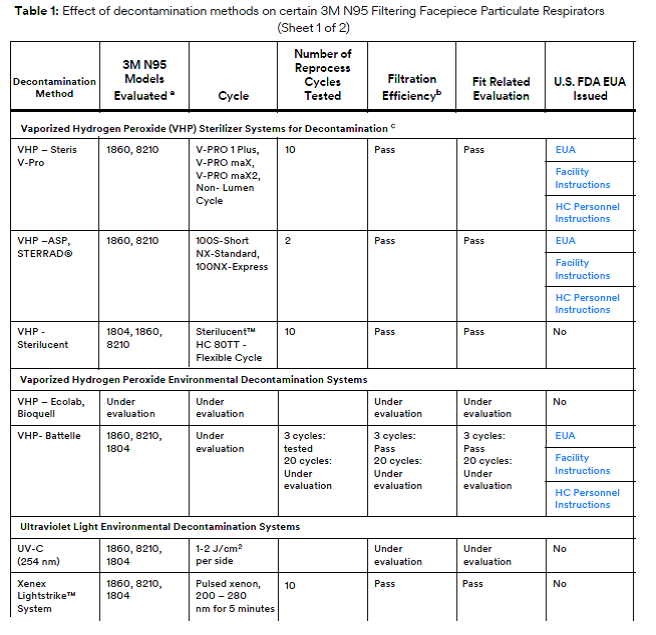

3M provides a regularly

updated Technical Bulletin that discusses the

CDC COVID-19 guidelines for decontaminating N95

respirators. The bulletin includes systems

acceptable for mask reprocessing and those to

avoid. The Sterilucent HC 80TT sterilizer is

listed in Table 1, which summarizes the effects

of decontamination methods on 3M respirators.

Details on the Sterilucent

guidelines by FDA are shown at

https://www.fda.gov/media/137170/download

Viruses Released to the Air While Doffing PPE

At two hospitals in Wuhan, China, researchers

found bits of the virus’s genetic material

floating in the air of hospital toilets, an

indoor space housing large crowds, and rooms

where medical staff take off protective gear.

The study, published Monday in the journal

Nature Research, didn’t seek to establish

whether the airborne particles could cause

infections.

People produce two types of droplets when they

breathe, cough or talk. Larger ones drop to the

ground before they evaporate, causing

contamination mostly via the objects on which

they settle. Smaller ones - those that make up

aerosols - can hang in the air for hours.

The researchers, led by Ke Lan of Wuhan

University, set up so-called aerosol

traps in and around two hospitals in the city

that was home to the pandemic’s first steps.

They found few aerosols in patient wards,

supermarkets and residential buildings. Many

more were detected in toilets and two areas that

had large crowds passing through, including an

indoor space near one of the hospitals.

Especially high concentrations appeared in the

rooms where medical staff doff protective

equipment, which may suggest that particles

contaminating their gear became airborne again

when masks, gloves and gowns are removed.

The findings highlight the importance of

ventilation, limiting crowds and careful

sanitation efforts, the researchers said.

Minimum Dose and Viral Load are Crucial Factors

Infectious respiratory diseases spread when a

healthy person comes in contact with virus

particles expelled by someone who is sick —

usually through a cough or sneeze. The amount of

particles a person is exposed to can affect how

likely they are to become infected and, once

infected, how severe the symptoms become. This

observation by Alex Hogan is included in a good

article on virus load and minimum dose.

The amount of virus necessary to make a person

sick is called the infectious dose. Viruses with

low infectious doses are especially contagious

in populations without significant immunity.

The minimum infectious dose of SARS-CoV-2, the

virus that causes Covid-19, is unknown so far,

but researchers suspect it is low. “The virus is

spread through very, very casual interpersonal

contact,” W. David Hardy, a professor of

infectious disease at Johns Hopkins University

School of Medicine, told STAT.

A high infectious dose may lead to a higher

viral load, which can impact the severity of

Covid-19 symptoms.

Viral load is a measure of virus particles. It

is the amount of virus present once a person has

been infected and the virus has had time to

replicate in their cells. With most viruses,

higher viral loads are associated with worse

outcomes.

The more viral particles that get into the

lungs, the more damage to the lungs that is

probably happening,” said Hardy.

One study of

Covid-19 patients in China found that those with

more severe symptoms tended to have higher viral

loads.

“It’s not proven, but it would make sense that

higher inoculating doses will lead to higher

viral loads, and higher viral loads would

translate into more pathogenic clinical

courses,” said Dan Barouch, director of the

Center for Virology and Vaccine Research at Beth

Israel Deaconess Medical Center.

People with higher viral loads may also shed

more whole viruses, which makes them more

contagious, compounding the danger of spreading

disease more widely.

If exposure to higher doses, or even frequent

low doses, of SARS-CoV-2 does lead to worse

health outcomes, there are significant

implications for health care workers who are

routinely exposed to Covid-19 patients.

“Someone caring for large numbers of patients on

the wards, if they’re not wearing PPE [personal

protective equipment], there might be a high

frequency of exposure as well as a high dose of

exposure,” Barouch said.

In Italy, a country particularly hard-hit by the

virus, about 9% of reported cases were

health care workers. In the U.S., 10% of

Covid-19 cases in California were

health care workers, according to the California

Department of Public Health.

Reverse Engineer a Semiconductor Cleanroom

Coronavirus Technology Solutions are available

to allow us to safely return to semi normal

routines but they involve masks instead of

social distancing, foot sanitizers and many

other technologies which are common practice in

cleanrooms. No pharmaceutical cleanroom would be

without an air shower in the room set up to put

on cleanroom clothing,

The opposite should be true in a hospital

where you are protecting the wearer rather than

the product. So the reverse engineering of

technology perfected for semiconductor and

pharmaceutical cleanroom should be utilized.

In a semiconductor cleanroom the air quality is

limited to one small particle per ft3

while the best hospital operating room is 10

particles and most are well over 100. Most areas

of the hospital will exceed 100,000 particles

per ft3 and 500,000 particles is

typical which is also the average for ambient

air in the U.S.

Masks with Valves have Advantages but Design and

Maintenance are a Challenge

Paul Gardner, former chief of the Army's

Edgewood Chemical Biological Center (ECBC)

Respiratory Protection Branch was asked by

McIlvaine to use his experience in evaluating

new filter media for the Army and comment on

recent coronavirus needs. His analysis was

included in the April 27 Alert.

He discussed challenges such as the

higher breathing resistance, moisture, and

comfort concerns.

So we asked Paul to comment on the use of

masks with valves which eliminate some of these

challenges. Here is his response.

Paul:

The obvious benefit of exhalation valves used in

some FFRs is that they reduce the exhalation

resistance and moisture within the mask thus

improving overall comfort. As you

mentioned, they are suitable for protecting the

wearer as opposed to those around you should you

be contagious.

One tradeoff is the added expense to

manufacture. The biggest downside, however, is

that they are potential leak sources and in a

reusable FFR would need to be checked and

maintained after each use to ensure they are

free of contaminants and functioning

properly. There is the added risk that people

will not perform the maintenance to ensure the

valve is clean, undistorted, and seated

properly.

I have seen flapper valves in half-mask

air-purifying respirators that had hair or bits

of paper towel from cleaning that caused them to

leak. Some were missing completely or

stuck open having been sucked behind their

spider support from heavy breathing. Most

of the flapper valves I have seen in disposable

N95 FFR are very thin and not very robust but

are well protected behind a non-removable

housing (cover) and not intended to be serviced.

There are much higher quality outlet valve

assemblies in elastomeric half-mask respirators

which are can be serviced. These types I

believe would be more suitable for a reusable

FFR. However, in my mind none would lend

themselves particularly well to washing,

assuming that was the primary method used to

decontaminate/reuse the masks, unless the entire

assembly or flapper valve could be removed

easily before washing the facepiece covering

and/or filter (if separate) and reinserted

without compromising the seal of the valve

assembly and/or the flapper valve.

In summary, I see the benefit of exhalation

valves in “single or limited use (i.e.,

disposable) ” N95 FFRs but due to the concerns

mentioned above not so much for “long-term or

extended use (i.e., reusable) ” FFRs, at least

those that would need to be cleaned (washed) and

maintained.

I would like to summarize my opinion in the

positive: I believe exhalation valves

would be a beneficial and desirable feature for

a “reusable” N95-equivalent FFR intended for

extended use by the general population.

That is, if the mask can be designed to be

maintained by the user (properly cleaned)

without compromising the performance of the

mask, especially with regards to the exhalation

valve.

Coronavirus Detected on Air Pollution Particles

Coronavirus has been detected on particles of

air pollution by scientists investigating

whether this could enable it to be carried over

longer distances and increase the number of

people infected.

The work is preliminary and it is not yet known

if the virus remains viable on pollution

particles and in sufficient quantity to cause

disease.

The Italian scientists used standard techniques

to collect outdoor air pollution samples at one

urban and one industrial site in Bergamo

province and identified a gene highly specific

to Covid-19 in multiple samples. The detection

was confirmed by blind testing at an independent

laboratory.

Leonardo Setti at the University of Bologna in

Italy, who

led the work,

said it was important to investigate if the

virus could be carried more widely by air

pollution.

“I am a scientist and I am worried when I don’t

know,” he said. “If we know, we can find a

solution. But if we don’t know, we can only

suffer the consequences.”

Two other research groups have

suggested air

pollution particles could

help coronavirus travel further in

the air.

A statistical

analysis by

Setti’s team suggests higher levels of particle

pollution could explain higher rates of

infection in parts of northern Italy before a

lockdown was imposed, an idea supported by another

preliminary analysis.

The region is one of the most polluted in

Europe.

Previous studies have shown that air

pollution particles do harbour microbes and

that pollution is likely to have carried the

viruses causing bird flu, measles and

foot-and-mouth disease over considerable

distances.

The potential role of air pollution particles is

linked to the broader question of how the

coronavirus is transmitted. Large virus-laden

droplets from infected people’s coughs and

sneezes fall to the ground within a meter or

two. But much smaller droplets, less than 5

microns in diameter, can remain in the air for

minutes to hours and travel further.

Experts are not sure whether these

tiny airborne droplets can cause coronavirus

infections, though they know the 2003

SARS coronavirus was spread in the air and

that the new virus can remain

viable for hours in

tiny droplets.

Trump

Orders Meat Processing Plants to Stay

Open

Faced with worries of a meat shortage caused by

the coronavirus, President Donald Trump has

ordered meat processing plants to remain open

and will try to protect them from legal

liability, officials said Tuesday.

Trump declared meat plants as critical

infrastructure and cited the Defense Production

Act to justify an order to keep them open, said

two officials familiar with the discussions,

speaking on condition of anonymity because the

order is not yet completed.

Trump also said he would issue an executive

order to shield meat plants from legal liability

if they are sued by employees who contract

coronavirus while on the job. While Trump only

mentioned Tyson Foods specifically, he suggested

his order would protect other businesses from

liability as well

Concerns about the nation’s meat supply have

been growing, as the number of meatpacking

facilities shuttered due to coronavirus

outbreaks has accelerated over the past several

weeks.

More than 4,400 meatpacking workers have tested

positive for the virus, and at least 18 have

died from the virus as of Tuesday morning,

according to USA

TODAY/Midwest Center for Investigative Reporting

tracking.

Workers have tested positive in at least 80

plants in 26 states, and there have been 28

closures of at least a day.

USA TODAY also found that 153 of the nation’s

largest meatpacking plants, about 1 in 3,

operates in a county with a high rate of

COVID-19 infection, raising concerns that more

workers at more plants will fall ill.

The US has about 2,700 slaughter plants, 800 of

which are federally inspected. In March, the

country saw meat, beef and pork production reach

record highs, according to the US

Agriculture Department (USDA).

The United Food and Commercial Workers

International Union, which represents more than

250,000 meatpacking and food processing

workers, said

on Thursday at

least 13 processing plants have closed over the

past two months, resulting in a 25 percent

reduction in pork slaughter capacity and 10

percent reduction in beef slaughter capacity.

Leprino Foods Shuts Dairy Food Plant Due to

Virus

Operations halted Sunday at the Leprino Foods

dairy foods processing plant in Fort Morgan, CO

after a high number of employees, some without

symptoms, tested positive

for coronavirus,

a plant

spokesperson told CBS4. The plant will remain

closed for a minimum of five days, according to

Kim DeVigil. A reassessment is planned for

Friday.

“We feel this extreme measure is necessary and

important for the safety and health of our

employees,” DeVigil said in a statement.

Aside from a complete cleaning of the facility,

DeVigil said all remaining employees who have

not been tested will undergo testing. Also,

employees 65 years old and older will be held

out of the workforce indefinitely. They will

receive pay.

“It is important to note that sanitation and

hygiene in our plant environments are robust on

a normal basis,” DeVigil stated. “During the

COVID-19 situation, we have further enhanced our

sanitation processes and instituted a number of

other protocols.”

When the plant restarts, employees will answer a

questionnaire and receive temperature checks

upon entering and be required to maintain social

distancing once inside. All will be required to

wear nose and mouth coverings as well.

DeVigil said Leprino will provide supplemental

pay to workers forced out of the plant by due to

coronavirus.

Leprino employs 350 people at the Fort Morgan

location. The company’s website states it has

produced dairy products since 1950 and is the

largest producer of mozzarella cheese in the

world.

According to DeVigil, the company initiated

testing April 19th in partnership with the

Northeast Colorado Health Department. Testing of

the entire workforce is expected to be completed

Monday. DeVigil said the company would share

results of the testing when it has been

completed and the data compiled

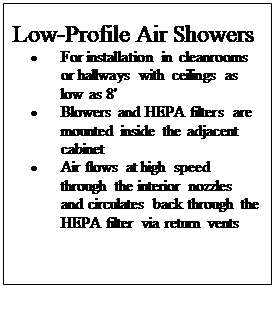

Air Showers are a Way to Reduce Virus in Locker

Room Areas

Air showers are routinely used in cleanrooms.

They are located at the entry to the

cleanroom but for healthcare personnel

can be located at the exit from

the healthcare environment to the locker

room.

Converting Patient Rooms to Negative Pressure

Isolation

Clean Rooms International, has successfully

reconfigured and repurposed stock products to

enable hospitals to convert standard patient

rooms into negative pressure rooms for patient

isolation.

"Healthcare systems are experiencing incredible

pressure to accommodate growing numbers of

patients impacted by the coronavirus," said Tim

Werkema,

president and CEO of CRI.

"Customers came to us seeking a new way to

quickly convert standard hospital rooms into

negative pressure rooms for quarantine. In less

than a week, our team of engineers repurposed

dozens of units. In less than a month, we’ve

shipped more than 1,000 from coast to coast. Due

to the nature of the COVID 19 disease, which can

be transmitted through respiratory droplets in

the air, CRI engineers looked at its HEPA air

filtration product inventory. Standard HEPA fan

filter units were inverted and paired with

exhaust systems or mounted to a small cradle

with castors to create mobile units. The

products are highly efficient in filtering and

evacuating contaminants from the air. This

creates a negative pressure environment,

minimizing airborne contagions from entering

hallways and corridors in a health facility."

As infection levels continue to rise, hospital

systems will look for new and inventive ways to

convert their facilities to meet patient needs,”

said Bret Asper, Chief Operating Officer at CRI.

Mecart Providing Modular Isolation Rooms to

Hospitals

Mecart is delivering critical isolation rooms to

hospitals and healthcare facilities. As the

coronavirus pandemic continues to spread

globally, the need for dedicated treatment and

patient space is increasing rapidly.

“Designing and building cleanrooms and clean-air

environments is our core business, and one that

we fully understand. We have the in-house

engineering and manufacturing capacity to

deliver solutions with short lead times to the

Health sector. We will of course share our

expertise in this critical time,” said Patrice

Genois, Mecart’s Executive VP.

The addition of Mecart isolation rooms will

drastically improve each hospital’s ability to

serve its community during the current crisis.

The rooms, which are available as modular

structures or pre-assembled PODs, can be

manufactured and delivered much more rapidly

than standard construction.

Precision HVAC systems ensure that pathogens are

contained, eliminating further spread of the

virus while providing fresh air for patients and

hospital staff. Post pandemic, these rooms can

be reconfigured, moved and/or redeployed for a

variety of other uses thanks to their complete

independence from the host building.

Based in Quebec City, Mecart has been designing

and manufacturing custom, modular cleanrooms for

nearly five decades. The need for cleanrooms and

clean environments spans many fields, from

health-related applications such as

pharmaceuticals, hazardous pharmacy compounding,

research and clinical trials, to industrial uses

in the electronics, aerospace and

nanofabrication sectors.

Puracore COVID -19 Containment Modules

Immediately Available

Thanks to their wholly independent operation,

with engineering and manufacturing all completed

in-house, medical isolation PODs are available

to hospitals and healthcare facilities in under

four weeks.

COVID-19 Containment modules/pods/rooms with the

maximum size of 6 metres wide, and up to 4

metres high with an unlimited length. Which is

easily cleaned with hygienic surfaces

manufactured by Gilcrest’s specialist cleanroom

division Puracore, Global Specialists in the

Manufacture and Delivery of FM Approved, High

Specification Cleanroom Systems. This enables a

clean space for production in a controlled

environment including converting non-sterile to

sterile spaces and clean areas for equipment

manufacture, in addition to COVID-19 human

isolation areas and controlled environment for

ventilator parts production.

We believe this is a simple cost effective and

fast solution which is what is needed in this

very challenging time. In addition, these can be

expandable as demand grows and the containment

modules are easy to relocate and reassemble with

this in mind.

This product is available immediately and is

part of Gilcrest Manufacturing’s commitment to

deliver and meet all different types of demands.

-

Standard unit 3 metres wide x

3.6 metres long x 2.4 high

-

Max size up to 6 metres wide, up

to 4 metres high, unlimited

length

-

Easily cleaned hygienic surfaces

manufactured by a UK based

specialist

-

Easy to relocate and reassemble

-

Clean space for production in a

controlled environments

including: Converting nonsterile

to sterile spaces, Clean areas

for equipment manufacture,

COVID-19 human isolation areas,

controlled environment for

ventilator parts production

-

Simple cost effective and fast

solution

-

Expandable as demand grows

-

Available with sealed doors or

strip curtains and pre fitted

lights as required

-

Worldwide shipping available

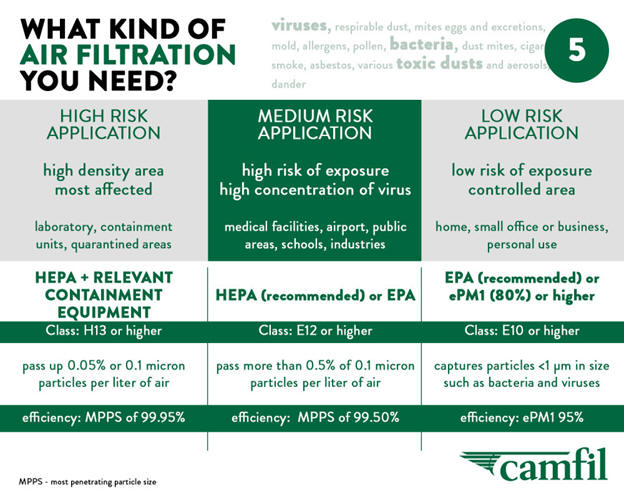

What Level of Filtration is Necessary?

With the coronavirus the medium and high risk

areas are greatly expanded.

Here is the Camfil view on filter

recommendations for each classification