Coronavirus Technology Solutions

May 5, 2020

Laminar Flow Not Partitions and Masks Not 6 ft

Distance are the New Recommendations

Many Opportunities in the U.S.

Kruger FFU for Hospital Isolation

Puracore Containment Modules Available for Quick

Shipment to Any Part of the World

PMS Supplies Both Viable and Nonviable Particle

Counters

Chinese N95 Masks Shipped to Massachusetts did

not Meet Requirements

Cleanbox Uses UV to Disinfect Masks

Huntair Supplies Floor by Floor Air Handling

Systems

GuangZhou Kelaichuang Purification is an

Exporter of Rooms and Showers

KLC has a Very High Efficiency Isolation Room

with PTFE ULPA Filters

Can a Smoker Transmit Virus in Smoke Particles?

Workers Return to Wisconsin Meat Plant with 85

Positive Cases

116 COVID Cases at Oklahoma Pork Plant

UNMC Provides a Draft Guidance on HVAC and Masks

for Meat Processors

_____________________________________________________________________________

Laminar Flow Not Partitions and Masks Not 6 ft

Distance are the New Recommendations

Meat processors, and many other entities trying

to mitigate COVID-19 are moving forward based on

guidelines which have been made not only

obsolete but dangerous.

Meat processors have received guidance from the

CDC to install partitions and to wear some type

of cloth mask.

Based on the latest evidence this is not

good advice.

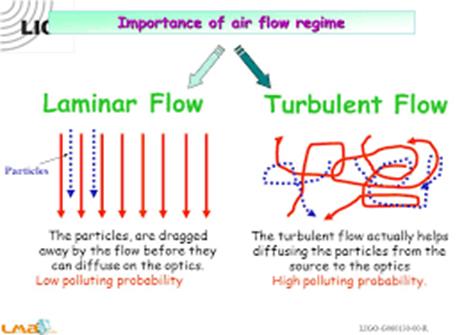

Fifty years of cleanroom design has resulted in

consensus that HEPA filtration and laminar

downward air flow are the ways to

deal with particles smaller than 5

microns. Air pollution control experts can cite

endless examples of small particles which

travel around the globe. No amount of

partitioning would restrict them.

Technology has been developed to deal with

COVID-19 in a safe and cost effective manner by

cleaning the air and directing the flow so it is

not from person to person. The 6 ft voting line

in Milwaukee is a good example of what not to

do. A slow sequence of people moving in a

straight line creates a lineal viral cloud and

so people in the rear are continually walking

into the cloud generated by their predecessors.

In Milwaukee seven COVID case were directly tied

to the voting and the entire Wisconsin caseload

rose noticeably.

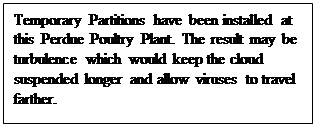

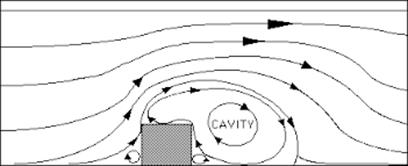

One takeaway is that air flow direction is very

important. If a cloud moves from one meat packer

under or around a partition to another worker,

the partition has no positive effect and in fact

may create turbulence and longer suspension.

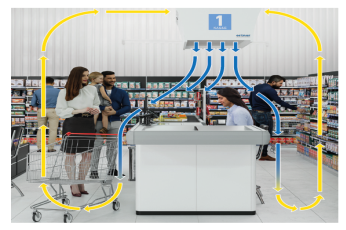

In the diagram below envision each worker

in a cavity area caused by the partition where

the virus keeps circulating.

There are ceiling mounted fan Filter Units (FFUs)

which will provide laminar flow of HEPA filtered

air. If placed properly they can provide laminar

flow of clean air downward.

Meat processors are only one of the many

applications where fan filter units and not

partitions should be used.

The aisles of stores can also be supplied with

laminar air flow ceiling

mounted FFFUs.

In terms of what is needed cigarette smoke can

be used to illustrate the effectiveness of a

design. In the laminar flow systems it will be

removed. It would easily circumvent partitions.

Masks

The guidance to meat processing workers to wear

a cloth mask but not an N95 mask because there

will not be enough for healthcare workers is

also obsolete advice. The production of N95

masks has increased by orders of magnitude in

recent months. The shortage of meltblown media

is being met in several ways including rapid

construction of new media lines and development

of nanofiber membranes as a washable

alternative. Various decontamination methods for

masks are now available.

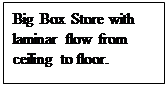

Everyone should be wearing an N95 efficiency

mask. The new evidence of transmission by small

aerosols including Italian research which found

coronavirus on air pollution particles in the

Lombardy region means that what is needed is to

remove particles smaller than 3 microns with

high efficiency on 0.3 microns and even 0.1

microns.

The N95 mask is actually tested with 0.l micron

aerosols and achieves 95% efficiency on these

particles. Single use face masks do not even

remove all the 3 micron droplets. Surgical masks

have only 30% capture rate on 0.1 micron

particles.

It is true that viruses are generally

found in droplets or on particulate which is

larger than 0.1 microns but the fact that

viruses are traveling long distances testifies

to the small carrier size.

Another challenge is leakage around the mask,

N95 masks are designed for minimum leakage.

Surgical masks are loose fitting with

considerable leakage. N95 masks can be supplied

with or without valves. There is lower leakage

and greater comfort if a valve is provided. On

the other hand the valve allows unfiltered

breath discharge. Both designs will have their

place.

The conclusion is that HEPA filtered laminar air

environments and high efficiency masks will

provide a relatively safe working or shopping

environment.

Partitions and 6 foot distancing with

cloth masks are not nearly as protective.

Many Opportunities in the U.S.

The traditional market for HEPA filters and fan

filter units has been for cleanrooms and

hospital isolation rooms. What is now needed is

investment in billions of dollars in fan filter

units for a variety of applications. Here are

some examples

|

Potential for Fan Filter Units in New Applications in the U.S |

|

|

Type of Establishment |

Quantity* |

|

Grocery Stores |

40,000 |

|

Convenience Stores |

140,00 |

|

Clothing Stores |

95,000 |

|

Fast Food Restaurants |

240,000 |

|

Other Restaurants |

400,000 |

|

Animal Slaughtering And Processing # of Workers |

40,000 |

|

# of Elevators |

900,000 |

|

Health Clubs |

40,000 |

|

Nursing Homes |

16,000 |

|

Nursing Home Patients |

1,400,000 |

|

Dentists |

200,000 |

*Number

of establishments or people as indicated

Studies of a restaurant in Southern China showed

that social distancing was irrelevant.

The air conditioner created a virus cloud

which impacted all diners in its flow pattern.

So tables nearby the transmitter but not in the

flow pattern escaped while those at some

distance in the flow pattern ended up with

numbers of COVID-19 cases.

The solution is the fan filter unit and

unidirectional air flow away from people.

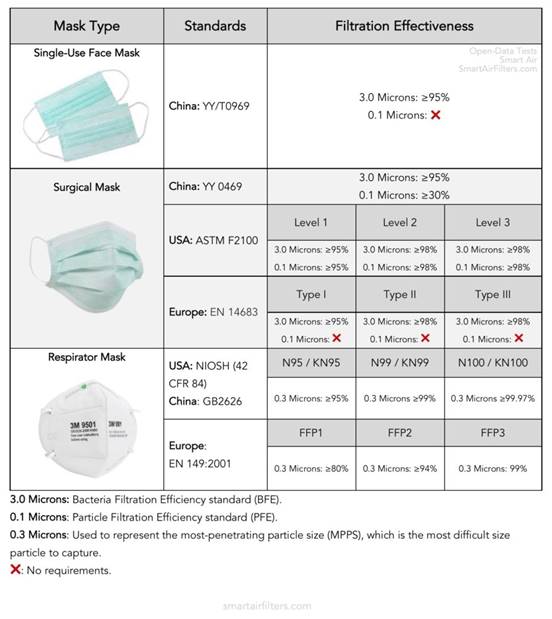

Kruger FFU for Hospital Isolation

Krueger’s new reverse-flow fan filter unit is

applicable for hospital isolation rooms housing

patients suffering from highly contagious

diseases. It works by creating a negative

pressure environment that removes air from an

isolation room, cleans it via the unit’s

built-in HEPA filter, and keeps airborne

contaminants from escaping back into the room.

The unit can be mounted in the ceiling or

provided as a rolling mobile version. The mobile

unit includes built-in, heavy-duty swivel

casters with brakes, allowing it to be moved

easily from location to location as the facility

requires.

Mobile units are also available. Whether for a

dedicated AII (Airborne Infection Isolation)

room or a temporary space, such as a tented area

within a convention center (with or without

ceiling), the mobile unit can provide a speedy

solution. It needs only to be rolled into place

and calibrated before being put into use. While

it is a floor-based model and not located

directly over the patient, it is strong enough

to overcome body plume buoyancy to effectively

remove contaminants from the space.

Puracore Containment Modules Available for Quick

Shipment to Any Part of the World

COVID-19 Containment modules/pods/rooms have

a maximum size of 6 meters wide, 4 meters high

and an unlimited length. Easily cleaned, with

hygienic surfaces manufactured by Gilcrest’s

specialist cleanroom division Puracore, Global

Specialists in the Manufacture and Delivery of

FM Approved, High-Specification Cleanroom

Systems. This containment module enables a clean

space for production in a controlled

environment, including converting non-sterile

spaces to sterile spaces and providing clean

areas for equipment manufacture, in addition to

COVID-19 human isolation areas and controlled

environment for ventilator parts production.

Puracore says this

is a simple, cost effective and fast solution

which is what is needed in this very challenging

time. In addition, these containment modules can

be expandable as demand grows and they are easy

to relocate and reassemble with this in mind.

They are available with sealed doors or strip

curtains and pre fitted lights as required with

worldwide shipping available.

PMS Supplies Both Viable and Nonviable Particle

Counters

Particle Measuring Systems specializes in viable

and nonviable particle counters that measure and

monitor contamination levels in clean and

controlled environments. Since 1972,

the PMS knowledgeable and experienced

team has been developing innovative technologies

to advance the cleanroom monitoring industry.

PMS is already monitoring both viable and

non-viable particles. Therefore they will

be able to provide insights on the

McIlvaine proposal that in many areas where

there is concern about coronavirus viable

particulate should be continuously monitored as

a surrogate for measuring virus loads.

Environmental Monitoring (EM), particularly in

pharmaceutical manufacturing facilities where

the risk of microbial contamination is

controlled through aseptic processing, comprises

both physical and microbiological test methods.

PMS says It is a common assumption that if fewer

total particulates are present in a cleanroom,

it is less likely that airborne microorganisms

will be present. This is true only if human

operators are the main source of particulate

matter in the air. However, it is not possible

to clearly distinguish between background total

particulate contamination generated largely by

mechanical operations and the total particulates

contributed by personnel. Thus, it is routine

for cleanroom environmental monitoring programs

to consist of both a total particulate component

and a microbiological component.

The proposal would be to adopt the protocols

used in toxic metal monitoring where total

particulate metal quantities are used as a

surrogate for toxic metals. Intermittent metals

sampling is undertaken to establish the

relationship.

Chinese N95 Masks Shipped to Massachusetts did

not Meet Requirements

A number of N95 facemasks from Chinese suppliers

were tested by MIT as requested by the State of

Massachusetts. Efficiency varied from 95% down

to as low as 28%. Many of the suppliers

delivered masks which were less than the 95%

efficiency.

Details of individual tests are shown in

the link.

https://www.mass.gov/doc/kn95-respirator-test-results/download

Cleanbox Uses UV to Disinfect Masks

The Cleanbox is designed specifically for

decontaminating four masks at once in a 1-2

minute cycle, allowing for the disinfection of

up to 100 masks per hour, per unit.

https://www.cleanboxtech.com/

Huntair Supplies Floor by Floor Air Handling

Systems

For various applications it will be desirable to

create separate air handling systems to protect

against the virus. If one person in one group

becomes infected the spread will be limited to

his group. Huntair supplies Floor-by-Floor Air

Handling Solutions for Better Building

Environments.

The Vertical Self-Contained Systems, are

ideal for floor-by-floor HVAC, provide an

efficient, flexible, cost-effective, and

reliable approach to creating comfortable

environments in mid-rise and high-rise

buildings, offices, and schools. These units are

custom designed to meet

specific application requirements,

offering coil, compressor, and filter options

along with multiple configurations

Custom Cleanroom

Air Handling solutions,

including both Makeup

Air Units and Recirculating

Air Handlers, are designed specifically for

cleanroom applications, offering low vibration

and noise levels. In addition, these units are

designed with quality features that can

withstand harsh chemicals used in pharmaceutical

environments and provide the efficiency and

flexibility to meet the operating requirements

of today’s cleanrooms. The company also offers

fan filter units and small cabinet fans.

GuangZhou Kelaichuang Purification is an

Exporter of Rooms and Showers

Here are exports to the U.S in 2018.

|

Date |

Supplier |

Customer |

Details |

|

2018-12-09 |

GUANGZHOU KELAICHUANG PURIFICATION |

BIOCREDE INC. |

MODULAR CLEANROOM |

|

2018-05-20 |

GUANGZHOU KELAICHUANG PURIFICATION |

CLARION MOBILE HOLDINGS INC. |

AIR SHOWER H. S CODE: 8424899990 LAMINAR FLOW PASS BOX H. S CODE: 8414609090 |

|

2018-05-13 |

GUANGZHOU KELAICHUANG PURIFICATION |

BETTER BODY SPORTS |

MODULAR CLEANROOM |

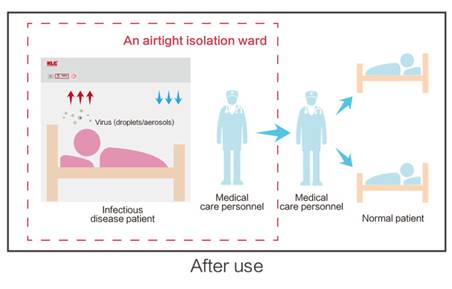

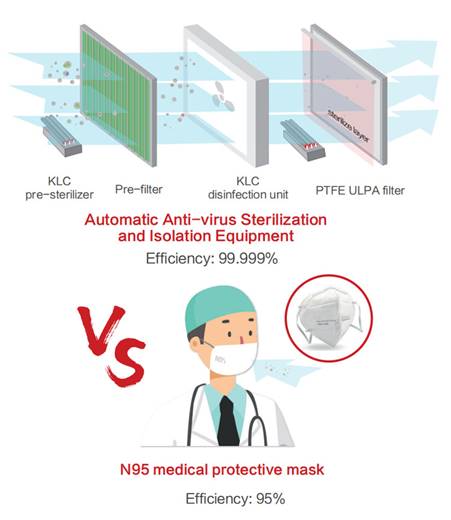

KLC has a Very High Efficiency Isolation Room

with PTFE ULPA Filters

KinglandClean claims to be

the world's leading manufacturer of air

purification equipment, KLC and Southern Medical

University have jointly developed a variety of

products to effectively prevent the spread of

COVID-19.

Upright Model / Ceiling Suspended Model

Automatic Anti-virus Sterilization and Isolation

Equipment

·

Below is the filtration system.

Can a Smoker Transmit Virus in Smoke Particles?

Italian researchers report that the coronavirus

has been found on air pollution particles. So it

stands to reason that a smoker could be a

transmitter according

to Dr. Jyotu Sandhu with Sharp Rees-Stealy, if a

smoker has the virus then yes, it is possible

the smoke the individual breathes out does carry

the virus. If an individual is in close

proximity to a person smoking, who has the

virus, he or she could breathe in that same

smoke.

"That person is

just expelling whatever they have in their

mouth," said Dr. Standhu.

Another question is

if you can smell tobacco smoke are you also

inhaling virus from that same source. McIlvaine

will be seeking this answer but it is likely to

be that the weaker the smell the more diluted

any transmission.

Workers Return to Wisconsin Meat Plant with 85

Positive Cases

Employees at the Cudahy-based Patrick Cudahy

meat processing plant headed back to work

Monday, May 4 after extensive testing at the

plant revealed at least 85 employees have been

infected with the coronavirus.

Smithfield Foods, Inc., the owner of the dry

sausage and bacon plant, temporarily shut down

operations originally saying that a "small

number" of employees had been affected.

City officials in Cudahy said the Wisconsin

National Guard assisted the Cudahy Health

Department in providing COVID-19 testing for

employees at the plant, and that a total of 503

people were tested over a five day period

between April 24-28.

State health officials are offering free

COVID-19 testing to all workers at the plant,

which employs about 1,000 people.

116 COVID Cases at Oklahoma Pork Plant

At least 116 employees at an Oklahoma pork

processing plant have

tested positive for coronavirus as

the industry attempts to keep doors open and

quell fears of a meat shortage.

The Guymon, Okla., plant is run by Seaboard

Foods. Any employee who exhibits symptoms or a

fever will be asked to go home, a company

spokesperson said in a statement.

UNMC Provides a Draft Guidance on HVAC and Masks

for Meat Processors

The Global Center for Health Security at the

University of Nebraska Medical Center is home to

the national Training,

Simulation and Quarantine Center,

which features the nation's only federal

quarantine unit and simulated biocontainment

units for advanced experiential training. The

Center has provided a draft guide for meat

processing plants with recommendations for

physical barriers, HEPA filtered unidirectional

air and efficient masks. The problem is that it

does not guide how to use these technologies. It

acknowledges the risk of

turbulence “

“turbulent airflow from fans may contribute to

re-aerosolization of viral particles from

surfaces” but does not explain why barriers may

lessen or increase the turbulence. There is no

statement that N95 efficiency masks should be

required.

McIlvaine has just interviewed Josh Santaparia

of UNMC relative to the air transmission of

viruses. In light of the findings by UNMC and

many others that significant transmission is

through aerosols barriers may be no more

effective in stopping virus transmission than

they would be stopping cigarette smoke.

McIlvaine hopes to pursue this in depth with

UNMC personnel.

Here are excerpts from the guidelines

Physical Barriers

When possible, use physical barriers to

separate workers from one another and minimize

the opportunities from person-to-person

transmission of COVID-19. Some strategies for

installing physical barriers include:

o Determine where it is possible to place a

physical barrier between workers on production

line (e.g., plexiglass)

Identify

opportunities to place physical barrier at

cafeteria lunch tables for tables with built-in

seating (e.g., cardboard, plexiglass partitions)

Extending partitions several inches past the end

of the table provides an additional measure to

prevent workers from leaning back and extending

over to space of person sitting next to them.

Identify

opportunities to place physical barrier (e.g.,

plastic sheeting) in hallways to guide employee

traffic to/from production and limit crossover

Ventilation

Wherever possible, exhaust room air and deliver

clean air; if re-circulation is required, this

should be done in concert with appropriate

filtering (HEPA) or sterilization measures

(e.g., UV)

§

This is especially relevant in high traffic and

high-density areas of the plant, including

production lines, cafeterias, locker rooms, and

congregating areas.

Wherever possible, create unidirectional,

laminar airflow.

If fans

are used in the facility, ensure fans blow clean

air toward workers’ breathing zone and are used

to create unidirectional airflow

§

Turbulent airflow from fans may contribute to

re-aerosolization of viral particles from

surfaces.

Universal Mask Policy

A policy

should be implemented for all employees and

essential visitors to wear a face mask/face

covering at all times while on the facility

premises. It is common for an individual to have

COVID-19 and be able to transmit the disease to

others in close contact while showing no signs

or symptoms. As a result, the Centers for

Disease Control and Prevention has issued

guidelines recommending all persons wear face

coverings in public settings where other social

distancing measures cannot be achieved. There

are different types of face coverings. It is

highly recommended, as available, to provide

employees in meat processing plants with

procedure (surgical) masks due to the close

contact they have with other employees and the

liquid contact frequency in the work

environment.

Cloth face-coverings may not provide the needed

protection for these workers. Hair and beard

covers provide no protection; they should not be

used as an alternative for a face mask. Provide

information to employees on proper face covering

use

Environmental Cleaning and Disinfection

Current

evidence suggests that the virus that causes

COVID-19 can remain viable on surfaces for hours

to days. As such, sound environmental cleaning

and disinfection is a key factor in preventing

COVID-19 transmission in meat processing

facilities. Daily and routine cleaning and

disinfection should be conducted to minimize

surface contamination in common areas and on

high-touch surfaces.

Develop Standard Operating Procedures (SOPs)

§

Develop an SOP for enhanced cleaning and

disinfection of common contact areas

§

Identify common high-touch surfaces (e.g.,

tables, door handles, microwaves, railings) and

develop a checklist to ensure frequent

sanitization throughout the day

§

Dedicate additional staff, as available, with

the only responsibility to disinfect high touch

surfaces

§

In the event an employee tests positive for

COVID-19, develop an SOP for cleaning and

disinfecting impacted areas (e.g., cafeteria,

washrooms, welfare areas, pathways, etc.)

§

Develop a process for routine deep cleaning of

common areas, either daily/nightly or, at

minimum, weekly

§

Develop a process to ensure lunch tables are

clean between use by self-cleaning or tools

(e.g., laminated card with green side and red

side) to notify environmental service employees

that the tables are in need of cleaning or to

notify employees the table is cleaned and ready

to be used o

Maintain

adequate supplies

§

Place hand sanitizer dispensers throughout

facility, particularly at entrance, exits, and

transition areas

§

The more accessible hand sanitizer dispensers

are, the more they will be used

§

Touchless hand sanitizer dispensers are

preferred to manual dispensers (e.g., pumps)

§

Assess supply of cleaning supplies, sanitizers,

and disinfectants and encourage practical use

§

Note: Follow manufacturer recommendations; some

disinfectants may be caustic and require gloves

and ventilation

§

Provide readily available sanitizing wipes,

soap, and paper towels in cafeterias and

breakrooms DRAFT Version Updated 4.28.20 7

§

Use only EPA-registered disinfectants for use

against SARS-CoV-2 o Minimize touching of items

by multiple workers

§

Minimize the number of workers using the same

tool

§

Identify common shared tools and develop

procedures to sanitize between users

§

Use no-touch receptacles and sanitizing stations

when possible

https://www.unmc.edu/healthsecurity/education/programs/docs/Playbook.pdf