Coronavirus Technology Solutions

April 22, 2020

Two Crucial Factual Errors Relative to

Coronavirus

Walk in Temperature Sensors Installed at City

Farmers Market

Tyson Foods Purchased More Than 150 Infrared

Walk-Through Temperature Scanners

JBS Closes Third Plant but Reopens One in

Pennsylvania

Kraft Heinz and

Conagra Plants Closed Due to Infected Workers

FBIA Relying on Outdated CDC Face Mask

Recommendations

Interim Guidelines for Non-Health Care Settings

_____________________________________________________________________________

Two Crucial Factual Errors Relative to

Coronavirus

There are two major misconceptions regarding the

coronavirus

1.

You are

relatively safe if you keep a distance of 6 feet

2.

Masks

cannot protect you

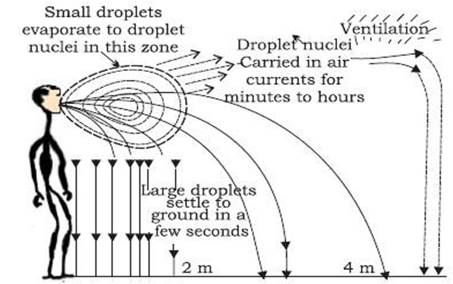

It has long been established that viruses can

travel long distances

Fine droplets or particulate with viruses can

travel through HVAC systems and in the case of

the Diamond Princess infect passengers who were

isolated in cabins.

In just two hours a singer in a

Washington State church choir managed to infect

45 of 60 choir members who were

practicing social distancing.

The fact that the virus is carried by air

currents means that you would be safer one foot

ahead and walking into the wind rather than 20

feet behind.

Since the droplets can remain airborne

for hours there is no really safe distance.

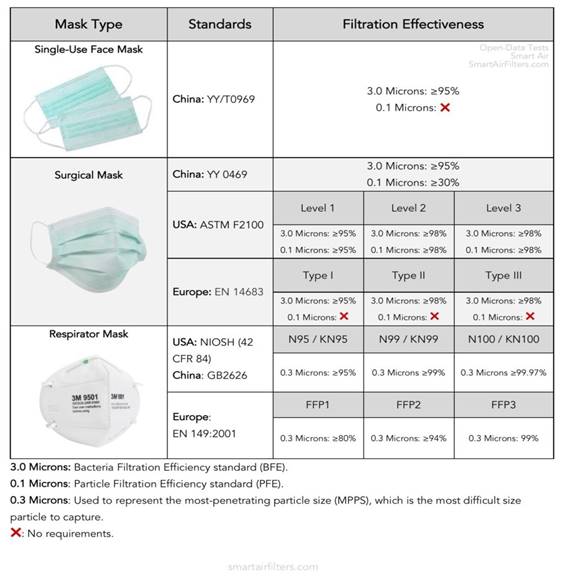

There is a big variation

in mask efficiency. Wearing a scarf

provides almost no protection.

Wearing an N100 mask keeps you well

protected.

Hospital personnel wearing N95 or higher

efficiency masks work in close proximity to

patients who are generating millions of viruses

per hour and yet they are protected. Viruses are

less than 0.2 microns and could pass through the

filter openings. But Brownian movement of these

small particles causes them to impinge on larger

particles or on the filter fibers. The N100 mask

would be the most desirable but in practice the

N95 provides a high measure of safety.

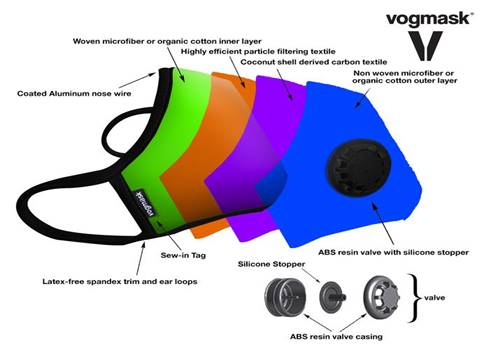

Comfort and breathability are two additional

concerns when N95 or higher efficiency masks are

used. The use of a valve allowing unfiltered

breath discharge keeps the wearer comfortable

but does not protect others.

Fashionable and comfortable high efficiency

masks have been sold in dedicated Chinese retail

stores since 2013. If everyone at risk wears a

mask then there is less concern about the direct

breath discharge feature.

Without the valve feature the general use

of higher efficiency but higher pressure drop

masks would not be practical.

New media being developed has lower resistance

and may result in masks which will protect both

the wearer and others. But in the meantime the

mask with the valve should become the primary

protection mechanism and not six foot

distancing.

The various technology impacts are reviewed in

the daily alerts which are part of Coronavirus

Market Intelligence

LINK

Walk in Temperature Sensors Installed at City

Farmers Market

In an attempt to protect shoppers and his

employees from contracting the coronavirus, Ben

Vo, the owner of City Farmers Market, a chain of

grocery stores in Georgia, recently set up

thermal cameras at the entrances of each of his

six locations.

"It’s focused on the face, so basically we

measure the head temperature as they walk into

the store," Vo said. "It’s in the corner, not

right in front of the entrance, and we have an

LCD monitor that security personnel can watch

and the customers can also see."

If an associate sees a reading that comes in at

100.4 degrees or higher, that shopper is pulled

aside and handed a flyer that asks them to

leave.

Vo said this has happened only twice in the two

weeks since he installed the cameras, which are

made by FLiR, a company that specializes in

thermal imaging cameras. There has been a

dramatic rise in demand for these kind of

cameras in recent weeks, even though experts say

they are an imprecise tool for identifying

people who are infected.

NBC News found more than ten security companies

in the U.S., Europe and China that are marketing

technologies as capable of picking out who in a

crowd is likely to have a fever, and thus a

possible coronavirus case. These companies are

actively pitching to police departments,

government agencies, schools, hospitals and

private businesses.

The idea is that thermal cameras can ferret out

sick people in a crowd by finding those who have

elevated temperatures, according to 11

surveillance companies NBC News found marketing

the technology as a form of coronavirus

detection. Fever is a symptom of COVID-19, the

disease caused by the coronavirus.

But the problems with this technology, according

to thermal imaging and virus surveillance

experts, is that thermal imaging is an imprecise

method for scanning crowds and doesn't measure

inner-body temperature.

They also noted that the coronavirus only

produces a fever after a person is infected for

days, if there are symptoms at all. A recent

study in Iceland looking

at tests from a sizable portion of the

population found that 50 percent of everyone who

tested positive were asymptomatic.

The rise in demand for thermal cameras also

comes as governments are looking for new ways to

track who is sick, including turning

to smartphone location data.

Forbes had a recent article

tracking the impact on the thermal

imaging industry. Wuhan Guide Infrared Co. is

bustling, with its 2,600 employees working round

the clock to fulfill a surge of orders for fever

detection systems to help contain the epidemic.

China’s largest maker of thermal imaging

equipment

sold thousands of fever screening systems

in just

two weeks as authorities and businesses

rush to deploy them at airports, railway

stations and other public gathering places,

sales manager Thomas Chen says via email.

Typically, the company typically only sells

about 100 a year.

Shares of Wuhan Guide Infrared surged 85.9%

recently, giving the company a market value of

$5.16 billion, making it the fourth-largest

technology company by market cap on the Shenzhen

stock exchange and inflating the fortune of

founder Huang Li to

$3.4 billion.

Smaller Chinese competitor Zhejiang Dali

Technology’s shares jumped 79% over the same

period to 19.00 yuan, while the benchmark

Shenzhen composite index is up 2.9%

Makers of thermal fever screening equipment in

other countries also say they’re being inundated

with inquiries from around the world from

airport operators, schools, hotels, malls and

theaters.

“The demand at this moment is unprecedented,”

says Leonard Lim, founder and CEO of

Singapore-based Omnisense. “If you try to call

our office now you probably won’t get through,

the lines are jammed.”

Infrared Cameras Inc., a small private company

in Beaumont, Texas, sells two fever detection

systems that have been approved by the FDA for

medical use that are priced at $5,000 and

$10,000. They require people to stand still

facing the camera, with a reference object in

the field of view called a “blackbody” that has

a known level of infrared emissions.

Founder Gary Strahan says he’s ramping up

staffing and production after receiving an order

for 230 systems from an individual customer two

weeks ago and quoting prices to thousands of

prospective buyers. They include a cruise ship

operator, a private girls high school in Hong

Kong and a manufacturer in China looking to add

an infrared camera to a robot so that humans

wouldn’t have to be exposed to someone suspected

of having an illness.

FLIR also makes FDA-approved cameras.

Distributors have been making large sales of

FLIR systems during the coronavirus outbreak

Omnisense has stopped production of its core

night vision cameras to crank out the latest

version of its mass fever screening system, the

Sentry Mark4, which CEO Lim says can detect skin

temperature differences as small as 0.2 degrees

Centigrade on the faces and necks of moving

people. It sells for $20,000 to $25,000, and

detection is automated, he says, allowing the

system to be deployed in large numbers quickly

during public health emergencies, with minimal

training of operators.

Tyson Foods Purchased More Than 150 Infrared

Walk-Through Temperature Scanners

Tyson Foods

has answered questions on their scanner

purchases. So far, the scanners have been

installed in four facilities; pork plants in

Iowa and Indiana and poultry plants in Arkansas

and Georgia. The company expects that eventually

every one of its food production facilities will

have at least one in place.

Tom Brower, Tyson Foods senior vice president of

health & safety, answers questions,

explaining why Tyson Foods installing the

scanners.

Q: Why are we using this technology?

A: We need to ensure a safe work environment for

our people. Exploring ways that are more

efficient in keeping our team members safe is

never a bad thing. This is a non-contact

temperature scanner, so it’s seamless for our

team members since all they need to do is walk

through the detector zone. It doesn’t disrupt

their routine, and it’s faster than using the

handheld thermometers.

Q: How do these walk-through scanners work?

A: All that team members have to do is walk

through the detector zone one at a time. The

non-contact thermal imaging system tracks them

as a screen provides a real-time display of the

maximum temperature reading of each person. If a

team member’s temperature exceeds a fever-grade

temperature, the system sets an alarm. One of

our trained professionals will take additional

steps and check that team members temperature

with a temporal thermometer to verify their

temperature. If a team member is sick, we’ll

send them home.

Q: Do infrared scanners detect COVID-19?

A: No. The makers of these devices have noted

that the scanners only detect a person’s body

temperature. We still choose to use them because

it’s a safer non-contact option to check

temperature.

Will we keep these walk-through temperature

scanners for the long-term?

A: Since we’ve invested in the equipment, we may

consider continuing to use them. This could help

in the future flu and cold seasons to identify

team members that are just starting to show

symptoms and have them go home.

https://www.wattagnet.com/articles/40053-tyson-explains-use-of-walk-through-temperature-scanners

JBS Closes Third Plant but Reopens One in

Pennsylvania

Beef and pork processor JBS

USA said Monday it will close a third facility

because of coronavirus as

the meat

industry deals

with virus clusters popping up at plants across

the country.

JBS announced the "indefinite closure" of its

Worthington, Minnesota, pork production plant

after 20 employees and five of their family

members tested positive for the virus, according

to CBS

4.

The plant employs 2,000 people, and workers will

be paid during the closure.

JBS has already closed its Greeley, Colorado,

and Souderton, Pennsylvania, beef facilities

because of the virus, although the Pennsylvania

plant reopened Monday.

"We don't make this decision lightly," Bob

Krebs, president of JBS USA Pork, said in a

statement. "We recognize JBS Worthington is

critical to local hog producers, the U.S. food

supply and the many businesses that support the

facility each and every day."

After decades of consolidation, there are about

800 federally inspected slaughterhouses in the

United States, processing billions of pounds of

meat for food stores each year. But a relatively

small number of them account for the vast

majority of production. In the cattle industry,

a little more than 50 plants are responsible for

as much as 98 percent of slaughtering and

processing in the United States.

Kraft Heinz and

Conagra Plants Closed Due to Infected Workers

Production has been curtailed at a Kraft Heinz

macaroni plant and at a Conagra frozen food

plant after workers tested positive for COVID

19.

The plants are to be reopened after cleaning.

The ConAgra plant in Marshall, Missouri, is

temporarily closing after a number of employees

were diagnosed with COVID-19.

A

company spokesperson said that 20 employees are

sick with coronavirus and that the closure is

necessary to maintain cleanliness at the

facility.

“The health and safety of our employees is our

top priority. In our facility in Marshall,

Missouri, we have been using social distancing

techniques, screening temperatures and increased

sanitization in common areas to prevent the

spread of COVID-19. Unfortunately, approximately

20 employees have been diagnosed with COVID-19

so we have made the decision to suspend

operations at the facility until April 27,” said

company spokesman Dan Hare.

Employees will receive a paycheck during the

closure, and the company will continue to pay

workers who need to take time off due to

COVID-19 illnesses, the company said.

Kraft Heinz Cedar Rapids factory reported a

positive case of coronavirus on Friday, April

4th.

An employee at Kraft Heinz in Lowville has

tested positive for COVID-19.

Company officials say they were notified of the

positive result on Tuesday. They say the

employee is at home in isolation and hasn’t been

at the plant since April 9. Senior vice

president of corporate affairs Michael Mullen

said the facility was deep cleaned on April 10.

“We encourage any employee who feels unwell to

take every precaution and seek medical

assistance,” Mullen said. “We’ll continue to

monitor this rapidly evolving situation and will

update all employees as appropriate.”

Lewis County Public Health officials confirmed

the positive test late Wednesday morning.

An employee who works at the Kraft Heinz

Davenport factory has tested positive for

COVID-19, a Kraft Heinz spokesman confirmed

Friday.

The employee last worked at the factory April 9,

according to the spokesman. The individual is at

home and in self-quarantine. The factory has

around 800 employees.

FBIA Relying on Outdated CDC Face Mask

Recommendations

The Food and Beverage Industry Association has

an excellent website with links to

relevant coronavirus information.

Relative to face masks they say “ Given this CDC

recommendation, companies in the food supply

chain may need to implement standard operating

procedures for the use of face coverings or

masks. It’s important to note that supplies of

cloth face coverings may be in high demand and

food companies should evaluate whether they can

provide disposable face coverings or masks; and

in their absence consider reusable cloth masks

that can be appropriately collected after their

use and laundered” The new evidence shows

that food companies will want to provide

N95 efficiency masks to employees under a number

of circumstances

Interim Guidelines for Non-Health Care Settings

The CDC interim guidance may help prevent

workplace exposures to COVID-19, in

non-healthcare settings. (CDC has provided

separate guidance for healthcare

settings.)

This guidance also provides planning

considerations for community spread of COVID-19.

The non-healthcare guide addresses

disinfection techniques and also the potential

for increasing the flow of outside air.