Coronavirus Technology Solutions

April 23, 2020

Copper is a Mitigation Solution

Queensland University Develops Highly Efficient

Nanocellulose Mask Media

Changing Guidelines Relative to PPE Use in

Hospitals

More Accurate Temperature Measurement Needed

Danone Closes Wuhan Plant but has High

Production Rates Elsewhere

Restaurant Ventilation Systems Spread Virus

More Coronavirus Outbreaks at Meatpacking Plants

Than Previously Estimated

State Investigating Outbreaks at Meat Processing

Plants in Texas

Five Meat Processing Plants in North Carolina

have 118 Coronavirus Cases

Mountaire has Coronavirus Cases and is Now

Issuing Masks

Midwest Center for Investigative Report has a

Tracking System on All

Meat Processing Plants With COVID 19

Cases

Flight Attendants are Both Victims and

Transmitters of COVID-19

100 American Airlines Flight Attendants have

COVID-19

Safety Steps to Mitigate Coronavirus in Airline

Travel

Bipolar Ionization Cited as a Coronavirus

Mitigation Solution at Airports

_____________________________________________________________________________

Copper is a Mitigation Solution

Currently, stainless steel or plastics are used

for sinks, counters, beds and other surfaces in

health care environments, but while stainless

steel and plastic are easy to clean (the main

reason they're used in such places), they also

demonstrably harbor far more bacteria and

viruses than a similar copper surface does — and

over time, small scratches, dings and holes can

hide even more.

It's especially important that the most

dangerous superbugs, responsible for the death

and illness of already-sick people, are killed

by copper. That includes methicillin-resistant

staph (MRSA); other staph bacteria;

adenoviruses; the flu virus (all types); and

even fungus. In

a study published in the International Journal

of Food Microbiology,

99.9 percent of E.coli bacteria was killed after

an hour on a copper table, whereas it survived

for weeks on stainless steel.

Considering that last fact, it seems that copper

tables and prep areas in restaurants and

food-prep areas would be another place copper

could make a dent in keeping the nastiest bugs

away from vulnerable people.

Copper kills the variety of bacteria and viruses

that it does because it works on several levels

to disable the organisms. It binds to proteins

that disrupt the basic function of the cell, it

breaks down membranes that cause cell drying and

then death, and it causes oxidative stress to

any cells it comes into contact with, also

destroying them.

We're used to seeing copper as a trendy metal in

kitchens and bathrooms or used in pots and pans

in kitchens — and using it in these places is

beneficial. In fact, it would make sense to use

copper, especially, in places that see a lot of

hands and don't get washed often, like drawer

pulls in the kitchen, or bathroom taps.

But the material could be used to save lives in

far more fraught and dangerous settings, like

hospitals, elder-care facilities, and places

where the sickest and most vulnerable of us

spend time. That's why there are already several

hundred patents for health care surfaces and

tools made from copper, though a materials

transition will take time, especially where

health care budgets are stretched thin or

otherwise constrained

Queensland University Develops Highly Efficient

Nanocellulose Mask Media

The new mask media is biodegradable, efficient

in capturing virus and has low resistance.

Process engineer Thomas Rainey and his research

team are stepping up work on a

nanoparticle-removing new material they were

developing for biodegradable anti-pollution

masks.

“We have developed and tested a highly

breathable nanocellulose material that can

remove particles smaller than 100 nanometres,

the size of viruses,” Rainey said. “I see many

people wearing masks which are not tested for

viruses. We have tested this material thoroughly

and found it to be more efficient in its ability

to remove virus-size nanoparticles than the

high-quality commercially available masks we

tested and compared it with.”

Rainey said the team also tested the new

material for breathability.

“By breathability we mean the pressure or effort

the wearer has to use to breathe through the

mask. The higher the breathability the greater

the comfort and reduction in fatigue,” he said.

“This is an important factor for people who have

to wear masks for long periods or those with

existing respiratory conditions. Our tests

showed the new material was more breathable than

commercial face masks, including surgical

masks."

This new material has excellent breathability,

and greater ability to remove the smallest

particles. Rainey said the material could be

used as a disposable filter cartridge in face

masks.

This material would be relatively inexpensive to

produce and would therefore be suitable for

single-use. The cellulose nanofiber component is

made from waste plant material, such as sugar

cane bagasse and other agricultural waste

products and is, therefore, biodegradable. It

can be made using relatively simple equipment,

and so we can quickly produce large quantities

of the material.

“We have established proof-of-concept as a

nanoparticulate filtration material and we are

currently seeking industry partners," said

Rainey.

Republished courtesy of Queensland University of

Technology.

Changing Guidelines Relative to PPE Use in

Hospitals

The specifics of PPE use

have been controversial

since the pandemic first hit US shores. But once

the Centers for Disease Control and Prevention

(CDC) issued the recommendation two weeks ago

that everyone wear masks in public, hospital PPE

policies began shifting rapidly. Many providers

welcomed the change, and the number of

healthcare workers being

reprimanded for using their own PPE

appears to have plummeted.

But rolling out new policies in the midst of a

pandemic has created new problems: Frontline

providers aren't always clear on current

protocols. Institutional instructions on donning

and doffing a wider variety of PPE sometimes lag

behind or are completely lacking. And some

medical organizations, including

The American Association of Nurse Attorneys,

have urged the CDC to reconsider its loosened

standards, which allow for the use of bandanas

in lieu of masks, saying they "will most likely

result in the increased spread of the virus."

"Hospitals all over have greatly changed their

practices around PPE use in response to existing

shortages," said Eric Toner, MD, a senior

scholar at the Johns Hopkins Center for Health

Security who conducted

a new analysis

on how much PPE may be needed. "And these will

continue to evolve in response to local supply

and demand mismatches."

More Accurate Temperature Measurement Needed

I &E Technologies

have been deploying hundreds of

EBT (Elevated Body Temperature) Detection

Systems in food plants, manufacturing plants,

office buildings, hospitals, airports,

retirement facilities, amusement parks, etc.,

for over a month now across the country to help

screen individuals. While these thermal imaging

instruments are not medical devices and do not

replace conventional medical testing, they can

be used to give an early indication when

evaluating or screening a large population and

are quick and effective at a safe distance.

According to Eric Fritz, I.E, president “Systems

that claim to effectively scan groups of people

at once as they pass by the camera, we believe

will lead to a less accurate screening process

and ultimately could put the facility and it's

personnel at risk of "false-positives" or worse,

"false-negatives". Due to many parameters

that affect temperature measurement accuracy

with any thermal imaging camera, it is important

that the targets remove any glasses to open the

view to the tear ducts, the cameras are in

focus, the target is at the correct distance,

the camera has the correct resolution and field

of view for the distance, the camera has the

correct frame rate, the system collects

accurate, repeatable, and reliable temperature

data, and the system accounts for other elements

like environmental temperatures inside/outside,

stabilization of the target, etc., to minimize

interpretation of the data being collected.

Danone Closes Wuhan Plant but has High

Production Rates Elsewhere

The French-based beverage company behind Evian

and other bottled water has closed its factory

in Wuhan, China - its second largest market - as

a result of COVID-19.

But other plants are compensating .

Danone SA sales in the first quarter rose,

driven by Europe and North America, while it

withdrew full-year guidance due to the

coronavirus.

The French food company said sales came in at

6.24 billion euros ($6.78 billion) compared with

EUR 6.14 billion in the previous year period.

Sales rose 1.7% on a reported basis and 3.7% on

a like-for-like basis.

"First-quarter like-for-like sales growth is

ahead of the expectations set by the company

earlier in the year," Danone said.

The growth was partly attributed to a sales rise

in March, boosted by the short-term effects of

both a shift to at-home consumption as well as

pantry loading in Europe and North America.

Danone's water division registered a decline of

6.8% like-for-like, while the essential diary

and plant-based business grew 4.6%. Specialized

nutrition recorded a growth of 7.9% on a

like-for-like basis.

Danone virus protection measures at plants

include

§

Hourly workers will receive a premium payment

equivalent to 15% of their base hourly rate for

all hours worked.

§

If a worker contracts coronavirus or must stay

isolated at home because they have been in close

contact with someone with the virus, they are

eligible for up to 80 hours of paid quarantine

leave.

§

Workers who have childcare needs are eligible to

utilize any state, city or provincial paid sick

leave where applicable.

Danone Indonesia is producing bottles for hand

sanitizers.

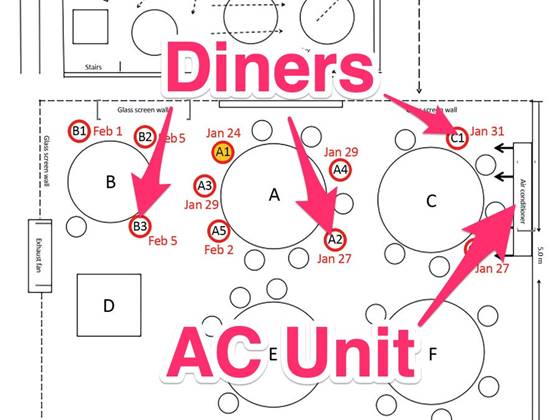

Restaurant Ventilation Systems Spread Virus

In an

early-release research letter

in the journal Emerging Infectious Diseases,

researchers said they found that 10 people who

were sitting near one another at a restaurant in

China in January got COVID-19, and that it

likely spread because of the restaurant's air

conditioner.

·

Three seemingly healthy families were struck by

COVID-19 after dining at neighboring tables in a

windowless restaurant in Guangzhou, China, in

January.

·

Researchers studying the case think that the

restaurant's air conditioner blew the viral

droplets of one person who was asymptomatic

farther than they might have normally gone. Nine

other people across the three families later got

sick.

·

The researchers described their findings in an

early-release research letter published

in the journal Emerging Infectious Diseases

earlier this month.

-

Patient A1 was

infected with

COVID-19, but

asymptomatic

when they dined

with their

family (A2-5) on

January 24.

-

The AC picked up

air droplets

from the breath

of patient A1

and blew them

around the room.

Water droplets

usually don't

travel more than

a meter without

assistance.

-

Nine other

people (four

members of A,

three of B, and

two of C) later

tested positive

for COVID-19 and

were traced to

A1.

-

"The key factor

for infection

was the

direction of the

airflow," a

group of

scientists from

Guangzhou wrote

in a letter published

in the Emerging

Infectious

Diseases

Journal. "Droplet

transmission was

prompted by

air-conditioned

ventilation."

·

It's a frightening prospect for people who are

trying to keep a healthy distance from others.

However, in a potentially hopeful finding for

the locked-down restaurant industry, none of the

73 other diners and eight employees in the

restaurant at the time got sick, the researchers

said.

·

"To prevent the spread of the virus in

restaurants, experts recommend increasing the

distance between tables and improving

ventilation.

·

For the struggling restaurants desperate to

reopen in the coming months, the researchers'

findings are evidence that work will not just

return to normal after the pandemic, but there

might be ways to limit the risk of spreading the

virus. There will likely be caps on how long

patrons can spend eating, restaurants will

operate at lower capacity, air conditioning or

heating may have to stay off, and employees

might be advised to wear masks.

·

McIlvaine comes to a different conclusion

relative to the air conditioning. HEPA filters

should be installed and air flow directed from

ceiling to floor and designed as much as

possible to capture any virus clouds and remove

the virus as it passes through the AC system.

Turning off the air conditioning system will

still allow virus clouds to follow air currents.

The result could have been transmission of the

infection to D,E, and F

tables and even more infections.

More Coronavirus Outbreaks at Meatpacking Plants

Than Previously Estimated

The number of coronavirus

outbreaks at dozens of meatpacking plants across

the nation is far more extensive than previously

thought, according to an exclusive review of

cases by USA TODAY and the Midwest Center for

Investigative Reporting.

And it could get worse. More than 150 of

America’s largest meat processing plants operate

in counties where the rate of coronavirus

infection is already among the nation’s highest,

based on the media outlets’ analysis of

slaughterhouse locations and county-level

COVID-19 infection rates.

These facilities represent more than 1 in 3 of

the nation’s biggest beef, pork and poultry

processing plants. Rates of infection around

these plants are higher than those of 75% of

other U.S. counties, the analysis found.

And while experts say the industry has thus far

maintained sufficient production despite

infections in at least 2,200 workers at 48

plants,

there are fears that the number of cases could

continue to rise and that meatpacking plants

will become the next disaster zones.

"Initially

our concern was long-term care facilities,"

said Gary Anthone, Nebraska's chief medical

officer, in a Facebook Live video Sunday. “If

there's one thing that might keep me up at

night, it's the meat processing plants and the

manufacturing plants."

Workers can stand too close together in certain

areas of a meat packing facilities, enabling the

spread of coronavirus. This is a look inside a

chicken processing plant, but the process is

similar no matter what type of meat is being

processed.