Coronavirus Technology Solutions

September 16, 2020

Disinfection Webinar October 1

Dynamic Filter and Media Market Could Reach $80 billion in 2022

Concerns about Excess Meltblown Capacity

Protective Health Making 50,000 N95 Respirators per Day

UV Light has Risks as Well as Benefits

___________________________________________________________________________

Disinfection Webinar October 1

A webinar on disinfection technologies to mitigate COVID is scheduled for 10:00AM CDT October 1, 2020. To register Click here

Inactivation of aerosols is beneficial for

· building and furniture surfaces

· air

· masks

· filters

· ductwork

· clothing

· shoes

· transportation

· Industrial space

· hands

There are ample products in the form of hand sanitizers which are available and do not need to be covered in this webinar. Disinfectant wipes that are effective in cleaning building and furniture surfaces. Although important this technology will not be covered in the webinar.

What will be covered are other technologies such as UV light and chemical aerosols. The Alerts have covered these technologies along with anti-bacterial coatings for surfaces, masks and even filters. Excerpts and links to these articles are found at. Search All Alerts by Keyword

Search results for: disinfection

69 results found.

7 pages of results.

Sorted by relevance / Sort by date

1. McIlvaine Coronavirus Market Ale

... Most Facilities are Increasing Their Cleaning Programs to Combat COVID New York Subway Testing UV Disinfection Battelle H2O2 System for Oklahoma Altapure Uses Ultrasonic Dispersion in its Mask Disinfection Systems Russian ...

Terms matched: 1 - Score: 160 - 27 May 2020 - URL: http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-05-27/Alert_202005027.html

2. McIlvaine Coronavirus Market Ale

... of Nebraska Study Noverus Blog Confirms the Dangers of Air Borne Virus Transmission Novaerus Air Disinfection Unit Recognized by Chinese Regulatory Agency Plasma Treatment of Airborne Viruses is Effective Daikin Technology ...

Terms matched: 1 - Score: 149 - 29 Apr 2020 - URL: http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-04-28/Alert_20200428.html

3. McIlvaine Coronavirus Market Ale

... Delivery Problems Microwave can Sterilize N95 Masks Lots of Decontamination Investigations Lysol Approved as a Disinfectant for COVID Wipes Demand Still Exceeds Supply OZ Health Contracts with Oerlikon for Spunbond and ...

Terms matched: 1 - Score: 128 - 14 Jul 2020 - URL: http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-07-13/Alert_20200713.html

4. McIlvaine Coronavirus Market Ale

... July 16, 2020 The Semantics of Masks and Airborne COVID Transmission Altapure Offers Both Disinfection Systems and Cabinets CRI has New Mobile Air Purifier Trane has Suite of Services to ...

Terms matched: 1 - Score: 116 - 16 Jul 2020 - URL: http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-07-16/Alert_20200716.html

5. McIlvaine Coronavirus Market Ale

... Already Launched at U of I Urbana Airborne Transmission Workshop, August 26 and 27 Disinfection Using UV Light and Nanoscan3 from Sick Sweden Doesn't Recommend Face Masks But is Paying ...

Terms matched: 1 - Score: 116 - 21 Aug 2020 - URL: http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-08-21/Alert_20200821.html

6. McIlvaine Coronavirus Market Ale

... Surfaces? Study on Hamsters Confirms Efficacy of Face Masks Contec Expands Supply of Sporicidin Disinfectant Silicon Based Membrane for Masks has Efficiency and Other Advantages Black & Veatch Develops Boarding ...

Terms matched: 1 - Score: 98 - 4 Jun 2020 - URL: http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-06-03/Alert_20200603.html

7. Coronavirus Alerts Table of Contents

... a Week Early by Sewage Tracing H2O2 Fogger Used at Columbia MD Swimming Pool H2O2 Disinfection for Super Yachts August 28, 2020 LG PuriCare is a Powered Respirator and Monitor ...

Terms matched: 1 - Score: 94 - 15 Sep 2020 - URL: http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/TofC.html

8. McIlvaine Coronavirus Market Ale

... World Market March 13, 2020 Air Filtration and Purification World Markets with Coronavirus Supplement Disinfectant Wipes Market Demand is Unprecedented Comparing eSpin, Hifyber, Big Nano, and NXT ...

Terms matched: 1 - Score: 85 - 23 Jun 2020 - URL: http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-06-22/Alert_20200622.html

9. McIlvaine Coronavirus Market Ale

... HEPA Filters for Indian Government Buildings CDC Recommends HEPA Filters to Capture Viruses in Buildings Disinfection Tunnel for Sports Stadiums ____ More on Precipitators for Virus Capture In the Alert ...

Terms matched: 1 - Score: 84 - 5 Jun 2020 - URL: http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-06-05/Alert_20200605.html

10. McIlvaine Coronavirus Market Ale

... Many Countries Including Australia Kuraray will Produce Meltblowns for 300 Million Masks per Year Large-scale Disinfection Using Ultraviolet (UV) Technology from LED (light-emitting diode ____ Filters and ...

Terms matched: 1 - Score: 82 - 22 Jul 2020 - URL: http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-07-21/Alert_20200721.html

Result Pages: 1 2 3 4 5 6 7 Next >>

The webinar will include discussions of the options as well as several presentations

Young L. Kim of Purdue will be discussing a disinfection system which has no harmful chemicals. Photodynamic therapy uses a photosensitizer, a chemical that reacts with oxygen in the presence of light, to produce oxygen free radicals. These radicals are highly reactive, meaning they trigger other chemical reactions, including ones that kill harmful pathogens.

Instead of using expensive medical photosensitizers, Purdue has identified several FDA-approved food coloring dyes that can be used to generate free radicals in visible light. The system uses ultrasound to generate small aerosols containing the food coloring so that the dyes can float and linger in the air. The aerosols are barely visible, and their small size and short lifespan in light means they don’t stain surfaces.

PathO3Gen Solutions executives will be discussing foot sanitizers relative to the reduction of HAI including coronavirus at hospitals, pharmaceutical, food manufacturers as well as public places. In past webinars they have established the effectiveness of these sanitizers. Their findings are also significant in showing the risks of virus transmitted from shoes which become airborne either directly or after contaminating floors.

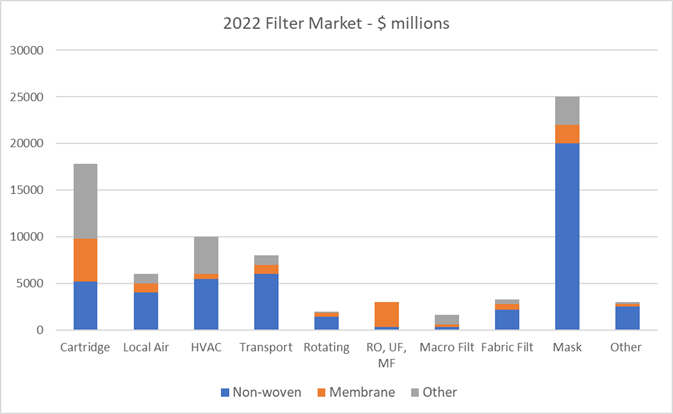

Dynamic Filter and Media Market Could Reach $80 billion in 2022

The segments of the filtration industry which use non-woven and membrane filter media are poised to grow to $80 billion in 2022. This represents an increase of 33% over the 2019 revenues. Most of the growth is attributable to coronavirus related mitigation efforts. The assumption is that the filtration industry will be able to deliver the needed masks and filters. Air pollution and drought caused by climate change create the balance of the growth. The air pollution prevention benefits of masks, HVAC filters, and dust collectors are greater due to the steady increase in wildfires. Increasing use of desalination and water reuse will be another consequence of climate change. Battery separator markets will also increase as electric vehicles are viewed as a climate change solution.

If the filtration industry cannot meet the demand or if it fails to convince purchasers of the real benefits of better filtration, revenues could plateau at 2019 levels or even fall depending on the havoc wrought by COVID.

These are filter revenues FOB manufacturer.

Media revenues range from 20 % for masks to 60% for fabric filters.

There is now strong evidence the Coronavirus is spread by small aerosols. Cloth masks and inefficient filters act as aerosol generators. The medical community is finally realizing that the solution lies in high efficiency masks and filters. In the past the assumption was that these products could not be made available to the general public. The filtration industry is capable of meeting the very large demand with a mix of meltblown, nanofiber, membrane and other media.

The same media which can be used in masks and HVAC filters has applicability in gas turbine intake filters, dust collectors, and liquid cartridges. The non-woven media market will be over $25 billion of which only 40% will be mask media. Concerns that media manufacturers have about building capacity which will go unused after a vaccine is perfected are unwarranted. Not only are there non-mask uses but air pollution, indoor pollution, wildfires, and new viruses will boost mask demand.

The “other segment” includes vacuum cleaner bags and battery separators. It does not include medical and cleanroom garments. However, these can use the same media and are analyzed in McIlvaine Cleanroom and other publications.

This is a very dynamic market. The U.S. election in November will determine the extent of future trade barriers and the amount of international trade. Technical developments in media and products will continue to shape the market.

It is therefore essential that filter and media companies prepare comprehensive strategies which are flexible enough to adjust as conditions change. The Mcilvaine Company has a Filter and Media Strategic Management Program which includes continually updated and detailed forecasts plus tools to pursue the market opportunities.

Bob McIlvaine can provide more information on the program. He can be reached at rmcilvaine@mcilvainecompany.com or 847 226 2391.

Concerns about Excess Meltblown Capacity

In 2019, the U.S. produced 15% of meltblown in the world while China accounted for 45%. Peter Navarro has long advocated moving manufacturing back to the United States, and during the Republican National Convention President Donald Trump pledged to do just that with crucial medical supplies.

“We are taking our business out of China. We are bringing it home,” he said.

But the meltblown example illustrates the failure of this administration to take necessary steps to fulfill this promise.

Meltblown is spun out of plastic pellets made from oil, typically polypropylene or polyethylene. The pellets are fed into a heated metal extruder, and jets of hot air force the liquefied plastic through an array of extremely small holes, producing fine plastic fibers. As the fibers cool, they overlap and stick together, forming a dense mesh.

This year, American meltblown makers have been ramping up supply. But some say they need more government support to meet the demand.

Mike Clark, a division president at Hollingsworth and Vose of East Walpole, Massachusetts, said his company has tripled production of meltblown by ramping up and exiting other markets. But he and other makers have reservations about investing significant sums of their own money.

After the H1N1 epidemic in 2009, Hollingsworth and Vose purchased a new meltblown machine, but the demand for N95s plummeted when the virus dissipated, Clark said.

The company received a government contract for $1.9 million to produce an additional 27.5 million N95 masks, but it doesn’t include long-term purchase guarantees.

“It’s half the problem solved,” Clark said.

Dan Reese, president of Prestige Ameritech, the largest domestic maker of medical N95 masks, said he emptied his own savings during the H1N1 flu outbreak to boost his output, only to end up near-bankrupt and laying off workers when demand dried up.

He currently buys meltblown fabric from wherever he can get it and estimates it would cost $15 million and take a year to start producing his own. A machine alone costs $5 million.

“I don’t have the cash,” he said. “If we continue to ramp up our production like we plan, we’re going to run out of meltblown.”

Between mid-April and early May, four N95 manufacturers — O&M Halyard, Honeywell, 3M and Hollingsworth and Vose — received a total of $134.5 million to increase production. The federal government also approved smaller contracts this summer with NPS Corp. and Lydall to bolster meltblown production.

But the Trump administration has not specifically restricted exports of meltblown material, a power it can use under the Defense Production Act. And U.S. manufacturers have continued exporting this textile overseas.

They’ve sent more than 40 shipping containers of meltblown material and related supplies offshore, with about 40% of it going to Pakistan, according to an Associated Press analysis of data from Panjiva, the supply-chain research unit at S&P Global Market Intelligence. That compares with only six shipping containers during the same period in 2019.

Pre-pandemic, 24 U.S. companies were making meltblown, with 79 machine lines in operation, according to Brad Kalil of the Association of the Nonwoven Fabrics Industry. But only a fraction of that was going into medical respirators, Kalil said.

By the end of 2021, he said, there will be 28 new lines. The Trump administration has helped pay for seven of those lines, said Kalil. But mostly they’re being built through private investment, which may not pay off.

“If every single country and region decides they’re going to make their own to be self-sufficient, we’ll have way too much meltblown probably within the end of next year,” Kalil said.

Still, some U.S. companies are rolling the dice.

As Seattle became a major coronavirus hot spot this spring, the clothing and sportswear company Outdoor Research also switched gears. It had the money, two U.S. factories and highly skilled employees, so it set out to make masks, said Jason Duncan, a company vice president.

The company started with cloth masks for the general public, but soon pursued making medical-grade masks, investing millions to convert an entire floor of its downtown headquarters into an FDA-approved facility.

Outdoor Research used its deep ties in the industry to secure meltblown material and, this summer, the FDA approved its N95 masks.

Where is it getting its meltblown? “That’s a closely guarded secret,” Duncan said

Protective Health Making 50,000 N95 Respirators per Day

A manufacturing plant that produced store display fixtures before the coronavirus pandemic has retooled to produce N95 respirators that are certified by the National Institute for Occupational Safety and Health (NIOSH).

Paterson-based Protective Health Gear (PHG) can produce approximately 50,000 respirators a day, amounting to 1.5 million per month.

“We are thrilled to have begun production of the N95 masks at our Paterson, New Jersey headquarters,” said Brian Wolin, chief executive officer for Protective Health Gear, during a ribbon cutting ceremony outside the 255 Iowa Avenue facility on Wednesday afternoon. He was disheartened at seeing healthcare workers pleading for personal protective equipment like high-quality masks in March. “I listened and watched day in and day out about the dire need for PPE and the need to bring the manufacturing of that PPE back to the United States.

Wolin said the firm began making masks earlier this month. His firm has secured a contract from the Veterans Affairs to supply them with masks. His firm has the capability to produce and distribute millions of masks, he said, as a deadly mix of flu and Covid-19 is expected to hit the country in the fall.

Wolin and his colleagues received accolades from mayor Andre Sayegh and congressman Bill Pascrell for making the respirators vital to battling the coronavirus pandemic in Paterson and the United States.

“As we prepare for the anticipated second wave, we will be properly prepared because of what you see here,” said Sayegh. “I want to salute them.”

Sayegh said most of the company’s several dozen workers are residents of Paterson. The firm employs 30-40 people.

“We are honored to bring jobs to Paterson and to make a product for frontline workers and first responders that is made in America,” said Wolin.

The company’s N95 mask also has features such as foam cushions on the interior to reduce the discomfort of wearing a mask for hours.

UV Light has Risks as Well as Benefits

During the coronavirus pandemic, some are turning to ultraviolet light to disinfect objects, but how safe are they? And are they effective at fighting the coronavirus?

The U.S. Food and Drug Administration warned about the use of these lights during this pandemic in a statement at the end of August.

“UVC lamps used for disinfection purposes may pose potential health and safety risks depending on the UVC wavelength, dose, and duration of radiation exposure,” the FDA stated.

The FDA said there is limited knowledge about the effectiveness of these UVC lights when it comes to inactivating the novel coronavirus, and in some cases, the lamps have the potential to cause harm.

The effectiveness of UVC lamps in inactivating the SARS-CoV-2 virus is unknown because there is limited published data about the wavelength, dose, and duration of UVC radiation required to inactivate the SARS-CoV-2 virus,” the report stated. “It is important to recognize that, generally, UVC cannot inactivate a virus or bacterium if it is not directly exposed to UVC. In other words, the virus or bacterium will not be inactivated if it is covered by dust or soil, embedded in porous surface or on the underside of a surface."

The report, said UVC radiation has been used in some cases to disinfect water, air and nonporous surfaces. It has also been used for decades to stop the spread of tuberculosis and certain bacteria, which led to UVC lamps often being called "germicidal" lamps, according to the agency.

UVC radiation has been shown to attack the surface protein of SARS-coronavirus leading to inactivation of the virus, but that is different to the current SARS-CoV-2 virus that causes COVID-19, according the report.

Aside from needing direct exposure to a virus on an unsoiled surface, the FDA stated that UVC radiation has other limitations with inactivating viruses. Many home-use UVC lamps are low dose, so it requires a longer surface exposure time with the light to inactivate the virus or bacteria.

UVC radiation is often used to disinfect the air through ducts, health experts told Fox News. This type of disinfection is typically used in hospitals when no humans are present.

“This is the safest way to employ UVC radiation because direct UVC exposure to human skin or eyes may cause injuries, and installation of UVC within an air duct is less likely to cause exposure to skin and eyes," the FDA added in Wednesday's report.

The report also cautioned about the risks of using UVC light and said direct exposure can cause burns to the skin and eye injury. Another concern mentioned is ozone, which is emitted from the UVC lamps and can irritate airways, according to the FDA report. Materials like plastic and dyed textiles can be degraded by UVC light, and some lamps can even contain mercury, which is extremely toxic and poses a health threat if the lamp is broken, the FDA cautioned.

The FDA further cautioned that there are different types of UV lamps, with different applications. Pulsed xenon lamps, which are filtered to emit UVC radiation, are used at times in hospitals to treat environmental surfaces such as operating rooms when humans are not present. Light-emitting diodes (LEDs) are also becoming more available, emit a very narrow wavelength band of radiation, and don’t contain mercury. However, this lamp may be less effective for germicidal applications, the agency stated.