Variable Speed Drives can save Billions of Dollars in meeting 316B – Hot Topic

Hour September 11

The Hot Topic Webinar on power plant pumps had benefits which were both general

and specific. The format of the webinars is flexible to allow for introduction

of important new subjects. The one which was introduced for this session

was the ability of variable speed drives to potentially save power companies

billions of dollars. There is evidence that power plants can use this technology

and avoid installing cooling towers to meet the 316B water intake rules.

Starting with the general benefits,

Randal Ferman of EKWESTREL

discussed the purpose of identifying “minimum flow.”

The main purposes of minimum flow are to establish

The minimum flow has to take into account a number of pump phenomena.

William Livoti

of WEB recommended that power

plants assess their pump requirements and consider variable speed drives to

reduce energy consumption. He cited the advantages when handling off peak loads.

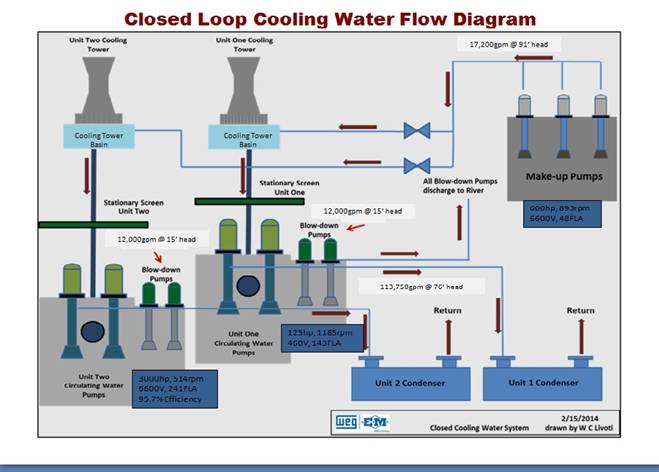

A specific example was given for the VFD saving with cooling water makeup pumps.

The number of pumps and potential savings is substantial.

Jason Hoover

of Siemens was able to cite

very detailed analyses which show that variable speed drives can be used with

once through cooling systems to meet the requirements of 316B. This regulation

is designed to prevent fish kill and is based on requiring minimal entrainment

of fish and harm to fish which are temporarily entrained. Jason showed that the

use of variable speed drives reduces the entrainment and harm by over 80

percent. There are many nuances to the rules and flexibility in the way they can

be treated by the individual states. So the extensive work done by Siemens

will be valuable to the plants seeking to obtain compliance

Bob McIlvaine provided an overview of the pump coverage in

Power Plant Systems and Components

and

Gas Turbine and Combined Cycle Decisions. Coverage

includes basic design considerations as well specifics such as the 316B

requirements. Each process option will be evaluated. For example, the conversion

of coal-fired power plants to burn natural gas introduces a new challenge. How

do you marry the existing water systems with the new gas turbine?

Sargent

& Lundy has published several papers addressing solutions for specific

plants. These are included in the Systems.

The individual presentations follow:

Power Plant Pumps Webinar - Hot Topic

Hour September 11, 2014

For power plant pumps, discussion was the ability of variable speed drives to

potentially save power companies billions of dollars. There is evidence that

power plants can use this technology and avoid installing cooling towers to meet

the 316B water intake rules.

Revision Date:

9/11/2014

Tags:

221112 - Fossil Fuel

化石燃料,

221112 - Fossil Fuel

化石燃料,

WEG, Ekwestrel, McIlvaine, Pump

Bob McIlvaine provided an overview of the pump coverage in Power Plant Systems

and Components and Gas Turbine and Combined Cycle Decisions. Coverage includes

basic design considerations as well specifics such as the 316B requirements.

Revision Date:

9/11/2014

Tags:

221112 - Fossil Fuel

化石燃料,

221112 - Fossil Fuel

化石燃料,

McIlvaine, Pump

William Livoti of WEB recommended that power plants assess their pump

requirements and consider variable speed drives to reduce energy consumption. He

cited the advantages when handling off peak loads. A specific example was given

for the VFD saving with cooling water makeup pumps. The number of pumps and

potential savings is substantial.

Revision Date:

9/11/2014

Tags:

221112 - Fossil Fuel

化石燃料,

221112 - Fossil Fuel

化石燃料,

WEG, Pump

Purpose of Minimum Flow by Randal

Ferman, EKWESTREL - Hot Topic Hour September 11, 2014

Randal Ferman of EKWESTREL discussed the purpose of identifying “minimum flow.”

§

The lowest continuous flow the pump is permitted to operate

§

Without reference to a specific vibration limit or other criteria

§

The ‘default’ pump manufacturer’s recommendation The main purposes of minimum

flow are to establish

§

Permissible vibration

§

Impeller cavitation erosion life

§

Radial bearing loading, shaft bending

§

Temperature rise The minimum flow has to take into account a number of pump

phenomena.

Revision Date:

9/11/2014

Tags:

221112 - Fossil Fuel

化石燃料,

221112 - Fossil Fuel

化石燃料,

Ekwestrel, Pump

“Monitoring for

Gas Turbine Combined Cycle Power Plants” - Hot Topic Webinar on September 18 at

10 a.m. Central

This webinar will be both organizational and informative. It is all part of a

whole knowledge system for gas turbine combined cycle plant operators -

Gas Turbine and Combined Cycle Decisions. The

free website and periodic webinars empower the operators to buy the best

products rather than the most familiar or least expensive.

The webinar on the 18th will try to answer the question: What are

the most important and difficult decisions you will have to make regarding air

and water monitoring equipment and services?

Panelists for Water Monitoring for Combined Cycle

Power Plants on Sept. 18, 2014:

Kai D. Rondum,

Product Manager for Boiler Water Treatment at

Ashland Water Technologies

Joe Zimmerman,

Director of Marketing at Chemtrac

Systems, Inc.

Ken Kuruc,

Manager of Industry Accounts, Fossil at

Hach Ultra Analytics

David M. Gray,

Senior Product Manager at Mettler-Toledo

Thornton, Inc.

On August 28 we conducted a webinar on

Degasification and Demineralization. One

of the discussions was “Critical

Measurements”

by Jean Holz of Hach. She

described which measurements were needed at each point in the boiler feedwater

and condensate return system. When asked about optical vs. electrochemical

choices, she replied that the range of choices depend on the point at which you

are measuring and whether you need to measure a few ppb or some higher number.

She observed that dissolved oxygen is measured in three accepted methods:

Winkler Titration, Clark Cell Electrodes and Luminescence-based Optodes.

LDO has proven to be the best choice except where you need to measure at very

low levels.

These are the types of pertinent questions that the operators want

answered. Others would be:

With fast start HRSGs and constant cycling what instrumentation solutions will

counter some of the negative consequences of this operating mode?

What are the water chemistry issues facing GTCC operators which are unique to

this type of power generation? Which require continuous measurement and which

can be measured periodically?

What are the monitoring needs if zero liquid discharge technology is mandated?

What other questions are GTCC operators asking?

This webinar is free for power plant owners and operators.

Click here to view schedule and register.