“MATS Timing

and Technology Options” discussed in Hot Topic on August 7, 2014

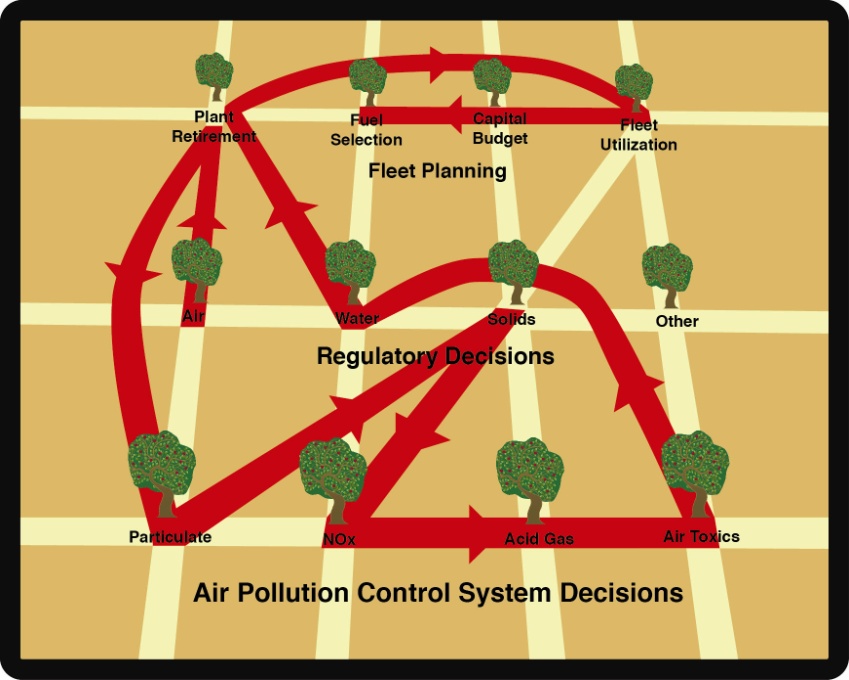

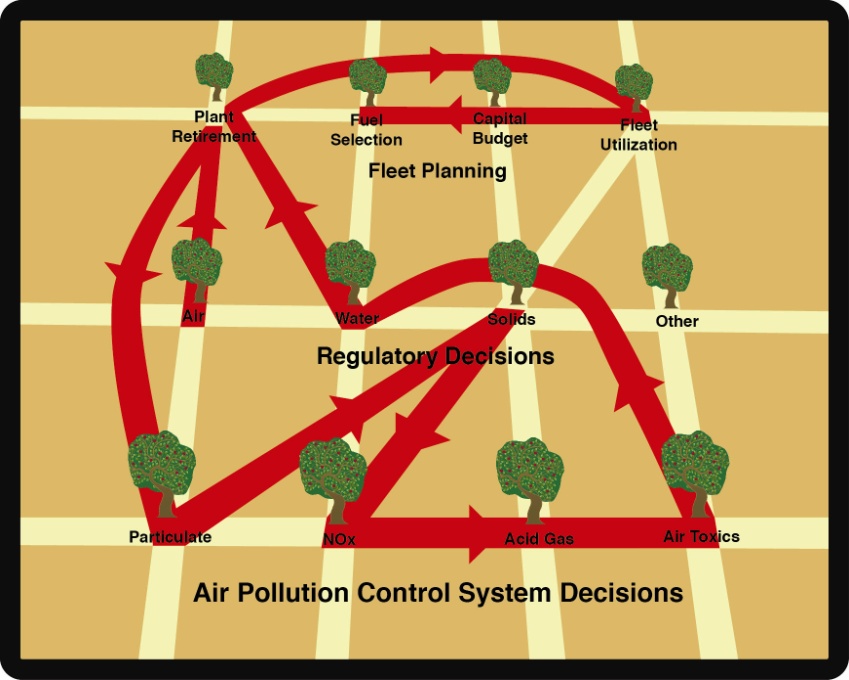

The webinar was crafted to assist power plants dealing with meeting the new

Mercury and Air Toxic Standards (MATS rules). The challenge is that the best

solution for mercury removal may not be the best solution for removing the

necessary quantities of acid gases and fine particulate. The best air pollution

solution may not be the best environmental solution when water and solid waste

aspects are considered. So you need to travel back and forth between technology

solutions to find the one most appropriate to your needs. The McIlvaine system

for doing this is equivalent to a trip using GPS and is labeled Global Decisions

Positioning System (GDPS).

This GDPS takes you back and forth through a number of free websites each

focused on one of these decision areas

Continuous Analyses.

The webinar referenced these websites and displays.

The webinar included insights from experts on the latest developments and how

they may affect decision making.

Those experts included:

§

Gifford

Broderick, Combustion

Components Associates, Inc

§

Kevin Crosby, Technical Director,

The Avogadro Group, LLC

§

Paul Barilla, P.E., Consultant

The large number of uncertainties makes it difficult to determine a course of

action to deal with the Mercury and Air Toxics Standard.

You may initially reject plant retirement as a solution but as the cost

of the compliance options mount, you may have to revisit that decision. You may

make a tentative decision to use wet scrubbing but then find that the water

pollution control costs make this unattractive.

A dry scrubber may look attractive until you evaluate the restrictions on

flyash sales and landfill costs.

The result is that the MATS decision process is complex and can be likened to a

maze. This webinar provided the equivalent of a GPS system to negotiate the

maze. It could be called the MATS Global Decisions Positioning System™

(GDPS).

MATS GDPS

Plant retirement is the first consideration.

Capital investment to meet MATS will be substantial.

An old plant may only be valued at $500/kW. Expenditures to meet MATS may

in an extreme case be $400/kW. So

you are nearly doubling your investment. Will it be worthwhile? Here are some of

the factors to be considered.

|

Factors Favoring Retirement |

Factors Favoring Retention |

|

|

Excessive Regulatory Cost |

Alternative

Options |

Factors Favoring

MATS Investment |

|

MATS |

GTCC |

Demand Growth |

|

CCR And Effluent |

Wind |

High Gas Prices |

|

Ambient Air Quality |

Solar |

Technology to Make MATS Lower Cost |

|

Carbon Tax |

Demand Reduction |

Marginal Coal Plants Retired Instead |

Another option is to convert to natural gas-firing in your existing boiler.

Gifford Broderick, Combustion

Components Associates, addressed this option.

Converting to natural gas-firing could cost less than $ 100/kW. This compares

favorably to the cost of scrubbers and other air pollution control to upgrade

the coal-fired power plant. It is also 1/10 the cost of a new GTCC plant.

This is the initial stop but will need to be revisted as the cost of the MATS

compliance option is further developed.

The decision to upgrade to meet MATS has to start with particulate

control. The MATS rule allows the operator to either meet a very low PM2.5

limit or to separately measure toxic metals. Due to the difficulty in measuring

toxic metals virtually all plants will opt for the lower particulate limit.

You need to determine what measurements need to be made in advance of an

investment decision and then what measurements will be needed to avoid

violations when the solution is up and operating.

Kevin Crosby, Technical Director, The

Avogadro Group, LLC, addressed the monitoring needs

at all points along the way. There are continuous monitoring and periodic

testing options for toxic metals, mercury and HCl. So these approaches should be

determined in advance.

Due to some oversights in the mercury monitoring rules, the selection of

a monitoring method may affect the

equipment choices. If you use sorbent traps rather than mercury CEMS you may

need better particulate control. The reasoning is that the sorbent traps pick up

particulate mercury. Kevin addressed this observation by saying that a filter

prior to the sorbent trap would eliminate the measurement of particulate mercury

in the sorbent trap itself. However, if particulate mercury is substantial it

would need to be addressed.

|

Keep the Existing Precipitator |

Change to Fabric Filter |

|

New downstream scrubber will obtain additional particulate removal. |

Can be inserted into existing precipitator casing. |

|

Can add a wet ESP after the scrubber. |

Will be used in conjunction with dry scrubbing or DSI. |

|

Upgrade the existing precipitator. |

Reduce the sorbent injection for mercury control. |

|

|

Hot Gas Filtration for all MATS requirements—See McIlvaine Website

Hot Gas Filters - Continuous Analyses |

There are proposed regulations in the U.S. dealing with coal combustion residues

and effluent water quality. Dry

scrubbers create combustion residues and wet scrubbers create effluent.

So MATS decisions have to take these future standards into consideration.

|

Choice of dry scrubbers with fabric filter for both particulate control

and SO2 capture will result in unsalable flyash. |

|

Activated carbon in ash may make flyash unsalable. |

|

New CCR regulations can impact the MACT choice. |

|

Ramifications of CCR and effluent analyzed on McIlvaine website: |

|

Many plants will have to meet new NOx limits as a result of

federal or state rules. SCR is a big investment and takes up lots of

space. So you will want to

integrate NOx and MATS decisions |

|

NOx catalysts can also oxidize mercury and allow the wet

scrubber to capture more mercury. |

|

Hot gas filtration for all MATS requirements—See McIlvaine Website

|

There is a requirement in MATS to reduce HCl. EPA says much of the benefit of

MATS is the SO2 reduction which will coincidently take place with HCl

capture.

MATS HCl Capture Table Low Sulfur Coal and Use Existing Precipitator

|

|

a

FGD Type |

b

Reagent |

c

Efficiency |

d

Performance |

e

Maintenance |

f

Capital Cost |

g

Operation Cost |

|

1 |

Wet |

Limestone |

High |

Reliable |

Medium |

High |

Low |

|

2 |

Wet |

Lime |

High |

Reliable |

Low |

Medium |

Medium |

|

3 |

Spray Drier |

Hydrated Lime |

High but limits |

Atomizer Changes |

Medium |

Medium |

Medium |

|

4 |

Circulating Dry |

Hydrated Lime |

High |

Reliable |

Medium |

Medium |

Medium |

|

5 |

DSI |

Hydrated Lime |

Medium |

Qualified |

Low |

Low |

High |

|

6 |

DSI |

High Reactivity Hydrated Lime |

High |

Qualified

|

Low |

Low |

High |

|

7 |

DSI |

Trona |

High |

TBO* |

TBO* |

Medium |

High |

|

8 |

DSI |

Double Alkali |

High |

TBO*

|

Low |

Low |

High |

|

9 |

HCl Prescrubber |

Water |

High |

TBO* |

Low

|

Medium |

Low |

|

*To be determined |

|||||||

One McIlvaine website covers the wet option

Wet Calcium FGD - Continuous Analyses

Another McIlvaine website covers DSI, spray driers, and circulating dry

scrubbers

Dry Scrubbing - Continuous Analyses

Hot gas filtration for all MATS requirements—See McIlvaine Website

Hot Gas

Filters - Continuous Analyses

Three air toxics addressed in MATS are mercury, HCl and toxic metals. The HCl

reduction is tied into the FGD. The

toxic metals will be removed by the particulate collector. So that leaves

mercury as the remaining contaminant to address.

McIlvaine has covered all the options for mercury reduction at

Mercury Removal - Continuous Analyses.

Individual presentations follow:

MATS Timing and Technology Options Webinar - Hot Topic Hour August 7, 2014

The webinar was crafted to assist power plants dealing with meeting the new Mercury and Air Toxic Standards (MATS rules).

Revision Date: 8/7/2014

Kevin addressed monitoring needs. There are continuous monitoring and periodic testing options for toxic metals, mercury and HCl.

Revision Date: 8/7/2014

Giff Broderick addressed the option of converting to natural gas-firing in an existing boiler.

Revision Date: 8/7/2014