CDS vs. SDI vs. SDA in Dry Scrubber Hot Topic Discussion Yesterday

The Dry Scrubber Hot Topic Hour Webinar on October 23, 2014 contained valuable

decisive classifications as well as little known facts and insights. This

positive result was the work of some very experienced and knowledgeable

individuals.

The

Dry Scrubbing - Continuous Analyses website

is free of charge and is also part of

Power Plant Systems and Components, which is free to power plants around the

world. The goal is to make the McIlvaine website the default starting

point for owners and operators of air pollution control equipment throughout the

world. About 20 percent of the session was devoted to China.

Paul Farber, who was the keynote

presenter will be in Thailand conducting a training course early next year and

will make sure that his students are aware of this site.

KC Cottrell

as a presenter talked about installations in Taiwan, Korea, and China.

Successes on the hybrid SDA-DSI are the work of

B&W in the U.S. and

GEA in Europe.

No one area of the world has a monopoly on dry scrubber knowledge. The reality

is that China, with hundreds of dry scrubber installations, has accumulated

knowledge which puts it on equal footing with the U.S., European, and Japanese

companies which originally brought the dry scrubbing technology to China.

Regarding the development of the expertise,

Joe Riley of

BoldEco cited some of the

early European work by Solvay

and the BoldEco European partner as the first sodium dry scrubber installation.

The first power installation known to the McIlvaine Company came as a result of

a bid request by a western U.S. utility. They wanted an alternative to the wet

limestone approach and were willing to fund three pilot plants using spray

driers. Niro teamed with

Joy and became the early

developer of the spray drier technology. In recent years, B&W has acquired this

technology.

Mike Widico

and Kevin Cosman of KC Cottrell

presented a number of positive features about their design. It is compact and

even with the cyclone can be fitted into most power plants. Because of the

cyclone to capture the calcium sulfate, the downstream precipitator is not

contaminated by large quantities of high resistivity dust.

Paul Farber provided a valuable overview with decisive classification of the

alternatives. Each of the three options has some advantages and some

disadvantages. Spray Dryers are less costly than circulating dry scrubbers but

have more limited SO2 removal capability. Paul was asked about the

potential of the hybrid DSI–SDA to improve this capability. He is of the opinion

that this combination will expand the range for SDA.

Next came a discussion of the Dry Scrubber Users Conference with

Shawn Veurink of

RPM who is the treasurer of

the organization. The meeting last month combined topical discussions, vendor

displays and plant presentations such as

Sherco 3 Plant Report. Larry

Glass, Engineer Sherburne County Generating Plant, combined topical

discussions, vendor exhibits and papers such as these.

Michael Polachek,

- Technical Manager PSEG Fossil

Dry Scrubber Layup Strategies

Craig Henry

JW Turk Plant Report

Darren Farnworth, (Regional

Sales Mgr., SST

Enviro Corp Solutions)

Significant Improvements Made in Lime Slurry Preparation for Use in SO2

Jeff Lester

Comanche Station Plant Report

John Kersch (Maintenance

Manager, NAES Corp. Logan Generating Company)

Logan Generating Plant Scrubber Optimization Project

Jim Butz (VP

Product Management, Novinda Corporation)

BOP Impact of Amended Silicates for Mercury Control

Steve Rudolph

and Michael Polachek

PSEG Mercer & Hudson Plant Report

The meeting next September will be in Rapid City, SD where the attendees will be

dining with the presidents on Mt. Rushmore.

Shawn also provided a set of power points on

RPM Solutions activities. He

was asked about methods to ensure the operability of the rotary atomizers.

RPM has a monitoring program which includes real time monitoring and data

collection.

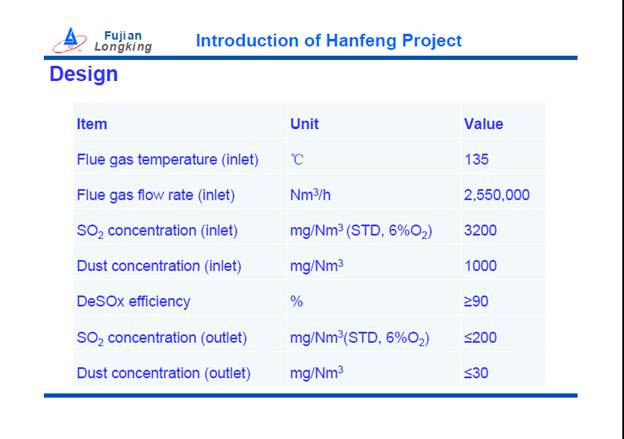

Jianchun Wang

of Lonjing Environment Technology

provided details on the Hangfeng Project. The installation has exceeded the

guarantee limits. SO2 removal is 93 percent.

An earlier paper by

Longking dealing with various

valuable end products produced from CDS calcium sulfate was also quickly

reviewed. The Chinese are ahead of the rest of the world in this

area. This paper is being uploaded to the website.

ITPE

in China has licensed MET in

the U.S. to supply its circulating dry scrubber with two humidification stages.

Here is the paper already on the site.

Over 140 installations of MET/ITPE dry scrubber

Joe Riley

of BoldEco provided insights

into the use of spray cooling and size reduction of reagents and how they are

enabling hazardous waste incinerator operators to reach SO2 emissions

as low as 1 or 2 ppm.

The information on the hybrid SDA-DSI was posted to the site earlier. It covers

work of B&W in the U.S. and GEA in Europe. GEA acquired Niro some years

ago and is a major worldwide spray drier supplier.

Boosting SDA efficiency with DSI at Wygen 3

Individual presentations follow:

Dry Scrubbing Webinar - Hot Topic Hour

October 23, 2014

The Dry Scrubber Hot Topic Hour Webinar on October 23, 2014 contained valuable

decisive classifications as well as little known facts and insights. This

positive result was the work of some very experienced and knowledgeable

individuals.

Revision Date:

10/23/2014

Tags:

221112 - Fossil Fuel

化石燃料,

KC Cottrell, BoldEco Environment, Longking, P. Farber & Associates, LLC,

McIlvaine, Dry FGD, Circulating Dry Scrubber, Spray Dryer, Dry Sorbent

Injection, Incinerator, Byproduct

Jianchun Wang of Lonjing Environment Technology provided details on the Hangfeng

Project. The installation has exceeded the guarantee limits. SO2 removal is 93

percent.

Revision Date:

10/23/2014

Tags:

221112 - Fossil Fuel

化石燃料,

Longking, Dry FGD, Circulating Dry Scrubber, Incinerator

McIlvaine Agenda by Bob McIlvaine - Hot

Topic Hour October 23, 2014

CDS vs. SDI vs. SDA in Dry Scrubber

Revision Date:

10/23/2014

Tags:

221112 - Fossil Fuel

化石燃料,

McIlvaine, Dry FGD, Circulating Dry Scrubber, Spray Dryer, Dry Sorbent

Injection, Incinerator

Paul Farber provided a valuable overview with decisive classification of the

alternatives. Each of the three options has some advantages and some

disadvantages.

Revision Date:

10/23/2014

Tags:

221112 - Fossil Fuel

化石燃料,

P. Farber & Associates, LLC, Dry FGD, Circulating Dry Scrubber, Spray Dryer, Dry

Sorbent Injection

Regarding the development of the expertise, Joe Riley of BoldEco cited some of

the early European work by Solvay and the BoldEco European partner as the first

sodium dry scrubber installation.

Revision Date:

10/23/2014

Tags:

221112 - Fossil Fuel

化石燃料,

BoldEco Environment, Dry FGD, Circulating Dry Scrubber, Spray Dryer, Dry Sorbent

Injection, Incinerator

Mike Widico and Kevin Cosman of KC Cottrell presented a number of positive

features about their design. It is compact and even with the cyclone can be

fitted into most power plants. Because of the cyclone to capture the calcium

sulfate, the downstream precipitator is not contaminated by large quantities of

high resistivity dust.

Revision Date:

10/23/2014

Tags:

221112 - Fossil Fuel

化石燃料,

KC Cottrell, Dry FGD, Circulating Dry Scrubber, Incinerator