Air Preheater Changes can greatly improve Plant Efficiency - Hot Topic on January 9, 2014

In the McIlvaine Hot Topic Hour on January 9, all three speakers addressed ways that heat exchange can be improved.

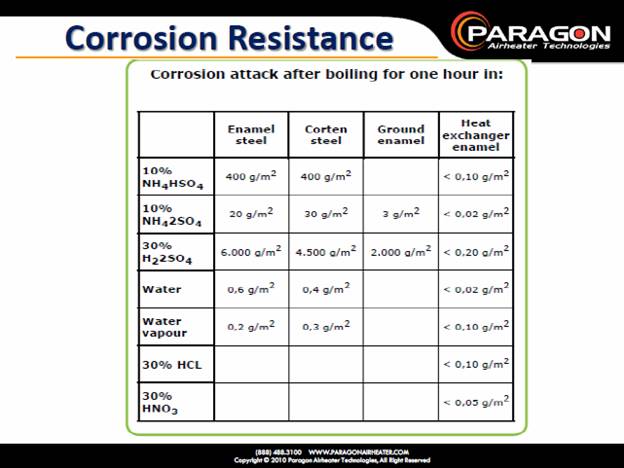

John Guffre, P.E., Research Scientist Paragon Airheater Technologies, Inc., covered the selection of materials and coatings for Regenerative Air Heaters (APH) to mitigate the corrosion and fouling issues associated with ABS and acid deposition. He pointed out that with the addition of ammonia and bromine ahead of the APH there are new corrosion challenges. A new type of enamel is far superior to the type used in the past. Following is a comparison.

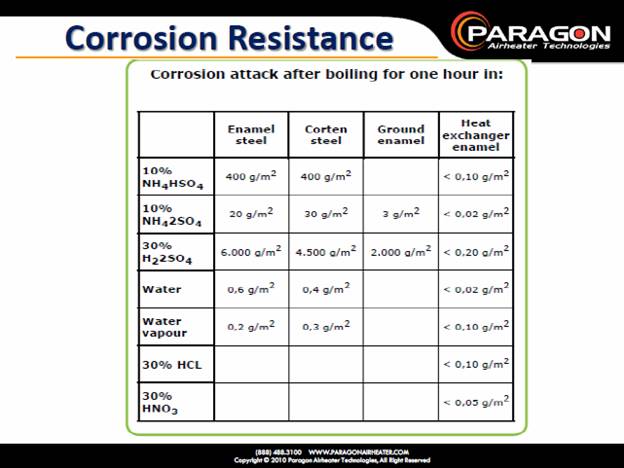

Sterling M. Gray, Manager SBS Injection Technology URS Corporation, showed how to improve thermal energy recovery from Air Preheaters which is typically limited by the presence of sulfuric acid and other fouling compounds in the flue gas stream. By eliminating these compounds from the gas upstream of the air preheater, its thermal performance and efficiency can be dramatically improved. Recent long-term testing by Alstom has shown successful operation at flue gas exit temperatures as low as 220oF, providing up to three percent improvement in plant heat rate and energy efficiency.

This successful 1500 hours test will be followed up by full scale implementation this year.

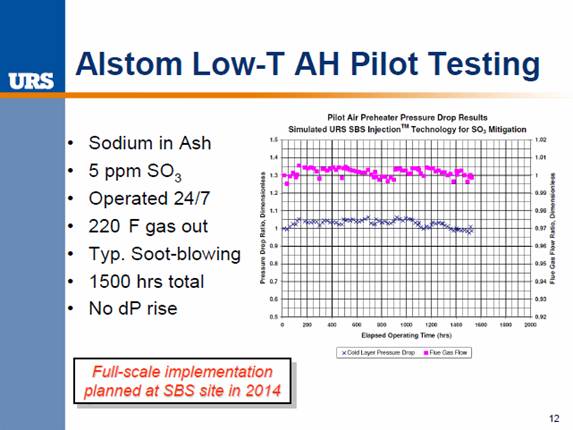

Bob McIlvaine discussed a number of alternatives based on presentations in previous Hot Topic Hours. Mitsubishi is cooling the gas to 195°F.

The Mitsubishi system, which reduces SO3, incorporates a gas-to-gas heat exchanger which is not new. But instead of providing gas reheat, the heat is used in the condenser thereby increasing efficiency and recovering 2 MW in a 600 MW boiler.

Placing the heat exchanger ahead of the precipitator and lowering the temperature below the acid dewpoint causes SO3 to condense on the flyash. In the case of a boiler with 10 ppm SO3, there is a 90 percent reduction. Also there is very high particulate removal. The secret to corrosion prevention is maintenance of the correct flyash to SO3 weight ratio.

The cost after three years compares very favorably to either a WESP or alkali injection. Nine installations all have SO3 stack concentrations of less than 1 ppm and particulate emissions as low as 0.002 gr/scf. Three of the units are more than 1,000 MW in size.

Both URS and Mitsubishi found that there was a need to have a certain ratio of flyash to SO3 to protect against corrosion.

Clear Edge and Tri-Mer have taken the concept of reducing acid gases and particulate to a much greater degree. The Clear Edge filter includes embedded nano-catalyst. With DSI and ammonia injection all the pollutants are eliminated.

There are a number of installations on biomass-fired boilers in Europe. So the system has been validated at full scale.

A good discussion among the participants revealed that to take advantage of this with the rotary air preheater you will have to use additional air and then find a way to utilize the heat in the excess air. So is it better to accomplish the reduction in this manner or to use a supplementary heat exchange system? Or should a heat pipe exchanger be used instead of a rotary? The answer depends on where the heat is going to be used.

McIlvaine believes that power plants can be innovative and follow the example of Great Rivers Energy which has an ethanol plant on site. Co-location of sewage treatment plants, recirculating aquaculture systems, desalination, zero liquid discharge, and many other possibilities exist.

The bottom line is that substantial plant efficiency increases can be achieved by extracting more heat from the flue gas.

Bios, Photos and Abstracts are as follows: BIOS, PHOTOS, ABSTRACTS - JANUARY 9, 2014.htm

The individual presentations are as follows:

§ Air Preheaters and Heat Exchangers Webinar - Hot Topic Hour January 9, 2014 (Webinar Recording dated: 1/9/2014)

§ Strategy to Improve Air Preheater Performance via SO3 Control by Sterling Gray, URS Corporation - Hot Topic Hour January 9, 2014 (Presentation dated: 1/9/2014)