Gas Turbine Inlet Filter – True Cost

Investigation

Speeches:

None are directly applicable although Mitchell

Krasnopoler of

Kiewit will be speaking about air

emissions and can address the fact that with

HEPA filter gas turbine inlets the outlets are

reduced below requirements in California where

ambient air levels exceed emission limits.

Stands:

The only stand displaying gas turbine inlet

filters is

DHA

stand 1331. An open meeting at their stand is

scheduled for 10:AM Wednesday but check updates

for changes.

Issues to be Discussed:

DHA will be displaying a rugged cleanable

HEPA filter. The debate has centered on whether

the theoretical value of lower maintenance with

the HEPA filter is worth the higher cost. The

argument against the HEPA filter has been

fragility.

(see separate analysis)

|

Company Name |

Last Name |

First Name |

Mobile |

Email |

|

DHA |

Vipperman |

Joe |

571 259 5840 |

|

|

DHA |

Hanna |

Jeff |

904 614 7226 |

|

|

DHA is a

supplier of

high efficiency

cleanable gas

turbine intake

filters |

||||

|

IAM |

Douglas |

Jerry |

xxxx |

|

As the costs and complexity of gas turbine

generators increase, end users seek ways to both

protect and maximize their investment. Many gas

turbine operators have explored high efficiency

options for their inlet filters. Switching to

HEPA grade intake filtration greatly reduces the

presence of contaminates in the turbine

compressor. This helps extend turbine life and

efficiency while reducing the costs in fuel and

maintenance. There have been a few drawbacks to

making the move to HEPA filters. One issue is

that with a more restrictive filter media comes

increased initial pressure drop. There have also

been questions surrounding the long-term

durability and lifespan of the HEPA filters.

The true cost of a gas turbine inlet filter can

be affected by a large number of factors. These

factors are not constants but are changing. The

filter purchaser is challenged to not only

identify these factors but to keep up with the

changes.

Large gas turbines are used to generate

electricity by utilities. Smaller gas turbines,

drive pumps and compressors in locations with

extreme conditions such as desert dust, artic

snow or sea spray on an oil rig. As turbines

have become more efficient, they have become

more susceptible to damage from contaminants in

the combustion air. This ambient air from the

surrounding environment can contain high dust

loads. In California, with very tight emission

standards, the particulate in the inlet air to

the turbine can exceed emission limits. Thus,

the gas turbine has to act as an air cleaning

device.

The challenge for gas turbine inlet fiber,

media, and filter suppliers is to increase gas

turbine availability in all environments with

newer and more sensitive gas turbines. The newer

turbine designs are negatively impacted by small

particles. This has led to the use of HEPA

filters with efficiencies classed as H10/E10 and

higher. Studies show that turbine maintenance

can be reduced with even higher efficiency

E12-U17. One study showed that even if the cost

of higher efficiency filtration were four times

higher than lower efficiency filters, the true

cost would be lower.

One can choose a system with non-cleanable

filters. They are relatively inexpensive but

require continuous filter replacement. By using

a sequence of inefficient but inexpensive pre

filters and a final high efficiency filter, the

replacement cost can be minimized.

An alternative is to use a cleanable filter.

Periodic air pulsing knocks off accumulated

dust. These systems are available from many

suppliers if the F-9 efficiency is all that is

desired. Cleanable filters with H12 efficiency

are available from only a few suppliers. On the

other hand, there are many new developments

which will expand the number of choices.

In terms of high efficiency dust capture

mechanisms there is a choice between wet laid

glass and synthetic nanofiber non-woven

laminates or membranes. The traditional glass

media for HEPA filtration has been used

primarily in non-cleanable filters.

Quantifying the benefit is a balance between

reduced fouling and increased pressure drop. The

increased pressure drop can be estimated to

restrict performance by approximately 0.4%,

while cutting fouling provides a 1.2%

improvement in output (empirical average).

Therefore, the overall result is a potential

efficiency improvement of 0.8%.

http://www.mcilvainecompany.com/GTairTech/Subscriber/Default.htm

Alliance Pipeline believes

that the E12 filters from Gore may

allow Alliance to extend the interval between

overhauls of its aero engines from 25,000 to as

many as 50,000 hours (from three to six years).

The many factors and media choices impacting gas

turbine inlet filter selection have been

discussed in a background document on display

at

In the past the most efficient filters that were

used on gas turbine inlets were rated F-9 with

efficiency of more than 95% on particles 0.4 um

diameter. The most penetrating particle size is

about 0.2 um where the efficiency is much lower.

Higher efficiency filters are rated based on the

most penetrating particle size as follows:

|

HEPA Class |

Retention (total) |

|

E10 |

> 85% |

|

E11 |

> 95% |

|

E12 |

> 99.5% |

|

H13 |

> 99.95% |

|

H14 |

> 99.995% |

|

U15 |

> 99.9995% |

|

U16 |

> 99.99995% |

|

U17 |

> 99.999995% |

Membrane laminates such as used for dust

collection can meet efficiencies up to E12. The

question is whether this is sufficient?

There are a number of new filter and media

designs, which need to be evaluated. Mann

& Hummel Vokes introduced

the Aircube Pro Power S, which utilizes a new

synthetic base media with much higher resistance

to mechanical stress than glass fiber media and

a stable high efficiency during operation. It is

water and salt repellent while being extremely

robust.

.

DHA Filter has

developed a new line of intake filters that

address many of these

concerns. DHA’s Duraweb™ Elite line features a

new 3-layer media that combines high efficiency

filtration with durability and breathability.

The base layer is a 100% synthetic material that

gives the media pack its strength and enable the

filter to be pulse cleanable. The 2nd layer

is a thin “relaxed” ePTFE membrane. The membrane

is what gives the filter its high E11 efficiency

while maintaining a low initial pressure drop.

The physical properties of this membrane repel

water and dust ensuring maximum filter

life. Finally, a synthetic top layer adds dust

holding capacity while protecting the

membrane. The media is hydro- and oleophobic

which helps it to perform in environments where

hydrocarbons and/or high humidity are present.

DHA’

Duraweb™ Elite line features a new filter media

that uses 3 layers to prove HEPA grade inlet

filtration:

DHA’

Duraweb™ Elite line features a new filter media

that uses 3 layers to prove HEPA grade inlet

filtration:

1.

The fully synthetic top layer adds dust holding

capacity and protects the membrane.

This layer is treated to be oleophobic

and hydrophobic to repel hydrocarbons and

moisture.

2.

A very thin “relaxed” ePTFE membrane gives the

filter an E12 efficiency while maintaining a low

initial pressure drop.

This membrane is applied with a

proprietary process that ensures durability and

maximum filter life.

3.

The synthetic base layer is made from a robust

material that provides strength for the media

pack.

This allows the filter to hold up over

time even after going through numerous pulse

cleaning cycles.

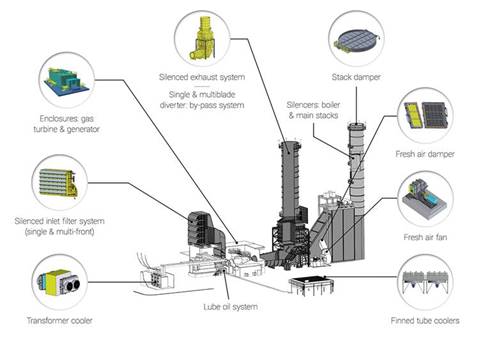

Boldrocchi

is offering complete systems including gas

intake filters.

Background Information In Gas Turbine Decisions

(Free To Operators)

Gas Turbine Intake Filters Webinar - Hot Topic

Hour May 21, 2015

The session covered four route maps in the Gas

Turbine Combined Cycle Air Treatment Guide

Revision Date: 5/21/2015

Nonwovens in Gas Turbine Air Filtration

Clarcor offers a full range of air inlet filters

for gas turbine applications including panel,

pocket V-cell and cartridge filters. This

presentation addresses ways to improve inlet

filtration to avoid fouling and corrosion of

turbine equipment.Revision Date:

4/24/20

Gas Turbine Air Filter System Optimization

Proper air filtration is critical to the overall

performance and reliability of gas turbines.

This article discusses various aspects of the

air filtration and conditioning process

including inlet cooling, filters and water wash

cycles.

Addressing Moisture Issues by McLeod Stephens,

Nederman - Hot Topic Hour May 15, 2014

McLeod explained that the filter is part of a

train of treatment elements with the screen,

weather hood coalescers, filters, evaporative

cooler and droplet eliminator. Revision

Date: 5/15/2014

Gas Intake Filters: HEPA or Medium Efficiency

Webinar - Hot Topic Hour May 15, 2014

A high level discussion attended by

knowledgeable end users, consultants, fiber

makers, media suppliers and filter

manufacturers. Revision Date:

5/15/2014

EMW recommends HEPA filters for air intakes to

reduce compressor cleaning

A new trend is emerging in the sector of gas

turbine inlet air filtration. Frequently,

highest-efficiency (H)EPA filters are selected

as the solution of choice for optimum protection

of gas turbines. A leader in (H)EPA technologies

for many years, EMW offers comprehensive product

solutions to keep your gas turbine plant at the

cutting edge.Revision Date:

4/2/2014

HEPA Air Filtration Technology Keeps Compressor

Blades Clean

Combustion turbine operators generally

experience turbine fouling from airborne

particles passing through existing inlet air

filters. Fouling can be caused by the particle

capture limitations of conventional F-class

(EN779:1998) or MERV-class (ASHRAE 52.2)

filters. The consequence is reduced performance

of the turbine operation. Revision

Date: 3/20/2014