|

||||||||||||||

|

||||||||||||||

|

||||||||||||||

|

||||||||||||||

· Cleanroom Air Process Automation and Control is a $353 Million Market

· Optimization and Process Monitoring for the Food, Pharmaceutical and Chemical Industries at IFPAC

· Online Control of Moisture and Integrated Data Management Capability will be Explained by Yokogawa

· Thermo Fisher will be an Exhibitor and will be Making a Number of Presentations

· Monitoring Temperature in Semiconductor Cleanrooms is Critical

· Facility Air Particle Counter Data Displayed and Recorded

· Ammonia Monitoring by Chemiluminescene in Cleanrooms

· Sierra Monitors Ammonia and Hazardous Gases in Semiconductor Plants but not at the Sensitivity Required inside the Cleanroom Space

· DaIfu Automates Cleanroom Material Handling Systems

· Innotech Offers a Variety of Instruments for Cleanrooms

· Kanomax Supplies Precision Instruments for Cleanrooms

· Continuous Particle Monitoring Networks Furnished by Met One

· Digital Air Control Staff has long Experience with Cleanroom Air Handling Systems

· European Conferences on the Horizon

Cleanroom Air Process Automation and Control is a $353 Million Market

There is a large opportunity to reduce product failure and energy consumption in clearnooms through more complete automation of processes and control of the air handling systems. In 2013, cleanroom operators will spend $353 million for automation and control solutions for the air handling systems. This is the latest forecast in the McIlvaine report, World Cleanroom Markets. (www.mcilvainecompany.com)

($ Millions)

|

Industry |

2013 |

|

Cleanroom Suppliers |

32 |

|

Other electronics |

88 |

|

Food |

15 |

|

Hospital |

20 |

|

Medical Devices |

17 |

|

Other Industries |

36 |

|

Pharmaceutical |

58 |

|

Semiconductor |

87 |

|

Total |

$353 |

The revenues include advanced process control software, distributed control systems, programmable logic controllers and instrumentation to measure air flow, pressure and temperature.

The semiconductor industry market will be equaled by a group of other electronics segments including flat panel displays and memory storage. The pharmaceutical industry is also a significant segment. The hospital segment is limited to the laboratories and special operating rooms which maintain high purity cleanroom environments.

In general, air handling systems in cleanrooms must control the vertical downward air flow. Temperature control is much more important than in typical manufacturing. A slight positive pressure is also required to ensure that no unclean air enters through any room openings.

More sophisticated systems can save energy by controlling and varying air flow to meet the cleanroom needs. It has been learned that the cleanliness of a room is a function of the number of people in the room and the movement of those people. With the use of variable speed fan drives and facility particle monitoring systems with multiple monitors, it is possible to reduce air flow when air cleanliness exceeds the needs. This can result in large energy savings.

This task is complicated in certain applications such as semiconductor manufacture by the need to control gaseous contaminants such as ammonia. There are now continuous ammonia monitors which can also be integrated into the control system.

The use of mini environments dictates the use of more complex automation systems. There is the need to control the air purity within the mini environments and also in the larger clearnoom where the mini environments reside.

One of the challenges for control has been the increasing popularity of the Fan Filter Unit (FFU). The ceiling of the cleanroom is fitted with small packages containing a filter and fan. There can be hundreds of these units in one ceiling. The advantage is flexibility and more even distribution. This requires a control system which must deal with each of the FFUs. An FFU interface can be as simple as manual controls to sophisticated stand-alone systems or even interfaces that will tie into building management central control rooms. With smart FFU products being more readily available, the utilization of these units in “smart systems” is the logical progression.

Low initial investment costs along with an equally low cost of system expansion make the distributed system both flexible and cost-effective.

Another function of the control system can be to alert operators as to when to change filters. Differential pressure sensors monitor the status of clean room air filters. Pressure ports are connected to either side of the filter; as the filter becomes clogged, the difference in pressure between the two sides increases. The differential pressure sensor is programmed to detect the point at which the pressure difference indicates the time for filter replacement, and when it is reached, the sensor triggers an output alarm.

For more information on World Cleanroom Markets, click on: http://www.mcilvainecompany.com/brochures/cleanroom.html

Optimization and Process Monitoring for the Food, Pharmaceutical and Chemical Industries at IFPAC

There are lots of good papers relative to monitoring, automation and process management which will be presented later this month at IFPAC.

IFPAC

- 2013

27th INTERNATIONAL FORUM AND EXHIBITION

PROCESS ANALYTICAL TECHNOLOGY

(Process Analysis & Control) - IFPAC

Jan. 22 - Jan. 25, 2013, Baltimore, Maryland, U.S.A.

Online Control of Moisture and Integrated Data Management Capability will be Explained by Yokogawa

Yokogawa will display PAT solution regarding online quality monitoring, quality data management to support RTRt (Real Time Release testing), and will demonstrate prototype products.

|

Presentation |

|

|

Title |

Integrated Data Management for Manufacturing Processes and QA Labs to Support RTRt |

|

Session |

Process Analysis |

|

Schedule |

Friday - Jan 25 PM |

|

Poster |

|

|

Title |

On-line Monitoring and Control of Moisture in the Fluidized Bed Granulator by High-speed and Highly Sensitive Near Infrared Spectrometer |

|

Exhibition |

|

|

Exhibits |

PAT tools (prototype) for quality analyzing, quality data management, and process monitoring |

|

Booth No. |

210 |

|

Presentation |

|

|

Title |

Moving Beyond Gen II to Achieve the NeSSITM Vision in Our Lifetime |

|

Session |

NeSSI |

|

Schedule |

Thursday - Jan 24 AM |

Thermo Fisher will be an Exhibitor and will be Making a Number of Presentations:

|

Process Mass Spectrometers – Now a PAT Tool for Cell Culture Todd Colin, Ph.D (presenting Author) thermo Fisher Scientific and Peter J. Traynor thermo Fisher Scientific, Macedon, NY

Real-Time Optimization of Ethylene Furnaces |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Peter J. Traynor, thermo Fisher Scientific, Scottsdale, AZ

Continuous Process Monitoring and Control in the Food Industry By Near-Infrared Spectroscopy Chris Heil, thermo Fisher Scientific, Madison WI

Other Papers also relevant to the Cleanroom Industr:y

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Monitoring Temperature in Semiconductor Cleanrooms is Critical

In semiconductor manufacturing processes, a deficient clean room environment can lead to defects and wasted resources, making a strictly controlled clean room indispensable. Maintaining the environment in the clean room requires control of air filters, HVAC systems, room temperature, humidity, airborne particles, and other factors.

For remote monitoring applications, the Yokogawa MW100 offers a full set of features that let the operator access data instantly by entering a unit’s URL into a Web browser. And, in addition to being able to acquire data files remotely, an e-mail function can be used for notification of abnormalities.

In food and beverage plants, monitoring and recording of production equipment is necessary inside clean rooms. Two important needs are:

· Easy method for writing messages on the recorded data

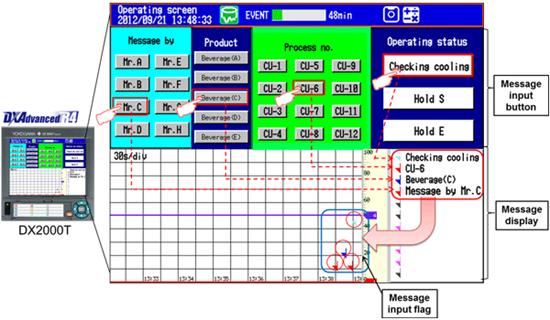

The Yokogowa DX1000T/DX2000T Paperless Recorder Touch Screen Model delivers all-digital data recording. It also provides for message input with custom displays*1 and the touch panel. The following display shows options for trends, bar graphs and screen shots.

Facility Air Particle Counter Data Displayed and Recorded

Air

particle counters are used for air climate control monitoring in semiconductor

and medical cleanrooms.

DXAdvanced can acquire the cleanliness factor data measured by the particle

counter via communication, and display and record it without degradation of

accuracy.

In the figure above, a particle counter acting as the Modbus slave is connected via RS-485, then data such as the cleanliness factor of 2 grain diameters (0.5 μ m/5.0 μm), sample flow rate, and CAL (measurement status) are displayed and recorded on DXAdvanced via Modbus/RTU communication.

Up to 16

DXAdvanced master commands can be set.

(The number that can be connected varies depending on the number of data

acquired from the counter and the register configuration.)

Ammonia Monitoring by Chemiluminescene in Cleanrooms

The Horiba TG-520 and CU-2 Ambient ammonia analyzer in Semiconductor clean rooms measures differential concentration between ambient nitrogen oxide and increased nitrogen oxide after oxidation catalyst reaction as ammonia concentration directly with cross-flow modulation type chemiluminescence method with 10ppb at min. detectable sensitivity

The CM501 clean room gas monitor measures ammonia and acid gases continuously at high sensitivity by utilizing a diffusion scrubber and an ion chromatograph. Diffusion scrubber is to absorb ammonia/acid gases in pure water. Then these are analyzed with an ion chromatograph.

Sierra Monitors Ammonia and Hazardous Gases in Semiconductor Plants but not at the Sensitivity Required inside the Cleanroom Space

There are major differences in the requirements to measure ammonia and other gases inside the semiconductor cleanoom and in the ambient space. One requires continuous ppb measurement and the other a simple alarm when the quantity exceeds 50 ppm.

The manufacturing of Semiconductors and other high technology devices usually entails the use of various hazardous and combustible gases including Silane, Hydrogen, and others. Sierra Monitor’s Sentry Gas Detection System includes sensors for many toxic gases used in the industry. In addition Sierra Monitor’s gas alarm monitors, including the CM980411 for Hydrides (including Silane) and CM99-447 for Ammonia are used in the Semiconductor manufacturing industry to monitor for these specialty gases.

The Ammonia and Hydride Gas Monitor is a continuous duty, low cost stationary monitor for detection for Hydride or Ammonia gas. The monitor has a green LED indicating the unit is on and in a safe condition. A red LED will light when the unit is in alarm. The 1 amp relay will activate when the gas concentration exceeds 5 ppm Silane or 50 ppm Ammonia. This relay is latching which means that the relay will stay activated until it is reset with the switch on the side of the monitor.

The monitor is an aluminum enclosure that is suitable for most applications. Test connections and adjustment controls are located on the outside of the enclosure and are easily accessible.

The CM98-411 is designed to monitor for Silane in the range of 1-50 ppm with an alarm setpoint at 5 ppm Silane.

The CM99-447 is designed to monitor for Ammonia in the range of 1-200 ppm with an alarm setpoint at 50 ppm Ammonia. The alarm used in this unit is an electrochemical gas sensor.

Fire is always a danger in Semiconductor clean rooms where the equipment houses a variety of flammable materials and liquids including IsoPropyl Alcohol. The Model 3200 Flame Detector is specially designed for these Wet Bench applications to constantly monitor for flames that could lead to a catastrophe in the clean room.

Bringing the data from the various sensors, devices and systems in a semiconductor plant to the central processing system is important in the safety, efficiency and operation of the semiconductor manufacturing facility. The FieldServer gateway is important in this situation since the extensive FieldServer driver library has a wide range of protocols used in this industry including Modbus, LonWorks, ControlNet and Profibus

DaIfu Automates Cleanroom Material Handling Systems

Electronics Factory Automation is the Daifuku division for cleanroom material handling systems. Daifuku America draws on more than 30 years of experience in electronics manufacturing, along with one of the largest installation base of cleanroom automation systems worldwide. Virtually every major electronics manufacturer (semiconductor, flat panel display, etc.) depends on a Daifuku system for on-time delivery, reliable performance, and cost-effective operations.

Complete solutions include:

· Logistics Studies

· Consulting

· Design

· Software

· Equipment

· Installation

· Support

· Bridge Technology

Innotech Offers a Variety of Instruments for Cleanrooms

Established in 1995, Innotech Products, Inc offers a full line of cleanroom equipment and supplies. These products range from complete, sophisticated air filtration enclosures, to furniture, gloves and swabs. Innotech provides modular hardwall and softwall cleanrooms as well as the components for a stick built room and technical design assistance to determine what type of cleanroom is best for your specific application.

Innotech Products offers a wide selection of cleanroom instrumentation to measure air velocity, particles, pressure, temperature, static and UV.

We offer Hot Wire Anemometers or Rotating Vane Anemometers to accurately

determine air velocity in cleanrooms, fume hoods or air ducts.

Air-borne Particle Counters to measure cleanrooms or cleanbenches are available

in several styles.

Magnahelic and Minihelic Pressure Gauges for cleanrooms and other critical

environment applications are supplied.

Microbial, bioburden Air Sampler, Ultra-Violet and Static Meters are also

offered.

Kanomax Supplies Precision Instruments for Cleanrooms

Kanomax group has its origins in Kano Laboratory established by Goro Kano who

was the founder of Kanomax Japan, Inc. incorporated back in 1951. For the past

60 years, Kanomax has been continuously growing due to its engineering in fluid,

aerosol/particle, environmental and integrated system measurement technologies.

By the 1970's Kanomax had become a leading manufacturer of anemometers and

particle measuring instruments in Japan.

Kanomax has recently launched its global operations to further provide the best

measurement solutions available in the mark.

During the technology boom, the semiconductor and HDD industries were the biggest users of cleanrooms and, in a stable way, they still remain one of the most important users. However, as the world of science rapidly progresses, the demand for cleanrooms from players especially in the bio-tech and pharmaceutical markets have become noticeably strong. The cleanroom class level of bio-techs and pharmaceuticals (typically around Class 5) is still less stringent than those of semiconductor cleanrooms (an extreme and rare example is a Subclass 0.1 cleanroom at the semiconductor R&D level). Nonetheless, only a small handful of precision measurement manufacturers have the genuine capabilities as Kanomax to satisfy their monitoring and measurement needs.

Continuous Particle Monitoring Networks Furnished by Met One

From assistance with SOP development for manual monitoring, to fully validated clean room production monitoring, MET ONE particle monitoring systems offer assured compliance. The MET ONE particle monitoring solution is a full service offer, including project management, on-site integration, and validation services

XOMA's QC Micro Automation Using MODA Solution

Paper-based processes still burden most QC micro programs with paper scheduling,

lab marker labeling of sample media, manual reconciliation, paper log book

entry, and manual notification on deviations. These steps are labor-intensive,

time consuming, and yield duplication of tasks and high error rates. XOMA, a

leader in the discovery, development, and manufacture of therapeutic antibodies

successfully implemented MODA™—a paperless QC micro solution by Lonza. As a

result, XOMA achieved their goal to automate their QC process for improved

environmental monitoring and compliance across their lab and manufacturing

operations

Digital Air Control Staff has long Experience with Cleanroom Air Handling Systems

Digital Air Control has extensive experience in cleanroom projects. The team received experience while working at Lepco and Luwa. The cleanroom team is made of project managers, technical sales people, project designers, construction superintendents, operations managers, quality control experts, and safety supervisors. Below is the list of projects where team members have been involved:

3M Corporation Product Development Rochester, New York Environmental

Abaxis Analysis Equipment Sunnyvale, California Environmental

Abbott Labs/Methodist Hospital Pharmaceuticals Houston, Texas Class 10,000

Advanced Micro Devices, Inc. Integrated Circuit Assembly San Antonio, Texas Class 100

Advanced Micro Devices, Inc. Test/Inspection Austin, Texas Class 10/1000

Advanced Micro Devices, Inc. Product Development San Antonio, Texas Class 10/100

Advanced Neuromodulation Systems Neuromodulation Products Allen, Texas Class 10,000/100,000

Advanced Vascular Technologies Medical Implant Production Webster, Texas Class 10,000

Agere Systems CMP Remodel Orlando, Florida Class 1/10

AGI Dermatics Pharmaceuticals Freeport, New York Class 1000

Air Products & Chemicals Gas Cabinet Manifolds Allentown, Pennsylvania Class 10/100

Alcon Laboratories Pharmaceuticals Dallas, Texas Class 1000

Allergan, Inc. Pharmaceuticals Waco, Texas Class 100/1000

Allied Signal, Inc. Government - Defense Kansas City, Missouri Class 1000/10,000

Amkor/Anam Assembly & Test Facility Sta. Rosa, Laguna, Philippines Class 10,000

AMP/Carroll Touch Component Packaging Round Rock, Texas Class 100,000

Apex Lithography Humidity Controlled Printing Austin, Texas & Lithography Plant Maintenance

A Plus International Cleanroom Laundry Suzhou, China Class 10/100/1,000

Applied Materials Development of Semiconductor Santa Clara, California Production Equipment

Class 10

Applied Materials Research & Development San Jose, California Class 10

AP Technoglass Product Development Sidney, Ohio Class 100,000

Ardex, Inc. Product Development Austin, Texas Class 1000

Ashland Chemical Application Lab Dublin, Ohio Class 10/100/1000

Asyst Technologies SMIF Technology Milpitas, California Class 1/1000

A T & T Dry Film - Etch Lab Richmond, Virginia Class 10,000

A T & T Pipe Fab Orlando, Florida Class 1,000

ATS South Semiconductor Packaging Dallas, Texas Class 1,000

Barrios Technologies, Inc. Instrument Cleaning & Calibration Houston, Texas Class 100/1000

Bayer Corporation Pharmaceuticals Clayton, South Carolina Class 100/1000

Biotech, Resources, Inc. Biomedical Research San Antonio, Texas Class 10

BOC Edwards/Kachina Wafer Fab Phoenix, Arizona Class 100/1000

Boehringer Weighting Stations Indianapolis, Indiana Class 100

Brice Building Company, Inc. Mineral Research Birmingham, Alabama Class 100/1,000

Brooks AFB Ground-Up Oxygen Chamber San Antonio, Texas Class 10,000

Bunker Plastics Plastic/Glass Coating Grand Saline, Texas Class 100

Cardiovascular Systems Medical-Blood Filtration The Woodlands, Texas Class 10,000

Cardiovascular Systems Medical-Blood Filtration The Woodlands, Texas Class 100,000

Chemtrace Trace Metal Analysis Hayward, California Class 1000

Choate/PDC Sterile Manufacturing Charleston, South Carolina Class 10,000/100,000

Cirent Semiconductor Chemical Machine Polishing Orlando, Florida Class 1/10

Clemson University Material Research Anderson, South Carolina Class 100 – ISO Class 5

Codeon Chip Processing Columbia, Maryland Class 10,000/100,000

Compaq Computer Corporation Electronic Assembly Houston, Texas Class 100

Compaq Computer Corporation R & D Manufacturing Houston, Texas Class 10,000/100,000

Compuworld, S.A. de C.V. Disk Drive Assembly Guadalajara, Jalisco, Mexico Class 100/1000

Compugraphics USA Photomask Los Gatos, California Class 100

Covance Pharmaceuticals Pharmaceuticals Raleigh, North Carolina Class 1000/10,000

Cray Research, Inc. Computer Assembly Colorado Springs, Colorado Class 1000

Cree Research Research and Development Durham, North Carolina Class 10,000

CTS Corporation Wireless Components Chicago, Illinois Class 100/1000

Cummins Engine Metrology Columbus, Indiana Class 1000

Cypress Semiconductor Wafer Assembly Austin, Texas Class 10

DNS Electronics Equipment Manufacturing Training Sunnyvale, California Class 100

Data Medical Association Development of Blood Arlington, Texas Chemical Reagents

Class 1000

Diamonex, Inc. Optical Coating Allentown, Pennsylvania Class 100

Digital Audio Disc Corporation Product Development Terre Haute, Indiana Class 100

Digital Optics Optics Charlotte, North Carolina Class 1000

Dow Chemical Analytical Group High Purity Chemical Production Freeport, Texas Class 100

Dow Chemical Co., Texas Oper. Polycarbonate Packaging Freeport, Texas Class 10,000

Dow Chemical Co., Texas Oper. Polycarbonate Processing Freeport, Texas Class 10,000

Dow Chemical Co., Texas Oper. Polycarbonate Research Freeport, Texas Class 1000

Dow Chemical U.S.A. Research & Development of Freeport, Texas Polycarbonate Plastics

Class 1000

DuPont de Mexico Packaging Sulfonyl Ureas Toluca, Mexico Class 10,000

DuPont Photomasks Photomask Lithography Danbury, Connecticut Class 1/10

E.I. du Pont de Nemours & Co., Inc. Agricultural Products Barranquilla, Columbia Environmental

E.I. du Pont de Nemours & Co., Inc. Agricultural Products Cagua, Venezuela Environmental

E-Systems, Inc. Military Electronics Assembly Garland, Texas Class 10,000

Eagle Picher Industries Lens Fabrication Miami, Oklahoma Environmental

Eastman Kodak Digital Photographic Rochester, New York Class 10

Eastman Kodak Digital Photography Rochester, New York Class 100

Eaton Corporation Ion Beam Implantation Austin, Texas Class 100/1000

Eaton Corporation Semiconductor Equipment Manuf. Austin, Texas Class 100/1000

Eaton Semiconductor Lighting Systems Rockville, Maryland Class 10/100/1000

Environmental Protection Agency Pollution Research Chapel Hill, North Carolina Environmental

Epitaxx-Division of JDS Uniphase Electronics Ewing, New Jersey Class 10,000/100,000

Eternal Technologies, Inc. Manufacturing Colonial Heights, Virginia Class 100/1000/10,000

Exxene Corporation Screen Printing Corpus Christi, Texas Class 100

Fanuc USA Corporation Silicon Wafer R & D Union City, California Class 10/100

FERF University Flat Panel Research Center Palm Bay, Florida Class 10/1000/10,000

Fisher Controls International Research & Development Austin, Texas Class 100

Flopure, Inc. Gas Panel Assembly San Antonio, Texas Class 10/100

Fusion Systems Etch Process Manufacturing Rockville, Maryland Class 10/100/1000

Gebex Corporation Photomask Lithography Irving, Texas Class 10/100/10,000

Gebex Corporation Photomask Lithography Irving, Texas Environmental

Georgia Institute of Technology Research & Development

Atlanta, Georgia

Class 10/100

Georgia Institute of Technology Nanolithography

Atlanta, Georgia

Class 10

Gillette Manufacturing Boston, Massachusetts HVAC Re-Design

Graham Magnetics High Density Tape Production Graham, Texas Class 10,000

Graham Magnetics, Carlisle High Density Tape Production N. Richard Hills, Texas Class 1000

Gray/Mitsubishi Developer Tube Coating Chesapeake, Virginia Class 10/100

Hercules Aerospace Paint Application McGregor, Texas Environmental

Hitachi Semiconductor Integrated Circuit Assembly Irving, Texas Class 1000

Hitachi Semiconductor Integrated Circuit Assembly Irving, Texas Class 1000

HMT Technology Product Development Fremont, California Class 100,000

Honeywell/AlliedSignal Silicon Production Redmond, Washington Class 10/100

Honeywell Optoelectronics Gallium Arsenide Semiconductor Richardson, Texas Production

Class 10

Honeywell Optoelectronics Fiber Optics Production Richardson, Texas Class 100/10,000

Honeywell Optoelectronics Military Electronics Production Richardson, Texas Class 100/10,000

Hughes Offshore Close Tolerance Hydraulic Houston, Texas Components Production

Class 10,000

Hughes Tools Close Tolerance Hydraulic Houston, Texas Components Production

Class 100,000

IBM Product Development Guadalajara, Mexico Class 100

IBM (B-650) Product Development Hopewell Jct., New York Class 1000/10,000

IBM Fishkill 330-D Sub Measurement Laboratory Hopewell Jct., New York Class 10

IBM-Data Systems Division Metal Artwork Poughkeepsie, New York Class 100/10,000

IBM-Data Systems Division Wet Lab Poughkeepsie, New York Class 10,000

In-Focus Systems N/A Tualatin, OR Class 100/1,000/10,000

Input/Output, Inc. Seismic Tool Manufacturing Stafford, Texas Class 100 thru Class 100,000

Integrated Gas Systems High Purity Piping Houston, Texas Class 100

Integrated Gas Systems High Purity Piping Houston, Texas Environmental

Integrated Pharmaceutical Systems Pharmaceuticals King of Prussia, Pennsylvania Class 10,000/100,000

Intel Corporation Semiconductor Fabrication Rio Rancho, New Mexico Class 100/1000

IntelliEPI N/A Richardson, Texas Class 1000

Intermedics, Inc. Medical Implants Freeport, Texas Class 10,000

International Resistive Corp. Resistor Fabrication Corpus Christi, Texas Class 100

Iowa State University Research & Development Ames, Iowa Class 100

JDS Uniphase – Epitaxx Division Optical Switch Ewing, New Jersey Class 1,000/10,000

Kachina/DPR Wafer Refabrication Austin, Texas Class 1000

Kajima/Hitachi Product Development Norman, Oklahoma Class 1000

KAO Infosystems 3.5" Disk Manufacturing Plymouth, Massachusetts Class 10,000

KAO Infosystems Magnetic Media Coating Plymouth, Massachusetts Class 100/1000

KAO Infosystems High Density Diskette Mfg. Plymouth, Massachusetts Class 10,000

Kemet Electronics Microelectronics Manufacturing Mexico Class 1000

Kent State University Liquid Crystal Institute Kent, Ohio Class 100/1000/10,000

Koch Specialty Chemical Company Chemical Manufacturing Houston, Texas Class 10/100

Lawrence Livermore Natl. Labs Research & Development Livermore, California Class 10,000

Lawrence Livermore Natl. Labs Wafer Research Livermore, California Environmental

Lawrence Livermore Natl. Labs Research Livermore, California Environmental

Lawrence Livermore Natl. Labs Metrology Livermore, California Class 1000/10,000

Libbey-Owens-Ford (L-O-F) Plastic/Glass Lamination Collingwood, Ontario Class 100/1000

Libbey-Owens-Ford (L-O-F) Plastic/Glass Lamination Sherman, Texas Class 100

Libbey-Owens-Ford (L-O-F) Plastic/Glass Lamination Lindsay, Ontario Class 100

Libbey-Owens-Ford (L-O-F) Plastic/Glass Lamination Toledo, Ohio Class 100

Libbey-Owens-Ford (L-O-F) Plastic/Glass Lamination Mexicali, Mexico Environmental

Litton Resource Systems Thick Film Circuit Production Houston, Texas Class 100

Lockheed Martin (formerly LTV) AeroSpace Electronics Grand Prairie, Texas Class 10

Loral Vought Systems Aerospace Electronics Grand Prairie, Texas Class 1000

Los Alamos Laboratories Electronic & Laser Research Los Alamos, New Mexico Class 100

LRS-Western Atlas Internat’l Fiber Optical Cable Bonding Alvin, Texas Class 100,000

LTV Missiles & Electronics Research & Development Grand Prairie, Texas Class 1,000

LTV Missiles & Electronics Aerospace Electronics Garland, Texas Class 1000/10,000

Lucent Technology Chemical Machine Polishing Orlando, Florida Class 1/10

Lucent Technologies/Cirent CMP Area Orlando, Florida Class 10

MacMillan, Inc. Defense Rockville, Maryland Class 100,000

Marcus Thomas & Company Semiconductor Research Houston, Texas Environmental

Martin Marietta Laser/Optics Warner Robins, Georgia Class 10,000

Matsui America, Inc. Process Support Piping Elk Grove Village, Illinois N/A

MCC Research & Development Austin, Texas Class 100/10,000

MCC Research & Development Austin, Texas Class 10,000

McGhan Medical Medical Device San Jose, Costa Rica Class 10,000

Mead Office Systems Ink Jet Printing Plano, Texas Environmental

Medrad Medical Devices Indianola, Pennsylvania Class 10,000/100,000

Medrad Medical Devices Expansion Indianola, Pennsylvania Class 10,000

MEMC Microelectronics Pasadena, Texas Class 1000/10,000

Merck Sharp & Dohme Pharmaceuticals Elkton, Virginia Environmental

Merck & Company Pharmaceuticals Elkton, Virginia Class 100/1,000

MicroDisplay Corporation Flat Panel Display R & D Richmond, California Class 100

MicroDisplay Corporation Miniature Information Displays (MIDs) San Pablo, California Class 10/100/1,000

Millipore Microelectronics Facility Plano, Texas Class 10/100/1000

Mobay Chemical Corporation Polycarbonate Manufacture Baytown, Texas Class 1000

Mobay Chemical Corporation Polycarbonate Manufacture Baytown, Texas Class 100,000

Mobay Chemical Corporation Polycarbonates Baytown, Texas Class 10,000

Monolithic Memories Integrated Circuit Santa Clara, California Class 10,000

Morgan Semiconductor Gallium Arsenide Wafer Fab. Garland, Texas Class 1000

Motif, Inc. LCD Manufacture Wilsonville, Oregon Class 100/10,000

Motorola, Inc. Packaging Lab Arlington Heights, Illinois Class 100/1000

Motorola, Inc. Electronic Research Schaumburg, Illinois Class 100,000

Motorola, Inc. Electronic Assembly Schaumburg, Illinois Class 100/1000

Motorola, Inc. Electronic Component Manufacturing Chung-Li, Taiwan Class 100/500/1000

Multiplex Optoelectronics South Plainfield, New Jersey Class 1000/10,000

NanoOpto Optoelectronics Somerset, New Jersey Class 10/100/1000

NASA - Johnson Space Center Instrument Cleaning Houston, Texas & Calibration

Class 100/1000/10,000

NASA - Johnson Space Center Development of Close Tolerance Houston, Texas Hydraulic Components

Class 100

NASA/Johnson Engineering Product Preparation Zone Houston, Texas Softwall Environment

National Research Council-Canada Metallurgy Ottawa, Ontario, Canada Class 100

National Semiconductor Corp. Semiconductor Fabrication Santa Clara, California Class 1/100

National Semiconductor Corp. Mask Making Annapolis Jct., Maryland Class 1

Naval Research Lab Shuttle Payload Washington, D.C. Class 1000

nCHIP Superconductor Research Fayetteville, Arkansas Class 100/1000

Northern Telecom Product Development Saskatoon, Saskatchewan N/A

Canada

Northern Telecom Product Development Saskatoon, Saskatchewan, Canada Class 10,000

Northrop Grumman Electronic Assembly Pittsburgh, Pennsylvania Class 100

Northrop Grumman Electronic Assembly Pittsburgh, Pennsylvania Class 1,000/10,000

Nysco Laboratories Pharma Production Hsin Chuang, Taiwan (ROC) Class 100,000

Ohio State University Research & Development Columbus, Ohio Class 100/1,000

Oklahoma State University Research & Development Stillwater, Oklahoma Class 1000

OMJ Pharmaceuticals Pharmaceuticals San German, Puerto Rico Class 100/1000

OnTrak Systems Equipment Manufacturing Milpitas, California Class 10/100

OnTrak Systems Semiconductor R & D Milpitas, California Class 10/100

Optical Coating Labs, Inc. Optical Coating Santa Rosa, California Class 100,000

Optical Coating Labs, Inc. Plastic Products Santa Rosa, California Class 100

Optical Imaging Systems Flat Panel Display Manufacture Northville, Michigan Class 10/100/1000/10,000

Optical Switch Corporation Semiconductor Bedford, Massachusetts Class 1,000/10,000

OpticNet, Inc. MEMS Facility Hayward, California Class 10/1000

Orbital Scientific Research Dulles, Virginia Class 10,000/100,000

Orbitek Engineering Semiconductor Support Manuf. Area Austin, Texas Class 100

Parker Hannifin Ultra High Purity Valve Manufacturing Huntsville, Alabama Class 100

Pennsylvania State University Submicron Processing Facility University Park, Pennsylvania Class 10 to Class 100,000

Photronics, Inc. Photolithography Brookfield Center, Connecticut Class 1

Photronics, Inc. Photomask Lithography Milpitas, California Class 10/100/10,000

Photronics, Inc. Photomask Lithography Milpitas, California Class 10/100

Photronics, Inc. Photolithography Milpitas, California Class 10/100

Photronics, Inc. Photolithography Brookfield Center, Connecticut Class 10/1000

Photronics, Inc. Photolithography Dallas, Texas Class 1 thru Class 100

Photronics, Inc. Photomask Back-End Colorado Springs, Colorado Class 10,000

Photronics, Inc. Pellicle/Manufacturing Allen, Texas Class 1/10

Photronics, Inc. E-Beam Room Colorado Springs, Colorado Class 10

Photronics, Inc. Photolithography Austin, Texas Class 1/100

Photronics, Inc. Photolithography Facility Maintenance Austin, Texas Class 1/100

Planar Systems Flat Panel Displays Beaverton, Oregon Class 10

Planar Systems Flat Panel Displays Beaverton, Oregon Class 100/10,000

Polytronics Electronic Assembly Richardson, Texas N/A

Praxair Gas Cabinet Manufacturing San Antonio, Texas Class 100

Precision Robots, Inc. Semiconductor Mini-Environments Billerica, Massachusetts Fab Tool Class 1

Precision Robots, Inc. Semiconductor Billerica, Massachusetts Class 10,000

Princeton University (Turner Construction) E-Quad Princeton, New Jersey Class 100/1,000

Red River Army Depot Defense Texarkana, Texas Class 100,000

Rexham, Inc. Product Development Mathews, North Carolina Class 100/10,000

Richardson Vicks Cooling Tunnel Mexico City, Mexico Class 10,000

Rocap Pharmaceuticals Orlando, Florida Class 100/10,000

Rollins Environmental Services Computer Room Deer Park, Texas Class 10,000

sVision, Inc. Flat Panel Display Twinsburg, Ohio Class 100/1000

Sage Technology Horizontal Cleanrooms Smyrna, Georgia Class 10

Sawtek, Inc. Radio Frequency Drive San Jose, Costa Rica Class 1000

Sawtek, Inc. M/I Assembly Apopka, Florida Class 100

Sawtek, Inc. Assembly Apopka, Florida Class 10

Schering Plough Pharmaceuticals Mexico City, Mexico Class 100/1000

Servitex Laundry Facility Atlanta, Georgia Class 1/10/100

Sierracin Plastic/Glass Lamination Sylmar, California Environmental

Sierracin Aircraft Canopy Lamination Sylmar, California Class 1000

Silicon Material Services Silicon Wafer Fabrication Garland, Texas Class 10

Silicon Material Services Silicon Wafer Fabrication Garland, Texas Class 100

Silicon Video Flat Panel Displays Cupertino, California Facility Selection Survey

Silicon Video Flat Panel Displays South San Jose, California Scale-Up / Certification

Sony AMD Wafer Manufacturing Austin, Texas Class 10

SubMicron Systems Microelectronic Equipment Mfg. Allentown, Pennsylvania Class 1/10/100

Sumitomo Electric Optical Cable Res. Tr. Park, North Carolina Class 1000

Sundstrand Data Controls Government Testing Redmond, Washington Class 10,000

Temp Glass Southern Plastic/Glass Lamination Arlington, Texas Environmental

Texas A & M University Biological Research College Station, Texas Class 100

Texas A & M University Plant Tissue Culture Research College Station, Texas Class 100

Texas Air Quality Control Air Sample Lab Austin, Texas Class 1000

Texas Instr.-Dallas Chem. Ctr. Chemical Packaging Dallas, Texas Class 10/10,000

Texas Instruments Electronic Assembly Richardson, Texas Class 100

Texas Instruments Product Development Richardson, Texas Class 100,000

Texas Instruments Electronics Assembly Plano, Texas Environmental

Texas Instruments Product Development Cypress, Texas Class 100

Texas Instruments Integrated Circuit Production Plano, Texas Environmental

Texas Instruments Integrated Circuit Production Lubbock, Texas Environmental

Texas Instruments Chemical Products Richardson, Texas Class 10

Texas Instruments Etch Operations Attleboro, Massachusetts Class 100

Thomson Consumer Electronics TV Picture Tube R & D Lancaster, Pennsylvania Class 100

Triquint Semiconductor Radio Frequency Drive San Jose, Costa Rica Class 1000

Triquint Semiconductor M/I Assembly Apopka, Florida Class 100

Triquint Semiconductor$ Assembly Apopka, Florida Class 10

Ultratek Screen Printing Corpus Christi, Texas Class 1000

Unicor Corporation Humidity Sens. Adhesive Assembly Bastrop, Texas Environmental

Union Carbide Polyolefins Packaging Seadrift, Texas Class 100,000

Union Carbide Polyolefins Packaging Seadrift, Texas Class 100,000

Union Carbide Tank Car Cleaning Facility Port Lavaca, Texas Ultra Clean Environment

Unit Instruments Instrumentation Richmond, Virginia Class 100

University of Alabama Mineral Research Tuscaloosa, Alabama Class 100/1000

University of Arkansas Research & Development Fayetteville, Arkansas Class 100

University of California Photo/Thin Films Riverside, California Class 100/1,000

University of Central Florida Research & Development Orlando, Florida Class 1000

University of Colorado @ Boulder Astrophysics Boulder, Colorado Class 1000/10,000

University of Houston Wafer Research Houston, Texas Class 100

University of Houston Space Vacuum Epitaxy Cntr. Houston, Texas Class 10,000/100,000

University of Houston Low Humidity Furnace Room Houston, Texas Class 100

University of N. Carolina-Charlotte Research & Development Charlotte, North Carolina Class 1000

University of N. Carolina-Charlotte Metrology Charlotte, North Carolina Class 100,000

University of Tennessee Nanophase Material Sciences Oak Ridge, Tennessee Class 1,000

University of Texas - Arlington Ion Implantation Arlington, Texas Class 10/100

University of Texas – Arlington R & D – Student Research Arlington, Texas Class 100/1,000

University of Texas - El Paso Microelectronic Research El Paso, Texas Class 100

Valex Corporation Ultra High Purity Piping Ventura, California Class 100

Varian Semiconductor Fabrication Fremont, California Class 100

Varo Semiconductor, Inc. Semiconductor Development Garland, Texas Class 100

VDO Instruments Close Tol. Inst. Silk Screening Mississauga, Ontario, Canada Class 100,000

Virginia Commonwealth University Research and Development Richmond, Virginia Class 100;/1,000 Process Laboratories

Visiting Nurse Association Pharmaceutical Packaging Houston, Texas Class 1000/10,000

William M. Rice University Geological Carbon Dating Houston, Texas Class 100,000

William M. Rice University Mass Spectroscopy Houston, Texas N/A

William Marsh Rice University Hulet Cleanroom Lab Houston, Texas Class 100

William Marsh Rice University Abercrombie Cleanroom Houston, Texas Class 1000

European Conferences on the Horizon:

|

Feb 5-7 |

Lounges 2013: The Clean Environment, Messe Karlruhe, Germany |

|

|

May 20-21 |

44th

R3Nordic Symposium, Gothenburg, Sweden |

© Digital Air Control

To make sure you receive the Cleanroom Insights newsletter regularly and also any of our other newsletters and alerts, click on: http://home.mcilvainecompany.com/index.php?option=com_content&view=article&id=73

----------

You can register for our free McIlvaine Newsletters at: http://www.mcilvainecompany.com/brochures/Free_Newsletter_Registration_Form.htm.

Bob McIlvaine

President

847 784 0012 ext 112

rmcilvaine@mcilvainecompany.com

191 Waukegan Road Suite 208 | Northfield | IL 60093

Ph: 847-784-0012 | Fax; 847-784-0061

Click here to un-subscribe from this mailing list