Cleanroom Garment IIoW Decision Loops

TABLE OF CONTENTS

·

OVERVIEW

·

BACKGROUND

o

Reusable

o

Disposable

o

Combination

·

DISPUTED COST OF OWNERSHIP FACTORS

____________________________________________________________________________

OVERVIEW

McIlvaine is initiating a number of IIoW

Decision Loops to help cleanroom operators make

the lowest total cost of ownership (LTCO)

choices. The Industrial Internet of Wisdom (IIoW)

connects all the knowledge to provide validation

of the choice. This can be labeled Lowest Total

Cost of Ownership Validation (LTCOV).

Validation is defined as successful

communication of a superior choice. This

communication requires a loop connecting the

media, events, niche experts, associations,

purchasers, and suppliers. It requires accurate

classification and easy access to support

documents.

McIlvaine is supplying the proposed structure

and encouraging the industry to provide the

details. Part of the effort needs to be

identification and debate of disputable issues.

Cleanroom Garment IIoW Decision Loops

·

Reusable vs Disposable

·

Reusable

o

fabric selection

o

garment selection

o

processing selection

o

vendor selection

·

Disposable

o

fabric selection

o

garment selection

o

vendor selection

These decision loops need to be unique depending

on the industry, cleanroom class and process.

The criteria for cytotoxic drugs need to

prioritize worker protection. 2nm chip

production requires

conditions better than ISO 3. A hospital

operating room, Covid isolation room, and

compounding pharmacy all have different cost

factors.

BACKGROUND

Here is background information for the loops.

The Case for Reusable Garments

Prudential Makes the Case for Reusable Garments

Environmental Impacts

Most companies that use cleanroom products do

not consider the environmental impacts. It

entails more than just solid wastes being dumped

in a landfill. The materials used to make

disposables can be broken down into two basic

components: fabrics and contaminates. Fabrics

are inert and will biodegrade over time without

any impact to the environment. Contaminates, on

the other hand, are those materials that

biodegrade and, in the process, release CO2

(carbon dioxide) and CH4 (methane) from chemical

reactions. Reusable garments are made from

polyethylene terephthalate (PET), which is the

same plastic used to manufacturer plastic

drinking bottles. PET is fully recyclable and

able to be reused numerous times, with minimal

impacts to the environment.

Lifecycle Comparison

The lifecycle of reusable and disposable

garments includes several different factors,

such as the cost for the garments, the company’s

CO2 footprint, energy use, and solid waste.

Disposables go through the following stages

during their lifecycle:

·

Manufacturing

·

Cleanroom Use

·

End of Life

Reusables go through the following stages during

their lifecycle:

·

Manufacturing

·

Cleanroom Use

·

Laundry Transport

·

End of Life

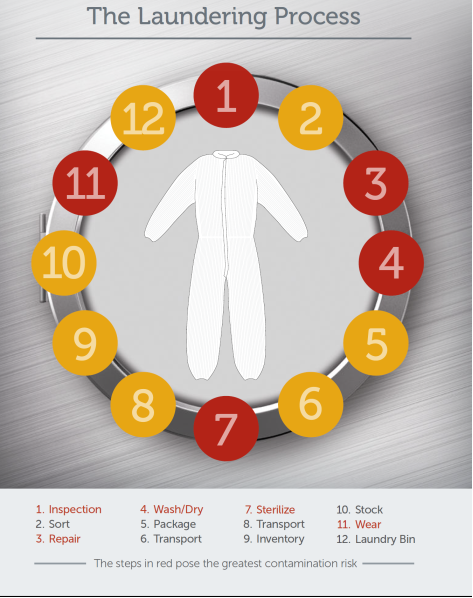

With reusables, after each cleanroom use, they

are transported to a laundry facility where they

are washed and, if needed, sterilized, before

being returned to the company to be used again.

The cycle continues until the end of life of the

garment.

Twenty reusables are able to be reused 50 times

on average, compared to using 1,000 disposables.

The costs for purchasing the reusables and

paying a laundry service to wash them is much

less than the cost paid for the disposables. In

addition, the total amount of energy and

resources used over the entire lifecycle in

megajoules (MJ) for reusables is about 8,380 MJ,

compared to 10,900 to 19,200 for disposables,

depending upon the materials used to make the

disposables.

Businesses which choose a disposable cleanroom

garment solution incur the following (per

520,000 units):

·

30-129% increase in natural resource usage

·

52-143% increase in energy use (throughout

lifecycle)

·

38-135% increase in the business’s CO2 footprint

·

17 times more solid waste contribution in

landfills

·

4 times more water usage (throughout lifecycle)

Alternatively, using 10,400 units of reusables

helps save approximately 3.5 million MJ of

energy, with a 210,000 kg reduction in CO2

emissions. In the end, using reusables is better

for the environment, saves com

Source: Overcash, Michael, Eric Vozzola, and

Evan Griffing. “Implications of Reusable Versus

Disposable Garments – Environmental Dimensions

of Cleanroom Coveralls.” 8 October 2015. PDF

File.panies money, and reduces overall waste

The American Reusable Textile Association (ARTA)

Study

A study was

conducted on the environmental and economic

impacts of using reusable and disposable

cleanroom garments. The ARTA-supported study was

conducted by Environmental Clarity

and

based, in part, on a previous life cycle

analysis on cleanroom coveralls published in the

PDA Journal.

In cleanroom facilities, both disposable and

reusable textile garments meet the particulate

standards from most rigorous to the most basic

levels. However, the reusables offer two

additional benefits, lower cost and reduced

environmental impact. The environmental and

economic benefits when cleanrooms select

reusable textile garments are now clearly

defined in detail (based on estimates from

detailed life cycle data on reusable and

disposable products) and can be used by both

suppliers and customers to add to their own

environmental sustainability scorecards.

Environmental and economic savings

The study found that when US cleanroom

operations choose reusable coveralls over

disposable ones:

-

More than 141 million megajoules

(MJ) non-renewable energy (nre)

(38 million kWh) is saved each

year. Over a decade, 1.4 billion

MJ nre is saved.

-

Annually, this

environmental

savings is

equivalent to

offsetting the

carbon emissions

from 1,650 cars

annually,

substituting for

the diet impact

of 4,100

persons, or

displacing

89,000 iPads

(design life).

-

Annually, this

environmental

savings is

equivalent to

offsetting the

carbon emissions

from 1,650 cars

annually,

substituting for

the diet impact

of 4,100

persons, or

displacing

89,000 iPads

(design life).

-

Costs are reduced by 58% over

disposables and provide an

economic savings estimated at

$120 million each year, which is

$1.2 billion over a decade.

-

The financial

savings of a

full-market use

of reusables

would be about

$210

million/year

(nearly $2.1

billion in a

decade). In

order to capture

the full benefit

of reusables for

a future market,

87.5% reusables

was analysed

(12.5% are

mandatory

disposables).

-

The financial

savings of a

full-market use

of reusables

would be about

$210

million/year

(nearly $2.1

billion in a

decade). In

order to capture

the full benefit

of reusables for

a future market,

87.5% reusables

was analysed

(12.5% are

mandatory

disposables).

These new US data quantify and reinforce the

economic and environmental benefits of cleanroom

decisions for selecting reusables. This

information can be used by policy makers,

sustainability program directors, purchasing

organizations, and others.

From this study, the reusable cost savings did

not appear to depend on the size of the

cleanroom operation nor the region of the

country located. These benefits are directly

accrued to the cleanroom organizations in their

financial reporting and increasingly to their

sustainability scorecards. In addition, the

manufacturers and the laundry organizations can

share the sustainability credits with all their

customers. The study concludes that providing

this information can help cleanroom firms'

decision-making and guide a path toward greater

cost savings and environmental improvements.

The environmental analysis was from

cradle-to-end-of-life (CTEOL) for each

disposable cleanroom package.

The current reusable cleanroom market (14.1

million packages) was assessed to be 60%

nonsterile and 40% sterilized and the total

market is 50% reusable and 50% disposable

https://pubmed.ncbi.nlm.nih.gov/29444994/

Dastex Case for Reusables

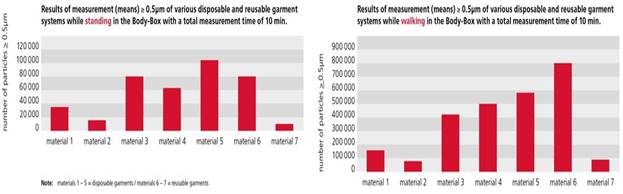

In various publications on the subject of

"Disposable garments for cleanroom use", the

impression has been – and still is – conveyed

that there are many technical arguments in favor

of using disposable garments from well-known

manufacturers without restrictions even in

cleanroom class ISO 5 (in accordance with ISO

14644-1). However, anyone who examines this

statement, application in classes ISO 5 or 6

more closely, will quickly come across an

essential detail that calls into question the

unconditional use of disposable garments. In

most cases, disposable garments are not

decontaminated after production. All impurities

from the manufacturing process thus enter the

respective cleanrooms 1: to 1 without hindrance.

We took this as an opportunity to check in our

own test cleanroom "Body-Box" to what extent

disposable garments are generally suitable for

cleanroom use, especially with regard to

particle emission.

Certainly there are special areas of application

where the use of cleanroom suitable disposable

garments are still useful. It is important,

however, that in critical areas (starting with

class ISO 6 or better, or ISO 4) care should be

taken to ensure that disposable garments have

been appropriately decontaminated before

packing. Only pre-cleaned disposable garments

(material 2) are qualitatively, in terms of

particle emission, comparable to decontaminated

reusable garments (material 7).

There are considerable qualitative differences

between the various disposable garment systems

on the market with regard to their particle

emission, which a user should definitely examine

more closely and adjust to his requirements

before using them in his cleanroom

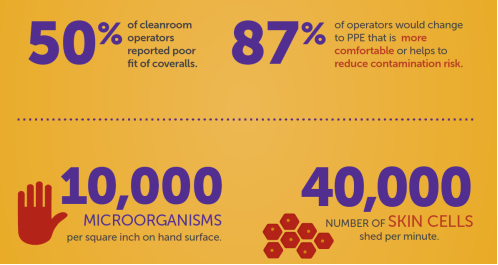

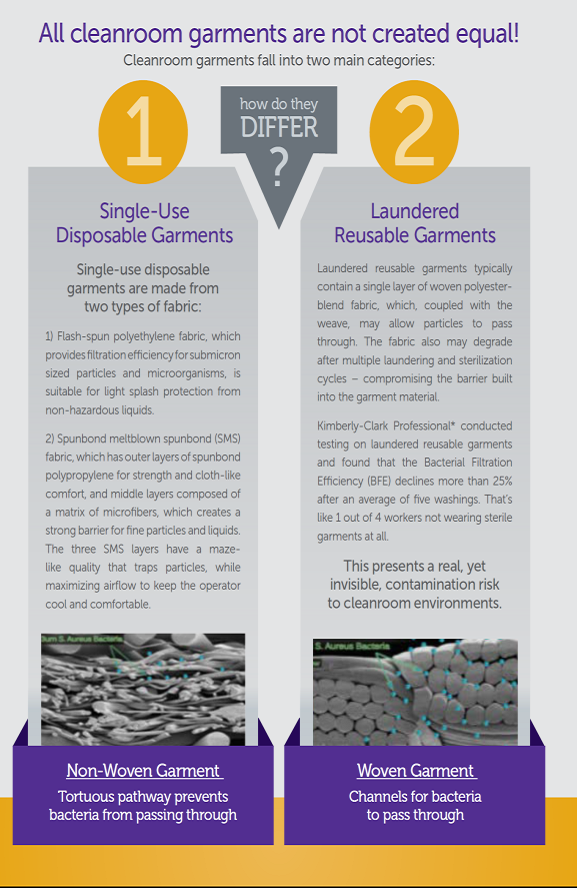

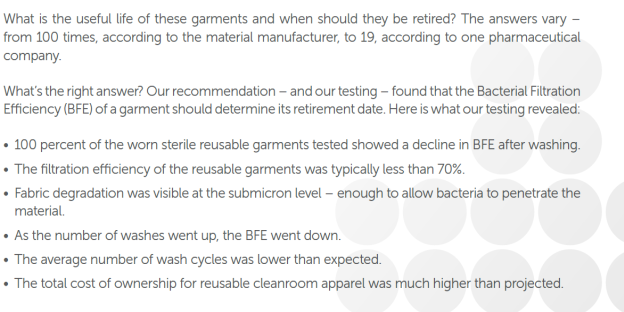

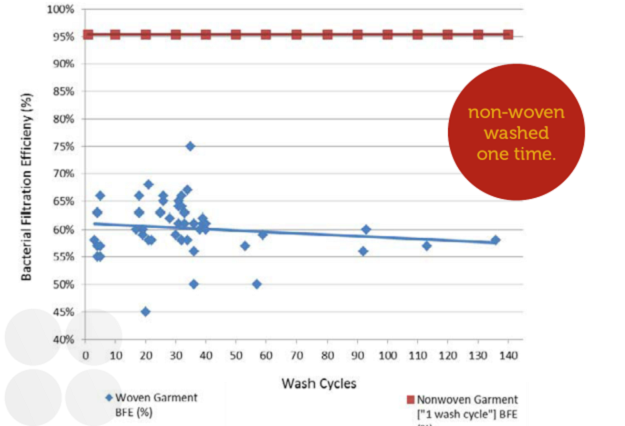

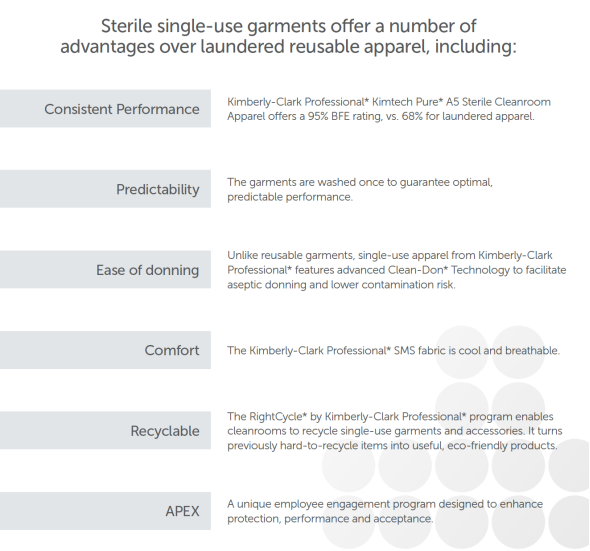

The Case for Single Use Garments

Here are results of a study by Kimberly Clark.

The Case for a Reusable/Disposable Combination

The analysis of Cleanroom World

Cleanroom apparel can be one of the most

significant costs in a cleanroom, and people

often ask whether it’s better to buy disposable

cleanroom clothing or launderable cleanroom

garments that can be washed and reused multiple

times.

The answer: It depends.

Pros and Cons of Disposable Cleanroom Apparel

The beauty of disposable cleanroom apparel is

that it’s easy to use. No need to launder

anything, just wear it and toss it out.

Particularly with the stricter classes of

cleanrooms (e.g. Class 1 or Class 2 cleanrooms),

disposable garments tend to be the most

effective.

However, the costs for using something just once

(or several times, depending on the

manufacturers’ specifications) can add up, as

you constantly have to replace the protective

garments. Some of the less expensive types of

disposable cleanroom garments tend to rip more

easily, which means that they might not even

make it through a single work shift. Also,

reusable cleanroom clothes might need to be

disposed of differently than ordinary waste, so

those costs and protocol need to be considered.

Pros and Cons of Washable Cleanroom Apparel

The primary benefit of washable cleanroom

apparel is that this type of cleanroom clothing

and accessories can cost less, over the long

haul. While reusable clothing and garments

typically cost more to purchase, the fact that

you can get multiple uses out of them

dramatically reduces the cost per use. Washable

cleanroom apparel also tends to be made out of

fabrics that are more “breathable,” which makes

them more comfortable to wear.

The downside of using launderable cleanroom

apparel is that you need to find a safe,

consistent, and effective way to wash the

clothing between uses. If you’re using an

outside company to launder your cleanroom

garments, you need to ensure that their

transportation and cleaning processes conform to

your cleanroom class requirements.

The Best of Both Worlds: Disposable and Reusable

Apparel

Often, when setting up a cleanroom environment

and protocols, people will choose to use a

combination of reusable and disposable garments.

For example, they might choose washable

cleanroom coveralls, but opt for disposable

bouffant caps. To make a good decision about

what to do for your cleanroom, you might

consider setting up a spreadsheet and listing

each individual item of clothing you need and

whether it would be better to use a disposable

or reusable version of the item (weighing in

cost, comfort, convenience, and cleanroom

conformance requirements).

Common Types of Cleanroom Apparel

The most common types of cleanroom apparel that

are available in disposable and washable options

include:

•cleanroom suits

•cleanroom coveralls

•cleanroom coats

•cleanroom gowns

•cleanroom frocks

•cleanroom sleeves

•bouffant caps

•hoods

•gloves

•masks

•shoe and boot covers

DISPUTABLE COST OF OWNERSHIP FACTORS

Discussions and webinars need to be conducted to

obtain the conflicting views and provide

purchasers with a better basis for decision

making. Environmental Impact-disposal is used as

an example

·

Comfort

·

Contamination

o

material properties

o

filtration efficiency

·

Total cost of ownership

·

Environmental Impact

o

garment production

o

processing

o

disposal

Environmental Contamination from Garment

Disposal

·

garment properties

o

life in a landfill

o

contaminants emitted e.g. methane, harmful

chemicals metals

·

garment fate

o

landfill

o

waste to energy facility

o

product from recycled plastic

o

ocean contamination

·

TCO Criteria

o

likelihood of a given fate

o

impact quantification

o

impact assessment

§

regulations present and future

§

measurement criteria

·

life quality

·

discounted future value

·

Tribal Values (do cleanroom owners in Montreal

prioritize reducing annual temperatures

or preventing sea rise as do operators in Los

Angeles)

Product from Recycled Waste

Input needs to be provided by the suppliers and

consultants

relative to the Product from Recycled

Waste option we need to learn more about the

KC program in terms of the cost versus virgin

plastic and the availability of this option for

a given location

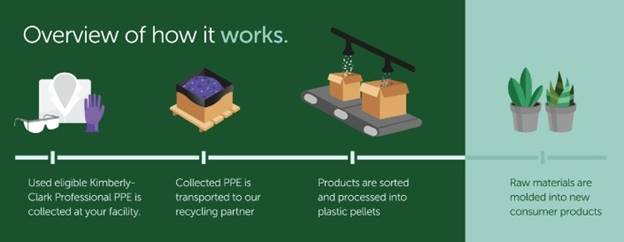

The RightCycle Program by Kimberly-Clark™

Professional turns hard-to-recycle PPE into new

consumer goods.

Items to recycle include:

-

Gloves

-

Disposable cleanroom and lab

apparel

-

Safety eyewear

With The RightCycle Program, these everyday

items get a second life when they are turned

into:

-

Patio furniture

-

Flower pots and planters

-

Plastic shelving

-

Recycling bins

Measurement Criteria

Cardinal Health engaged McIlvaine in an

extensive study which included the measurement

criteria for waste disposal harm. One important

output was a new metric to measure harm and good

based on life quality of the customers. This

includes discounted future values.

Global warming has a long term impact

whereas many impacts such as comfort are felt

immediately

Reducing world CO2 levels by purchasing reusable

gowns may help people on the equator 50 years

from now but if inefficient wastewater treatment

at the local laundry creates virus risks for the

hospital clients you have to consider what is

labeled tribal values. Life quality can be

measured in a unique way which makes comfort and

possibly even appearance important.

This factor cuts both ways. It can be argued

that comfortable and more attractive reusable

garments have a benefit measured in Quality

Enhanced Life Days (QELD). This is the new

metric to replace

QALY or quality adjusted life years. This

widely used metric does not consider comfort or

other life quality issues and emphasizes just

life quantity.

http://www.mcilvainecompany.com/SURS/subscriber/Text/White_Paper_8-17-09.pdf