SEMICONDUCTOR

UPDATE

July 2007

McIlvaine Company

TABLE OF CONTENTS

Top 10 Semiconductor Suppliers in Greater China

Top 10 Semiconductor Suppliers in China/Hong Kong

Top-10 Semiconductor Suppliers in Taiwan

Tower Plans Further Ramp Up of Fab 2

Horiba, Ltd. Announces the Grand Opening of the 'Horiba Technology Center' in Santa Clara, CA

ON Expands Philippines Presence

ST to Shut Down U.S. Manufacturing Operations

Anadigics Breaks Ground for Chinese Fabs

Taiwan Chip Packagers Will Invest in China

China Report: Capacity Reserve Challenges Small Fabless Companies

Top 10 Semiconductor Suppliers in Greater China

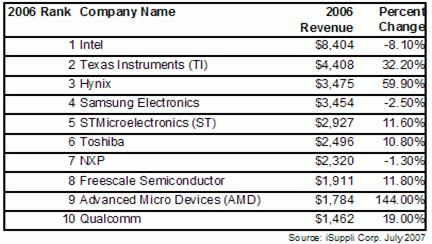

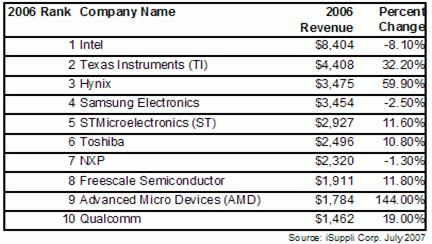

Intel Corp. in 2006 was the leading semiconductor supplier in the Greater China market with shipment revenue of US$8.4 billion. Texas Instruments Inc. (TI) ranked second in revenue last year, with sales about half those of Intel. However, TI recorded 32.2 percent growth in 2006 as some of its largest handset customers expanded production in the region.

Riding dramatic growth in the memory business, Hynix became the third leading semiconductor supplier in the region. Samsung Electronics Co. Ltd. took fourth place with a slight drop in Greater China shipments during 2006.

Meanwhile, NXP Semiconductors saw its revenue decline slightly because of its internal restructuring in 2006. STMicroelectronics and Toshiba Corp. in 2006 each achieved about 10 percent growth in the Greater China market. Advanced Micro Devices Inc.'s (AMD's) dramatic rise was driven by the company's acquisition of ATI Technologies. In comparison with previous years, Qualcomm Inc.'s growth rate lessened as its CDMA mobile communications business advanced at a slower pace in 2006.

Table 1 - Suppli's Ranking of the Top-10 Semiconductor Suppliers in Greater China in 2006.

Top 10 Semiconductor Suppliers in China/Hong Kong

In contrast with 2005, there was a major shift in China/Hong Kong rankings during 2006. Intel still held onto its leading position. However, its ratio of shipments-to-revenue declined by almost 13.3 percent as a result of fierce competition with AMD.

TI maintained strong growth momentum in China/Hong Kong thanks to its capable product line and effective sales strategies. In fact, TI has been the second largest semiconductor supplier in the China/Hong Kong market for the last three consecutive years.

Hynix Semiconductor Inc. climbed into the No. 3 spot due to significant DRAM shipment growth. STMicroelectronics, Toshiba Corp. and Freescale Inc. continued their healthy growth rates in China and were ranked fourth, fifth and seventh respectively. The market share of both Samsung Electronics and NXP in the region declined somewhat in 2006.

Table 2 - iSuppli's ranking of the Top-10 semiconductor suppliers in the China/Hong Kong area in 2006.

Top-10 Semiconductor Suppliers in Taiwan

It's not surprising that the top semiconductor rankings in Taiwan differ from China/Hong Kong in light of the regions' varying market focuses.

Taiwan concentrates mainly on data-processing system design and manufacturing, while China/Hong Kong focuses on consumer electronics and wireless equipment. Several semiconductor suppliers with Central Processing Unit (CPU), DRAM and graphic-card product lines, including Intel, Samsung, Powerchip, Hynix, Nvidia and AMD, are among the Top- 10 semiconductor suppliers in Taiwan.

TI, STMicroelectronics and NXP also are present in the ranking because their analog and power products are needed for data-processing applications.

Broadcom Corp. is an exception. It is neither a Top-10 supplier in Greater China or China/Hong Kong. Nonetheless, it ranked seventh in Taiwan because of its popular products for data communications.

Table 3 - iSuppli's Ranking of the Top-10 Semiconductor Suppliers in Taiwan in 2006.

Tower Plans Further Ramp Up of Fab 2

Tower Semiconductor Ltd., a pure-play independent specialty foundry, announced that the Company is exploring unique tool acquisition opportunities which would significantly expand Fab2 capacity beyond 24,000 wafers per month, primarily in advanced technologies (0.13u and below), in a cost effective manner.

Further to the recently announced raising of $40 million in long term-bonds, Tower concluded the signatures of letters of intent (“LOIs”) with its lender banks, Bank Leumi and Bank Hapoalim, and with Israel Corporation, a major shareholder, to provide credit lines totaling up to $60 million, in order to secure the funding of the equipment required for the ramp up. Loans borrowed under the credit lines will bear interest at an annual rate of LIBOR plus 3% and will be repayable by no later than March 2010. The LOIs are subject to the signing and closing of definitive agreements and the receipt of corporate approvals. They also contemplate that the Company will pay the banks and TIC customary fees, including issuing warrants for an aggregate amount of approximately 1.5% of the Company’s fully diluted share capital with an exercise price of $2.04.

Horiba, Ltd. Announces the Grand Opening of the 'Horiba Technology Center' in Santa Clara, CA

HORIBA, Ltd. will establish a new development facility, the "HORIBA Technology Center" on July 13 in Silicon Valley (Santa Clara, CA), following the Group's concerted efforts to meet the needs of the American hi-tech market for products such as semiconductors and biotechnology.

With the objective of conducting joint development with hi-tech corporate clients and offering collaborative proposals for solutions, the center will be set up amidst the world's frontier technology companies. The facility is complete with laboratories and clean rooms that are furnished with the latest equipment from Horiba's Group companies and will be joined by HORIBA STEC, Inc.

Staffed by a new R&D team, this facility will provide the venue and the opportunity for the kind of collaboration between vendors, integrators, and customers that is necessary to meet the challenges of next generation processes by providing value and enabling technology from Horiba's vast range of core technologies. Initially, a group of 10 engineers from Japan and the US will work together to develop fluid controlling devices and vacuum analyzing devices for subsystems on semiconductor producing equipment.

The initial investment, including plants and equipment, will amount to approximately 400 million yen and the building will be one-story above the ground, with an approximate gross floor area of 20,444 sq. ft.

ON Expands Philippines Presence

Phoenix-based power solutions vendor ON Semiconductor registered a vote of confidence in the Philippines, unveiling plans to increase its production presence there substantially by 2010.

President and CEO Keith Jackson said the company would spend approximately $80 million over the next three years to add a building to its 225,000-square-foot factory in Carmona, which churns out around 50 million power-management devices per week.

The expansion is expected to double the facility's capacity and create about 500 new jobs, Jackson said.

While the Philippines has often struggled to lure technology investments from regional competitors like China, Singapore and Malaysia, ON's decision and Texas Instruments' announcement in May that it would build a $1 billion assembly and test facility in the country have contributed to one of its best years in recent memory.

Philippines total electronics investments are likely to top $1 billion in 2007 for the first time in almost a decade, while export growth is expected to outpace the industry average, at around 10 percent.

ST to Shut Down U.S. Manufacturing Operations

STMicroelectronics is shutting down two U.S. wafer fabs and an IC assembly site, a move that ST estimates will involve about 4,000 employees worldwide.

This follows ST's recent move to exit the flash business, by forming a new and independent joint memory venture with Intel Corp. In that move, ST is also reducing its workforce by about 4,000 jobs. ST also shifted some memory fabs over to the venture in an apparent move towards a ''fab lite'' model.

Plants to go

Over the next two to three years—after all products manufactured at these sites are re-qualified at other facilities—ST said it will wind down operations at its older 6-inch wafer fab in Carrollton, Texas, its aging 8-inch fab in Phoenix, Arizona and its back-end packaging and test facility in Ain Sebaa, Morocco.

With the moves, ST will no longer have manufacturing in the U.S., according to a spokesman. These measures follow the completion of a program to migrate most of ST's global 6-inch wafer production to less-expensive 6-inch plants in Singapore or 8-inch facilities worldwide. The moves are said to save $150 million a year.

In addition, ST's R&D venture, the Crolles2 Alliance, will complete the development of 45nm CMOS process technology this year, but there would then be a "discontinuation" in the role of the Crolles development center and pilot fab.

Anadigics Breaks Ground for Chinese Fabs

Government dignitaries help mark the start of construction of the GaAs chip maker’s new facility, reflecting its national significance – while Johnson Matthey hopes to reap the rewards of the many more such fabs that it expects will follow.

Anadigics' current estimates suggest that construction of the new RFIC facility will be completed in the first half of 2008 and operational later the same year.

“The addition of the commercial 6-inch GaAs wafer fab to the development not only shows our ever growing interest of the semiconductor industry but marks a historical first for the city of Kunshan and the country of China,” said the city’s vice-mayor Feng-Quan Zhu.

Johnson Matthey is also entering the Chinese compound semiconductor industry, and recently sold two bulk hydrogen purifiers to LED companies in the country.

Johnson Matthey cites the Semiconductor Equipment and Materials International association's prediction that 20 new fabs will be operating in China by the end of 2008, attracted by tax incentives and subsidies.

Taiwan Chip Packagers Will Invest in China

Advanced Semiconductor Engineering and three other Taiwanese chip packagers won government approval to invest a combined $99.6 million in China. The approvals were granted to Advanced Semiconductor, and its smaller rivals, Siliconware Precision Industries, Greatek Electronics and Walton Advanced Engineering.

China Report: Capacity Reserve Challenges Small Fabless Companies

Semiconductor manufacturing is booming in China, but small indigenous fabless companies are turning to foundries outside of China to get their chips manufactured.

The reason: Large fabs in China will not turn out small volumes of chips for startups. While many claim to have multi-product wafer services for prototyping, they are leveraging the large contracts they have instead. That, in turn, has pushed an increasing amount of small manufacturing projects to foundries outside of China.

China is home to 47 fabs, according to the China Semiconductor Industry Association. The bulk of those produce four-, five-, six- and eight-inch wafers, (30 percent, 19 percent, 26 percent and 21 percent of total fab capacity, respectively) but new investment is flowing into 12-inch wafers, currently comprising four percent of fab capacity. Most of the newer fabs are financed by Taiwanese companies or investors.

Many fabs in China provide multi-product wafer or small-volume prototyping services, including Semiconductor Manufacturing International Corp. (SMIC), Shanghai Huahong NEC Electronics Co. Ltd., and Hejian Technology (Suzhou, Jiangsu). These fabs have programs to help start-up fabless companies manage small volume prototyping.

Many of China’s fabs, however, are focused on large-volume customers. Huahong NEC Electronics, for example, has committed itself to making China’s next-generation resident identification card, a combination of memory and CPU. Hejian Technology has mainly served Hong Kong-based Solomn Systech (LCD driver ICs), and Zhuhai Actions Semiconductor is focused on MP3/MP4 chips. Wuxi-based CSMC Technologies Corp., meanwhile, is focused on fabricating power management ICs for local Chinese fabless companies.

SMIC, China’s top foundry with a monthly capacity of 125,000 wafers, has strong relationships with some of the larger Chinese semiconductor companies. Many local Chinese semiconductor companies have their IC prototyped and manufactured in SMIC such as Beijing based Vimicro Electronics, which specializes in developing digital multi-media chips and SoCs, multi-media processor and SoC maker Chipnuts Technology Inc. and ZTEIC Design Co. Ltd., to name a few. SMIC has aggressively increased its capacity in Chengdu, Sichuan province and plans to open a new fab in Wuhan, Hubei province, as well.

"We use SMIC because of its quality service," said Bicheng Zhang, account manager at ZTE IC Design Company Ltd. He said that although fabs in China have multi-product wafer or special services for small volume, the services are very much dependent on the availability of capacity. Fabs usually give service priority to big orders, although they will service small orders in difficult situations. ZTEIC does not have problems reserving foundry capacity.

It helps that Shenzhen ZTEIC Design Company is a subsidiary of ZTE Corp., one of China’s top telecom equipment manufacturers. The company mainly serves its mother company’s demand on telecom and consumer electronics ICs. However, it also develops ICs for third parties, such as security chips for banking applications.

The Yangtze River Delta (Shanghai, Jiangsu and Zhejiang provinces) is home to most of the top fabs in China, such as SMIC (Shanghai), Shanghai Huahong NEC, Hejian Technology (Suzhou, Jiangsu province), Advanced Semiconductor Manufacturing (Shanghai), CSMC Technologies Corp. (Wuxi, Jiangsu), TSMC Technology (Shanghai). TSMC Technology (Shanghai) a capacity of just 30,000 wafers per month in its Shanghai fabs, however, the company plans to increase its capacity to 90,000 wafers through purchasing NXP’s 8-inch fab equipment and transferring it to Shanghai.

Fabs also are beginning to expand west and north to cut costs and better serve an emerging market. Due to labor and land cost increases over the past decade, many electronics manufacturers have opened new manufacturing facilities in less-developed areas. Intel invested $2.2 billion in Dalian, Liaoning province, for its first Chinese fab, which will use 90-nm processes for CPU chipsets.

In 2006, China’s fab sales revenue reached $4.18 billion, representing 38.9 percent growth year over year. Growth is expected to continue this year because of the growth of local semiconductor companies. However, for many start-up semiconductor companies, it still may be difficult to find fabs in China to produce their chips.

McIlvaine Company,

Northfield, IL 60093-2743

Tel: 847-784-0012; Fax: 847-784-0061;

E-mail: editor@mcilvainecompany.com;

Web site: www.mcilvainecompany.com