PULP MILLS UPDATE

October 2013

McIlvaine Company

TABLE OF CONTENTS

RISI Report: Global Pulp & Paper Production

Demerger Plan to Divide Metso into Two Companies: Valmet and Metso

Future Valmet to Supply a Complete Tissue Line for Faderco in Algeria

Stora Enso Third Quarter 2013 Results Announced

Arauco Installs Biomass Dryer at Valdivia Pulp Mill in Chile

Eldorado Seeks Funding for New 2-million-tonne/yr Pulp Line in Três Lagoas, Brazil

Honeywell to Provide Process Automation Technology for New Russian Pulp Paper Mill

ANDRITZ to Supply Two Tissue Machines with Steel Yankees to Shin-Ei Paper, Japan

Voith Supplies Complete Tissue Production Line to Celulosa Argentina

Uruguay Grants UPM Fray Bentos Mill Permit to Increase Annual Pulp Production

Montes del Plata in Uruguay to Begin Start-Up Process by Early 2014

Stora Enso to Revamp Pulp Line at its Oulu CWF Paper Mill in Finland

Sappi to Invest Euro 61M at Alfeld, Germany Paper Mill

Sappi Completes $170m Investment at Cloquet Mill, MN

SCA Considers Bioenergy Investment at Nokia Tissue Mill in Finland

Packaging Corp of America to Acquire Boise for $1.995 Billion

SCA Offer to Acquire Chinese Tissue Company Vinda

RISI's recently released 2013 Annual Review of Global Pulp & Paper Statistics is an independent, comprehensive information source of essential country-by-country statistics for the past two years (2011, 2012).

The report states that despite the continued decline in North America and Europe, global paper and board production still managed to advance at a meager 0.2% pace to reach a new record level of 400 million tonnes in 2012. Positive growth in tissue and packaging grades continued to offset the retreat in global graphic paper production.

"For the past four years, China has maintained the top spot for both demand and production of total paper and board, with the US remaining in second place. China accounted for 25% of world demand and 26% of global production of total paper and board in 2012," said Kevin Conley, Senior Economist of World Graphic Paper at RISI.

"In terms of pulp production, the United States remained the top producing country in the world with 50.4 million tonnes in 2012. China came in second producing 18.2 million tonnes," continued Conley. www.risi.com

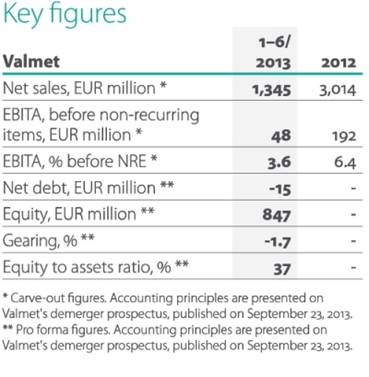

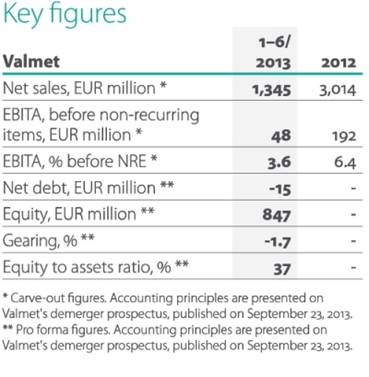

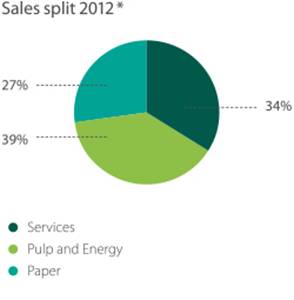

The demerger was approved by Metso's Extraordinary General Meeting on October 1, 2013. Metso's Pulp, paper and power business will form a new company Valmet Corporation and Mining and Construction and Automation business will form the continuing operations of Metso Corporation.

Starting from the beginning of 2014, the customers of Metso’s Pulp, Paper and Power businesses will be dealing with a new, independent company Valmet.

Metso’s Pulp, Paper and Power business, the future Valmet, supplies a complete tissue line for the Algerian company Faderco. The order also includes an automation solution for machine, process and quality controls. The tissue line will be installed on Faderco’s new site at Setif, Algeria. The start-up of the tissue machine is planned for the second quarter of 2015. The value of the order will not be disclosed. A part of the order is included in Metso’s Pulp, Paper and Power segment’s third quarter 2013 orders received, and the automation package in Automation segment's fourth quarter 2013 orders received.

The order is a result of a long and thorough planning and market evaluation process done by Faderco. "After thorough investigations and evaluation we came to the conclusion that Metso is the right partner for Faderco for such an important project which will establish high quality tissue paper production on the Algerian market,” says Amor Habes, owner of Faderco.

“We are very impressed with the well founded investment and technical analysis done for the project. The detailed preparation done already in an early stage will certainly contribute to the success of this project. We are proud to be part of the growth of the Faderco company,” says Jan Erikson, Vice President Sales, Pulp, Paper and Power, Metso.

The tissue production line will have a design capacity of around 30,000 tons a year of high-quality facial, toilet and towel grades. The raw material for the new lines will be virgin fiber.

Stora Enso CEO Jouko Karvinen recently commented on 3Q results, stating strong performance in Packaging, but European paper markets struggle.

“The third quarter ended with the operational profitability just slightly up year on year. Nevertheless, it was a very different quarter than a year ago, with 5% lower sales for the Group and significantly rebalanced contributions from the segments. However, most importantly lower sales were compensated by lower fixed and variable costs.

“Segmentally, there was a strong performance in Renewable Packaging and continued cost-driven turnaround in Building and Living. The good news was balanced by Printing and Reading continuing to contend with a weak market environment, and Biomaterials facing exchange-rate-related challenges as well as one-time costs from Veracel. In summary, it was a better than expected quarter that underlined the importance of our cost focus.

“The timetable for completing our joint-venture pulp mill Montes del Plata in Uruguay was revised during the quarter after the main technology contractors informed the company that they could not complete their work on schedule. That unexpected development was balanced by the view of the owners of the mill that the mill continues to be a good high-return investment and the delays can only lead to an even stronger effort to complete it well and ramp it up starting in early 2014.

“After announcing the revised two-phase timetable of our China investment, we have gradually started to initiate the mill site works. The target schedule for starting up the board machine remains in the beginning of 2016.

“The fourth quarter outlook for operational EBIT is clearly lower than a year ago because, in contrast to the other two segments, the two strongly performing segments Renewable Packaging and Building and Living, which together generate the majority of the Group’s earnings, both have a seasonal and market-driven pattern. In practical terms, the last quarter in these segments is clearly weaker than the first three quarters of the year, thus making the Group’s earnings especially seasonal this year and also weaker during the last quarter.

Arauco has implemented a unique piece of equipment in its Valdivia pulp mill in Chile, in order to reduce the moisture level and improve the quality of the biomass that feeds that facility’s power boiler. The new equipment has produced excellent results, positioning the company as

a reference point at the national level.

“For a while now, we’ve been searching for a way to improve the process that will allow us to deliver better product quality in terms of moisture, to our power boiler. We knew that if we were able to dry our bark, as well as third party bark, we could improve the production of steam and at the same time, reduce the use of bunker fuel No. 6 in the boiler, a vital factor in winter”, explains Manuel González, production assistant manager.

The biomass dryer was commissioned during the year. This piece of equipment was part of the facility project termed “Increase Steam Production in the Power Boiler”, in order to find a way to avoid the use of oil fuel during the winter months due to the high moisture content of biomass.

“The biomass dryer consists of a belt that transports the bark. When coming in contact with hot air, the moisture is extracted from the biomass. The hot and dry air is heated by secondary energy, which in our case is a surplus of the condensate to generator in the evaporators. The condensate goes through exchangers that preheat the air and at the same time, cool the condensate, which also improves its temperature, and then it goes to the effluents treatment plant,” adds González.

Brazilian pulp producer Eldorado Brasil has applied to the Brazilian middle west dvelopment fund (FDCO) to raise Real 1.4 billion ($0.6 billion) for the expansion of its 1.3-million-tonne/yr bleached eucalyptus kraft (BEK) pulp mill in Três Lagoas, Mato Grosso do Sul. The funds would be used for the construction of a new 2-million-tonne/ yr BEK pulp line, estimated at Real 7 billion (3 billion) and scheduled to start operating in 2017.

“This was a very important day for Eldorado Brasil. It’s one more step towards the construction of our second production line. After concluding this phase, Mato Grosso do Sul state will house, alongside Eldorado, the largest pulp industrial complex in the world,” Eldorado CEO, José Carlos Grubisich, commented.

Honeywell (NYSE:HON) announced recently that it has been selected to provide the process control system for a new pulp mill under construction in the Chita region of southeast Russia – the first greenfield pulp mill to be built in Russia in 35 years.

Built and operated by Russian North Star Pulp Industrial Complex LLC, but wholly owned by Chinese firm Heilongjiang Xingbang International Resources Investment Co. Ltd., the new pulp mill will use Honeywell's Experion® Process Knowledge System (PKS) to run plant operations. The new mill will have an annual capacity of 230,000 tons of unbleached market pulp when fully operational. Start-up is expected in mid-2015.

The entire output of the mill will be exported to China to meet the growing demand for paper goods there, including construction material, packaging and other products. Consumption of paper-based goods in China continues to rise at a rate of around 10 percent a year and is expected to reach 115 million tons in 2015. The new pulp mill project is one result of efforts for greater cooperation between Russia's Chita region and the neighboring Heilonhjiang province of China.

"Having efficient control systems in place helps improve production performance several times over, so we put a great emphasis on choosing the right ones. Honeywell's Experion PKS fully meets our requirements in terms of energy efficiency, reliability and safety," said Yang Guangwen, chief engineer and vice general manager, North Star Pulp Industrial Complex LLC. "In addition, Honeywell has offices in Siberia and in China, which will make our collaboration easier."

Honeywell's Experion® PKS will be installed in all of the mill's major process areas including wood preparation, pulping and drying, as well as the chemical recovery and combined heat and power plant.

"Honeywell has the innovative technologies and the depth of experience in the pulp and paper industry to meet North Star Pulp Industrial Complex's need for a highly productive and efficient pulp mill," said Jarmo Kosunen, program director for Honeywell Process Solutions. "Our technology will manage every main process in the mill, improving productivity, process reliability and helping to prevent unplanned shutdowns."

International technology Group ANDRITZ has received an order from Shin-Ei Paper, Japan, to supply two tissue machines with steel Yankees to its location in Fuji city. The machines, which will be used for producing high-quality tissue out of recycled fiber, are scheduled to start up at the beginning of 2015.

The new PrimeLineCOMPACT machines are designed for a speed of 1,800 m/min and for a paper width of 2.8 m. They will be equipped with PrimeDry Steel Yankees to enable a high drying capacity at minimized energy costs.

Mr. Satoshi Kurosaki, President of Shin-Ei Paper, states: “Doh-Ei Paper, one of our group’s companies, replaced a cast iron Yankee with an ANDRITZ Steel Yankee in 2012. As promised, higher drying capacity and energy savings were achieved. During the tender phase for the two new tissue machines we had a lot of constructive discussions with ANDRITZ engineers and they proposed various possibilities to improve the production efficiency. We consider ANDRITZ to be a reliable supplier.”

Voith Paper has won the order to supply a complete tissue processing line to Celulosa Argentina in Argentina. The system, to be supplied as a Process Line Package (PLP), will go on stream in Capitán Bermúdez (about 300 km to the north-west of Buenos Aires) in early 2015.

The new VTM 1 production line, which has a wire width of 2,760 mm and runs at 1,800 m/min, will produce around 30,000 metric tons of 15-21 g/m² basis weight toilet tissue and kitchen roll from virgin fiber.

It is therefore enabling Celulosa Argentina to break into the production of high-quality tissue papers and continue to pursue its long-term growth strategy. A special feature of this contract is the innovative long-term supplier financing concept configured and arranged by Voith that was a major factor in the realization of the project.

The scope of supply includes a VTM 1 tissue machine consisting of MasterJet T 1-layer headbox, Voith steel cylinder with high performance hood, the innovative shoe press technology NipcoFlex T and a MasterReel. Voith's OnQ quality control system equipped with non-radioactive sensors for the measurement of moisture content and fiber weight, the OnC process control system as well as the entire stock preparation, engineering and additional services complete the PLP package.

The State of Uruguay has granted permission for UPM Fray Bentos mill to increase its annual pulp production from the current 1.1 million to 1.2 million tonnes.

“The decision demonstrates the State of Uruguay’s continuing support to the development of the forestry sector in Uruguay” says Jaakko Sarantola, Senior Vice President of UPM’s Pulp Business.

UPM Fray Bentos will now immediately continue pulp production after the annual maintenance shutdown. Due to the efficiency and productivity of the mill, the production increase can be realised without additional investments in the production processes. However, UPM is expected to invest in a cooling system for the mill’s effluent water.

“The productivity has increased as a result of focused and professional work of the Uruguayan team throughout the whole forestry value chain. Since the start-up of the operations, the mill’s environmental performance has been excellent and UPM continues respecting the authorized permit limits”, says Sarantola.

Stora Enso’s and Arauco’s joint-venture pulp mill project Montes del Plata in Uruguay has been expected to begin the mill start-up process at the end of the third quarter of 2013. The mill site is 92% complete and the commissioning of certain areas has already begun. However, the main technology contractors have informed Montes del Plata that they will not be able to complete the work according to the agreed timetable. Montes del Plata is supporting the contractors and all local stakeholders to expedite the start-up process. The operational EBIT impact of the delay for Stora Enso during 2013 is estimated to be Euro 7 million ($9.3 million.).

Stora Enso will invest Euro 14 million ($19 million) in upgrading the pulp line at its Oulu mill in northern Finland. The revamp will reduce the mill’s environmental impact and decrease its energy consumption and chemical costs. The investment includes the installation of new parts in the digester and machinery related to screening, pulp washing and bleaching. Most of the work can be done during normal production, mill manager Jari Kärkkäinen said, adding that the new parts will be taken into operation in two phases during the mill’s annual maintenance stop in 2014 and 2015. The company has yet to pick a supplier for the project.

Kärkkäinen said that the upgrade will not increase the pulp capacity of the factory, but will improve capacity utilization, thus raising production by a few percentage points. It will have

no effect on paper production. The Oulu mill has a capacity of some 1.125 million tonnes/yr

of coated woodfree (CWF) paper on two machines and some 360,000 tonnes/yr of bleached softwood kraft pulp. Most of the pulp is consumed at the factory, but some is sold on the market.

The plant employs some 600 people.

An ambitious rebuild of Papermaking Machine 2 (PM2) at Sappi's Alfeld Mill will create the world's largest papermaking machine producing one-side coated and MGBK (Machine Glazed Bleached Kraft) speciality grades. This complex and meticulously planned project, a €61 Million Investment, has created a great deal of excitement, both in the local community and in the packaging world at large.

"This is the biggest investment that has been made at this 300-year-old mill in the past 20 years," said Rosemarie Asquino, Sappi Europe's Sales and Marketing Director Specialities. "Not only will it expand our capacity for producing high-demand speciality packaging materials, but it will reduce our environmental footprint and increase standards compliance."

Asquino explains that PM2 will be converted from the production of coated wood-free graphic arts grade papers to the production of a wide range of speciality papers. "In recent years there has been about a 6% decline in demand for graphic arts papers," she adds. "At the same time, growth in demand for speciality packaging papers is expected to be as high a 3.2%. Sappi has a creative portfolio of speciality grades for which demand is increasing, and this project was designed to enable us to continue to meet that need."

According to Asquino, with this rebuild, Sappi will add to its unmatched portfolio the capacity to produce higher volumes of a wide range of paper and packaging products including coated and uncoated papers for flexible packaging, premium SBS board for luxury boxes, topliner for high quality corrugated packaging, label papers for wet glue applications such as can and jar labels, banderols and wrappers, and last but not least, silicone-based papers for carriers for self-adhesive products such as plotter films and stickers.

Sappi Fine Paper North America has completed its $170 million capital conversion project at the Cloquet Mill in Minnesota to produce specialized cellulose, which is used in textile and consumer goods markets. The conversion initiated in 2011 was accomplished on time, within budget and safely says the company.

Sappi globally is one of the largest manufacturers of specialized cellulose in the world with capacity totaling to over 1.3 million metric tons per year. Specialized cellulose, also known as dissolving wood pulp, is a versatile raw material used by manufacturers to produce a wide range of products including textile fibers, pharmaceutical, beauty and household products.

"The Cloquet Mill is ideally suited to help Sappi secure its global leadership position regarding specialized cellulose. It is the newest pulp mill in America, close to its fiber basket and with a highly skilled and motivated workforce," says Ralph Boettger, CEO, Sappi Limited. "The mill adds to Sappi's flexibility in serving its global customer base and has, from start-up, produced excellent quality product. Cloquet's paper and now dissolving pulp capabilities are central to the ongoing success of Sappi in North America."

The company now has the capability to produce specialized cellulose on two continents including its South Africa expansion at the Sappi Ngodwana Mill and its Saiccor Mill in KwaZulu-Natal. With the Cloquet conversion now complete, the mill's specialized cellulose production is 330,000 metric tons per year.

SCA Tissue Finland is considering building a new steam boiler facility at its 80,000-tonne/yr tissue mill in Nokia, near Tampere, in Finland. The firm has applied for an environmental and operating permit for the plant from the Regional State Administrative Agency of Western and

Inland Finland.

According to the application, the facility is supposed to produce process steam which will be used at the Nokia paper mill as well as the Nokian Renkaat tyres factory. The main boiler will have a capacity of 41 MW. As raw material, SCA will mainly use wood-based fuels such as wood chips, but also by-products from the paper making process such as fiber clay and sludge from the mill’s wastewater treatment plant. It may also use peat.

SCA also plans to build a 33-MW natural gas-fuelled boiler to be used as back-up.

Packaging Corporation of America and Boise announced that they have entered into a definitive agreement under which PCA will acquire all of the outstanding common shares of Boise for

$12.55 per share in cash, for an aggregate transaction value of $1.995 billion, inclusive of $714 million of outstanding indebtedness of Boise. The transaction is expected to close in the fourth quarter of 2013 with committed debt financing, but is subject to certain customary conditions and regulatory approvals.

The combined companies generated $5.5 billion in sales and $879 million in EBITDA (excluding special items) in the last 12 ended June 30, 2013 (LTM). The combined packaging business generated 75% of sales and 83% of EBITDA over the period, with the remainder generated by Boise’s paper business.

PCA’s containerboard capacity will increase to 3.7 million tons from its current level of 2.6 million tons (a 42% increase) including the announced expansion of paper machine number 2 (D2) at Boise’s DeRidder, LA, mill. PCA’s corrugated products volume will increase by about 30% as a result of the acquisition, and PCA’s market presence will expand into the Pacific Northwest.

SCA has decided to make a public cash offer for the Chinese tissue company Vinda. The offer is conditional upon SCA achieving an ownership share in Vinda in excess of 50%. SCA is currently the second largest shareholder in Vinda, which is listed on the Hong Kong Exchange.

The offer will be Hong Kong Dollar (HKD) 11.00 per share, corresponding to a premium of approximately 34.5%, based on the average closing price over the past 30 trading days. The offer corresponds to a market capitalization of approximately SEK 9.4 billion for all shares in Vinda.

SCA became a part owner in the tissue manufacturer Vinda in 2007 and currently has a

21.7% holding in the company with two representatives on its Board of Directors. Vinda is the third largest tissue company in China, which represents the world’s second largest tissue market. In 2012, Vinda’s sales rose 26% and amounted to approximately SEK 5 billion ($0.7 billion).

McIlvaine Company

Northfield, IL 60093-2743

Tel: 847-784-0012 Fax: 847-784-0061

E-mail: editor@mcilvainecompany.com

Web site: www.mcilvainecompany.com