Coronavirus

Technology Solutions

October 7, 2021

ATI Introduces Automated Filter Tester With

Higher Flow Rates

AAF Netherlands HEPA Manufacturing Facility Now

Seven Years Old

Remploy has Been Testing Filters in Cumbria UK

for More Than Ten Years

High Efficiency Residential Air Filters Do Not

Significantly Increase Energy Consumption

SGS Expands Air Filter Testing Capability

INDA Forecasts Increasing Air Filter Market

Freudenberg Filtration Acquires Protect Plus Air

Holding

Park Group in India Assures High Quality HEPA

Products With Extensive Testing

ATI 100 X Has Been Extensively Used to Validate

N95 Masks

HEPA Filter Leak Testing was Incorporated in ISO

29463

Recognition Growing of the Importance of

Fitted Filter Efficiency (FFE)

_____________________________________________________________________________

ATI Introduces Automated Filter Tester With

Higher Flow Rates

Air Techniques International (ATI), a global

leader in the design and manufacture of

specialized testing equipment for HEPA filters,

media, filter cartridges, respirators, and

protective masks, has introduced he High Flow EN

13274-7:2019 compliant Paraffin Oil option to

its 100X Automated Filter Tester lineup.

The new High Flow option provides greater

flexibility for testing a wider range of masks

and cartridges, including PAPR cartridges, and

increases production throughput vs. standard

flow options.

“The High Flow option is a valuable feature for

manufacturers looking to increase production

rates while still complying with the strict

standards for particle size and concentration

specified in the EN 13274-7:2019 Paraffin Test,”

said Gautam Patel, Global Product Manager.

By offering a flow rate of 170 L/min vs. the

standard rate of 120 L/min manufacturers can

benefit from increased production throughput by

testing multiple filter cartridges at once.

The High Flow option also allows testing of a

wider range of applications. “A common

application that requires a higher aerosol

challenge flow rate is the testing of PAPR

(Powered Air Purifying Respirator) filter

cartridges. PAPRs typically require flow rates

much higher than standard filter cartridges,”

said Patel. The High Flow option is ideal for EN

12941 and EN 12942 PAPR testing standards.

The High Flow option allows more cartridges to

be tested at once vs. standard flow rate units.

This is important to manufacturers using the

100X in their high-capacity automated production

lines. Complete test cycles can be performed in

as little as six seconds.

In addition to EN 13274-7:2019, the 100X

Automated Filter Tester product range meets

other major industry standards, such as NIOSH 42

CFR Part 84, GB 2626, ISO 23328, JICOSH/JMOL,

ASTM F3502-21, and more. The 100X Automated

Filter Tester is used worldwide in production,

quality control, and R&D applications to test

and validate filter media, cartridges, and

respirators.

AAF Netherlands HEPA Manufacturing Facility Now

Seven Years Old

The AAF cleanroom facility for HEPA filter

manufacturing at its main European production

location in Emmen, the Netherlands was built in

2013.

The cleanroom is constructed as a separate area

inside the Emmen facility, AAF’s largest

European manufacturing plant. The total floor

area covers 900m2 and consists of

four core process steps: media pleating, filter

assembly, testing and packaging. For pleating

the media, assembly into HEPA filters and filter

testing according to the EN1822:2009 standard,

an ISO 7 controlled environment has been

designed.

Packaging of the HEPA filters is done in an ISO

6 controlled environment to minimize any

contamination risk from the filter itself, once

it enters the cleanroom at the customer’s site.

Both cleanroom areas are designed, constructed

and validated following ISO 14644 principles.

Remploy has Been Testing Filters in Cumbria UK

for More Than Ten Years

In 2011 ATI-DOP Solutions, designed, built and

installed a filter-testing facility at Remploy

Filters.

Remploy Filters,

based in Barrow in Furness, Cumbria, UK,

operates from a purpose-built 6,500ft2 manufacturing

facility and provides a complete range of soft

filters, pre-filters, bag filters, pleated panel

filters and media rolls.

The

filter-testing facility includes a three-fan

variable air handling unit capable of testing

single or multiple filters up to 1,830 mm long,

915 mm wide, or 450 mm high, and at airflows up

to 6,000 m3/hr.

The test bed,

which can have two operators testing in tandem,

is inside a pressurized clean area served by two

ceiling-mounted UDAF canopies. With white

lighting, white polypropylene test bed, wall

ceiling panels and two clear perspex side panels

and access doors it has been heralded by staff

as an excellent working area.

DOP Solutions’

aerosol photometry equipment is fully integrated

and gives audible and visual performance of each

filter tested, and with KIMO airflow instruments

installed, Remploy has every measurement it

needs to confirm production quality.

With the

downflow clean air and that from the filter

being tested, the room air is changed more than

100 times every hour, thus maintaining the test

environment at very low airborne particle

levels. Coupled with a clever filter sealing and

clamping arrangement, this allows for HEPA and

ULPA grade filters to be integrity tested with

confidence.

Special features

include being able to test the filter with its

gasket fitted in environmental conditions found

in high ISO class cleanrooms, with integrated

flow and differential pressure instruments and

easy adjustment and control of air delivery. DOP

Solutions’ data acquisition software is also

included.

Altogether,

these features allow fast, safe, accurate and

recordable testing of Remploy’s air filters to

meet or exceed the requirements of EN1822, the

European specification for HEPA and ULPA filters

used in all clean air and containment

applications, says DOP Solutions.

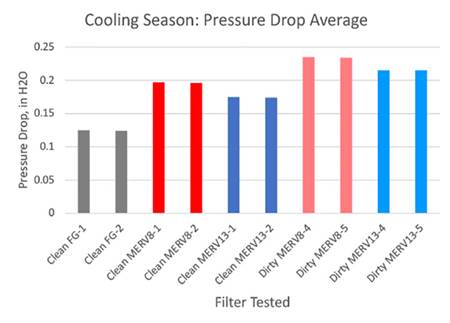

High Efficiency Residential Air Filters Do Not

Significantly Increase Energy Consumption

A comprehensive study was conducted

by Emerson Electric to understand: (1)

the relationship between filter efficiency and

CADR (clean air delivery rate) and reduction of

the PM (particulate matter) concentration in a

house with a forced-air residential HVAC

(Heating Ventilation air-Conditioning and

Refrigeration) system; and (2) the interaction

between the event room, where the PM is

generated, and other rooms based on different

filters and RAP (room air purifier)

configurations.

This study concluded that: (1) high-efficiency

filters had a negligible impact on HVAC energy

consumption when compared to fiberglass filters;

(2) high-efficiency filters maintained the same

level of energy consumption throughout the

designed service life; and (3) high-efficiency

filters do not necessarily have higher pressure

drop versus lower-efficiency filters, because

the filter pressure drop depends mostly on the

filter media and filter design, not necessarily

on the filter efficiency.

https://www.filtnews.com/impact-of-high-efficiency-filters-on-energy-consumption/

SGS Expands Air Filter Testing Capability

Post Covid-19, SGS IBR’s air filtration testing,

certification and consultancy services have been

in particular demand. Now, following significant

investment, SGS IBR has extended these

capabilities in China and the UK. The company’s

new and expanded, laboratories in Suzhou and

Milton Keynes are equipped with cutting-edge

testing technology to offer enhanced performance

tests with rapid turnaround and accurate

results. These new facilities complement SGS

IBR’s existing laboratories in Asia, the UK and

USA, providing even greater presence and

industry expertise.

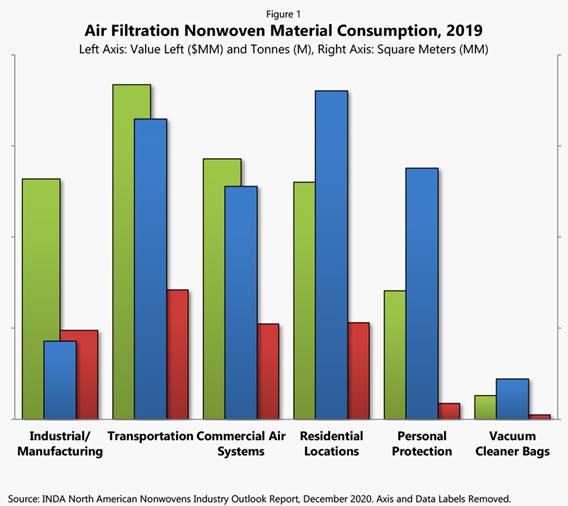

INDA Forecasts Increasing Air Filter Market

Brad Kali of INDA is optimistic about the market

for air filters in coronavirus-related

mitigation efforts but also other applications.

Consumer and workplace health and safety is

creating new filtration needs and is raising the

bar on performance. The assumption is that the

filtration industry will be able to deliver the

needed filters and masks.

The air pollution prevention benefits of masks,

HVAC filters, and dust collectors are also

greater due to the steady increase in wildfires.

Concerns that media manufacturers have about

building capacity, which will go unused after a

vaccine is perfected, is somewhat unwarranted.

Not only are there non-mask uses, but air

pollution, indoor pollution, wildfires, and new

viruses will boost mask demand.

Increases in filtration efficiency for

commercial air systems and at residential

locations will cause dollar sales to increase at

a more rapid rate than units, given the higher

cost per unit.

https://www.filtnews.com/core-applications-and-drivers-in-the-north-american-air-filtration-market/

Freudenberg Filtration Acquires Protect Plus Air

Holding

Freudenberg’s Filtration Technologies business

is acquiring Protect Plus Air Holding, Inc. from

its current owner, the Indianapolis-based

private equity firm HKW. Based in Hickory, North

Carolina, Protect Plus Air is a producer of air

filters that are mainly sold through retailers

for residential buildings. The company has 940

employees and generated $118 million in revenue

in 2020. Terms of the acquisition were not

disclosed.

“With the acquisition of Protect Plus Air, we

are expanding our portfolio of filtration

solutions in the important North American market

by adding the attractive, fast-growing field of

residential building ventilation,” said Dr. Mohsen

Sohi, CEO of the Freudenberg Group. “Protect

Plus Air is expanding and strengthening our

already existing filtration portfolio for

mobility and industrial applications worldwide.”

Park Group in India Assures High Quality HEPA

Products With Extensive Testing

PARK Group specializes in

quality filtration media through globally

accredited and renowned analytical instruments,

such as Palas GmbH & Anton Paar GmbH, Mitutoyo

[Japan] and RBM.

·

Quality Testing: In house testing lab with

well-renowned equipment for Breathing

Resistance, Tensile Strength, Elongation, GSM

Test, Dust Holding Capacity, Particulate

Efficiency, Pressure Drop, Pore Size.

·

Manufacturing Technologies: PARK excels in

various manufacturing technologies, including

meltblown, needle punch, chemical/thermal bond.

·

Air Filtration: PARK offers a variety of media

for air filtration, including HEPA/ULPA/HVAC

that meet or exceed different global standards,

while also offering low pressure drop,

energy-saving and longer media life.

PARK Group was incorporated in 1997 at Haryana,

India where the group has its headquarters and a

massive production plant. PARK Group specializes

in the production of a variety of products under

the nonwoven and polymer categories.

PARK serves 1,000+ customers in 25+ industries,

exporting to 75+ countries with 10+ plants in

all major cities of India.

ATI 100 X Has Been Extensively Used to Validate

N95 Masks

The 100X has played a key role during the

COVID-19 pandemic to perform the sodium chloride

(NaCl) aerosol challenge required to test and

validate the filtration efficiency of

N95/FFP2,3/KN95 style respirator masks. As the

COVID-19 pandemic began to spread in early 2020,

demand for respirator masks far exceeded supply.

With this increased demand came the need for

test equipment to validate the filter media and

masks to the relevant regional standards such as

NIOSH 42 CFR Part 84, GB 2626, EN 13274-7, etc.

ATI has experienced an unprecedented surge in

requests from filter media and respirator mask

manufacturers seeking its technology to perform

the critical tests required by global standards.

An essential requirement of an automated filter

tester is its ability to accurately test filter

media for resistance and penetration. Precise,

repeatable results are vital to minimizing false

failures while at the same time not failing

product that is within spec. ATI’s 100% Sampling

Aerosol Detection System is designed to produce

accurate results and can test a wide range of

HEPA and ULPA grade filters, up to 99.9995%

efficiency, respirator masks and high-efficiency

filtration media.

https://www.filtnews.com/high-accuracy-low-maintenance-filter-testing/

HEPA Filter Leak Testing was Incorporated in ISO

29463

In 2015

global standard, ISO 29463: High Efficiency

Filter and Filter Media for Removing Particles

in Air was developed. Although having roots in

the prevailing European norm, EN 1822 (1), the

new ISO standard has similarities to current

testing practices and filter classification of

the major standards in use around the world.

Part 4: Test method for determining leakage of

filter elements (Scan method)

Among test methods for filters, leak testing is

unique to HEPA and ULPA filters. This section of

the standard prescribes a normative method for

all filter classes that requires leak to be

determined at the MPPS of the filter. In

recognition of prevailing methods in many parts

of the world, the standard also allows two

alternate normative methods for testing filter

classes < ISO 40. One method common in the U.S.

and pharmaceutical, military, and nuclear

industries around the world uses the photometers

and polydisperse aerosols. The other method uses

the oil thread and visual leak detection

procedure common in many European countries.

https://www.filtnews.com/iso-29463-a-global-standard-for-hepa-and-ulpa-filters/

Recognition Growing of the Importance of Fitted

Filter Efficiency (FFE)

“A year ago we could say that we were concerned

about shortages for health care workers, so we

were telling people to make your cloth mask, and

any mask is better than no mask,” says Linsey

Marr, an environmental engineer and aerosol

science expert at Virginia Tech. But given what

scientists know now—especially with the virus’s

highly transmissible Delta variant spreading and

people spending more time indoors in schools,

for example—“I think the CDC should be

recommending high-performance masks for everyone

when they’re in these risky indoor situations,”

she says

When it comes to mask effectiveness, the most

important parameters are filtration, fit and

comfort. Filtration generally refers to the

percentage of particles the mask material

blocks. For example, an N95 filters at least 95

percent of airborne particles. But that does

little good if gaps around the mask let air in

freely. A well-fitted mask should sit snugly

against the face and over the chin, with no gaps

around the nose or mouth. Comfort is also an

extremely important metric: a mask does no good

if people simply find it intolerable to wear.

In the absence of more specific guidance from

health authorities such as the CDC as to which

brands of respirators and other masks provide

the best protection, some skilled amateurs have

stepped in to fill the gap.

Aaron Collins, aka “Mask Nerd,” is a mechanical

engineer at Seagate Technology with a background

in aerosol science. In his free time, he makes YouTube

videos in

which he tests and reviews high-filtration masks

made by various manufacturers. Collins says he

does not earn any money from mask manufacturers

or his videos themselves—he considers them a

service and wants them to be objective.

Collins has a mask-testing setup in his

bathroom, where he assesses masks’ filtration

efficiency by generating aerosols of sodium

chloride (salt). He then uses a condensation

particle counter—a device that measures the

concentration of particles inside and outside a

mask he is wearing—to determine the total inward

leakage through and around the mask. (For

comparison, NIOSH’s N95 standard requires

manufacturers to measure leakage through the

respirator material itself. And OSHA measures

how a respirator fits on someone’s face, which

often involves wearing an N95 in an enclosed

space with saccharin or another distinctly

flavored test aerosol sprayed in: if the wearer

reports tasting the substance, the mask fails

the fit test.)

Collins also tests “pressure drop,” which is

basically how easy it is to breathe while

wearing a mask. If doing so is too difficult, a

wearer might not only find the mask less

comfortable but also suck in air around its

sides, negating its filtration. Some cloth

masks—including those outfitted with coffee

filters—have this problem. “There’s a reason

N95s aren’t made from cloth,” Collins says.

In general, he recommends KN95s made by Chinese

company Powecom and others, a variety of KF94s

such as the Bluna FaceFit and N95s made by

reputable brands such as 3M, Moldex or

Honeywell. All of these masks had close to 99

percent filtration efficiencies and fairly low

pressure drops in Collins’s setup. (For

comparison, he found that a surgical mask alone

had between about 50 and 75 percent filtration

efficiency, depending on the fit, and a good

cloth mask had about 70 percent.) But when

choosing the best mask, comfort should be a

deciding factor, he says. Not everyone needs to

wear an N95.

“To me, the minimum I want to see people wear is

a KN95 or KF94 with the Delta variant,” Collins

says. “I don’t think surgical masks are good

enough anymore, and we should’ve gotten rid of

cloth masks last summer—they’re not even in the

spectrum” of good filtration. (To be clear, some

studies have found that surgical and cloth

masks can provide

at least some protection against COVID. A recent

large, randomized study in Bangladesh found

that surgical

masks significantly lowered the risk of

infection;

cloth masks did not have a measurable benefit,

although other studies suggest they provide some

protection.)

With children starting school in-person, many

parents are understandably worried about their

kids, especially those who are too young to be

eligible for vaccination—and particularly in

states where politicians have tried to ban mask

mandates in schools. These parents might find

Collins’s recommendations for high-filtration kids’

masks particularly

helpful. There is no N95 standard for children,

but plenty of manufacturers make KF94 or KN95

masks for them. Such masks are designed for

small faces and are easy to put on. Collins sees

no reason why kids could not tolerate them. “I

have my own son,” Collins says. “He’s five years

old. He wore them all summer.”

An issue with commercially available

high-filtration masks is that they may not come

from reputable suppliers. The CDC’s Web site

warns that about 60 percent of KN95

respirators available in the U.S. are

counterfeit. To find ones that are legitimate,

Prather recommends the Web site Project

N95.

Masks can also be ordered directly from

suppliers such as Bona Fide Masks, which sells

KN95s made by Powecom. “That’s the one people

swear by,” Prather says. They cost around $1

each. DemeTECH sells

N95s for around $4 apiece, as well as other

types of masks.

One reason people may be reluctant to use KN95s

and similar masks is because they are usually

considered disposable. But several experts say

they can in fact be worn multiple times. “You

can probably reuse it until it becomes visibly

damaged or soiled,” Marr says. Collins’s amateur

testing suggests mask can be used for up 40

hours with no decrease in their filtration

efficacy (he recommends using them within six

months of opening a package). The virus likely

does not survive long on these masks, but it is

not a bad idea to have a few in rotation,

reusing one every three days or so, Collins

says.

One popular way to increase effectiveness is to

wear a cloth mask on top of a surgical mask.

This strategy, which the CDC has recommended,

combines the filtration efficiency of the

surgical mask material with the fit of a cloth

mask. But how well does it actually work?

According to Collins, pretty well. He measured a

filtration efficiency of upward of 90 percent

for a cloth mask (with nose wire) over a

surgical mask. But the pressure drop was almost

twice as high as that of an N95. One reason the

CDC and others have recommended against the use

of N95s by the general public, apart from their

previous scarcity, is that they can be difficult

to breathe through—so Collins finds it

“baffling” that the CDC would recommend double

masking. “So does double masking work? Yes, but

… I think there are better solutions,” he said

in one of his videos.

Another way to get a better fit is to use masks

with straps that go around the back of the head

or to use a mask brace if one only has access to

a surgical mask.