Coronavirus

Technology Solutions

April 27, 2021

COVID Worries

Are Not All

Rational

Mask Market will

be Determined by

Life Quality

Perceptions

Spunmelt

Capacity

Increasing

Rapidly

____________________________________________________________________________

COVID Worries

Are Not All

Rational

The following

fable has been

widely

circulated in

the last few

days and

reported in the

NY Times.

Guido Calabresi,

a federal judge

and Yale law

professor,

invented a

little fable

that he has been

telling law

students for

more than three

decades.

He tells the

students to

imagine a god

coming forth to

offer society a

wondrous

invention that

would improve

everyday life in

almost every

way. It would

allow people to

spend more time

with friends and

family, see new

places and do

jobs they

otherwise could

not do. But it

would also come

with a high

cost. In

exchange for

bestowing this

invention on

society, the god

would choose

1,000 young men

and women and

strike them

dead.

Calabresi then

asks: Would you

take the deal?

Almost

invariably, the

students say no.

The professor

then delivers

the fable’s

lesson: “What’s

the difference

between this and

the automobile?”

In truth,

automobiles kill

many more than

1,000 young

Americans each

year; the total

U.S. death toll

hovers at

about 40,000 annually.

We accept this

toll, almost

unthinkingly,

because vehicle

crashes have

always been part

of our lives. We

can’t fathom a

world without

them.

It’s a classic

example of human

irrationality

about risk. We

often

underestimate

large, chronic

dangers, like

car crashes or

chemical

pollution, and

fixate on tiny

but salient

risks, like

plane crashes or

shark attacks.

One way for a

risk to become

salient is for

it to be new.

That’s a core

idea behind

Calabresi’s

fable. He asks

students to

consider whether

they would

accept the cost

of vehicle

travel if it did

not already

exist. That they

say no

underscores the

very different

ways we treat

new risks and

enduring ones.

The New York

Times cited

the fable

recently because

of Covid-19.

Covid certainly

presents a

salient risk:

It’s a global

pandemic that

has upended

daily life for

more than a

year. It has

changed how we

live, where we

work, even what

we wear on our

faces. Covid

feels

ubiquitous.

Fortunately, it

is also curable.

The vaccines

have nearly

eliminated

death,

hospitalization

and other

serious Covid

illness among

people who have

received shots.

The vaccines

have also

radically

reduced the

chances that

people contract

even a mild

version of Covid

or can pass it

on to others.

Yet many

vaccinated

people continue

to obsess over

the risks from

Covid — because

they are so new

and salient.

‘Psychologically

hard’

To take just one

example, major

media outlets

trumpeted new

government data

last week

showing that

5,800 fully

vaccinated

Americans had

contracted Covid.

That may sound

like a big

number, but it

indicates that a

vaccinated

person’s chances

of getting Covid

are about one in

11,000. The

chances of a

getting a

version any

worse than a

common cold are

even more

remote.

But they are not

zero. And they

will not be zero

anytime in the

foreseeable

future. Victory

over Covid will

not involve its

elimination.

Victory will

instead mean

turning it into

the sort of

danger that

plane crashes or

shark attacks

present — too

small to be

worth reordering

our lives.

That is what the

vaccines do. If

you’re

vaccinated,

Covid presents a

minuscule risk

to you, and you

present a

minuscule Covid

risk to anyone

else. A car trip

is a bigger

threat, to you

and others.

About 100

Americans are

likely to die in

car crashes

today. The new

federal data

suggests that

either zero or

one vaccinated

person will die

today from Covid.

It’s true that

experts believe

vaccinated

people should

still sometimes

wear a mask,

partly because

it’s a modest

inconvenience

that further

reduces a tiny

risk — and

mostly because

it contributes

to a culture of

mask wearing. It

is the decent

thing to do when

most people

still aren’t

vaccinated. If

you’re

vaccinated, a

mask is more of

a symbol of

solidarity than

anything else.

Coming to grips

with the

comforting

realities of

post-vaccination

life is going to

take some time

for most of us.

It’s only

natural that so

many vaccinated

people continue

to harbor

irrational

fears. Yet

slowly

recognizing that

irrationality

will be a vital

part of

overcoming Covid.

“We’re not going

to get to a

place of zero

risk,” Jennifer

Nuzzo, a Johns

Hopkins

epidemiologist,

said during a

virtual Times

event last week.

“I don’t think

that’s the right

metric for

feeling like

things are

normal.”

After Nuzzo made

that point, Dr.

Ashish Jha of

Brown University

told us about

his own struggle

to return to

normal. He has

been fully

vaccinated for

almost two

months, he said,

and only

recently decided

to meet a

vaccinated

friend for a

drink, unmasked.

“It was hard —

psychologically

hard — for me,”

Jha said.

“There are going

to be some

challenges to

re-acclimating

and

re-entering,” he

added. “But

we’ve got to do

it.”

And how did it

feel in the end,

I asked, to get

together with

his friend?

“It was

awesome,” Jha

said.

Mask Market will

be Determined by

Life Quality

Perceptions

The previous

article

indicated

choices

including masks

are made in part

on risks that

are observed to

be salient. What

is salient is

likely to be new

rather than what

is of highest

risk? So

irrational

beliefs will be

a factor in mask

selection. Since

the risk of

COVID has been

real for more

than a year it

may be no longer

as salient to

the individual.

There are other

irrational

beliefs based on

perceived life

quality

enhancement.

Take

the

market for

sports footwear.

Because of

perceived life

quality impacts

purchasers are

spending

billions of

dollars per year

for shoes that

are ten times

more costly than

functional

equivalents.

Hoodies are more

uncomfortable

than masks and

yet they are

valued highly by

many teenagers.

CATE is an

acronym for

Comfortable,

Attractive,

Tight fitting,

Efficient. Mask

sales in the

future will be

determined by

how well the

product fits

these needs.

Comfortable and

attractive are

drivers

based on

emotional life

quality impacts.

Tight fitting

and efficient

are drivers

based on

extending life

and avoiding

sickness. Tight

fitting and

efficient masks

may be more

uncomfortable

than loose

fitting masks

but they offer

better

protection.

The cost is also

a function of

the performance.

The rational and

emotional

drivers lead to

mask decisions.

There is a

measurement tool

which takes both

into account and

can be used to

predict the mask

market.

This metric

measures all

harm and good.

This was

developed by

McIlvaine and is

called Quality

Enhanced Life

Days (QELD).

Below is a link

to a feature

article on it in

Healthcare

Development

Magazine.

http://www.mcilvainecompany.com/Decision_Tree/subscriber/Masks/QELD/Quality_Enhanced_Life_Days.htm

Most

sustainability

rating tools

rely on third

party

determination of

political and

social impacts

of any decision.

QELD is straight

forward and most

valuable because

it represents

the actual life

quality choices

being made by

the group

impacted by the

decision. If a

majority of the

group believes

that allowing

the elderly to

die at an

accelerated rate

is worth the

life quality

benefits of mask

avoidance, then

this will be

reflected in the

QELD rating. A

group is defined

as eligible

voters.

The basis of

QELD is that

people would

rather live only

80 years,

socialize and

eat ice

cream rather

than to 100 as

risk adverse

hermits. The

group would

rather raise the

speed limit to

65 mph knowing

that it

statistically

will shorten

their lives by a

day or two for

the life quality

benefits of

shorter travel

times.

Insights on the

future mask

market can be

gained by

substantial

effort to

quantify and

even shape the

life quality

impacts of

wearing masks.

The fact that

CATE masks are

both comfortable

and attractive

is very

important in

assessing life

quality impacts.

The negative

health life

quality risks

need to be

determined for

all the

different

combinations of

variables. They

include general

variables such

as

·

Immunity percent

in the group

based on the

percent which

are vaccinated

·

testing activity

·

virus positivity

testing percent

·

ambient air

pollution and

wildfires

They include

individual

variables

·

age and health

·

environment

·

travel

·

work

·

leisure time

·

infectious

illnesses such

as colds

If an individual

is fully

vaccinated and

is running

outdoors in his

leisure time the

risk is

negligible. So

he may justify

not wearing a

mask. On the

other hand if it

is a crowded

path he may want

to wear a mask

just as a

courtesy to

others who may

not know he is

vaccinated.

This decision

will also be

influenced by

the positivity

rate in the

area. In India

where the crisis

is peaking the

need to wear

masks will be

substantially

different than

in Israel where

infection rates

are low.

Even in a worst

case scenario it

is unlikely that

the market will

shrink to pre

COVID levels. In

many Asian

countries the

courtesy mask

has become

common. This is

likely to become

a worldwide life

quality

enhancement. The

lack of a mask

may someday be

equated with

spitting on the

sidewalk.

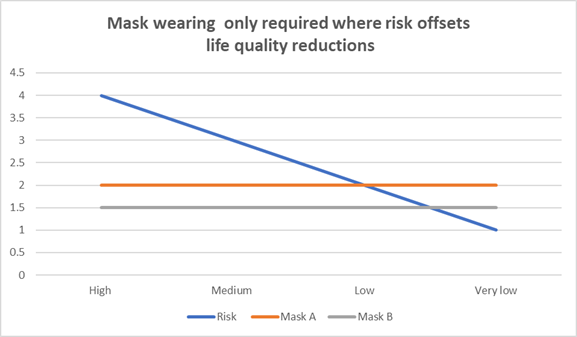

At high virus

load (High V)

the negative

life quality

impacts are high

compared to any

negative life

quality impacts

of wearing masks

such as

discomfort or

unattractiveness.

However at low

virus loads

uncomfortable

and unattractive

mask life

quality impacts

may outweigh the

benefits in the

minds of the

wearer. On the

other hand

comfortable and

attractive

(CA) masks have

lower negative

life quality

impacts than the

virus (Low V).

The benefits of

requiring CATE

masks to any

visitor to a

hospital or

nursing home are

clear. Mask

wearing during

air or subway

travel is likely

to remain.

The average

person is

infectious 14

days per year.

In the future it

is likely that

masks will be

worn by anyone

with a cold. A

waiter at a

restaurant or

hairdresser who

is infectious

will also need

to wear a mask.

Establishment

owners will

likely prefer

that all service

personnel wear

masks rather

than make the

public aware of

infectious

servers.

As more people

become

vaccinated, the

risk factor will

be greatly

reduced. However

this can be

offset by

adverse behavior

or new variants

or a combination

such as

in Michigan. In

India, the risk

factor today

equals what it

was a year ago

in any country.

Regulations

should be

based on

life quality

risk reduction

benefits

offsetting

discomfort and

inconvenience. A

person might be

willing to give

up a month of an

85 year life in

order to avoid

wearing a

comfortable and

attractive mask

for a year. He

might be willing

to give up two

months to avoid

wearing an

uncomfortable

mask for a year.

But the stakes

could be much

higher. They

could involve

years of life

lost for the

individual or

his friends and

family. A

teenager

responsible for

the death of a

grandparent

would in

retrospect

likely be

willing to give

up years of life

to have avoided

this.

The mask

discomfort and

inconvenience is

variable. Rules

can require

wearing masks

only in certain

settings or all

the

time. The

life quality

benefits are a

function of how

many illnesses

and deaths are

avoided.

There is the

discussion of

public health

versus

individual

liberty. In most

cases it is a

public heath

issue where

government has

the right and

obligation to

protect citizens

from dangerous

behavior from

others.

Mask A is

uncomfortable

and the risk is

outweighed by

life quality

considerations

before Mask B

which is

comfortable and

attractive.

Tight fitting

and efficient

masks are

proving to be

the best

protection

against COVID.

Social

distancing and

therefore

occupancy are

not nearly as

effective. The

requirement for

tight fitting

and efficient

masks along with

100% occupancy

can pose a risk

lower than 25%

occupancy with

inefficient

loose fitting

masks.

Spunmelt

Capacity

Increasing

Rapidly

Nonwoven

Industry

recently

assessed the

increase in

spunmelt

capacity which

is underway. The

big increase in

demand for

medical fabrics

and other

personal

protective

equipment has

led to a surge

in demand for

spunmelt

nonwovens

globally.

Industry

estimates put

the level of new

investment in

2020 at about

210,000 tons

with about

three-quarters

of this capacity

centered on

Reicofil 5

technology. In

2021, another

166,000 tons of

spunmelt

technology is

expected to be

commissioned.

Avgol is

relocating an

existing asset

from Israel to

India as part of

an immediate

strategic

investment in

the region.

Avgol, an

Indorama

Ventures Limited

company, leads

the global

hygiene market

with a

comprehensive

range of

ultra-lightweight

spunmelt

nonwoven

fabrics.

Relocation of

the Avgol line

from Barkan,

Israel to India

is underway now,

with

installation

expected to be

completed by end

of 2021.

Avgol entered

the market in

India in 2018

when it

completed its

first spunmelt

line, which was

reported at the

time to be a

non-Reicofil

asset. At the

time, the

company said the

investment was

intended to help

support existing

customers as

they entered the

Indian market.

Avgol also has

spunmelt

operations in

North Carolina,

Russia and

China.

Berry Global

continues to

invest heavily

in spunbond

nonwovens.

Recent

announcements

from the company

include a

state-of-the-art

Reicofil 5 SMS

asset to serve

the rapidly

growing medical

fabrics markets

in the region

and around the

globe. Start-up

of the line is

targeted for

late 2022.

Additionally,

Berry is

investing $8

million in new

equipment and

enhancements to

existing

production lines

at its

Statesville, NC,

site, to further

optimize its

production of

in-demand

spunmelt for

applications

including

fabrication of

medical gowns,

face masks, and

other personal

protection

equipment. The

additional

equipment and

expanded

capacity are

expected to be

operational in

December 2021.

Berry reported

that face mask

and N95

respirator

demand alone

created

significant

increases for

meltblown and

spunbond

materials used

to make those

products, in

addition to SMS

materials used

for other

infection

control PPE

products.”

In addition to

significantly

expanding

capacity to

support growing

market needs,

these

investments,

combined with

Berry’s market

leading know-how

and proprietary

raw material

blends, will

expand the

company’s

portfolio of the

highest quality

and highest

performing

materials in the

market, which

provide

consumers with

improved visual,

tactile and

comfort

attributes.

Fibertex

Personal Care is

investing

approximately

$40 million to

add new lines at

its sites in

Malaysia and the

U.S. The

Malaysian site

will be expanded

with the

addition of a

specialty

nonwovens line

while a printing

line will be

added to the

U.S. site in

Asheboro, NC.

Both lines are

expected to

begin operations

in the second

half of 2021.

Fibertex

Personal Care

currently

operates five

lines at two

sites in

Malaysia, which

make about

90,000 tons of

spunmelt

nonwovens

capacity. Its

most recent line

came onstream in

mid-2017.

Increased wealth

and growth in

the Asian middle

class segment is

leading to

growth in the

hygiene market

of approximately

10%.

Fitesa, Brazil’s

largest

nonwovens

producer is

adding two

large-scale

Reicofil

spunmelt lines

as part of an

ambitious global

expansion plan,

announced late

last year. At

its site in

Simpsonville,

SC, Fitesa is in

the process of

adding a

state-of-the-art

Reicofil 5

spunmelt

nonwovens line

with startup

scheduled for

the second half

of next year.

Since 2011, more

than 80,000

metric tons of

capacity have

been installed

with 138 jobs

created at

Simpsonville.

Most recently,

Fitesa started a

meltblown line

there to supply

nonwovens for

the production

of face masks

and respirators.

Elsewhere in the

world, Fitesa is

adding spunbond

capacity in

Brazil as well

as meltblown

lines in Brazil,

Germany and

Italy as part of

a 55,000-ton

global expansion

plan announced

in November.

Fitesa recently

completed

construction on

a multibeam

Reicofil line in

Cosmoplis,

Brazil. This new

line is being

described as one

of the most

advanced

spunmelt

nonwovens lines

in the region.

In addition to

these new line

investments,

Fitesa is

increasing

production

volumes,

modernizing

assets and

enhancing the

flexibility of

the current

asset base.

These efforts

will add another

20,000 metric

tons of spunmelt

capacity in the

second and third

quarters of

2021. The

capacity, which

will be split

evenly between

the U.S. and

Europe, will

serve the

healthcare and

hygiene markets.

In 2020, Fitesa

added a second

spunmelt line to

its CNC

International

operation in

Thailand. Fitesa

acquired a share

in this

operation in

2019.

PFNonwovens has

announced a

multi-phase

expansion to its

facility in

Hazleton, PA.

Six months after

saying it would

add a Reicofil 5

line at the

facility, the

company

announced in

December 2020 it

would add a

second new line

there. These

investments will

grow its

manufacturing

capacity and

help the company

expand in the

medical and

hygiene markets.

Phase two of the

expansion, which

will involve a

second new

production line,

is scheduled to

be complete in

2022. The

company has not

yet revealed

details on this

new line. It

will be the

eighth nonwoven

line located in

PFNonwovens’

Hazleton, PA,

site, which it

acquired from

First Quality

Nonwovens in

2018.

In the Czech

Republic,

PFNonwovens is

completing work

on a

semi-commercial

line in Znojmo.

The new line,

based on

Reicofil 5

technology,

allows the

company to

supply products

which cannot be

produced

currently with

conventional

methods. It uses

bicomponent

technologies,

offers a wide

range of fiber

types and

profiles and

enables the use

of a variety of

raw materials.

Another

significant

element of this

technology is

the nonwoven

textile bonding

system, which is

an alternative

to the presently

used

conventional

systems. The

line is

considered a

fundamental

building block

to PFN’s newly

built global

innovation

center expected

to help the

company achieve

significant

success in

research,

testing and

commercialization

of new products.

Meanwhile,

PFNonwovens has

streamlined its

operation

through the

divestment of

its Wuxi, China,

operation to

Jofo Nonwovens.

The site, which

was also a part

of First

Quality,

contains one

spunmelt line.

Jofo has already

announced plans

to expand the

site with an

additional line.

Spunweb is in

the process of

adding two new

polypropylene

spunbond

lines—an SSS and

SS. These

investments will

bring the

company’s

capacity to

35,000 MT/year

by Q3 of 2021.

These new lines

will meet the

ever growing

demands of its

existing

customers and

also aims add

new customers in

the medical,

packaging and

hygiene

segments. The

company expects

the new lines to

be complete by

the end of

August 2021, on

schedule.

Spunweb

currently

operates three

polypropylene

spunbond

nonwovens lines

which produce

11,000 metric

tons per year

put together. It

started its

first production

line in 2016

with the vision

to meet the

needs of the

hygiene and

medical sectors

with high

quality nonwoven

fabrics at

affordable

prices and

shorter delivery

schedules.

Toray added a

new facility,

capable of

making 20,000

tons of spunbond

nonwovens per

year in Foshan,

China, in April.

This investment

brought the

company’s total

Chinese capacity

to 93,000 tons

at two

facilities. One

of the largest

makers of

nonwovens in

Asia, Toray also

makes 61,000

tons of the

material in

Korea and 37,000

tons per year in

Indonesia and is

planning to

start production

of an

18,000-ton-per-year

line in India.

This investment

will bring the

group’s total

production

capacity to

209,000 tons per

year.

The largest

manufacturer of

polypropylene-based

spunbond

nonwovens in

Asia, Toray has

facilities in

China,

Indonesia, Korea

and India.

However,

production on

its first Indian

investment, a

18,000-ton-per-year

spunbond line,

has been delayed

due to the

Covid-19

epidemic.