Coronavirus

Technology Solutions

April 15, 2021

NXTNano, LLC

Installing Three

Additional

HYPR-Spun

Nanofiber

Production Lines

Four Hundred

Million Infected

People in India

and One Billion

At Risk

New Variants in

India Could be

Trouble

Centrifugal

Multispinning

Could Be 300

Times Faster

Than

Electrospinning

Nanofibers for

Fit, Function,

and

Sustainability

Pursued at

Cornell

_____________________________________________________________________________

NXTNano, LLC

Installing Three

Additional

HYPR-Spun

Nanofiber

Production Lines

NXTNano, LLC has

begun to install

three additional

HYPR-Spun

Nanofiber

production

lines. The first

of the lines is

expected to be

operational in

June, and all

three within the

year. The new

lines will take

their total line

count to six,

and like their

existing

production

lines, the

newest equipment

will facilitate

high volume

nanofiber

manufacturing up

to a maximum

roll width of

2.15 meters.

“2020 was an

incredible year

for NXTNano. We

saw rapid

adoption of the

technology in to

a number of new

markets, and

more importantly

we have a social

obligation to

continue serving

our mask,

respirator, and

indoor air

purification

customers who

have taken up

the fight

against COVID.

In

existing markets

we expected

COVID to produce

a pronounced

slowdown, but

that never

materialized.

As a

result of the

growth and new

projects moving

to commercial

sales, the time

has arrived for

us to add

capacity” said

Andrew McDowell,

NXTNano, LLC’s

Director of

Sales.

The number of

markets

commercially

consuming

nanofiber has

continued to

exhibit strong

growth, and

according to

industry

reports, is

expected to

continue this

trend.

Industry

wide forecasts

for CAGR are

expected to be

above 36% though

2023. This level

of growth,

combined with

their unique

focus on

application

know-how has

allowed NxtNano

to lead the pack

in both

innovation and

economics based

adoption.

“I’ve spent

nearly my entire

career in

nonwovens and

filtration, over

30 years now,

and the last

nine months have

been unique to

anything I’ve

seen before”

Said Alan

Smithies,

NxtNano’s VP of

technology. “The

growth has not

been without

challenges, but

I firmly believe

we as a company

have stepped

forward and

embraced them.

Our head count

is now over 80

people, more

than two and a

half times what

it was in 2019,

and we are

putting out full

truckloads of

material every

day. Our

customers have

been absolutely

phenomenal in

working with us

to execute

innovative

products the

market

desperately

needed, and for

that, I must

give them

credit. These

new lines are

our commitment

to ensuring they

continue to

succeed.

Four Hundred

Million Infected

People in India

and One Billion

At Risk

India became the

country with the

world’s second

highest number

of

confirmed COVID-19 cases

on Monday,

surpassing

Brazil, and now

second only to

the United

States. But

experts say that

low testing in

the country

suggests the

real total is

far higher than

both.

India now has

13.5 million

confirmed cases,

compared to

the U.S.’s 31.1

million. The

country is

currently in the

midst of a

second wave of

the virus, with

confirmed daily

infections

reaching an

all-time high of

168,912 on

Monday.

But the official

numbers only

tell part of the

story, according

to multiple

studies. “From

what has been

reported, I

think India

definitely has

the most

infections in

the world,” says

Ramanan

Laxminarayan,

director of the

Washington,

D.C.-based

Center for

Disease

Dynamics,

Economics and

Policy.

The reason is

that even now,

testing is only

detecting a

fraction of the

cases that

actually exist

in India’s

massive

population of

1.3 billion

people. A

serological

survey conducted

between August

and September

2020, which

measured the

presence of the

virus in a

sample group of

the Indian

population,

estimated that

there

were between 26

and

32 infections

for every

reported case of

the virus.

“For every 30

infections,

you’re pretty

much only

picking up one

as a case,” says

Laxminarayan,

who says a

similar

disparity likely

still exists

now, even though

India’s testing

capacity is

higher than last

year, because of

the signs

pointing to the

fact that the

virus is running

rampant in the

population. “I

would still

apply the

30-fold

undercount even

now,” he says.

If accurate,

that math would

put the real

number of

COVID-19

infections to

date in India

somewhere around

400 million —

more than the

entire

population of

the United

States. “400

million

infections in a

country the size

of India still

means that a

billion people

are not

infected,”

Laxminarayan

says. “So

there’s still

plenty of room

for infection,

even with a lot

of people

[already] being

infected.”

At the start of

the pandemic,

health experts

had predicted

that India, with

a population

more than four

times the size

of the U.S.,

would quickly

become the

world’s

worst-hit

country—especially

given

that China, the

only country in

the world with a

larger

population,

mounted an

effective

campaign to

suppress the

virus. But bad

outbreaks in the

U.S.

and Brazil meant

India never

officially

reached that

point.

India’s first

wave of COVID-19

infections

peaked in

September, then

began a steady

decline. New

infections began

to tick up again

in March, and

every day since

April 7 the

country has

recorded more

new cases than

at the height of

its first wave

last year. India

has also begun a

vaccination

drive,

announcing on

Sunday that more

than 100 million

doses have been

administered,

mostly to

over-60s and

frontline

workers.

Monday’s

milestone came

as thousands of

Hindu devotees,

many of them

maskless,

gathered at the

city of Haridwar

on the banks of

the River Ganges

to mark the Maha

Kumbh Mela

festival. Health

experts had

called for the

festival, one of

the largest

religious

gatherings in

the world, to be

canceled. But

authorities said

the pilgrimage

would go ahead

for those able

to produce

negative

COVID-19 tests.

Photographs from

Monday showed

large crowds

gathering to

bathe in the

Ganges, with

police powerless

to enforce

social

distancing

measures. “We

are continuously

appealing to

people to follow

COVID-19

appropriate

behavior. But

due to the huge

crowd, it is

practically not

possible,” said

a police officer

in Haridwar, according

to Al Jazeera.

The number of

confirmed

COVID-19 deaths

in India stands

at just over

170,000, the

fourth-highest

in the world,

behind the U.S.,

Brazil and

Mexico. But

those numbers

too might not

tell the whole

story. Even

before the

pandemic, as few

as 21% of deaths

in India were

recorded by a

medical

professional

along with a

cause of death,

according to the

World Health

Organization.

“If you’re

undercounting

cases by a

factor of 30, is

it possible that

we’re

undercounting

deaths as well?”

says

Laxminarayan.

“Of course. For

80% of deaths,

we have no

medically

identified cause

of death at any

given time.”

As a percentage

of the total

number of cases,

the official

death numbers

put India’s case

fatality rate at

around 1.25%,

lower than the

United States

(1.8%), Brazil

(2.6%) and

others. The

Indian

government has

focused on these

numbers in

public

pronouncements

as evidence of

success in

tackling the

virus. Just as

the country’s

second wave

began to take

off in March,

a report by

India’s health

ministry cast

the situation in

positive terms.

“Today we have

least number of

COVID-19 cases,

highest recovery

rate, least

number of deaths

due to COVID-19

and now moving

towards a

Greater Win by

developing

Vaccines against

the dreaded

disease,” it

said.

Part of the

reason for

India’s low

death rate is

its young

population, more

than half of

whom are under

the age of 25.

Younger people

are less likely

to suffer severe

reactions to

COVID-19, or to

die from the

disease.

Experts worry

that the Indian

government has

used statistics

pointing to high

recovery rates

from the

virus to paint a

picture of

Indians as a

whole being more

immune to

COVID-19. But

calculations by

the Center for

Disease

Dynamics,

Economics &

Policy show that

Indians between

the ages of 30

and 70 are in

fact more likely

to die from the

disease than

people of

similar ages in

China, the U.S.,

and Brazil. “It

is a myth that

Indians have a

lower fatality

rate,” says

Laxminarayan.

“That is simply

not true. It is

not borne out by

the data.”

The result,

Laxminarayan

fears, is that

the Indian

population has

been encouraged

to be

complacent. “The

declarations of

victory were not

really helpful

in terms of

getting people

to continue to

take the virus

seriously,” he

says. “And

that’s largely

responsible for

the attitudes

that have

brought the

virus back.”

New Variants in

India Could be

Trouble

After genome

sequencing of

over 10,000

COVID-19 cases

in India,

researchers have

discovered a new

variant with two

new mutations

which may be

better at

evading the

immune system.

In 15-20% of

samples from the

Indian state of

Maharashtra (the

state accounting

for 62% of cases

in the country)

a new, double

mutation in key

areas of the

virus has been

detected. These

are now known as

the E484Q and

L452R mutations.

Both these

mutations are

concerning

because they are

located in a key

portion of the

virus – the

spike protein –

that it uses to

penetrate human

cells. Spike

proteins attach

via a “receptor

binding domain”,

meaning the

virus can attach

to receptors in

our cells.

These new

mutations

include changes

to the spike

protein that

make it a

“better fit” for

human cells.

This means the

virus can gain

entry more

easily and

multiply faster.

Given what we

have seen

with other

similar

mutations, it

might also make

it harder for

our immune

system to

recognize the

virus due to its

slightly

different shape.

This means our

immune system

may not be able

to recognize the

virus as

something it has

to produce

antibodies

against.

The emergence of

these new

variants has

only been

possible because

of the continued

viral

replication in

areas with high

circulation.

Though

the Indian

government has

said the data on

the variants

circulating in

India (including

this new Indian

variant and

others including

the UK strain)

are not

sufficient to

link them to the

rapid increase

in the number of

cases in the

country, we

think it’s the

most likely

explanation. The

country had

managed to bring

down the rate in

February, but a

sudden increase

in the number of

reported cases

is now being

reported.

The implications

of these

developments are

greatly

concerning – not

just for India,

but for the rest

of the world.

Mutations can

result in 20%

more in-hospital

deaths, as we

witnessed during

the second wave

in South Africa.

This is because

some mutant

variants have

the ability to

spread faster,

resulting in

sudden surges

and, therefore,

an overburdened

health system.

But there’s

hope. Places

around the world

with higher

vaccination

coverage such as

the UK and

Israel are

witnessing

a steady

decrease in

cases.

Most of the

currently

approved

vaccines around

the world have

been found to

evoke an immune

response to some

extent against

multiple

variants. But no

trials have yet

been undertaken

on the

effectiveness of

vaccines against

these new Indian

mutations.

To make it

difficult for

the mutant

strains to

develop vaccine

resistance, we

have to ensure

wider and faster

vaccine coverage

across the

world.

Apart from

vaccine

manufacturers’

efforts to

update the

composition of

vaccines to

better deal with

new strains, it

is important to

contain

transmission

across the

world. Countries

can use the

World Health

Organization’s

SARS-CoV-2 Risk

Monitoring and

Evaluation

Framework to

help identify,

monitor and

assess variants

of concern,

swiftly.

To establish a

direct link

between a

variant and a

steep rise in

cases in a short

time, it is

important to use

genomic

sequencing to

link clusters

together. But

unless contact

tracing is done

meticulously, it

isn’t easy to do

so.

It is also

important to

understand the

mechanisms

involved in the

infectiousness

and virulence of

the newer

variants. For

this, lab models

are needed to

mimic spread and

virulence

mechanisms

efficiently.

To combat the

consequences of

mutations in

India, its

pandemic

response will

have to

incorporate

several

measures.

Genomic

surveillance

will have to be

proactive and

coincide with

the

epidemiological

investigation of

the cluster of

cases for early

identification

and swift

action.

As some variants

can escape

naturally

induced

immunity,

vaccine

manufacturers in

India will need

to develop

better vaccines

to cover these

new variants.

Ongoing

surveillance and

containment

measures need to

be strengthened

to prevent the

emergence of new

variants by

minimizing viral

replication.

And finally,

swift and rapid

vaccine coverage

is not only

necessary but

essential for

ensuring any

modest levels of

success in

tackling this

pandemic.

Centrifugal

Multispinning

Could Be 300

Times Faster

Than

Electrospinning

KAIST

researchers have

developed a

novel nanofiber

production

technique called

'centrifugal

multispinning'

that will open

the door for the

safe and

cost-effective

mass production

of

high-performance

polymer

nanofibers. This

new technique,

which has shown

up to a 300

times higher

nanofiber

production rate

per hour than

that of the

conventional

electrospinning

method, has many

potential

applications

including the

development of

face mask

filters for

coronavirus

protection.

Nanofibers make

good face mask

filters because

their mechanical

interactions

with aerosol

particles give

them a greater

ability to

capture more

than 90% of

harmful

particles such

as fine dust and

virus-containing

droplets.

The impact of

the COVID-19

pandemic has

further

accelerated the

growing demand

in recent years

for a better

kind of face

mask. A polymer

nanofiber-based

mask filter that

can more

effectively

block harmful

particles has

also been in

higher demand as

the pandemic

continues.

'Electrospinning'

has been a

common process

used to prepare

fine and uniform

polymer

nanofibers, but

in terms of

safety,

cost-effectiveness,

and mass

production, it

has several

drawbacks. The

electrospinning

method requires

a high-voltage

electric field

and electrically

conductive

target, and this

hinders the safe

and

cost-effective

mass production

of polymer

nanofibers.

In response to

this

shortcoming,

'centrifugal

spinning' that

utilizes

centrifugal

force instead of

high voltage to

produce polymer

nanofibers has

been suggested

as a safer and

more

cost-effective

alternative to

the

electrospinning.

Easy scalability

is another

advantage, as

this technology

only requires a

rotating

spinneret and a

collector.

However, since

the existing

centrifugal

force-based

spinning

technology

employs only a

single rotating

spinneret,

productivity is

limited and not

much higher than

that of some

advanced

electrospinning

technologies

such as

'multi-nozzle

electrospinning'

and 'nozzle less

electrospinning.'

This problem

persists even

when the size of

the spinneret is

increased.

Inspired by

these

limitations, a

research team

led by Professor

Do Hyun Kim from

the Department

of Chemical and

Biomolecular

Engineering at

KAIST developed

a centrifugal

multispinning

spinneret with

mass-producibility,

by sectioning a

rotating

spinneret into

three sub-disks.

This study was

published as a

front cover

article of ACS

Macro Letters,

Volume 10, Issue

3 in March 2021.

Using this new

centrifugal

multispinning

spinneret with

three sub-disks,

the lead author

of the paper PhD

candidate Byeong

Eun Kwak and his

fellow

researchers Hyo

Jeong Yoo and

Eungjun Lee

demonstrated the

gram-scale

production of

various polymer

nanofibers with

a maximum

production rate

of up to 25

grams per hour,

which is

approximately

300 times higher

than that of the

conventional

electrospinning

system. The

production rate

of up to 25

grams of polymer

nanofibers per

hour corresponds

to the

production rate

of about 30 face

mask filters per

day in a

lab-scale

manufacturing

system.

By integrating

the

mass-produced

polymer

nanofibers into

the form of a

mask filter, the

researchers were

able to

fabricate face

masks that have

comparable

filtration

performance with

the KF80 and

KF94 face masks

that are

currently

available in the

Korean market.

The KF80 and

KF94 masks have

been approved by

the Ministry of

Food and Drug

Safety of Korea

to filter out at

least 80% and

94% of harmful

particles,

respectively.

"When our system

is scaled up

from the lab

scale to an

industrial

scale, the

large-scale

production of

centrifugal

multispun

polymer

nanofibers will

be made

possible, and

the cost of

polymer

nanofiber-based

face mask

filters will

also be lowered

dramatically,"

Kwak explained.

This work was

supported by the

KAIST-funded

Global

Singularity

Research Program

for 2020.

Nanofibers for

Fit, Function,

and

Sustainability

Pursued at

Cornell

Even as the

vaccine roll-out

picks up speed,

the end of face

masks in public

could be a year

or more away as

questions of

transmissibility

post-vaccine and

effectiveness

against emerging

strains remain.

One thing is

clear: when it

comes to fit,

function,

fashion, and

sustainability,

current face

masks leave a

lot of room for

improvement.

Multiple ongoing

research

projects in the

College of Human

Ecology’s

Department of

Fiber Science &

Apparel Design

(FSAD) aim to

improve the

efficiency,

breathability,

comfort and

environmental

costs of face

masks. The six

projects, five

funded through

the Cornell

Atkinson Center

for

Sustainability,

highlight the

depth and

breadth of the

research done in

the only Ivy

League

department that

brings fiber

scientists,

design experts,

fashion

creatives, fiber

artists, and

social

scientists

together in one

program.

Dropped or

discarded

disposable face

masks are a

commonplace

sight these

days. Made of

petroleum-based

polypropylene

fibers, disposal

surgical and N95

masks are bad

for the

environment and

the wildlife in

it. Their

singular

function is to

provide a

physical barrier

against viruses

and bacteria,

which can

collect on the

outside and

inside of the

mask.

Associate

Professor Tamer

Uyar,

his postdoctoral

researcher Asli

Celebioglu and

undergraduate

students in his

lab are

developing

biodegradable

nanofiber mask

inserts with

naturally

antibacterial

materials to

lighten the

environmental

costs of masks

and improve

their

functionality.

Uyar lab

postdoctoral

researcher Asli

Celebioglu and

undergraduate

students are

developing

biodegradable

nanofiber mask

inserts with

naturally

antibacterial

materials to

lighten the

environmental

costs of masks

and improve

their

functionality.

The nanofiber

inserts have a

nano-porous

structure with

pore sizes that

are much smaller

than the size of

viruses and

bacteria, making

them an

excellent

physical barrier

to COVID-19. In

addition, these

nanofibrous mask

inserts have

antibacterial

properties,

offering users

protection

against bacteria

they encounter

or exhale

throughout the

day.

“Face masks can

be a good

platform for

bacteria to

attach itself,

not only

creating health

concerns, but

they can also

produce bad

odor, which

makes the face

mask

uncomfortable,”

Uyar said.

There are

already masks

that boast

antimicrobial

properties, but

they come with a

steep cost to

the environment.

“They use silver

nanoparticles,

which is a very

good

antimicrobial

agent, but at

the same time,

it creates a

huge problem for

the environment

when it gets

into the water

stream,” Uyar

explained.

“There are many

good bacteria

out there that

clean lakes,

rivers and soils

from pollutants

by

bioremediation,

but the silver

nanoparticles

kill them. We’re

making our

nanofiber

inserts

biodegradable

and

antimicrobial

without using

silver

nanoparticles,

which makes them

better for the

user and for the

environment.”

The students in

Uyar’s lab are

at work

producing

nanofiber

inserts that he

hopes to

distribute for

wear-testing

this spring. He

said combining

his

biodegradable

and

antimicrobial

nanofiber

inserts with the

innovations in

design and fit

taking place in

the rest of the

department could

result in masks

that block 99

percent of

airborne

particles,

making them more

effective than

the current

gold-standard

N95 masks.

One such

innovation is a

project from

Associate

Professor Juan

Hinestroza to

create

personalized

masks using face

scans.

Hinestroza’s lab

would create an

algorithm that

takes a three

dimensional

object (the

face) and

translates it

into a two

dimensional item

(the mask)

which, when

worn, becomes a

three

dimensional

item. The scans

would be sent to

a manufacturing

machine, such as

an online

retailer or even

the local copy

shop, that would

make a mask

customized to

the unique

characteristics

of the user.

This would make

the masks more

effective, more

comfortable, and

decrease waste.

“Instead of

having to

mass-produce

masks that don’t

fit anyone very

well, and I’ve

seen orders for

10 million masks

that are all the

same when we all

have different

faces, we could

create a mask

that fits the

individual’s

profile

perfectly,”

Hinestroza said.

He is applying

for funding to

pay students to

work on the

complicated math

required to

create the

algorithm.

Hinestroza sees

this kind of

on-demand

fabrication

technology as

the future of

clothing

manufacturing

that will

provide items

fit perfectly to

individual

shapes and

sizes, while

decreasing the

massive amounts

of waste created

by the fashion

industry and

improve

conditions for

factory workers.

Understanding

the mask-wearing

experience:

The first of the

projects to

be completed was

led by Associate

Professor Denise

Green along with

Senior

Lecturer Frances

Kozen and

Lecturer Catherine

Blumenkamp,

and will be

published in a

forthcoming

open-access

issue of the Clothing

and Textiles

Research Journal focused

on COVID-19.

They conducted a

demographically

representative

survey of

18-24-year-olds

back in August,

asking

respondents

about their

mask-wearing

habits,

preferences, and

experiences. The

survey results

revealed a

wide-range of

information,

from how

mask-wearing or

not-wearing

lined up with

geographic

location, race,

gender, or

political

affiliation, to

what

improvements

respondents

would most like

to see in mask

design and

construction.

Over half of

those surveyed

wanted more

breathable

fabrics and a

little over

two-thirds

wanted a better

fit.

“Understanding

user experience

will help us to

improve design,”

Green said.

“Through better

design – which

brings comfort,

efficacy, and

aesthetics

together – we’ll

improve mask

compliance and

help to mitigate

the spread of

COVID-19.”

Kozen is working

on another

project with

Associate

Professor Huiju

Park and Senior

Lecturer Kim

Phoenix wear-testing

three popular

styles of masks

to elicit data

on comfort

factors that

affect user

willingness to

wear masks for a

full day.

“Wear testing is

used to evaluate

consumer

perceptions of

garment

comfort,” Kozen

said, “as

laboratory

measures of

textile

properties or

fit are

one-dimensional

and may not

correlate well

with the actual

experience of

moving in a

garment over a

period of time.

It is a helpful

tool for

development of

performance

apparel and

could be

employed to

assess designs

or materials

developed by

other teams in

FSAD.”

Kozen said they

are about

halfway through

data collection,

asking about

issues like heat

build-up,

fogging,

difficulty

enunciating

clearly through

masks, and

breathability.

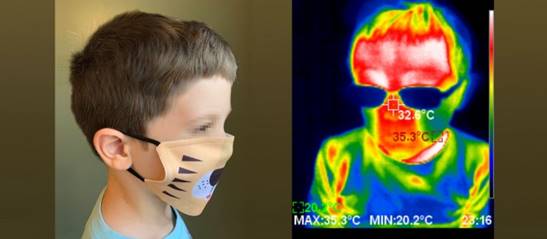

Better masks for

children:

Children have a

high risk of

self-contamination

when taking off

and putting on

their masks due

to limited

dexterity. They

have difficulty

maintaining

social

distancing in

classrooms and

their

respiration rate

is 30% higher

than adults.

That means

longer exposure

to airborne

particulates and

more chance to

spread the virus

to other people.

Project leader

Huiju Park is

working with

Frey, Assistant

Professor Fatma

Baytar, Goodge

and other

graduate and

undergraduate

students on four

goals: improving

the design of

children’s face

masks,

developing a

head form and

size guidelines

based on

anthropometric

data,

identifying

optimal fabric

and layer

structure, and

producing

educational

materials on

best practices

and fabric

choices for

caregivers,

childcare

workers,

teachers and

healthcare

workers.

Utilizing an

online survey,

Park collected

data on some of

the biggest

concerns and

complaints from

people

responsible for

caring for

children ages

4-6 in one

capacity or

another. The

major issues

reported related

to sizing and

fit.

“Simply

downsizing an

adult face mask

does not work,”

Park said.

“Children’s face

and head shape

proportions

differ

significantly

from adult

proportions.

Children

experience fit

issues with

commercial face

masks, mostly

revolving around

general

oversizing, lack

of depth for

facial features,

and few shaping

considerations

around the sides

and bottom of

the mask that

could help to

prevent air

gaps.”

Park’s team is

working to

develop methods

for evaluating

mask fit by

using 3D body

scanning

technology and

3D virtual

modeling, which

will give them

data to improve

fit.

Using the

simulated

breathing

apparatus

developed by

Frey and Goodge,

adjusted for the

higher

respiratory rate

of children,

this project

tested the

filtration

efficacy of

available masks

for

children--data

that can be used

to further

improve the

design of masks.

While there has

been some mixed

messaging and

lack of

information

around the risks

of COVID-19 in

children, Park

pointed out that

children

experiencing

even a mild

infection can

spread the virus

and there are

still too many

unknowns on the

effects to

children.

“Infected

children go

through not only

some typical

symptoms, such

as fever and

breathing

difficulty, but

some experience

Multisystem

inflammatory

syndrome in

children

(MIS-C), which

is a very rare,

new, unknown

symptom.

Unfortunately,

there is no

proven medicine

or effective

medical solution

to this rare

symptom as it is

just so new.

Nobody seems to

have enough

knowledge about

this symptom and

how it would

impact

children’s

health from

short-term and

long-term

perspectives.

This is another

reason that

offering

adequate

protection

through improved

design of

children’s masks

is important.”

The silhouette

on the right

shows air paths

(and leakage) to

the glasses and

the bottom of

face masks for

children.

Park, an expert

in protective

and performance

apparel, will

turn next to

creating a

children’s face

mask design

based on the

data his team

collected along

with the results

of Frey’s fabric

tests.

FSAD Professor

and Chair Yasser

Gowayed said

there are other

research

programs around

the world with

projects working

to identify and

solve the

problems and

shortcomings of

face masks, but

none with FSAD’s

depth and

breadth.

“FSAD is unique

because we do

not study the

problem from a

single point of

view. We

integrate the

social impact,

the behavioral

science and the

physical

science. This is

only feasible

because FSAD has

scholars in

these fields who

can speak a

common language

and work

together to

present

solutions that

are not only

efficient, but

also grounded in

reality.”