Coronavirus

Technology Solutions

April 13, 2021

Biota Launches

COVID-19

Diagnostic in

Wastewater

A

First-Of-Its-Kind

Antimicrobial

Stainless Steel

Copper Foam as a

Highly

Efficient,

Durable Filter

for Reusable

Masks and Air

Cleaners

3M HVAC Filters

have Viral

Removal

Efficiencies

from 60% to 90%

Lydall Increases

Filter Media

Prices

HEPA Room

Purifiers in

Every Classroom

at a Cost of $1

billion

KYMIRA has Two

Nanofiber Layers

to Maximize Mask

Efficiency

_________________________________________________________________________

Biota Launches

COVID-19

Diagnostic in

Wastewater

Biota

Technology, a

pioneer of

industrial

genomics,

announced the

creation of a

new business

line to manage

pathogen risk in

the

post-pandemic

economy.

Following

the

recent transaction with

Novozymes, Biota

is launching

diagnostics in

an emerging,

high-growth

opportunity to

further broaden

its genomic

platform: high

throughput

genomic

monitoring of

wastewater to

detect and

defend against

pathogen risks.

"Biota's new

offering

addresses a

global,

long-term need

to detect and

proactively

mitigate risks

associated with

potential

disease

outbreaks," said

Ajay Kshatriya,

Board Chairman.

"Genomic

wastewater

monitoring

enables early

intervention and

broad protection

for employees,

customers, and

the general

public in a

variety of

enterprise

segments."

Biota recently

entered into a

collaboration

with Pangolin

Health to

develop

technical

workflows and

analytic methods

for a number of

customers in the

Southwestern US.

"Biota offered

us the

opportunity to

leverage their

extraordinary

work in

difficult

industrial

environments

into the

similarly

challenging

wastewater

setting.

Because pathogen

detection in

wastewater is

comprehensive,

inclusive and

always on, it's

an instrumental

source of

critical data

for pandemic

management and

control. This is

relevant both

for the current

coronavirus and

its variant

strains, and the

next

pathogen," says, Dr. Bryan

Walser, M.D.,

Executive

Chairman of

Pangolin Health.

Along with

new investments

in pathogen

diagnostics,

Biota continues

to grow its core

energy business.

Recent efforts

include

geographic

expansion via

strategic

engagements with

a national oil

company in

the Middle East,

and further

developing

solutions for

customers in

conventional and

unconventional

plays.

Additionally,

Biota is

expanding the

energy market

opportunity with

low carbon

product concepts

in carbon

capture,

utilization and

storage (CCUS)

and geothermal

energy.

As Biota

continues to

advance its

industrial

genomics

platform across

multiple

sectors, the

company

leadership is

evolving with

the appointment

of Mathias

Schlecht,

Ph.D. to Chief

Executive

Officer and Ajay

Kshatriya to

Chairman of the

Board.

"I've never been

more excited

about Biota's

vision to

pioneer

industrial

genomics across

multiple

sectors,"

said Mathias

Schlecht, Chief

Executive

Officer. "With a

global footprint

in the energy

market and

rapidly growing

market for

pathogen risk

management,

Biota has the

corporate

strategy,

commercial

scale, and

technical

capabilities to

develop new

solutions across

the industrial

sector and

create a

billion-dollar

enterprise."

A

First-Of-Its-Kind

Antimicrobial

Stainless Steel

Advancing

Medical

Innovations

(AMI) announced

that its client,

Performance

Compounds Inside

(PCI), has made

historic

advancements in

metallurgy with

its 3PRE

Technology, a

novel and

proprietary

process of

activating

antimicrobial

properties.

PCI's first use

of its 3PRE

Technology is

with molybdenum,

an essential

element.

When activated

through 3PRE

Technology,

molybdenum takes

on antimicrobial

properties and

can be added to

stainless steel

during the

foundry process

to render it

capable of

destroying and

inhibiting

bacteria and

other

disease-causing

microorganisms.

The result is a

stainless steel

that retains the

characteristics

of 304 and 316

stainless steel

while also

imbuing

antimicrobial

properties

directly and

thoroughly into

the steel – not

as a coating.

Jim Stachowiak,

president & CEO

of Stainless

Foundry &

Engineering

said, "Our

foundry is

pleased to have

been involved in

the manufacture

of the first

antimicrobial

stainless steel.

We are impressed

with the

homogeneity and

consistency of

the end product

and can

anticipate

multiple uses

across any

number of

industries."

Dr. Amod

Paranjpe,

co-founder and

researcher at

PCI said, "This

is the first

time a stainless

steel has been

manufactured

with

antimicrobial

properties at

the foundry

process level.

Activation of

3PRE within the

steel enables a

bactericidal

effect with an

extremely high

24-hour kill

rate." Paranjpe

added, "We

anticipate this

process would be

equally

effective with

any form of

steel product."

3PRE Technology

carries

significant IP

protection and

can be used to

imbue a range of

materials with

antimicrobial

protection.

AMI and PCI are

actively seeking

licensing

partners for

this

antimicrobial

technology. Inquiries

can be directed

by email to AMI

at info@admedinno.com.

Established

in 1946 by John

McBroom, &

headquartered

in Milwaukee,

Wisconsin,

Stainless

Foundry &

Engineering Inc.

(SFE) is a

well-established

and highly

regarded

manufacturer of

raw and machined

castings in both

sand and

investment. SFE

is a prominent

supplier to

OEM's servicing

the Chemical,

Petrochemical,

Nuclear, Pulp &

Paper,

Pharmaceutical,

Food & Dairy,

Metering, &

Military

markets with

corrosion-resistant,

high heat, and

wear resistant

steel, stainless

steel & high

alloy parts.

Performance

Compounds Inside

(PCI)

specializes in

the research and

development of

patented

technologies

involving

antimicrobial

metals. Its 3PRE

Antimicrobial

Technology is an

activation

technology

involving

PREparing

products to be

antimicrobial,

PREventing

contamination

and degradation,

PREserving

product

integrity and

safety. PCI's

3PRE Technology

has utility

across a variety

of industries

including,

healthcare,

consumer goods,

agriculture, and

general

manufacturing.

Advancing

Medical

Innovations

(AMI) is

committed to

helping provide

select companies

focused on

highly

innovative

solutions in

healthcare with

the resources

and support

necessary to

successfully

commercialize.

Copper Foam as a

Highly

Efficient,

Durable Filter

for Reusable

Masks and Air

Cleaners

During the

COVID-19

pandemic, people

have grown

accustomed to

wearing

facemasks, but

many coverings

are fragile and

not easily

disinfected.

Metal foams are

durable, and

their small

pores and large

surface areas

suggest they

could

effectively

filter out

microbes. Now,

researchers

reporting in

ACS’ Nano

Letters

have transformed

copper nanowires

into metal foams

that could be

used in

facemasks and

air filtration

systems. The

foams filter

efficiently,

decontaminate

easily for reuse

and are

recyclable.

When a person

with a

respiratory

infection, such

as SARS-CoV-2,

coughs or

sneezes, they

release small

droplets and

aerosolized

particles into

the air.

Particles

smaller than 0.3

µm can stay

airborne for

hours, so

materials that

can trap these

tiny particles

are ideal for

use in facemasks

and air filters.

But some

existing filter

materials have

drawbacks. For

example,

fiberglass,

carbon nanotubes

and

polypropylene

fibers are not

durable enough

to undergo

repeated

decontamination

procedures,

while some

further rely on

electrostatics

so they can’t be

washed, leading

to large amounts

of waste.

Recently,

researchers have

developed

metallic foams

with microscopic

pores that are

stronger and

more resistant

to deformation,

solvents, and

high

temperatures and

pressures. So,

Kai Liu and

colleagues

wanted to

develop and test

copper foams to

see if they

could

effectively

remove

submicron-sized

aerosols while

also being

durable enough

to be

decontaminated

and reused.

The researchers

fabricated metal

foams by

harvesting

electrodeposited

copper nanowires

and casting them

into a

free-standing 3D

network, which

was solidified

with heat to

form strong

bonds. A second

copper layer was

added to further

strengthen the

material. In

tests, the

copper foam held

its form when

pressurized and

at high air

speeds,

suggesting it’s

durable for

reusable

facemasks or air

filters and

could be cleaned

with washing or

compressed air.

The team found

the metal foams

had excellent

filtration

efficiency for

particles within

the 0.1-1.6 µm

size range,

which is

relevant for

filtering out

SARS-CoV-2.

Their most

effective

material was a

2.5 mm-thick

version, with

copper taking up

15% of the

volume. This

foam had a large

surface area and

trapped 97% of

0.1-0.4 µm

aerosolized salt

particles, which

are commonly

used in facemask

tests. According

to the team’s

calculations,

the

breathability of

their foams was

generally

comparable to

that of

commercially

available

polypropylene

N95 facemasks.

Because the new

material is

copper-based,

the filters

should be

resistant to

cleaning agents,

allowing for

many

disinfection

options, and its

antimicrobial

properties will

help kill

trapped bacteria

and viruses, say

the researchers.

In addition,

they are

recyclable. The

researchers

estimate that

the materials

would cost

around $2 per

mask at present,

and disinfection

and reuse would

extend their

lifetime, making

them

economically

competitive with

current

products.

The authors

acknowledge

funding from the

Georgetown

Environmental

Initiative

3M HVAC Filters

have Viral

Removal

Efficiencies

from 60% to 90%

An experimental

study was

carried out to

investigate

effectiveness of

residential HVAC

filters at

removing

airborne virus

particles. MS-2

bacteriophage

organisms were

grown on

appropriate

media,

harvested,

resuspended in

saline, and then

aerosolized into

the ASHRAE 52.2

test duct using

a nebulizer.

Upstream and

downstream air

samples were

taken using SKC

BioStage cascade

impactors. The

collection

plates were

incubated, and

the recovered

plaque-forming

units (PFU) were

enumerated to

determine the

filtration

efficiency of

filters against

virus particles.

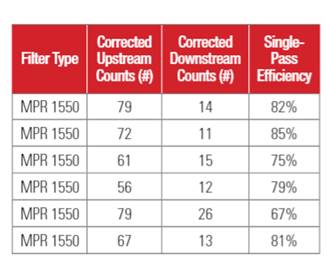

The following

conclusions can

be drawn from

this study.

(1) High

efficiency

residential HVAC

filters were

found to be

effective at

capturing

airborne virus

particles.

(2) Filter viral

filtration

efficiency was

found to be

generally

correlated to

its MPR rating,

i.e., the higher

the MPR rating,

the higher the

viral filtration

efficiency.

In comparison to

E1, E2 and E3

efficiencies

measured per

ASHRAE 52.2, VFE

was found to be

higher than

initial E1

efficiency, but

lower than

initial E2 and

E3 efficiencies.

Test results for

4-inch depth (20

x 25 x 4) filter

are shown

below..

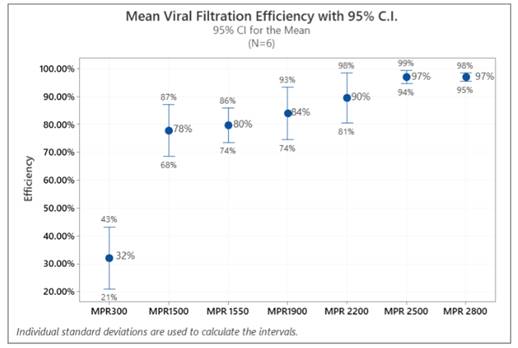

The figure below

shows the mean

and 95%

confidence

interval of VFEs

for all filters.

MPR 300 through

MPR 2200 filters

had a relatively

widespread in

efficiency data,

which can also

be attributed

the same reasons

discussed above.

John Zhang,

Ph.D., is a

senior product

development

specialist at

3M’s

Construction and

Home Improvement

Markets

Division. Doug

Huntley, Ph.D.,

is senior global

R&D manager for

3M, having spent

the last 25

years with the

company

developing the

people and

products to

deliver novel,

high-value

solutions to a

range of

industries Andy

Fox is a lead

product

development

specialist at

the 3M

Construction and

Home Improvement

Markets

Division. He

specializes in

filter media

development and

holds 42 issued

U.S. patents.

Bryan Gerhardt

is an Advanced

Product

Development

Specialist at

the 3M

Construction and

Home Improvement

Markets

Division.

The full paper

is found in IFN

through the

following link

Lydall Increases

Filter Media

Prices

Lydall announced

that its

Performance

Materials

business segment

is increasing

prices for its

Filtration and

Specialty

Insulation

products

supplied

globally. The

price adjustment

is driven by

significant and

ongoing

increases in key

raw material and

freight costs.

“Lydall remains

committed to

reducing overall

costs and making

our operations

more efficient

through our One

Lydall strategy

and focused

transformation

initiatives,”

says Lydall

Performance

Materials

president Ashish

Diwanji.

“However, these

extensive

efforts are not

enough to offset

the sustained

inflationary

pressures that

are widespread

in today’s

market. We must

modify our

pricing to

ensure that we

can continue to

deliver the

innovative

products and

high-quality,

advanced

materials our

customers depend

on to bring the

world’s most

essential

products to

market.”

HEPA Room

Purifiers in

Every Classroom

at a Cost of $1

billion

Amid the

stimulus checks

and unemployment

extension in the

$1.9 trillion

relief package

signed into law,

is $130 billion

to help schools

reopen safely —

including for

personal

protective

equipment,

reducing class

sizes and,

importantly,

improving

ventilation.

School safety

measures call to

mind images of

masked students

spread out among

plexiglass-enclosed

desks. But one

of the most

important things

schools can do

might be

something you

can’t see said

Donald Milton, a

professor of

environmental

health at the

University of

Maryland.

“Ventilation is

critical because

respiratory

viruses can be

transmitted by

inhalation,” he

said. “And the

way to cut down

on what people

are inhaling, is

to remove it

from the air.”

But until recent

weeks, the

Centers for

Disease Control

and Prevention

had offered

little guidance

on improving

ventilation in

schools, and

many had turned

to unproven

measures said

Professor Joseph

Allen, director

of the Healthy

Buildings

program at

Harvard.

“This is where

the hygiene

theater has come

into play,” he

said. “You see

someone in

gloves wiping

down every

surface — walls,

and things that

just don’t make

sense.”

Much more

important, he

said, is

ensuring the air

in rooms is

completely

refreshed, known

as air exchange,

about five times

per hour.

That can be

achieved by

adjusting HVAC

systems,

something that

might be tough

for the many

schools with old

and failing air

conditioning.

“So it’s not as

simple as put a

filter in,

you’re going to

have to upgrade

the whole system

to be able to do

that,” said

engineer Maria

Lehman,

treasurer of the

American Society

of Civil

Engineers. The

group gave U.S.

public schools

a D+

in its last

infrastructure

report,

which found more

than 40% of

schools had HVAC

systems in need

of repair.

“It’s of concern

particularly

because of

evidence that

we’re starting

to build, that

air pollution is

harmful to

student

learning,” said

Claudia Persico,

a professor of

public policy at

American

University.

Millions of

students in the

U.S. attend

schools in close

proximity to freeways or other

sources of

pollution,

she said, so

opening windows

to improve

airflow isn’t

always a great

option.

Though having a

window to open

would be a

luxury for New

York special

education

teacher Annie

Tan.

“Right before

COVID hit, I was

in a windowless

classroom,” she

said. “I bought

an air purifier

for my class

because there

was a smell my

classroom.”

In fact portable HEPA air purifiers, the kind some people have in their homes, are an effective way to clear viruses from the air.

By one analysis from

Richard Corsi,

an indoor air

expert at

Portland State

University, the

devices could be

installed in

every classroom

in America for

about a billion

dollars.

KYMIRA has Two

Nanofiber Layers

to Maximize Mask

Efficiency

The KYMIRA

K-Mask, with the

integrated

Nanofibre

K-Filter, is

designed to

protect from

viruses,

bacteria and

environmental

particulates,

with a 99.6%

filtration

efficiency. That

is claimed as

one of the best

in the world.

Looking to help

during the

pandemic, KYMIRA

researched and

adjusted one of

its existing

technologies,

it’s electrospun

nanofiber

material, with

partner Radical

Fibres..

Using a triple

sandwich layer,

nanofiber

combination,

the K-filters

have been

designed as a

reusable, world

class filter.

Layer 1:

Nanofibres

capture viruses,

bacteria and

pollutants via

electrostatic

attraction

Layer 2:

Activated carbon

layer for

environmental

pollutants

Layer 3:

Nanofibres

capture viruses,

bacteria and

pollutants via

electrostatic

attraction.

The filters have

been

independently

tested to ASTM

F2100, ASTM

FT101 and EN

1486 standards,

certifying the

99.6% filtration

rating*.

The K-Filter

offer its

protection for

200 hours and

for particles as

small as 0.03

microns. The

effectiveness of

the filtration

level is due to

this microscopic

level of

protection

offered by the

electrospun

nanofibers, that

ionically

attract the

particles before

trapping them

within the

filter layers.

To contextualize

this, the

Covid-19 virus

has a particle

micron size of

0.06 -0.5 and

bacteria has a

particle size of

0.3 microns.

Healthcare

workers on the

front line have

so far been

using N95

rated masks that

have a

particulate

protection size

of 0.3 microns;

so the wearer

can feel

confident in

their protection

when using

the K-Filter.

The nanofibers

within

the K-Filter are

made from

biocompatible

hydrophobic

material which

are elastic and

electrostatic,

meaning they are

highly

breathable,

flexible and

will not become

wet with water

vapor from

breathing, this

also reduces the

carbon dioxide

re-breathing

occurrence that

is a problem

among even

medical grade

respirators.

The K-Mask is

designed to

house the

Nanofibre K-Filter

and is made

from KYMIRA Kynergy

infrared fabric.

The infrared

fabric offers

the wearer

temperature

regulation, due

it it’s

efficiencies in

cellular

excitation and

enhanced

circulation. The

infrared fabric

itself supports

the wearer to

cool or warm,

depending on

need and

provides a

cooling effect

as you inhale,

helping you stay

comfortable

during use. To

note, KYMIRA KYnergy

infrared fabric

is safe to use,

certified by the

FDA as a class 1

medical device

and CE marked.

Designed for

comfort,

prolonged use

and protection,

the fit and

design of the

K-Mask is

claimed to be

second

to none.

Available in

sizes small,

suitable for

smaller or teen

sizes and

medium/large,

the mask is

designed to fit

close to the

wearer, high up

on the nose and

wrapping around

the cheeks

towards the ears

to provide

greater

protection to

and from the

wearer.

The extended

sides offer

pressure

balance, so that

it forces the

inhale and

exhale through

the viral

filtration, even

with use at high

exertion or

during coughing

or sneezing.

This makes

the mask ideal

for not just

everyday

activities but

for work, travel

and playing

sport too. The

nose has a

comfort strip

underneath and a

wired pinch bar

so the wearer

can ensure a

close,

comfortable fit,

with attractive

leather

detailing. The

straps fit

around the head,

fastening on the

crown of the

head and at the

nape of the

neck, providing

comfort for long

use that does

not put pressure

on the ears.

The Nanofibre K-Filters

offer the wearer

200 hours of

viral, bacterial

and pollutant

filtration

protection. Once

this time period

is completed,

the filter can

be replaced with

a fresh filter

and the

protection will

continue.

The masks and

filters can also

be cleaned and

reused during

this 200 hour

period.

The masks and

filters can be

baked in the

oven at 60

degrees and this

will ensure that

all trapped

virus and

bacteria

particles

are killed.

The mask itself

is also machine

washable at 30

degrees. so it

can stay looking

fresh and clean

(please note the

filters should

not go through

the washing

machine, unless

your goal is to

collect the

pollutants in

the washing

machine itself).

The Nanofibre K-Filters

can be used in

the KYMIRA K-Mask,

or any other

reusable mask to

increase the

efficacy of

any mask.

Fibertex

Nonwovens has

developed a

versatile

component –

Adhetex 40A90NP0

– which is

designed to

improve the

filtration

efficiency of

protective face

masks and to

also extend

their safe

storage period.

By utilizing

premium,

high-efficiency

Fibertex

nanofibre layers

in the

production of

protective face

masks, end-users

can expect to

reach N95 and

FFP2 level of

protection.

The main benefit

of Fibertex

nanofibre

layers, being a

purely

mechanical

filtration

layer, is

guaranteed

efficiency of

the filtration

layer during the

lifetime of the

mask.

Another

important

benefit of this

advanced

technology, is

durability of

the nanofiber

layer, which

enables extended

storage time of

masks, making

them suitable

for use as

disaster and

epidemic relief

safety stocks.

Fibertex Adhetex

nano materials

are most

commonly used in

HEPA

(High-Efficiency

Particulate Air)

filters for

masks,

industrial dust

collection, gas

turbine air

inlet

filtration,

air-conditioning

units,

automotive

components and

filters in

domestic vacuum

cleaners.

Fibertex depth

filtration media

– which extend

the service-life

of the filter –

have a gradient

structure

comprising an

initial

pre-filter

layer, a

dust-holding

layer and the

final nanofiber

layer. Media is

available in

various

thicknesses,

depending on

specific

end-user

requirements.

The standard

Adhetex roll is

1.55 m wide x 2

000 m and

requires special

handling to

protect the

delicate

nanofiber

component.

Face Masks

Fibertex

Breathetex 140WH

is one of the

components used

to mold and

shape masks.

This material,

with FFP1 and

FFP 2 / N95

efficiency

levels, is

positioned

adjacent to the

melt-blown and

outer spunbond

layer of the

protective mask.

The standard

Breathetex roll

is 2 400 mm x

200 m and is

available in

typical widths

of 1 200 mm or

200 mm x 200 m.

All Fibertex

products can be

delivered

slitted to

specific end-use

widths required.