Coronavirus

Technology Solutions

February 18, 2021

Concentrated

Contamination

Capture is the

Route to Cost

Effectiveness

ICS is Active in

Europe as Well

as the U.S. with

Certification

Services

JABIL Delivering

Three Ply

Surgical Masks

from Memphis

Facility

American

Surgical Mask

Producing Up to

150,000 Surgical

Masks per Day

Lanaco is and is Not Sheepish About Their Filters

Extraction Arm

from Nederman is

a Great CCC

Example

Freudenberg has

the Products to

Create Safe

Bubbles.

Pfizer and

Moderna Vaccines

Less Effective

Against South

African

Variant

Education

Week Weighs

in on School

Ventilation

_____________________________________________________________________________

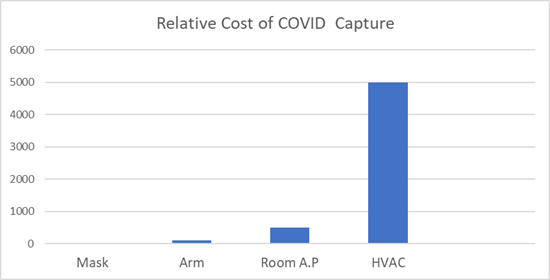

Concentrated

Contamination

Capture is the

Route to Cost

Effectiveness

There are two

ways to battle

COVID: avoidance

and or capture.

Avoidance

involves

lockdowns and

social

distancing and

should be

minimized if

capture will

provide the same

level of safety.

Capture

can very cost

effective

depending

on the degree of

Concentrated

Contaminant

Capture (CCC)

The cost of

capture is a

function of the

amount of air

treated and not

the amount of

contamination

removed So the

goal is CCC.

The ultimate in

diluted capture

is the cleanroom.

If you have an

entire ceiling

of HEPA filters

and you blow air

through them and

then provide a

perforated floor

to insure all

contaminants

flow down and

out, then that

may be all you

need.

But keep

in mind that the

Class 100

cleanroom

cost is

typically

$1000/ft2. But

even with all

this filtered

air it is

recognized that

people shed

millions of skin

particles as

well as

potential

viruses and

therefore all

the cleanroom

personnel have

more PPE than

would a surgeon.

It is well

recognized that

once

contaminants are

dispersed it is

very costly to

filter them. The

reason is

simple. Cost is

a function of

the amount of

air processed

and not the

amount of

contaminants

removed. A mask

can eliminate

all the COVID-19

generated by the

wearer and

handle less than

1 cfm and a

total cost of a

few dollars.

If a localized

capture device

such as the

Nederman

extraction arm,

described today

in

Coronavirus

Technology

Solutions,

is utilized,

most of the

contaminant is

captured with

less than 100

cfm.

A room air

purifier in the

bedroom of an

infected person

can remove as

much contaminant

with 500 cfm as

would a house

HVAC system with

5,000 cfm.

If both

transmitter and

recipient are

wearing

efficient masks

then other

measures such as

social

distancing

become minor by

comparison. All

the controversy

over occupancy

rates is better

served focusing

on mask

efficiency

including

penetration and

leakage. There

is a direct

numerical

relationship

between

occupancy rate

and mask

effectiveness.

If people wear

masks which are

60% effective

and the

occupancy rate

is 60% the risks

is the same as

with people

wearing 90%

effective masks

and the

occupancy rate

is 90%.

ICS is Active in

Europe as Well

as the U.S. with

Certification

Services

ICS Laboratories

is a leading

source for

accredited

third-party

conformity

assessment of

respiratory

protective

equipment. ICS

tests

respirators,

filters,

cartridges and

their many

associated

devices and

accessories to a

wide range of US

(NIOSH),

European (EN)

and Australian

(AS/NZS)

standards. Their

capabilities are

extensive and

range from

disposable

half-mask

filtering face

piece

respirators to

specialized

equipment

designed to

protect against

chemical,

biological,

radiological and

nuclear

respiratory

hazards (CBRN).

Within the

European Union,

regulations

mandate that

personal

protective

products be

CE-certified

before they can

legally be

placed on the

market. ICS

Laboratories is

a complete

resource for any

manufacturer

seeking to

attain CE

certification in

order to sell

their protective

equipment in the

United Kingdom

or Europe. ICS’

facilities and

personnel enable

it to offer the

most competitive

prices and lead

times for the

requisite EN and

ISO tests that

must support CE

certification

for PPE. Beyond

the utmost

quality test

work and the

associated

endorsed

reports, ICS

Labs truly makes

CE-certification

a turn-key

service for

their clients,

coordinating

documentation

and facilitating

assembly and

review of the

final technical

file.

ICS Laboratories

is accredited to

perform

conformity

assessments on a

wide range of

Category 2 and

Category 3 PPE

according to EN

and ISO product

standards and

test methods.

ICS has

cultivated a

working

relationship

with CCQS UK, a

premier

certification

organization.

CCQS is a

registered

European

Notified Body

and is

positioned to

efficiently

process CE

certifications

for products

that are tested

by ICS Labs.

They maintain

contacts

throughout the

world, and

operate an

office in the

Republic of

Ireland,

enabling

hassle-free

processing

CE-mark

processing with

regard to the

Brexit

narrative.

Working

together, ICS

Laboratories

and CCQS offer

an integrated

resource for

personal

protective

equipment

manufacturers

working to

comply with

EU PPE

Regulation 2016/425.

Both

organizations

are accredited

and

internationally

recognized as

experts at their

respective

functions:

conformity

assessment and

product

certification.

ICS not only has

expertise in

protective

equipment

testing, but

through decades

of experience,

has also

attained

familiarity with

certification programs

and schemes over

the world. Their

alliances with

highly competent

organizations

means that their

CE-certification

customers

receive valuable

information and

attentive

support through

the

certification

process.

JABIL Delivering

Three Ply

Surgical Masks

from Memphis

Facility

Jabil announced

that together

with its

subsidiary

medical device

company, NP

Medical, Inc.,

the company is

ready to deliver

personal

protective

equipment (PPE)

orders of

medical-quality, FDA-cleared,

made in USA face

masks, directly

and reliably

sourced through

Jabil’s

U.S.-based

operations in

Memphis,

Tennessee. As a

GSA-Schedule

holder, Jabil is

positioned to

quickly support

the mask mandate

recently issued

by President

Biden, requiring

individuals to

wear masks on

federal property

as well as on

planes, trains,

buses and at

airports.

“Our work with

local and state

governments to

fulfill

high-volume

orders of PPE

made in the USA

means the

general

population can

get access to

these highly

effective

masks,” said

Charlie Main,

senior vice

president of

business

development,

Jabil. “Designed

to meet the

stringent

protection

requirements of

operating room

personnel,

general

healthcare

workers and

their patients,

these masks are

ideal for

protecting

employees and

complying with

the mask

mandate.”

The NP Medical

nPro™

single-use,

disposable,

FDA-cleared

three-ply

surgical masks

provide

excellent

protection and

are designed to

meet ASTM

F2100-19 Level 1

requirements,

providing over

99% Sub-micron

Particulate

(PFE) and

Bacterial

Filtration

Efficiency

(BFE). The masks

feature elastic

ear loops, an

adjustable nose

wire and

vertically

adjustable

pleats to ensure

a snug and

comfortable fit.

“Jabil, like so

many

manufacturers in

America, has

stepped up to

the challenges

of the pandemic,

including

shifting U.S.

facilities to

mask and PPE

production, for

which there is

much demand,”

said National

Association of

Manufacturers

President and

CEO Jay Timmons.

Jabil is

offering these

masks as a

directly

sourced,

reliable supply

of PPE for large

orders.

Jabil is a

manufacturing

solutions

provider with

over 260,000

employees across

100 locations in

30 countries.

The world's

leading brands

rely on Jabil's

unmatched

breadth and

depth of

end-market

experience,

technical and

design

capabilities,

manufacturing

know-how, supply

chain insights

and global

product

management

expertise.

American

Surgical Mask

Producing Up to

150,000 Surgical

Masks per Day

Company CEO Matt

Brandman

recently

provided

insights to the

media about the

masks made

locally in the

Tampa Bay area.

“American

Surgical Mask is

a U.S. based

3-ply mask

manufacturer

based in Tampa,

FL. The company

currently

operates a

10,000 square

foot facility

producing over

150,000 ASTM

Level 1 masks

per day.

Their 3-Ply disposable surgical masks are manufactured in Tampa, Florida with US sourced materials. Their executive and management team is highly diverse and minority. Their ownership is highly diversified and consists of professionals with experience in medical, energy, construction and the food/beverage industries.

Their

state-of-the-art

10,000 sf

manufacturing

facility has

been upgraded to

house up to

eight automated

machines that

are each capable

of producing

over 80 masks a

minute. Their

facility follows

the strictest

guidelines of

the CDC to

protect their

employees and

their families

in this pandemic

environment.

Lanaco is and is

Not Sheepish

About Their

Filters

A New Zealand

Company touts

the benefits of

sheep’s

wool with strong

electrostatic

charges.

Lanaco

makes several

types of masks

with varying

efficiencies.

The WAIRE™ P2 respirator

mask must be

fitted and

adjusted

correctly to

your face to

provide the

intended

protection.

·

WAIRE™ P2 can

also be used in

certain

applications

against some

bio-aerosols,

such as COVID

and FLU

virus. Helps

protect against

airborne

biological

particles -

Fluid resistant

(120 mm Hg

synthetic blood

resistance)

·

Lightweight

construction for

added comfort

that may

increase wearer

time. Has

a 4-point head

harness for a

secure and

comfortable fit

·

Nose wire allows

the wearer to

shape to the

nose, reducing

eyewear fogging

and forming a

better seal.

·

Made from Lanaco

HELIX™ Advanced

Filter Material

for effective

filtration with

low breathing

resistance

(104Pa @ 95l/m)

·

Does not contain

components made

from natural

rubber latex

·

Protects against

hazards, such as

dust, mists,

smoke and fumes

·

Complies with

AS/NZS

1716:2012 standard

and approved at

a P2 level

·

Exceeds 95%

filtration

efficiency in

laboratory

testing when

tested at 95

L/min against a

salt aerosol (VicLab

Australia,

INSPEC United

Kingdom)

·

Advanced wool

hybrid

electrostatic

filter media –

low breathing

resistance,

moisture-wicking

and naturally

bacteriostatic

Jacobs had a

NASA contract

under which it

searched around

the world for

organizations

that might have

the technical

expertise to

extend the life

of NASA’s

current

respirator.

In May 2018, a

call went out to

Lanaco, a New

Zealand company

that develops

and produces

wool filter

material, with a

focus at that

point on

personal

protective

equipment in the

workspace and

air pollution

filtration.

The Jacobs team

was especially

interested in

particle

filtration,

which intrigued

Lanaco founder

Nick Davenport

because, though

his company

hadn’t been

working on

emergency

breathing

devices, he knew

wool was well

suited to such

an application.

Davenport, a

materials

applications

engineer, and

his colleagues

had noticed the

interesting

properties of

wool while

working with

polymers about a

decade earlier.

“The deeper we

dug into the

science of wool

and how it could

perform in an

industrial

application,

using new

science, the

more we saw

there was an

opportunity,” he

says. Wool is

naturally

resistant to

fire and

bacteria, and it

manages water

well.

Davenport and

his colleagues

wondered why

this

extraordinary

material wasn’t

being used for

filtration

around the

world. They

realized air

filter

technology was

focused on

synthetic

materials,

overlooking this

natural

alternative.

He founded

Lanaco and

developed his

proprietary wool

filter

technology. The

company has

built up a

specialized

commercial flock

of sheep by

working with a

top breeder to

maximize the

qualities that

make good

filters and to

reduce the

material’s

variability.

“We analyzed the

wool fiber from

hundreds of

different types

of sheep and

then established

a breeding

program to

specifically

focus on the

attributes that

we needed to

make the world’s

best all-natural

fiber air filter

for respiratory

applications,”

Davenport says.

Wiles and her

team at Jacobs

were looking

specifically for

a prefilter that

could fit over

NASA’s existing

fire cartridge

to increase the

life of the

system for

Orion. Lanaco

then began to

tailor its Helix

filter for the

application.

The particles

that would fly

around in the

event of a

spacecraft

fire—including

droplets of

water used to

extinguish a

blaze—are

potentially

small and hot,

and the existing

technology is

typically made

of polymers with

a relatively low

melting point,

Davenport says.

A product like

wool, which

doesn’t promote

a fire or

degrade rapidly

under hot

particles, has

clear

advantages.

“As a prefilter,

our technology

enables the main

filter to

function in the

presence of

those hot

particles and

dangerous

gases,”

Davenport says.

Prior to the

NASA contract,

Lanaco had not

been working

directly in the

area of critical

breathing

applications.

Now the company

has some

expertise, with

wool performing

particularly

well in fire

resistance and

moisture.

We have

commenced

developing some

of the features

in the NASA

application of

our filters for

use in critical

respiratory

applications,”

says Davenport.

Extraction Arm

from Nederman is

a Great CCC

Example

Concentrated

Contaminant

Capture (CCC) is

exemplified in

the Nederman

extraction arm.

During the

COVID-19

pandemic, health

risks associated

with exposure to

hazardous

aerosols during

routine dental

procedures and

the potential

transmission of

infectious

diseases became

even more of a

concern.

Considering the

potential for

patients

infected with

COVID-19 to

transmit the

virus while

asymptomatic, it

should be

assumed that all

patients can

transmit

disease. As the

most important

layer of the

total protection

strategy, the

effectiveness of

Nederman’s

enhanced disease

protection

system was

evaluated in

collaboration

with the leading

dental

university in

Istanbul, Turkey

- Marmara

University

Faculty of

Dentistry,

established in

1952.

Aerosol

generating

processes (AGPs)

during dental

procedures

create high

concentrations

of aerosols

containing

particulates of

various sizes.

This particulate

matter carry

contaminants,

viruses, saliva,

blood etc. Due

to the nature of

how dental

procedures are

conducted,

dentists who

work closely

with patients

are frequently

exposed to

potentially

dangerous

aerosols and

media

frequently. If

this media is

not collected

from where it is

generated, it

will spread and

travel with

ambient air onto

equipment and

surfaces,

potentially

infecting dental

healthcare

staff, patients

and more. There

was no available

study on a real

dental setting

evaluating

effectiveness of

the Nederman

Aerosol Control

System,

especially

during the

pandemic period.

With the

collaboration of

Marmara

University

Faculty of

Dentistry, a

study was done

with four

different

operation types

and six cases

using Nederman FX2

Extraction Arm, Combi-Hood and N-Series

Fan in

order to

evaluate the

system

effectiveness by

comparing

aerosol

concentrations

of cases with

and without

aerosol control

system use. The

main objective

of the tests are

to see if the

system is able

to decrease

aerosol

concentration

close to ideal

levels avoiding

aerosols to

spread

throughout the

room and into

the patient’s

and staff’s

breathing zone.

|

|

|

|

|

Without aerosol control |

|

With aerosol control |

It was observed

that without any

aerosol control

system, aerosol

concentrations

increased

dramatically

during AGP’s.

Also, after the

Nederman aerosol

control system

was turned on,

the aerosol

concentration

decreased close

to the ideal

reference

levels. If the

complete test

data is examined

together, it can

be concluded

that the red

shaded area of

high aerosol

concentrations

can be removed

successfully by

aerosol suction

before into a

controlled

environment.

In addition, the

observed amounts

of aerosols

accumulating

onto the

dentists’

glasses, masks

and protective

equipment

decreased

substantially

and created a

comfortable

working

environment.

The test results

showed a

reduction in

aerosol exposure

of greater than

90% to the

dentist.

Freudenberg has

the Products to

Create Safe

Bubbles

With its air

filters, masks,

and service

Freudenberg can

provide

substantial

assistance in

creating safe

bubbles.

“For more than

60 years, we

have been using

our filters at

our customers'

sites and

providing

maintenance

services to

ensure

consistent

quality and

safety – the

filters are

tailored to each

individual

customer and

application,"

explains Dr.

Thomas Caesar,

Director Global

Filter

Engineering of

the Industrial

Filtration

Division.

In addition to

pure filtration

products,

Freudenberg also

offers

tailor-made

service

solutions.

Ventilation

systems that are

well maintained,

hygienically

perfect and

equipped with

highly effective

air filters make

a valuable

contribution to

this. In the

current

coronavirus

situation,

Freudenberg

Filtration

Technologies has

added two new

hygiene modules

to its Viledon

filterCair air

quality

management

system. Both

include a

ventilation

system check to

protect

employees from

infections and

food from

contamination,

and thus protect

companies from

the economic

consequences of

temporary

closure.

"In the long

run,

cost-savings can

be made if the

filters are not

only adapted to

the application

but also to

local fine dust

pollution,"

explains Caesar.

There is

increasing

evidence that

higher levels of

air pollution

lead to more

severe disease.

Filter

technology will

therefore

continue to

become

increasingly

relevant in the

future. In the

context of

infection

control, it

offers – in

addition to its

previous use in

clinics and

industry – a

solution for

reducing the

risk of

infections

associated with

the accumulation

of people in

indoor public

spaces.

We reported on

the FDA

clearance of

Freudenberg

surgical masks

yesterday. It is

also providing

masks for the

public using a

novel spunbond

media produced

by NWI.

Freudenberg

provides the

textile

manufacturing

expertise and

work force

needed to

install, operate

and maintain the

four new

production

lines. "As the

leader in the

development of

the next

generation of

nonwovens, we

knew we could

step in and help

fill this

critical need.

By partnering

with Freudenberg,

we will ensure

the reliable

completion of

millions of

protective face

coverings to

battle the

coronavirus

using NWI’s

novel filter

media”, says

Behnam

Pourdeyhimi,

executive

director of the

Nonwovens

Institute. Once

fully

operational the

site will be

able to produce

more than one

million masks a

month.

In addition to

the face mask

lines provided

by NC State,

Freudenberg has

installed six

additional

production lines

to manufacture

surgical and N95

masks.

Pfizer and

Moderna Vaccines

Less Effective

Against South

African Variant

The two

coronavirus

vaccines

developed

by Pfizer-BioNTech and Moderna appear

to be highly

effective

against the more

transmissible

variant of the

virus first

detected in

Britain,

according to

newly published

studies in the

New England

Journal of

Medicine, in a

potential boost

to vaccination

efforts around

the globe.

The vaccines,

however, showed

a decreased

ability to

neutralize the

strain now

dominant in

South Africa,

worrying some

researchers and

prompting Pfizer

and BioNTech to

announce they

were taking

necessary steps

to develop a

booster shot or

updated vaccine.

A day after

Pfizer’s

announcement, a

top White House

coronavirus adviser

said each

vaccine

developer is

planning to

update shots to

address

variants.

“Each of the

vaccine

companies — and

I’ve talked to

all of them,

both the ones

approved and the

candidates —

have plans to

continue to

update their

vaccines, and if

need be, create

boosters down

the road if

there continue

to be additional

mutants, as

there likely

will be,” Andy

Slavitt said

during a

Washington Post

live interview

on Thursday.

Here are some

significant

developments:

- Life expectancy in the United States fell by a full year during the first half of 2020, a staggering decline that reflects the toll of the pandemic as well as a rise in deaths from drug overdoses, heart attacks and diseases that accompanied the outbreak, according to government data released Thursday.

- Lack of access to vaccines from their own country means U.S. diplomats abroad are accepting host government offers of their supply of U.S.-made vaccines to get inoculated.

- The Department of Homeland Security has seized more than 11 million counterfeit N95 masks meant for front-line workers in recent weeks, including more than 1 million on Wednesday, officials said.

- About 33 percent of service members have declined voluntary coronavirus vaccinations, defense officials said Wednesday, acknowledging that more inoculations would better prepare the military for worldwide missions.

- Nearly 28 million cases have been reported in the United States, with 489,000 deaths, but the numbers of new cases continue to fall, reaching rates now comparable to those in late October.

Education Week

Weighs in on

School

Ventilation

The importance

of good

ventilation in

schools is the

theme of Sarah

Sparks in a

recent

Education Week

article which is

excerpted below.

Similar articles

on the benefits

of efficient

tight fitting

masks are one of

the routes to

insure that the

right choices

are made by

teachers and

parents relative

to mask

selection.

Guidance from

the Centers for

Disease Control

and Prevention

released last

week provided

significantly

more detail on

how schools

should approach

issues like

community spread

and mask use

when deciding

how to reopen

schools safely

during the

pandemic. But

critics say the

new

recommendations

downplay the

importance of improving

indoor air

quality and

ventilation to

prevent the

spread of the

airborne virus.

The CDC guidance

encourages

schools to

improve

ventilation as

part of their

overall cleaning

strategy, and

particularly

points to

opening doors

and windows to

“increase

circulation of

outdoor air to

increase the

delivery of

clean air and

dilute potential

contaminants.

In separate tips

on ventilation,

the agency

describes this

as a cost-free

way to reduce

the spread of

the virus, along

with inspecting

and maintaining

local exhaust

ventilation;

repositioning

outdoor air

dampers; and

disabling

demand-controlled

ventilation, a

common

energy-saving

system that

reduces the rate

at which outdoor

air is pulled

into a building.

“The guidance

addresses

near-field

(close contact)

inhalation dose

with masks and

distancing.

That’s good,”

said Richard

Corsi, the dean

of engineering

and computer

science at

Portland State

University, an

expert on indoor

air quality, via

a tweet.

“Ventilation is

given lip

service with

little guidance.

Incredibly

disappointing.

The lack of

understanding of

ventilation or

its importance

(or perhaps just

disregard) is

wholly obvious.”

And 13

scientists this

week, in

a letter to

President Joe

Biden’s

administration,

are calling for

a greater focus

on limiting

airborne

transmission in

schools,

meatpacking

plants, prisons,

and other indoor

settings.

Early in the

pandemic, public

health officials

believed the

coronavirus was

spread mainly

through

droplets—virus-laden

liquids larger

than 5 microns

across. The

current rules on

social

distancing come

in part from

studies that

find a cough or

sneeze can

project these

droplets several

feet away, where

they may hang in

the air for

several minutes

before landing

on surfaces.

But more recent

studies have

found that

COVID-19 spreads

through much

smaller

aerosolized

particles, which

both travel

farther and hang

in the air

indefinitely

unless blown

away. That makes

keeping air

circulating—safely—much

more important.

Studies find

that opening

windows and

doors can help

replace the

concentration of

air inside more

quickly—but how

quickly depends

on whether there

are multiple

openings

available to

provide better

air flow.

One new study of

the coronavirus

in buildings

found that

because of the

viruses’

transmissibility

and tendency to

hang in the air

over time,

administrators

may not be able

to rely on

the normal rate

of air flow from

their

ventilation

systems to clear

virus particles

from the air.

And a separate

new study of

Dutch schools

found aerosols

built up

steadily in

school gyms even

when they had

ventilation,

but the

combination of

increased

ventilation and

the use of

mobile air

filters cut the

concentration of

aerosols in the

rooms by 80 to

90 percent.

However, the

CDC’s other

recommendations to

bolster

ventilation beyond

opening doors

and windows have

costs that can

add up quickly

for schools: The

agency estimated

fans at $100

each; $500 each

for portable

HEPA filters;

and $1,500 to

provide

ultraviolet

germicidal

irradiation to

counter the

coronavirus in

ducts above

rooms with

limited

ventilation.

A government

study released

this summer found

more than 2 out

of 5 U.S.

districts need

to update or

replace the

heating, air

conditioning,

and ventilation

systems in at

least half of

their schools.

The report found

some 36,000

schools had

outdated HVAC

systems or those

in need of

repair or

replacement—making

it by far the

most common

infrastructure

problem in

schools. Federal

researchers

estimated

high-poverty

school districts

spent on average

$300 less per

student on

capital projects

like HVAC upkeep

and replacement

than did

low-poverty

districts, $719

per student

versus $1,016

per student.

But Kanecia

Zimmerman, an

associate

professor of

pediatrics at

Duke University

Medical Center

and co-head of a

National

Institutes of

Health project

studying safe

school

reopening,

argues basic

maintenance can

go a long way.

“What is most

helpful is that

ventilation

systems work as

they were

designed,’ said

Zimmerman in a

briefing.

“Overhauling

ventilation

systems, HEPA

filters, those

types of things

have not been

demonstrated to

result in

reduced

transmission.

Certainly, we

think they could

potentially work

based on the

fact that they

are filtering

air and things

of that nature,

but there is no

evidence that

reduced

transmission has

occurred because

we had these

things in place.

So, the most

important thing

would be to have

ventilation

systems that

actually work.”

Yet what “works”

when it comes to

getting rid of

aerosolized

virus can seem

to run counter

to what schools

might otherwise

want in their

building’s HVAC

system. Take,

for example, one

new study

of COVID-19

transmission

rates in New

York City

schools as

they started to

reopen.

Researchers

tracked COVID-19

transmission

rates in more

than 100

classrooms

across the city

as the seasons

changed.

Transmission

rates rose as

schools switched

over from air

conditioning—which

often

incorporates

more natural

ventilation— to

heating. Newer

and better

resourced

schools were

also more likely

to have higher

transmission

rates.

Why? Those

schools were

more likely to

be

weather-proofed

and energy

efficient.

That’s great for

maintaining a

stable

temperature and

cost-savings,

but it means

indoor air

doesn’t move as

much and doesn’t

get exchanged

with fresh air

as often—leaving

virus particles

to build up.

“Surprisingly,”

the researchers

noted, “schools

located in older

buildings and

lower-income

neighborhoods

had lower

transmission

probabilities,

likely due to

the greater

outdoor airflow

associated with

an older,

nonrenovated

buildings that

allow air to

leak in (in

other words,

drafty

buildings).

Likewise, the

study also found

all else being

equal, that

little more than

a third of

schools that had

mechanical

ventilation,

such as fans or

central heating

and air

conditioning

systems, had

lower rates of

transmission

overall. The

study noted that

all but 18

percent of the

schools studied

had either no

windows or

windows that

were broken and

would not open,

making it

difficult or

impossible to

get natural

ventilation.

Recent studies

that have found

proper

ventilation to

help prevent

school outbreaks

when community

coronavirus

levels are high,

but Zimmerman

cautioned that

it cannot work

without being

part of a

comprehensive

mitigation plan.

“We know that

even in settings

of poor

ventilation,

masking and

distancing can

be very

helpful,”

Zimmerman said.

“Ventilation is

potentially one

part” of school

mitigation

strategies.

Improving indoor

air quality may

do more than

just help

schools tamp

down on COVID-19

outbreaks,

though. One

study last year

found improving

air quality also

boosted reading

and math

achievement,

particularly for

disadvantaged

students living

in areas with

outdoor

pollution.

https://www.edweek.org/leadership/what-the-cdc-guidelines-dont-say-about-classroom-ventilation-and-covid-19-spread/2021/02