Coronavirus

Technology Solutions

February 3, 2021

Three Step Mask Strategy Webinar Friday Feb 5 at

10:AM CST will Address a Market Five Times

Larger than the Present One

The U.S. Tight Fitting Mask Market is Five Times Higher Than the Present One

TAIJI Medical Supplies Single-Use Face Masks

Designed to be Protective and Comfortable

Behind the KandyMask Micro Filter System

Mask Shortages Continue for Medical Workers

____________________________________________________________________________

Three Step Mask Strategy Webinar Friday Feb 5 at

10:AM CST will Address a Market Five Times

Larger than the Present One

We need a program to insure that everyone is

fitted with tight fitting efficient masks as

quickly as possible. This is a new market

involving 97% of the people who will need

84% of the masks Distinguished researchers have

developed a three step plan which we will

be discussing on Friday.

On the 28th we covered the background

for Step 1 of the Friday webinar. Monday we

covered Step 2 and Tuesday Step 3.

The three steps are (l) launching an awareness

blitz, (2) advise on which masks should be worn

and (3) prioritize masks for the vulnerable.

View the previous Alerts at

http://www.mcilvainecompany.com/CATER/subscriber/default.htm

The webinar will include a display and

discussion of the three steps. We are

encouraging input from all the participants and

hope for a lively discussion and debate.

The U.S. Tight Fitting Mask Market is Five Times

Higher Than the Present One

McIlvaine is analyzing the potential market if

everyone is equipped with tight fitting

efficient masks.

At this stage it can be said that this

market is at least five times larger than the

one being served.

The U.S. population is 331 million people. The

question is how many masks will it take to

insure safety for all citizens.

Nearly 20 million are less than 4 years

old. Over 50 million are in kindergarten through

high school.

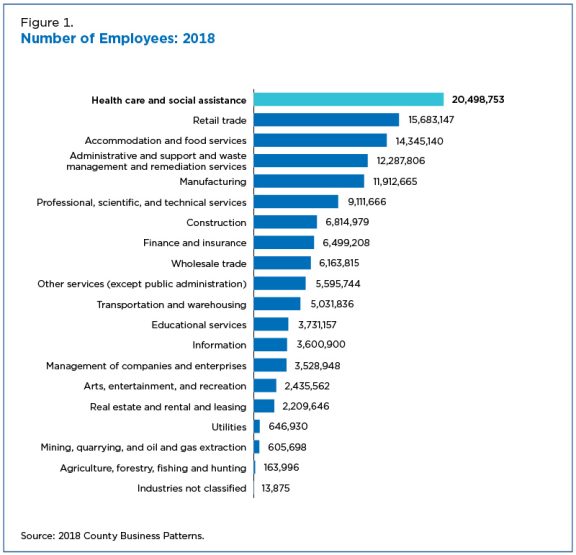

Over 20 million people are in healthcare and

social assistance.

The number of doctors is less than 1

million. There are 2.8 million people in

nursing.

Some of these people are wearing 10 surgical

masks per day or several N95s.

But the maximum consumption is by people

within three feet of infectious patients.

Many people are not in contact with

patients on a daily basis.

DHHS estimated that 3 billion masks would be

needed to fight COVID in March.

this would supply 3 million people

wearing 3 masks per day for one year.

There are over 1 million firefighters but only

400,000 of them are permanent and the others are

volunteer. There are 800,000 law enforcement

officials.

|

Age group |

Data Type |

2015 |

2016 |

2017 |

2018 |

|

0 to 4 |

Number |

19,918,078 |

19,921,759 |

19,890,972 |

19,762,962 |

|

Percent |

27% |

27% |

27% |

27% |

|

|

5 to 11 |

Number |

28,722,259 |

28,710,158 |

28,655,926 |

28,570,534 |

|

Percent |

39% |

39% |

39% |

39% |

|

|

12 to 14 |

Number |

12,358,887 |

12,345,395 |

12,421,214 |

12,486,380 |

|

Percent |

17% |

17% |

17% |

17% |

|

|

15 to 17 |

Number |

12,618,827 |

12,672,101 |

12,617,234 |

12,499,269 |

|

Percent |

17% |

17% |

17% |

17% |

Many in the population are not employed and

spend relatively little time in public. Possibly

8 million of the 16 million people in retail are

meeting with customers continually.

There are 14 million in accommodations and food

service. But it is likely that only a few

million would be in contact with many clients

each day.

The McIlvaine Company will be analyzing all

these categories and make forecasts in terms of

tight fitting and efficient masks. But the

analysis is likely to show that the present

market for medical workers is only 16% of the

total. The most exposed group uses 15 times as

many masks as the least exposed group

but only represents 3% of the population.

So the challenge is supplying the other 84% of

the expanded market.

This is a high efficiency market five

times larger than the present one.

|

Number of People

millions |

Mask Ratio |

Number of masks

in equivalent

period |

% |

|

10 |

15 |

150 |

24 |

|

50 |

5 |

250 |

39 |

|

240 |

1 |

240 |

37 |

|

30 |

0 |

0 |

0 |

|

330 |

|

640 |

100 |

TAIJI Medical Supplies Single-Use Face Masks

Designed to be Protective and Comfortable

TMS occupies a 120,000 sq ft facility in

Lincolnton, NC that is already producing

volumes of masks and will scale to millions.

Masks can be made for nearly the same price as

those made in China. TMS believes America should

not have to choose between quality and price in

a time of need.

·

TMS has two (2) melt-blown fabric machines

in-house. Melt-blown fabric is the center layer

of each mask and is what provides filtration.

Many manufacturers were hindered during the

height of the pandemic as they rely on sourcing

from overseas.

·

The company says it has combined automation,

vertical integration and American ingenuity to

solve the problem

· Medical-grade surgical and protective face masks are designed, developed and produced end-to-end in America (Lincolnton, NC).

· 20 fully-automated assembly lines can produce thousands of masks per minute.

·

Vertically integrated factory takes raw

polypropylene and transforms it into surgical

and protective face masks in seconds.

The general Consumer Series single-use face

masks are designed to provide enhanced coverage

with a more comfortable fit. They are wider than

the average mask, reducing the gap between the

edge of the mask and the ears. The nose bridge

is built with higher ductility, allowing it to

bend more easily and stay in place without

discomfort. The ear loops on their masks are

created with a thicker, more comfortable

material that has been tested to stretch to

two-and-a-half times the original length without

losing elasticity.

Mask Specifications

·

Engineered with three (3) layers of protection

·

Hypo-allergenic, soft, non-woven polypropylene

outer layers

·

Melt-blown proprietary material inner layer for

improved filtration

·

Latex free

·

Single-use

·

6.9 in ± 0.2 in (Length) x 3.5 ± 0.2 in (Width)

·

Made in Lincolnton, North Carolina

Dan Grayson, VP Sales and Marketing agrees that

there is a need for a tight fitting mask but

believes there are ways to accomplish this

without use of a brace. He will be traveling on

Friday and unable to participate in the webinar

but believes that TMS can play an important role

in seeing that everyone has tight fitting

efficient masks. Here are his comments.

“The pandemic has created a whole new twist on

the meaning of ‘start-up’ endeavors here in the

United States and globally as a whole. As the

Director of Sales & Marketing for TAIJI Medical,

I can speak firsthand regarding the struggles

and successes of an American-based face mask

manufacturer. From $0 sales, to now over 100

healthcare customers, twq massive distribution

partners and a top major retailer under our

umbrella, it’s been an overload of planning and

strategy. But, at least in our case, the

strategy is paying off.

Defining the Industry

The one word that’s beginning to look like it

will define the entire face mask industry in the

United States is “capacity”. As demand increases

for now, it will stabilize over time when the

pandemic spread slows. One then has to ask

themselves, “did I position my efforts for

long-term stability or did I just fill a void”.

That’s a scary question that I don’t believe

many new mask manufacturers have given much

thought.

The ability to continue, after the pandemic

subsides will be based upon the ability to

manufacture and ship large volume orders at

almost import pricing. This especially rings

true if the new manufacturer wants a shot at a

government contract or partnering with a large

distribution source, a GPO or IDN.

A National Masking Strategy?

There is simply no “national strategy” for

masking and that’s the problem. The just “wear

anything over one’s nose and mouth” strategy

that has been disseminated, by many government

officials and even doctors, has not played-out

well for the past nine months. It’s simply not a

strategy, rather a “hail Mary” attempt at their

meaning of “mask compliance”.

I’ve seen a lot of mask manufacturers now add

the manufacture of N95 or similar respirators to

their capabilities. Some others have added the

manufacture of cloth masks, which while having a

more “stylish” appearance than that of a

surgical mask or respirator, offer inefficient

bacterial and particulate filtration. Some

companies are even offering a “brace” for

regular and surgical face masks in an attempt to

make them more like a respirator.

I believe that a superior quality surgical mask

offers a great level of protection as the

Bacterial and Particulate Filtration

Efficiencies are superior to that of a

respirator or cloth mask. If one combines a face

shield with the surgical mask, well, that would

only serve to increase the level of protection.

The concern with any traditional surgical mask

is the seal around the mouth and nose areas. Our

company believes that can be overcome to make

the surgical mask the best overall masking

choice.

Buy American but “Economically Forced” to Buy

Imports

Along with a “national strategy” has to come a

reasonable price point for surgical masks and

respirators being manufactured domestically.

Potential buying sources and users of these

masks must realize that American-made products

cost slightly more. It’s a combination of

superior quality, increased material and labor

costs that drive-up the per piece price.

One of the biggest issues that I have seen is

government entities, whether state or federal,

list a Request for Pricing (bid) for millions of

masks and then award the bid contract to the

lowest bidder. Do they not realize in today’s

world that most likely the mask that will be

provided will be an inferior imported mask

supplied by an entity that is not a mask

manufacturer or specialist? I’ve literally seen

a large (5,000,000 masks) bid opportunity

awarded to “Joe’s Body Shop” at 4.5 cents per

mask. There need to be established rules on

these bid requests that the bidder has to be an

actual mask manufacturer or long-time supplier /

distributor as part of the qualifications to

bid.

Another great example is that healthcare

facilities want to buy from U.S. PPE

manufacturers. But, because of “economics”, they

are forced to buy imported masks. Their budgets

have been overloaded from buying PPE and the

last thing they can afford to do is to

completely short-circuit their budget by

purchasing masks, gowns, etc. that have a higher

per piece price. In fact, some healthcare

facilities are now directly sourcing their PPE

from China, Thailand and Vietnam in an attempt

to get the lowest price. Again, they want

to “Buy American” but are forced to

purchase elsewhere.

The Solutions

I can say this with great confidence. U.S. mask

manufacturers will have to find a way to

successfully (and quickly) increase their

capacity while driving down the cost of each

item of PPE to a point where they are slightly

above an imported item's landed cost. The

manufacturers that can do this will survive.

Those that cannot will have to wait until

there’s another national emergency in order to

capitalize. And, in the end, we all hope that

doesn’t occur again.

In the end, it's all about the mask, the comfort

and the associated filtration capabilities that

offer protection. At TAIJI, we have developed a

more well-fitting and comfortable Class 2

surgical mask that can also be offered to the

general public. We have the innovation and

capacity to put the residents here in

American-made masks.

Behind the KandyMask Micro Filter System

1st Layer: A

high thread count microfiber which acts as a

pre-filter for large particles and helps extend

the life of our inner micro filter layers.

2nd Layer:

A thin activated carbon material that filters

out PM 2.5 particles, light gases and chemicals.

3rd Layer: 2

stacked layers of our proprietary melt blown

polypropylene blend tested to filter microscopic

airborne contaminants between 0.3 and 0.075

microns.

4th Layer:

Is the soft microfiber inner layer making

KandyMask comfortable to wear for long periods

of time.

The filtration results conform with ASTM F2100

medical mask standards on these tests below.

* 99.80% Viral Filtration Efficiency

* 99.76% Bacterial Filtration Efficiency

* 97.14% Particle Filtration Efficiency @

0.075 to 0.26 micron (yes, that is 10-25 times

smaller than PM2.5)

The company uses

GB, Underwriters Laboratory and Nelson

Labs for testing.

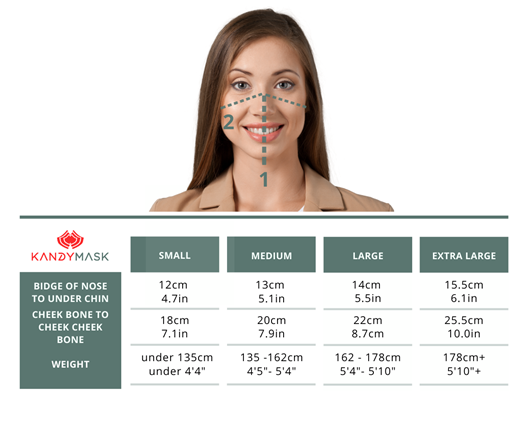

Choosing the right mask size is important for

good filtration and comfort.

All the KandyMask models come in four sizes.

Height is used as a method to choose the right

size mask size. In all our years of being in the

protective mask space, we have found that

it works for about 95% of people. The 5% usually

have longer or shorter faces from nose to chin.

If you feel you are in this 5% you should

potentially choose one size up or one size

down. We are also aware that everyone comes in

different shapes and sizes so it's important to

layout actual measurements for you to make an

informed decision.

Below is the mask size and measurement for our KandyMask

6.0 model.

1. For the height of the mask, measure from

the bridge of your nose down to the right under

the chin. It is actually good to measure

about 2cm / 0.7inc under your chin for a more

accurate fit because the bottom of the mask

tucks slightly under your chin.

2. For the width of the mask, measure from

your left cheekbone to your right cheekbone.

This measurement rarely has an effect on the

wearer and is not always necessary unless you

have skinnier or heavier set facial features.

Mask Shortages Continue for Medical Workers

The initial shortage has eased, but there still

aren’t enough medical masks for health-care

workers, let alone others. Demand for N95s is

500 to 1,000 percent higher than it was a year

ago, said Megan Ranney, co-founder of Get Us

PPE, which helps front-line workers obtain

personal protective equipment

Even many health-care workers at well-financed

hospitals wear N95s for anywhere from a day to a

month, instead of changing them in between

patients like they did before the pandemic.

Smaller facilities are struggling even more,

Ranney said. Some are relying on KN95s, a

Chinese equivalent that U.S. health-care workers

consider less desirable.

N95s, which once cost $1 or less each, now sell

for up to $5. And for both N95s and KN95s, a

surge of fraudulent or faulty products on the

market has sometimes made identifying

high-quality options difficult.

“Everyone is cutting corners,” Ranney said.

“There is no health-care facility in the country

that is using PPE the way that it did

pre-pandemic.”

Why is there still a shortage?

Both the market for N95 masks and the national

stockpile were small before the pandemic. The

U.S. imported at least half of its PPE,

including medical masks, from China, where

exports shrank for months because of the

outbreak, said Scott Paul, president of the

Alliance for American Manufacturing, a nonprofit

organization that advocates for public policies

to benefit U.S. manufacturers.

Major suppliers such as 3M and Honeywell

dramatically increased production last spring

and summer but didn’t come close to the 3.5

billion masks that federal officials estimated

were needed to fight the virus. Barriers to

entry, including uncertainty about demand

post-pandemic, discouraged other companies from

entering the market, Paul said.

The N95 shortage America can’t seem to fix

The Trump administration took a relatively

hands-off approach in encouraging the production

of N95s. Federal officials arranged contracts

with manufacturers, but the president mostly

avoided using the Korean War-era Defense

Production Act to compel companies to make

masks.

“I think it’s fair to say that there were some

efforts,” Paul said, “but those fell short, as

well-intentioned as they may be.”

How can I tell if a medical mask is high

quality?

Unlike N95 masks, KN95s are easy to find through

online retailers, major chain stores and

pharmacies.

If you’re going to buy KN95s, choose a type that

has received emergency use authorization from

the Food and Drug Administration, said Anne

Miller, executive director of Project N95, a

nonprofit organization that helps health-care

and other essential workers access protective

gear. The FDA keeps a

list of approved products,

which the agency refers to as “respirator models

manufactured in China.”

The Centers for Disease Control and Prevention’s

National Institute for Occupational Safety and

Health also maintains

a website focused

on counterfeit N95s for reference.

Whatever face covering you choose, it should be

snug and without gaps.

If I buy medical masks, am I taking them away

from health-care workers?

It’s not clear whether buying N95s on the open

market affects the supply available to doctors

and nurses, whose contact with coronavirus patients

puts them at heightened risk of infection.

Health-care facilities don’t usually get N95s

from the retailers where an everyday shopper

might buy them, said Tom Frieden, former

director of the CDC.

Ranney cautioned that while shortages persist,

there’s no way to guarantee that buying an N95

doesn’t mean one fewer mask for a doctor.

Instead, she suggested choosing KN95s or KF94s,

a Korean-made equivalent.

Do other countries have enough N95s?

Several countries have made N95s or their

equivalents widely available to the public.

The South Korean government seized control of

KF94 production and sends masks to pharmacies to

sell at a set price. Singapore has offered free

reusable masks in vending machines. Hong Kong

residents can pick up masks at post offices.

In Europe, medical masks are now widely

available at pharmacies. Austrian grocery

stores distributed free masks last month after

the government mandated them in stores and on

public transportation.

Europe’s growing mask ask: Ditch the cloth ones

for medical-grade coverings

Germany launched a $3 billion program in

December to give three free medical masks to

older people and those with preexisting health

conditions — about one-third of the population.

The southern state of Bavaria recently made N95

equivalents mandatory in some public settings.

Will the U.S. supply of these masks increase?

Although President Biden signed an executive

order last month expressing a need to develop a

sustainable supply chain for protective gear,

his administration has not released a specific

plan to increase manufacturing. White House

press secretary Jen Psaki has suggested that any

additional supply would be directed toward

health-care workers involved in the vaccination

effort.

Biden’s stimulus proposal also requested $30

billion for “supplies and protective gear,” but

Congress has yet to reach a deal.

Ensuring greater access to medical masks, for

health-care workers and others, should be a

critical part of the U.S. response as the more

highly transmissible variants threaten to

reverse declining infections, said Abraar Karan,

a doctor at Brigham and Women’s Hospital and

Harvard Medical School.

“As the virus gets better,” he said, “we need to

get better in our response.”