Coronavirus

Technology Solutions

January 20, 2021

Webinar Agenda for Tomorrow

Speed is the Basis for the Webinar Tomorrow

A Push-Pull Program will Provide the Speed and

Efficacy

Validation of Fitted Mask Efficiency Still will

be Needed

Five Step Approach Needed

Eurofins has a Tested Quality Seal for Community

Masks

ATI Supplies Both Mask PFE and Resistance

Testers

Ambrust American Expands Meltblown Capacity

______________________________________________________________________________

Webinar Agenda for Tomorrow

Individuals are encouraged to present their

views in the webinar tomorrow. The format will

be to display the relevant material from

previous Alerts in chronological order. We will

then encourage discussion. People who have

already committed to making comments are listed.

January 20, 2021

Speed is the Basis for the Webinar Tomorrow

A Push-Pull Program will Provide the Speed and

Efficacy

Validation of Fitted Mask Efficiency Still will

be Needed

Five Step Approach Needed

Eurofins has Tested Quality Seal for Community

Masks

January 19, 2021

Join Us on Thursday to Debate the Mask Issues

Media Supply will be Substantial According to

Dave Rousse

·

Dave Rousse

Mobile Device to Insure Selection of the Mask

with the Right Fit

·

Keith Dellagrotta

Leveraging ASTM Label Initiative for Efficient

Public Masks

·

Erich Couch

Breathing Resistance, Filtration Efficiency and

Media Area

FFP 2 Masks Now Required in Retail Stores and

Public Transport in Austria and Germany

January 18, 2021

Sufficient Essential Braces can be Supplied to

Meet Needs

·

Sabrina Paseman

Quick Fit Testing Methods are Needed- How About

Thermal Imaging?

Some Thermal Imagers Already Recognize Face

Masks

How About the Temperature Scanners Presently

Being Used

January 15, 2021

Biden Mask Mandate Debate Next Thursday - Join

the Discussion

·

Chance for anyone to weigh in on any of the

issues

Review of Coronavirus Mask Decisions

the webinar will be recorded and available to

view in the webinar section of CMD.

To register for the event click on

http://www.mcilvainecompany.com/CATER/subscriber/default.htm

Speed is the Basis for the Webinar Tomorrow

In his inauguration speech this morning

President Biden spoke of speed and urgency in

dealing with COVID. He needs to know as quickly

as possible whether mask efficiency should be a

major factor in reducing COVID spread. The goal

of the webinar tomorrow is to help accelerate

the communication and decision making.

It is logical to ask why has McIlvaine

undertaken what would logically be the province

of an association or government body. The answer

is speed. McIlvaine has proven in past crises

that it can make a contribution when quick

decisions have to be made about air and water

issues.

At the time of the Gulf oil spill decisions had

to be immediately made as to whether chemical or

non-chemical O2 sensors would be used in the

undersea drones to chart the oil spill.

McIlvaine organized a series of webinars

in just a few days. Experts, operators and

governments shared valuable insights.

EPA was within days of promulgating the

1990 power plant air regulations when it was

discovered that all three methods for velocity

measurement had flaws. A series of McIlvaine

webinars including EPA, power plants,

consultants, and suppliers provided the needed

answers.

A failure of 2205 nickel alloy SO2 scrubbers

resulted in many hours of webinars in just a few

weeks as solutions were pursued for what turned

out to be a multibillion dollar problem.

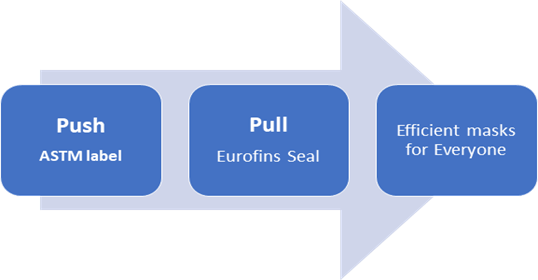

A Push-Pull Program will Provide the Speed and

Efficacy

Erick Couch, tomorrow, will be advocating that

the Biden Administration mandate or endorse ASTM

labels which would specify performance in either

the 20-50% range or 50-100% range. He will

further emphasize that this range can be the

basis for further effort. The ASTM label can be

conceived as the Push effort in a two part

push-pull sequence.

In the push-pull concept you want to minimize

Push e.g. “require” and to maximize

Pull e.g. “incentivize ”.

.

.

What incentives do individuals, universities,

fitness centers, and malls have to require

something more than the ASTM 50-100 label? The

answer is survival. Let’s say occupancy

and mask efficiency are directly proportional.

As a theater operator would you rather have 50%

or 100% of the seats filled.

The basic requirement

for anyone in public space can be the

ASTM 50-100 in the U.S. In Europe it will be the

tough regulations already in place (see below).

In addition there can be safe bubbles where

efficiency requirements higher than 50% are the

price of entry. Europe has 70% and 90%

efficiency levels. When people understand that

90% + 90% x 10% = 99%

whereas 70% + 70% x 30% = 91% and that

the virus risk is nine times lower with the 90%

masks there will be many safe bubble operators

who will opt for the higher efficiency. If the

hotel down the street has a 90% bubble the other

hotels will want to offer the same level of

safety.

The “Pull” safety level can be validated by a

seal similar to the Eurofins “Tested Quality

Seal” shown below. Eurofins with many thousands

of employees around the world is well positioned

to create a seal which the public will

recognize.

SGS is another large organization which could

create its own seal. A few organizations with

international reach can create competing seals.

A mask could carry both the ASTM 50-100 label

and the Tested Quality Seal which would show a

specific level of efficiency e.g. 90%.

The Tested Quality Seal validates not only the

theoretical performance of a mask but the

adherence to quality control throughout the

manufacturing and distribution process. The

quality control problems with a number of

Chinese masks demonstrates the need for quality

control validation.

Do we create a monopoly for a few large

organizations such as Eurofins or SGS? We can

avoid this by having sufficient numbers of

Tested Quality Seal providers. A large testing

organization such as Nelson Laboratories can

elect to partner with quality control

capabilities such as MPR and create an

alternative Tested Quality Seal.

Validation of Fitted Mask Efficiency Still will

be Needed

Some mask companies such as Vogmask have five

different sizes and spend a lot of time making

sure customers wear masks properly. Keith

Dellagrotta will be speaking tomorrow about

using the iPhone for a facial scan and then

analysis of the Vogmask fit. We also asked Keith

about the broader use for people entering a

facility. He replied “As an ER doctor, I am very

familiar with the annual N95 fit test

requirement by OSHA. Our technology involving

just the facial scan and virtual overlay of the

mask would be simpler and much less subjective.

We have not pursued this pathway yet but it

remains on our radar.”

Our recent Alerts have pursued thermal imaging

at entrances as a way to validate mask fit.

Alternatively just a visual inspection

may be an option. Mask fit inspection will be

both difficult and politically challenging. But

with reference to our automobile safety analysis

in the previous Alert it is achievable. It may

take time. After all seat belts were only

required decades after people started driving.

On the other hand operators of safe bubbles will

not want to take chances. A restaurant is less

worried about being shut down for sanitary

violations than it is in sickening a number of

people and creating damage to its public image.

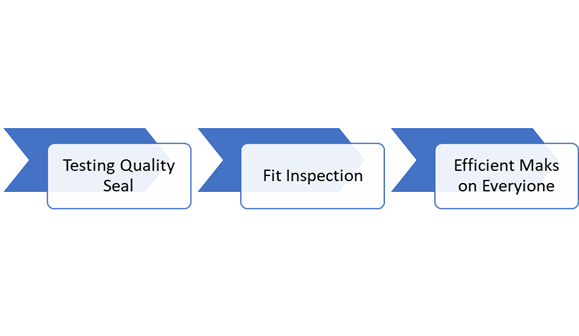

Five Step Approach Needed

Success depends on a five-stage sequence. Mask

quality has to be addressed starting with

manufacturing and ending with the final fit

inspection.

Fit Inspection will be the last step in a

process which will insure efficient masks for

everyone.

the process has built in flexibility.

Much of it can be implemented immediately. Other

parts will need to be improved over time.

Since speed is crtical the five step

process is a route which will most quickly

accomplish the objectives

Eurofins has a Tested Quality Seal for Community

Masks

Eurofins provides high-standard quality

assurance and control services throughout the

supply chain.

Manufacturers are responsible for ensuring that

the masks they supply and put on the market

comply with safety and effectiveness

requirements and the standards required in the

country in which they are sold. Eurofins

laboratories are ISO/IEC17025:2017 accredited

for Particulate Filtration Efficiency testing

(PFE), Bacterial Filtration Efficiency testing

(BFE) and differential pressure (breathability),

delivering precise, reliable and accurate

testing results to customers for EN, ISO and

ASTM test methods. Another important

consideration is the information made available

to consumers at the point of purchase.

Well-designed product specifications and claims

help to ensure that the user can easily and

correctly access, understand and use the mask.

Eurofins offers check service for marking,

labelling and instructions of use, according to

the recommendations by the national Authorities.

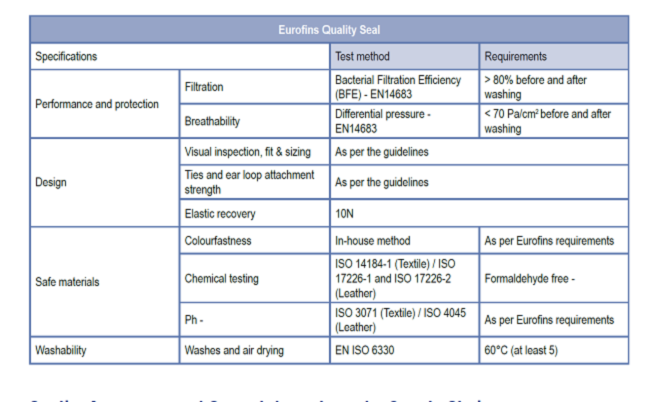

Tested Quality Seal

In an effort to provide

clients with proof of compliance for

hygienic masks, Eurofins experts have developed

the Tested Quality Seal for Community masks,

which will be granted to masks meeting the

thoroughly designed testing protocols.

Quality Assurance and Control throughout the

Supply Chain: Whatever the role in the supply

chain, it’s important to safeguard the

reputation of the brand and/or that of the

client. From suppliers’ assessments and R&D

support to regulatory guidance and supply chain

mapping, all the way through to compliance and

bespoke testing, QC inspections, failure

analysis and market surveillance, Eurofins cover

every stage of the product’s quality journey.

Marking checks on labels, packaging and

instructions for use: Marking on the product,

whether directly or on a label, and/or on its

packaging and instruction manual, is mandatory

and must be displayed in the applicable official

domestic language(s) and observe the wording as

defined in the country-specific legislation.

Eurofins’ label and marking check service

includes: • Completion of name, trademark,

address and contact details of the responsible

actor (producer or importer) • Product batch ID

(whenever applicable) • If tested against the

CWA document: “Community face coverings CWA”,

followed by the version of the CWA document

concerned • The filtration efficiency level,

method used and standard • Durability i.e.

reusable or disposable • Targeted user age e.g.

child or adult • Restriction warning e.g. “Not

suitable for children under 3 years of age”.

Eurofins experts

have developed the Tested Quality seal for

Community masks, which will be granted to masks

meeting the thoroughly designed testing

protocols

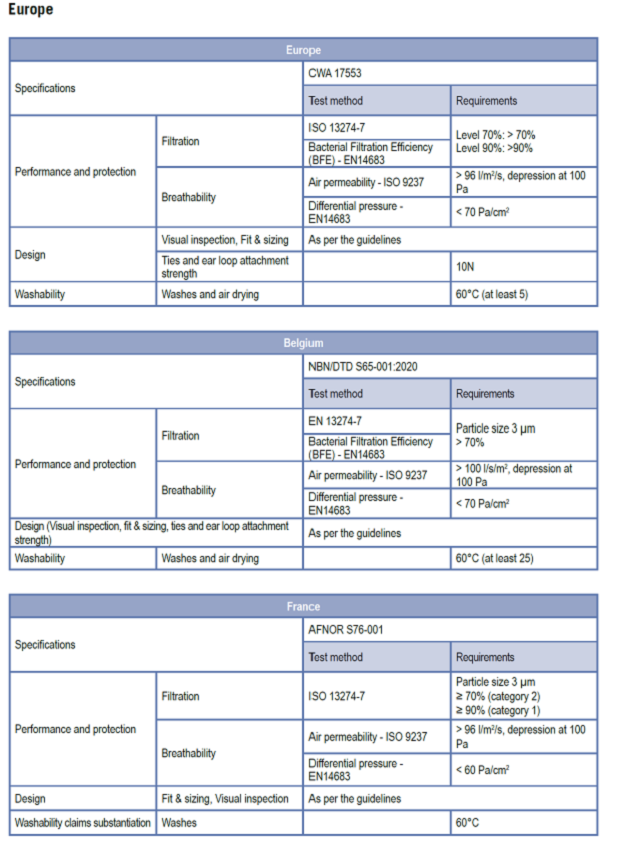

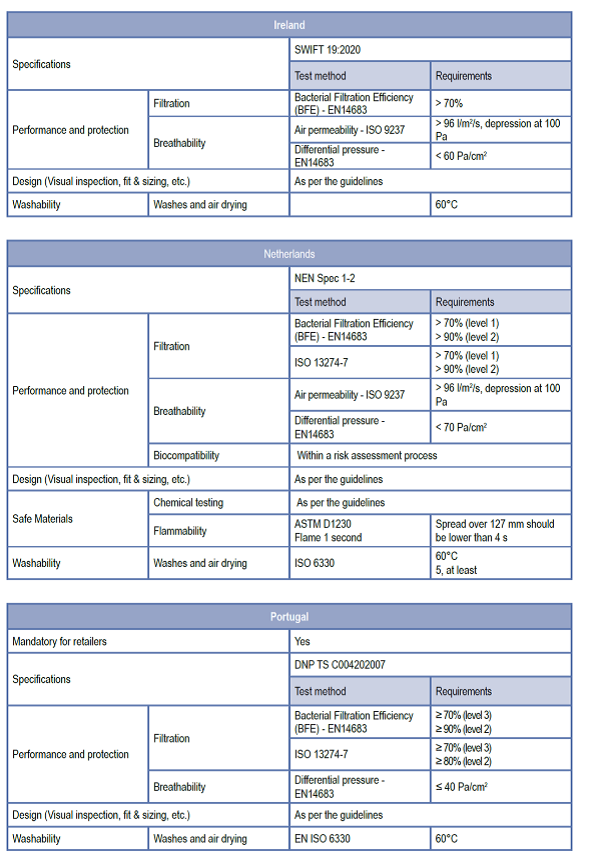

The specific requirements in Europe and

individual countries are shown below.

Details on other European regulations are also

provided on the Eurofins site at

https://cdnmedia.eurofins.com/corporate-eurofins/media/12153917/ef-brochure-community-masks-en.pdf

ATI Supplies Both Mask PFE and Resistance

Testers

Mask Particle Filtration Efficiency (PFE) Tester

is used to test the particle filtration

efficiency (oil or non-oil particle) of face

masks, mask raw fabric (meltblown non-woven),

results in percentage level, such N95 means 95%

filtration level.

Mask Respiratory Resistance Tester adopts a

replaceable head-shape model, can test varied

mask sizes for adults or children; Equipped with

a high-quality flowmeter providing steady

airflow, which increases the accuracy of the

resistance testing results.

SPECIFICATIONS:

-

Air source: air compressor

-

Flowmeter range: 0L/min ~

100L/min, accuracy is ±2%.

-

Micro-pressure measuring range:

-1000Pa~1000Pa,

precision 1Pa

-

Pump capacity requirement:

≥100L/min

-

Constant ventilation volume:

(85±1)L/min

-

Display mode: touch screen

display

-

Test time: As required,

adjustable

-

Automatically record the test

data: Yes

-

Power supply: AC220V±10%, 50Hz,

0.6KW

Ambrust American Expands Meltblown Capacity

With first responders across the country

suffering from shortages, PPE manufacturer Armbrust

American today announced that its factories are

now capable of producing meltblown, the

non-woven fabric material that is crucial to

filtering out microscopic particulate matter

such as the coronavirus.

Armbrust American's Texas-based medical mask

facility & meltblown machine.

In 2019 less than 3 million tons of meltblown

material was produced in China, which isn't

enough to manufacture a sufficient supply of PPE

like surgical and N95 respirator masks. The move

to produce its own meltblown allows Armbrust

American to control costs and better scale its

operations so that America's first responders

have the protection they need.

"Nine months into this pandemic, a lack of

domestic manufacturing is the only explanation

for why America still does not have enough PPE,"

said Founder and CEO Lloyd Armbrust.

"Investing to produce our own meltblown means we

aren't dependent on other countries, who are

more than willing to profit from our lack of

preparation."

Meltblown is made from plastic polypropylene

pellets that are melted down and "blown" into a

nonwoven fabric sheet, which then gets a static

charge to improve filter effectiveness. The

majority of meltblown material is manufactured

in China and sold to U.S. manufacturers at a

great cost. This has caused prices for PPE to

skyrocket, with some health service providers

now passing those exuberant expenses to patients

in the form of surcharges, according to recent reports.

"PPE prices skyrocketed globally during this

pandemic because China controls the supply, and

the situation is scarcely better today. So when

demand for PPE rises, America is once again at

their mercy, unable to deliver products and held

hostage to rampant price gouging," said Armbrust

American President Landon Morales. "We can't

rely on other countries to supply masks. America

needs to take care of itself."

Armbrust is manufacturing a new Electrostatic

Armor ® Meltblown, the company's new proprietary

blend of meltblown filtration material that more

easily adds a static charge and allows those

wearing a mask greater breathability. Despite

the premium quality and proprietary process, the

company is still able to keep costs lower than

what is sold from China.

"The shortage has caused people to rely on

reusable cloth masks that offer as little as 10%

protection against the coronavirus. And now our

hospitals are subsidizing Chinese companies to

produce something that can be made better and

cheaper at home," Armbrust said.