Coronavirus

Technology Solutions

December 18, 2020

The Foundation

of COVID

Mitigation

Strategy Should

be Mask

Effectiveness

Cummins is

Making Masks

with Uniquely

Charged

Meltblowns

BelEmsa

Producing

200 Million

Masks per Month

H+V will

Expand to 100

Million Mask

Equivalents per

Year

Lincoln, RI

Buys Air

Purifiers for

Schools

Outdoor Air

Reliance in NY

is not a Great

Winter Solution

________________________________________________________________________

The Foundation

of COVID

Mitigation

Strategy Should

be Mask

Effectiveness

The strategy to

defeat COVID

should be based

on use of highly

efficient masks.

All other

options are more

costly and less

effective with

the exception of

total lockdowns.

The virus spread

with near normal

activity but

correct use of

CATER 95 masks

will be less

than if there is

a partial

lockdown and use

of ASTM 20

masks.

The strategy

which treats all

masks as equal

makes little

sense. It is the

equivalent of

saying that

whether a room

has one occupant

or 100 the risks

are the same. In

fact if all

occupants are

wearing CATER 95

masks the risk

is equivalent to

the room with

one unmasked

occupant. If

every one of the

100 people is

wearing

an ASTM

20 mask you have

the equivalent

of 71 unmasked

people. This 70

to 1 ratio means

that mask

efficiency

should be the

cornerstone of

COVID policy.

The following

examples were

calculated based

on available

information for

various types of

masks. The net

efficiency

equals the media

efficiency less

leaks.

|

Mask |

Efficiency % |

Leaks % |

Net Efficiency % |

|

CATER 99 |

99 |

-4 |

95 |

|

CATER 95 |

95 |

-4 |

91 |

|

CATER 93 |

93 |

-4 |

89 |

|

ASTM 50 |

50 |

-20 |

40 |

|

ASTM 20 |

20 |

-20 |

16 |

The leaks are

derived from fit

testing and

cannot be

precisely

quantified in a

given case. One

comprehensive

set of tests

with a CATER 95

masks showed

leakage between

2 and 8 %. The

actual leakage

depends on the

face, the mask

dimensions and

construction.

Where suppliers

can show a range

of mask sizes

and extensive

testing under

various motion

conditions a low

leakage level

can be assessed.

In the case of

the upcoming

ASTM standards

the leakage

declaration is

left to the

manufacturer

with little

assurance that

low leakage will

be achieved in

any specific

situation.

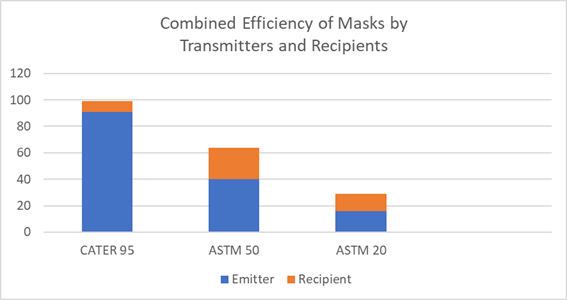

Masks are worn

by the both the

transmitter and

the recipient.

So the total

virus inhaled

becomes a

function of the

removal in the

two sets of

masks.

|

Virus Penetration as a Percent of Total Load |

||||

|

Mask Type |

Location |

CATER 95 |

ASTM 50 |

ASTM 20 |

|

Virus Leaks |

Emitter |

4 |

20 |

20 |

|

Virus Penetration |

Emitter

|

5 |

40 |

64 |

|

Total Virus Emission |

Emitter |

9 |

60 |

84 |

|

Virus Leaks |

Recipient |

0.36 |

12 |

17 |

|

Virus Penetration |

Recipient |

0.45 |

24 |

54 |

|

Total Virus Inhaled |

Recipient |

0.85 |

36 |

71 |

The CATER 95

mask is

therefore 71

times more

effective at

preventing virus

inhalation than

is an ASTM 20

mask. Granted

that fitness and

other variables

are not

precisely

quantified but

this is a

reasonable

comparison.

Another approach

is to compare

combined

efficiency.

If the decision

is made on a

basis of

comparative

efficiency it is

easy to argue

that a less

efficient mask

is better than

nothing. At

least an ASTM 20

will remove 29%

of the virus if

worn by all.

But when

you consider

that it allows

71 times as much

virus to

penetrate as

does a CATER 95

mask this is a

powerful metric

and one that can

be used in a

total plan which

includes social

distancing,

HVAC, and

lockdowns.

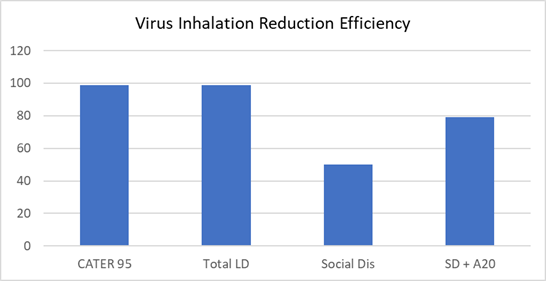

The selection of

more efficient

masks can be

viewed from the

perspective of

resumption of

more normal

behavior.

Rigorous Social

distancing

including

prevention of

large gatherings

could have an

effect of

reducing virus

inhalation by

40%.

If

partial lockdown

is combined with

ASTM 20 masks a

total reduction

of 79% might be

achieved. It

could be argued

that if everyone

wore CATER 95

mask you could

eliminate most

social

distancing. In

the case of bars

fan filter units

and directional

air flow would

be needed

because of the

need to remove

masks while

drinking or

eating.

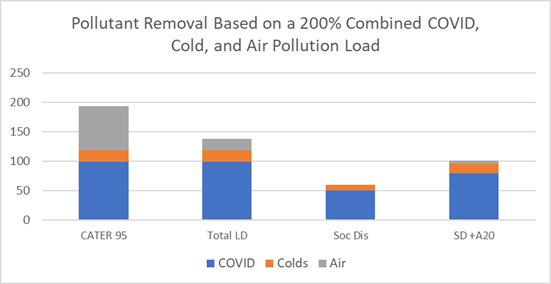

The value of

CATER 95 masks

is even greater

compared to

alternatives

when you

consider that

air pollution,

wildfires and

other air

contaminants are

equally

important.

Hypothetically

let’s assume a

total load which

is 200% of the

COVID. So the

COVID load could

equal 50% of the

contamination

(100), colds and

other virus

related

infections are

10% (20) and air

pollutants and

other air

contaminants are

40% (80).

The graph

then reflects a

total

contaminant load

of 200

It is clear that

the benefit of

CATER 95 masks

is far superior

to the

alternatives

when all

pollutants are

considered.

Social

distancing does

not reduce the

amount of air

pollutants

inhaled.

Mask efficiency

should be the

basis of all the

social

distancing,

lockdowns,

school, bar and

restaurant

openings. If

everyone wears a

highly efficient

mask there will

be the ability

to return to

near normal

activities while

reducing the

COVID spread.

Ignoring mask

efficiency is as

illogical as

saying social

distancing of

one foot or one

mile should be

treated equally.

The mask

protection has

been proven in

every pandemic.

Doctors were

kept safe from

EBOLA by wearing

masks and taking

other

protections. The

highly

efficient masks

provided the 99

% protection but

other PPE

assured that the

protection was

99.9999%.

It is

recommended that

we immediately

change our

strategy and

consider mask

effectiveness as

the foundation

of any program.

Cummins is

Making Masks

with Uniquely

Charged

Meltblowns

Cummins is

making material

for millions of

face masks out

of its

Cookeville, TN,

filtration plant

— thanks to a

partnership with

the U.S.

Department of

Energy’s Oak

Ridge National

Laboratory nearby.

“Because of our

expertise in the

automotive

filtration

industry, we

believed we

could adapt to

supply the

filter media

used in the face

masks worn by

healthcare

providers, which

are also in high

demand across

the nation,”

Christopher

Holm, director

of filter media

technology and

IP at Cummins,

said in a news

release posted

yesterday.

Oak Ridge’s

Carbon Fiber

Technology

Facility

meanwhile worked

with Peter Tsai,

the inventor of

N95 filter

media, to

develop a novel

in-line charging

device that

could be placed

on the precursor

production line

to

electrostatically

charge

melt-blown

material made of

polypropylene or

PP.

Electrostatically

charging the

material with

millions of

microfibers

layered on top

of each other

creates a filter

material able to

remove more than

95% of submicron

particles and

viruses such as

the one that

causes COVID-19.

“We reached our

target goal in

only a few weeks

on pilot scale

melt blowing

capability at

the CFTF and had

the capability

to produce

filter media for

9,000 masks per

hour when we

connected with

Cummins for

potential

technology

transfer and

scale up,” said

Merlin Theodore,

director of the

CFTF at Oak

Ridge. “Cummins

was an ideal

partner to scale

what we had

accomplished and

helped us

produce material

that passed all

required testing

for filter

media.”

ORNL’s research

team designed

and manufactured

a custom

electrostatic

charging device

for Cummins,

assisting in the

installation of

the device on

the company’s

Cookeville

facility

production line.

“Their research

has made it

possible to be

where we are

today,” Holm

said. “We can

manufacture

material that

has passed all

the required

testing for N95

filter media.”

Two months ago,

Cummins had

never produced

filter media for

face masks.

Today, it’s

already shipped

material to

multiple

customers across

the country for

the production

of millions of

masks.

BelEmsa

Producing 200

Million Masks

per Month

BelEmsa, one of

the leading

manufacturers of

disposable

hygienic

products, has

increased mask

production to

200 million

pieces per month

in Europe,

according to

Aleksandr

Kolesnov, the

first deputy

director of

BelEmsa in an

article in

Nonwovens

Industry.

In the fight

against the

novel

coronavirus,

medical masks

are a vital item

for healthcare

workers on the

frontline.

Kolesnov states,

“We are fully

aware that

access to PPE is

challenging and

we must secure

the production

of such an

important item

to encourage

business

organizations

and public

health through

the recovery

period.”

Detailed

research on face

masks have been

conducted by the

BelEmsa R&D

project team

since the

beginning of the

Covid-19

outbreak,

Kolesnov adds.

“We were aware

that performance

and comfort

requirements

must be offered

under hygienic

conditions due

to public needs.

We applied

extensive

know-how

accumulated

through our

experience and

created soft ear

loop masks for

perfect fit and

comfortable use.

Meanwhile,

BelEmsa worked

closely with EC

accredited

laboratories and

German Federal

Institute for

Drugs and

Medical Devices

(BfArM) for

manufacturing

facilities at

European

standards.

"We risk

significant

amount of funds

and invested

millions in

machinery, raw

materials,

hundreds of new

employees and

factory space to

manufacture an

item projected

to have a

short-lived

demand. However,

contributing to

society has

become one of

our key

priorities under

the current

circumstances,”

he continues.

According to

Kolesnov,

BelEmsa has

never

experienced

challenges in

nonwoven

materials,

logistics and

other key

equipment thanks

to its long

standing

experience and

reputation in

the hygiene

industry. He

adds, “We have

always been a

reliable partner

to the

governments and

healthcare

institutions to

ensure

high-quality

medical

products."

Kolesnov ends,

“I’m proud of

the fantastic

efforts of our

operational team

who took our

business out of

China and

brought to home.

BelEmsa become

the first

company

producing what

it says is a

unique

comfortable ear

loop mask in

Europe and

offering this

innovative item

with the Senso

Med brand since

June.”

H+V will Expand

to 100 Million

Mask Equivalents

per Year

The Department

of Defense

(DOD), in

coordination

with the

Department of

Health and Human

Services (HHS),

has awarded a

$2.5 million

contract to

nonwovens

manufacturer

Hollingsworth &

Vose, to

increase

domestic

production

capability of

filter media.

This industrial

base expansion

effort will

allow

Hollingsworth &

Vose to increase

production

capacity to 100

million mask

equivalents per

year in Floyd,

VA by October

2021, to support

the production

of filter media.

The DOD’s

Defense Assisted

Acquisition Cell

led this effort

in coordination

with the

Department of

the Air Force’s

Acquisition

COVID-19 Task

Force. This

effort, funded

through the HHS

Coronavirus Aid,

Relief and

Economic

Security (CARES)

Act, supports

domestic

industrial base

expansion for

critical medical

resources.

Lincoln, RI Buys

Air Purifiers

for Schools

All told,

Lincoln Public

Schools have

spent roughly

$1.2 million in

unbudgeted funds

responding to

the COVID-19

pandemic.

Lincoln schools

received four

separate grants

to assist with

safely reopening

in the COVID

environment.

The first source

was the

Coronavirus Aid,

Relief and

Economic

Security (CARES)

Act – money

specifically

allocated to

elementary and

secondary

schools for a

wide range of

activities,

including the

prevention,

preparation for

and response to

the coronavirus.

Gov. Gina

Raimondo awarded

Lincoln with

$472,779 to help

fill a gap in

state aid to

education.

Essentially,

McNamee said the

state shorted

Lincoln in

education aid

this year but

replaced the

shortfall with

CARES Act

Elementary and

Secondary School

Emergency Relief

funds.

Secondly, the

state of Rhode

Island was

provided with

roughly $1.25

billion in

federal

coronavirus

relief funds

under the CARES

Act. Of that

number, Raimondo

allocated $50

million for the

schools, with

Lincoln

receiving

$570,908.

Lincoln spent an

additional

$64,234,

provided by the

Council on

Elementary and

Secondary

Education, to

purchase

portable air

filtration units

and make

improvements to

all of the

schools’

existing air

filtration and

ventilation

systems.

In total,

Lincoln schools

received

$1,159,916 in

COVID relief.

Outdoor Air

Reliance in NY

is not a Great

Winter Solution

My feet are

starting to

freeze,” a

Brooklyn

public-school

teacher tweeted on

December 9, when

she had two

classroom

windows open

despite the

temperature

outdoors

dropping to 31

degrees. Despite

the weather

getting colder,

she said

teachers in her

building have

been told to

keep the windows

open

indefinitely.

It’s the same in

schools across

the city, where

scores of NYC

elementary

teachers and

students are

bundled up in

frigid

classrooms to

prevent the

spread of the

coronavirus.

Is this the best

that New York

City schools can

offer? Until the

city upgrades

hundreds of New

York City school

buildings, the

short answer is

yes. Ventilation

systems in the

buildings built

in the early

1900s “basically

rely entirely on

open windows,

like the whole

one wall of a

classroom is

just all

windows,” said

Edward Olmsted,

an industrial

hygienist, whose

job it is to

make sure that

an indoor space

has good air

quality with no

mold or other

contaminants.

Olmsted serves

as a consultant

for the United

Federation of

Teachers (UFT)

and has been

working on

fixing school

ventilation

issues since the

summer. A lot of

these prewar

school buildings

built during the

Spanish flu

pandemic were

designed to keep

airborne

illnesses at bay

with steam

radiators overheating

rooms and the

windows always

open — but a

century later,

that doesn’t

always work in

practice. The

city’s

Department of

Education also

issued new

guidance that

when the room

temperatures are

uncomfortably

cold, custodians

should raise

boiler settings

and preheat the

building — but

this still

leaves teachers

and students

shivering in

class.

Newer school

buildings have

better

ventilations

systems, but the

problem is that

schools — old or

new — now need

the kinds of

systems found in

hospitals.

“Nobody builds a

regular building

that way, so

suddenly

everybody is

being asked to

upgrade their

ventilation

systems, to

really perform

like it would in

a hospital,”

Olmsted said.

“[But] you can’t

just easily make

a few changes,

turn a few

screws, or

change a couple

pieces or parts,

and suddenly

it’s a hospital

system; it can’t

be done.” A

typical fan

system’s filter

is rated MERV 8,

while hospitals

usually have

MERV 15 or 16

filters (the

higher the MERV

numbers, the

smaller the dust

particles it can

filter out).

Experts are now

recommending

MERV 13 filters,

which remove

about 90 percent

of the aerosol

that could carry

infectious virus

particles.

The DOE is now installing

thousands of

MERV 13 filters,

prioritizing

buildings with a

central HVAC

system or no

windows. The

agency is also

installing

30,000 High

Efficiency

Particulate Air

or HEPA purifier

units in

classrooms,

which capture over

99 percent of

particles in the

air.

Once these

purifiers are

installed,

classroom

windows don’t

need to remain

open, said a DOE

spokesperson.

The agency

expects to

deliver an

additional

30,000 purifiers

by January,

according to an

internal memo

sent to DOE

custodians. Once

the 60,000 units

are installed,

this should

cover most of

the classrooms

that need it,

said the

department.

But some parents

are skeptical.

“I am not

confident that

those air

purifiers will

be enough to

circulate the

air. I am not

confident that

if they do show

up, they will be

working,” Naomi

Peña, director

of the Community

Education

Council for

District 1 and

public-school

mom, told me.

She may have a

point. According

to the EPA,

both filters and

air purifiers

are effective at

filtering out

coronavirus

particles, but

by themselves

are not enough —

they should be

used in

conjunction with

mask-wearing,

social

distancing, and

other common

safety

practices — like

opening windows.

Though Peña’s

children are

studying

remotely, they

see their

classmates at

the school via

Zoom. Her

11-year old son

was puzzled to

see one of his

friends wearing

a coat inside

the classroom

and asked her,

“Why can’t he

just come over

to our house so

he can be warm?”

And he has a

point, Peña

says. “When it’s

cold and you’re

wearing gloves

and a coat … How

can you possibly

learn?”

Doug Engel

analyzed the

changes in

thinking

relative to HVAC

strategy to

fight Covid in

the December

issue of

Facility

Executive.

As he

points out

ASHRAE’s

Epidemic Task

Force (ETF) has

been at the

forefront of

providing

actionable

recommendations

for mitigating

the airborne

transmission of

COVID-19 in

buildings.

Initially ASHRAE

recommended

maximizing the

outside air

intake of

mechanical

systems and

minimizing

recirculation.

It encouraged

opening windows

and increasing

ventilation with

fans.

High-efficiency

filtration was

an additional

key

consideration,

with guidance

urging an

upgrade to a

minimum of MERV

13 filters for

central HVAC

systems. In the

absence of

central systems,

or if they could

not accommodate

high-efficiency

filtration, then

it was

recommended that

“demonstrated

safe and

effective”

in-room air

cleaners be

employed.

Since the

Spring, however,

several

developments

have contributed

to a shift in

thinking

regarding early

guidance. Dr.

Bill Bahnfleth,

Professor of

Architectural

Engineering at

Penn State and

Chair of the

ASHRAE ETF,

recently shared

in a widely

attended October

webinar that

early guidance

from the ETF in

April was driven

by perceived

risk and

possible

effectiveness.

He referred to

the initial

recommendations

as

“conservative”

and that they

“did not factor

in cost and

operational

impacts.” Also,

he outlined key

factors that

have prompted a

re-evaluation of

the guidance and

previewed new

core

recommendations

that will be

forthcoming from

ASHRAE.

KEY FACTORS

Risk

estimations. Increased

use of tools

that estimate

airborne

transmission

offers a

quantitative

prediction of

risk. There are

a number of

estimators, but

the most widely

used is The

COVID Airborne

Transmission

Estimator,²

created by

Professor

Jimenez of the

CIRES

(Cooperative

Institute for

Research in

Environmental

Sciences) at CU

Boulder. This

estimator, and

others, rely on

the Wells-Riley

model, an

accepted

industry

standard

approach for

assessing the

risk of airborne

infection in

buildings. The

Wells-Riley

model takes into

account factors

such as the size

of the building,

number of

occupants,

number of

infected people,

and the amount

of time infected

individuals

spend in the

building.

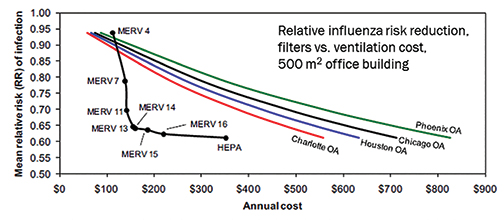

Equivalent

filtration

effectiveness. In

numerous

presentations,

Prof. Bahnfleth

has emphasized

high efficiency

filtration, and

reiterated that

guidance in the

recent webinar,

“We have

evidence that

better

filtration is as

effective as

ventilation and

lower cost.” He

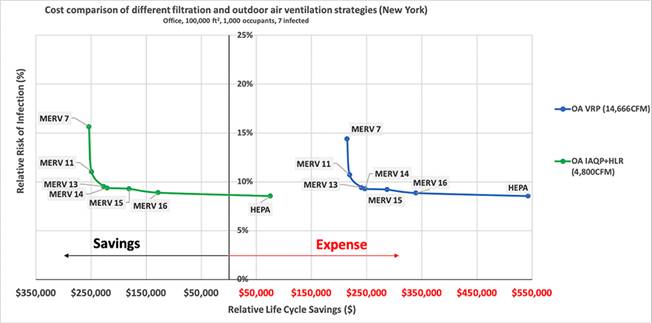

referenced this

analysis

conducted by

Prof. Brent

Stephens and

Parham Azimi for

the Built

Environment

Research Group

at Illinois Tech

that shows the

relative cost of

outside air

ventilation in

different U.S.

locations versus

filtration.

The graph below

shows that the

most

cost-effective

and efficient

approach to

reducing

infection rates

is using a MERV

13 filter, and

that outdoor air

increases cost

at least four

times as much to

achieve the same

benefit.

Energy,

economic, and

operational

considerations. Prof.

Bahnfleth also

spoke to the

fact that ASHRAE

has taken a

closer look at

the energy,

economic, and

operational

impacts of HVAC

strategies for

COVID

mitigation,

particularly its

guidance on

ventilation. As

many in the

industry have

pointed out,

maximizing

outside air

ventilation is

expensive and

energy

intensive—the

often-cited

“energy penalty”

associated with

conditioning

increased

amounts of

outdoor air. It

is even more of

a concern during

the

energy-intensive

winter months.

Additionally,

there are other

environmental

considerations

that need to be

factored in: PM

2.5 from

pollution and

the smoke from

wildfires

plaguing the

western U.S. are

two significant

concerns.

Relative

humidity also

plays a role, as

research

emphasizes³ the

need to keep

relative

humidity between

40-60% to both

reduce the

transmission

risk of the

virus and to

support the

respiratory

health of

building

occupants.

Equivalent

outdoor air

changes. The

Air Change Rate,

e.g., the rate

at which the air

in a specific

space is

replaced with

clean air is

typically

expressed in Air

Changes per Hour

(ACH). ACH has

been assumed to

refer to outdoor

air exchanges.

However, with

limitations of

HVAC systems,

the superiority

of highly

filtered air

given

environmental

issues such as

pollution/smoke,

and new

consideration of

energy impacts,

experts are now

promoting

“equivalent

outdoor air”

changes. These

equivalencies

can be achieved

by deploying

high-efficiency

filtration,

in-room HEPA

filters, as well

as innovative

approaches such

as sorbent-based

filtration.

A helpful tool

for school

facility

managers is the

Harvard-CU

Boulder Portable

Air Cleaner

Calculator for

Schools. It

simplifies

decision making

around deploying

in-room air

cleaners and can

also be adapted

for office and

retail

settings. Experts

from the Harvard

T.H. Chan School

for Public

Health recommend

5 ACH per hour,

but provide

ranges, with 4-5

ACH as Good, 5-6

as Excellent and

6 ACH as Ideal.

SIMPLIFYING

GUIDANCE

The ASHRAE ETF

will likely

share new core

recommendations

before the end

of 2020, with

the goal of

updating

guidance to

reflect the

above factors,

and to simplify

recommendations

across its

various

subcommittees.

From the preview

Prof. Bahnfleth

offered,

the

update will

likely

emphasize:

·

Use of minimum

outdoor air as

required by

Standard 62.1

·

Employ

high-efficiency

MERV 13

filtration

and/or

stand-alone HEPA

air cleaners for

recirculated air

·

Achieve

equivalent air

changes using a

combination of

outdoor air,

filtration, and

air cleaners

·

HVAC controls

that achieve

exposure

reduction goals

while minimizing

associated

energy penalties

ENERGY,

ECONOMIC, AND

CARBON

With the renewed

focus on cost

from increased

energy

consumption,

there is a need

for a tool to

help calculate

costs of various

ventilation and

filtration

approaches.

While risk is

the paramount

consideration,

models providing

a more complete

picture allows

for more

informed

decision-making

Doug says

his

company, enVerid,

has released the

enVerid COVID-19

Energy

Estimator, an

open-source,

vetted tool

building upon

Prof. Jimenez’s

COVID Airborne

Transmission

Estimator. This

tool performs

predictive

calculations for

energy

expenditures. In

addition to

enabling a

comparison of

energy use among

HVAC strategies,

it offers

insight into

anticipated

carbon emissions

associated with

each approach.

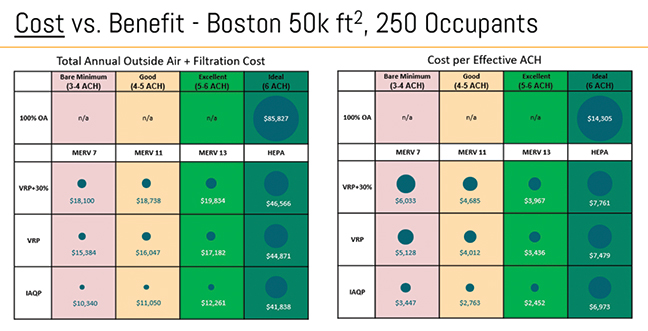

For example,

building

engineers

evaluating a

50,000 square

foot office in

Boston with 250

occupants and

design supply

air of 50,000

CFM can compare

two

approaches—switching

to 100% outside

air (OA) or

upgrading to

MERV 13

high-efficiency

filters and

bringing in

minimum OA as

per ASHRAE’s

Indoor Air

Quality

Procedure

(IAQP).

As shown in the

table below, the

Energy Estimator

shows both

strategies will

deliver over

five effective

air changes per

hour (ACH),

considered

excellent by the

Harvard School

of Public

Health, but the

100% OA strategy

will cost

$85,827 per year

compared to

$12,261 per year

for the

MERV13/IAQP

approach. When

reviewing the

carbon impacts

of the two

approaches, the

Energy Estimator

shows the 100%

OA strategy will

generate 325

metric tons of

CO2 per year

versus 28 metric

tons for the

MERV 13/IAQP

approach.

This graph shows

findings that

the most

cost-effective

and efficient

approach to

reducing

infection rates

is using a MERV

13 filter, and

that outdoor air

increases cost

at least four

times as much to

achieve the same

benefit. (Graph:

Provided by

enVerid)

AN UNDERUTILIZED

APPROACH

Given the

current focus on

IAQ, it makes

sense that

building

management and

engineers take a

close look at

ASHRAE’s Indoor

Air Quality

Procedure. In

its Standard

62.1, ASHRAE

defines two

procedures for

mechanical

ventilation: the

Ventilation Rate

Procedure (VRP)

and the Indoor

Air Quality

Procedure

(IAQP). VRP

defines

ventilation

requirements

based on space

size and

occupancy

without

factoring in the

efficiency

benefits

afforded by air

cleaning

technologies.

Alternatively,

IAQP is a

performance-based

ventilation

approach that

achieves the

same results

with less

outside air, and

therefore a

reduction in

energy expenses,

particularly

when employing

air scrubbing

technology.

Designing HVAC

systems using

IAQP combined

with sorbent-based

air cleaning and

high-efficiency

filtration

significantly

reduces first

and operating

costs without

increasing the

risk of airborne

transmission of

viruses. When

put to the test

utilizing the

Wells-Riley

equation

described above,

it was found

that same

relative risk of

airborne

transmission can

be achieved with

improved

filtration and

reduced

ventilation when

ASHRAE’s 62.1

IAQP is used

with sorbent-based

air cleaning

technology.

Using this

approach,

savings from

reduced

ventilation can

more than offset

the cost of

increasing

filtration (see

graph below).

Modeling the

cost-benefit of

filtration and

ventilation to

reduce the risk

of infection by

SARS-CoV-2 in a

100,000 square

foot office

building in New

York City.

Comparison of

VRP (blue line)

and IAQP +

sorbent-based

air cleaning

(green). Life

cycle cost

includes first

cost and20 years

of operational

cost. (Graph:

Provided by

enVerid)

There are other

important IAQ

considerations

that arise from

utilizing

high-efficiency

filtration and

air scrubbing

technology:

·

ASHRAE’s

contaminants of

concern,

including

formaldehyde,

are scrubbed out

of the air.

·

By using less

outside air, it

is easier to

maintain

relative

humidity (RH) in

the 40-60% range

which experts

posit inhibits

the spread of

viruses. In

winter we are

concerned with

the dry air and

introducing more

outside air

would likely

cause the RH

figure to drop

below 40%.

·

Air scrubbing

reduces fine

particulates (PM

2.5) from

pollution or

smoke, while

ventilation

increases them.

Particulates

inflame the

lungs, making

catching the

virus

potentially more

likely and its

impacts more

severe.

·

Certain air

scrubbing

technologies can

also reduce CO2

levels. Research

from

Harvard points

to the

degradation of

cognitive

function when

CO2 levels rise

in indoor air,

an issue of

particular

concern in

schools and

offices.

·

Ozone exists in

outside air and

is known to

damage the lungs

and exacerbate

chronic

respiratory

conditions.

Building

engineers

evaluated a

50,000 square

foot office in

Boston with 250

occupants and

design supply

air of 50,000

CFM using the

enVerid COVID-19

Energy

Estimator. This

open-source,

vetted tool

performs

predictive

calculations for

energy

expenditures.

(Chart: Provided

by enVerid)

COVID-19 has

thrust IAQ

issues into the

spotlight.

Controlling

airborne

transmission of

the virus is the

most pressing

task, yet there

are a host of

IAQ

considerations

that need to be

addressed.

Facilities need

to employ

effective and

energy efficient

solutions to

respond to the

pandemic today,

and to future

proof for the

next crisis.

Additionally,

for many,

addressing IAQ

must also be

managed within

the context of

lowering a

building’s

carbon

footprint. This

is a tall order,

but all within

reach.

Doug Engel is

SVP quality

products

including

localized high-,

sales and

marketing for

enVerid Systems,

a Westwood-MA

provider of

commercial

indoor air

filtration

devices and the

award-winning

HVAC Load

Reduction®

(HLR®) module.

The complete

article is found

at

https://facilityexecutive.com/2020/12/indoor-air-quality-and-the-pandemic/