Coronavirus

Technology Solutions

December 15, 2020

WFI

Knows how

to Make a

Virtual

Conference

Valuable

Gates Says We

Will Not Be Back

to Normal Until

Sometime in the

First Half of

2022

Serum Institute

of India will be

a Critical

Vaccine Supplier

Allergens can be

Removed Along

with COVID

Mann + Hummel Uses Nanofiber Media in Engine Air Filters as Well as Masks

______________________________________________________________________________

WFI

Knows how

to Make a

Virtual

Conference

Valuable

Waterloo

Filtration

Institute

conducted the

first session in

a two day

conference on

air filtration

and COVID. There

were meaty

presentations,

good questions,

and a smooth

transition

between

speakers. This

first day

focused on

filters while

the one tomorrow

will focus on

masks. Here are

summaries for

the first day.

Cleaning Air

during A Global

Pandemic, Dr.

Thomas Caesar,

Freudenberg

Filtration

Technologies

General:

Air filtration

has never been

under such a

high public

focus than it is

today, during

the Covid19

pandemic,

especially as

there is strong

indication that

the SARS-CoV2

virus can spread

as aerosols via

the air. As the

virus may attach

to smaller or

larger particles

(solid or

liquid), a large

range of

particle sizes

has to be

considered from

some micrometers

down to the nano

scale. Air

handling units

using high

quality and

efficient fine

filters and by

regarding

specific advice

given that the

pandemic times

do reduce the

virus

concentration in

buildings.

Together with

other measures

like keeping

distance and

wearing face

masks this can

reduce the

infection risk

significantly.

Insight:

It is complex to

select the best

combination of

tactics to

achieve maximum

cost

effectiveness.

Recent advances

in assessing the

role of

respiratory

droplets in

spreading of

COVID-19, Dr.

Abhishek Saha,

University of

California San

Diego

General:

Respiratory

droplets play a

critical role in

the transmission

of the SARS-CoV2

virus,

responsible for

the current

COVID-19

pandemic. Hence,

it is important

to understand

and analyze the

mechanisms of

evaporation,

precipitation,

and transport of

these droplets

ejected from our

oral or nasal

cavities during

respiratory

events such as

sneezing,

coughing,

talking, or

breathing. In

this talk,

Ahishek

highlighted some

key aspects

which control

the lifetime of

these droplets

and connect it

to a pandemic

model in an

effort to assess

the growth in

the infected

population. He

also discussed

the relative

probabilistic

contributions

from droplets vs

aerosol in the

transmission of

this virus at

given ambient

climate

conditions. He

concluded the

presentation

with a note on

the importance

of masks in

restricting the

transmission of

respiratory

droplets and

showed how

improperly

designed masks

can have

severely

opposite

effects.

Insight:

Droplets

evaporate and

create small

salts which will

penetrate

inefficient

media.

Impact of COVID

2019 on the Air

Filtration

Industry, Bob

McIlvaine,

The McIlvaine

Company

General:

The Coronavirus

is not

disappearing. As

school has

started in

Europe, new

outbreaks have

arisen. Experts

now warn that

the deaths in

the U.S. will

range from

300,000 to

600,000 by the

end of the year.

India is

registering

90,000 new cases

per day. A

vaccine is not

going to be 100%

effective. There

is increasing

evidence that

much of the

transmission is

through small

aerosols. MERV 8

filters will not

remove a high

percentage of

the virus and

are likely to be

aerosol

generators for

larger droplets.

These conditions

create a very

large market

opportunity for

the filtration

industry. The

market will not

experience a

sharp peak as

the benefits of

cleaner indoor

air become

permanently

established.

Insight:

Media

effectiveness

for masks or

HVAC filters is

efficiency minus

resistance.

Center of

Excellence in

Protective

Equipment and

Materials, Dr.

Ravi

Selvaganapathy,

McMaster

University,

Canada

General:

The current

COVID-19

pandemic caught

Canada on a flat

foot. The

country did not

have sufficient

local

manufacturing

capability nor

testing and

validation

facilities to

respond quickly

when supply

chains across

the world shut

down. In this

talk, Ravi

described one of

Canada’s most

comprehensive

responses in

assisting local

manufacturing

and

establishment of

a test facility

that has enabled

local

manufacturers of

apparel,

automotive

components, and

construction to

pivot to the

manufacture of

personnel

protective

equipment (PPE).

In assisting

these companies,

broad outlines

of an integrated

research and

development

program were

realized, which

led to the

establishment of

the Center of

Excellence in

Protective

Equipment and

Materials

(CEPEM) as a one

of a kind

facility in

Canada.

The COVID

pandemic and its

aftermath have

significantly

changed how PPEs

are used. These

changes in use

call for a

significant

redesign of PPEs

as well as the

development of

new materials

and

manufacturing

processes suited

for further use

cases. There is

also a need for

the development

of specific and

custom standards

for the

evaluation of

PPEs in these

settings.

Finally, natural

and sustainable

materials need

to be

incorporated

into PPEs

instead of

fossil

fuel-derived

materials in

order to reduce

the impact of

their increased

use. All of

these

considerations

are

interrelated,

and a

comprehensive

research program

is required to

address all

aspects of this

problem. In this

talk, Ravi

provided

some examples of

such an

integrated

approach to the

development of

PPEs.

Insight:

A combination of

face shield and

filter has a

large amount of

filter media.

Shifting

Paradigms for

the Future of

Air Filtration,

Hunter Most, AAF

Flanders

General:

Indoor air

quality is at

the forefront of

the public

consciousness

more than ever

as facilities of

all types

continue to be

reoccupied after

pausing

operations due

to Covid-19.

Once a passing

thought for many

facility

managers, air

filtration is

now extremely

important as

they strive to

address the

concerns of

occupants.

Thinking of air

quality as a

matter of

safety, as

opposed to

simply comfort,

has dramatically

changed the way

that consumers

make decisions

regarding the

products and

services used to

attain clean

air. The

approach to

solving air

quality problems

has

fundamentally

changed as

decisions have

been informed by

shifting

paradigms with

respect to

almost every

aspect of the

technology. A

previously

common view of

filtration as a

commodity

product has

given way to a

highly

engineered,

value-driven

selection

process.

Facilities have

a renewed level

of focus on

materials,

performance

verification,

and cost

optimization as

they explore new

use cases for

filtration

technologies.

These paradigm

shifts affect

multiple

professional

disciplines. It

is critical that

these factors

are prioritized

as the

filtration and

HVAC industries

mobilize to meet

these new

challenges with

novel and

innovative

solutions. A

comprehensive

grasp of this

information is

also essential

across facility

management, life

safety, and

academia.

Cooperation from

such a

cross-sectional

shared

understanding

will provide the

best possible

built

environments

today and ensure

that the

environments of

tomorrow are

even better. IAQ

Health and

Safety Solutions

Associated with

COVID-19

Insight:

One paradigm

shift is from

comfort to

safety as a

driving force.

How the onset of

the Coronavirus

Pandemic has

forever

influenced the

air filtration

industry, Joe,

Gorman, Camfil

General:

On March 11,

2020, the World

Health

Organization

announced

publicly that

COVID-19 disease

was officially a

global pandemic.

During the

proceeding

months, and as

COVID-19 cases

grew across the

globe, a lot of

speculation grew

around the path

of transmission

of the

SARS-CoV-2

virus. To this

day, there is

still debate

around the

primary path of

transmission,

even though

there are

numerous studies

and research

professionals

who suggest the

virus can in

fact be

transmitted

through the air.

In May of 2020,

through the

advice of

ASHRAE, the

Center for

Disease Control

announced

publicly that

the recommended

filtration

efficiency for

public HVAC

systems should

be a minimum of

MERV 13 in order

to provide a

safe

environment.

This

announcement

sparked an

unprecedented

demand for

high-efficiency

air filters

without the

preparedness of

the air

filtration

industry, the

nonwoven media

suppliers and

the facility

engineers who

were blind-sided

by the HVAC

system changes

that would need

to be made. Now

that the general

population is

aware that

high-efficiency

air filtration

is crucial to

the overall

health of the

building

occupants, the

air filtration

industry as a

whole will

forever be

driven towards

delivering

high-performance

air filters to

the market.

Insight:

MERV 13 charged

meltblowns

quickly loses

efficiency to

below MERV

8.

A Closer Look at

Air Filtration,

Indoor Air

Quality and

Covid-19, Jim

Rosenthal,

Tex-Air Filters

General:

The world of

Indoor Air

Quality has gone

through a major

transition since

January of 2020.

Researchers and

practitioners,

including those

in the air

filtration

industry, are in

high demand to

provide good

information on

how to deal with

the spread of

Covid-19.

Building owners

and managers

need answers to

the many

questions about

making their

facilities safer

so that they can

be used

productively.

This

presentation

focused on how

air filters

affect indoor

air quality and

how air filters

can be used to

limit exposure

to Covid-19

aerosols. It

covered filter

efficiency and

explained why

certain levels

of filtration

are being

recommended. But

also focused on

filter

“effectiveness”

and drew on

recent research

to cover how and

where filters

should be used

to obtain

optimum results.

Insight:

Some

charged

meltblowns do

not lose

efficiency

quickly. If high

resistance in

MERV 13 reduces

air changes per

hour then it may

be less

effective than

MERV 8.

The Digital

Transformation

of Clean Air

Management, Dr.

Ellie, Amirnasr,

qlair

General:

It is no secret

that our world

has become

rapidly

digitized, and

facility

management is no

exception. With

the introduction

of smart

buildings and

IoT devices,

digital

solutions are

being developed

every day to

help facility

managers save

time, money, and

energy. But

while we attach

sensors and

monitors to just

about every

piece of

equipment in our

buildings, we

often overlook

the world’s most

valuable

asset... clean

air. Utilizing

clean air

management

effectively

involves

selecting the

right sensors

for your

facility’s

goals,

compiling, and

analyzing the

data to develop

actionable

insights, and

ultimately using

these data to

make critical,

informed

decisions on

what to do next.

In doing so,

your facility

will realize

significant

energy,

material, labor,

and operating

costs savings.

Insight:

Continuous

monitoring of

CO2,

particulate, and

RH provide very

valuable air

quality

management

tools.

Gates Says We

Will Not Be Back

to Normal Until

Sometime in the

First Half of

2022

Bill Gates says

the recent

groundbreaking

developments in

vaccines are a

good sign that

the end of the

pandemic could

be in sight, but

it will be some

time until the

entire world

sees its

benefits.

"By the summer

of 2021, the

rich countries

will have more

vaccine coverage

than other

countries," he

told the

Hindustan Times.

"So, the rich

countries will

be going mostly

back to normal.

But I still

think because

the virus will

be in the world,

we still will be

somewhat

conservative

about large

public events,

we will still

have some

mask-wearing.

"We really need

to get this

virus

eliminated,

almost

everywhere or

else we have

seen even in

countries that

have done a

super good job —

like Australia

or Singapore or

Hong Kong or

South Korea —

they always run

a risk of

reinfection.

"So they've had

to restrict

tourism and

other travel,

but by summer

that will start

to open up.

"They won't be

totally back to

normal but

sometime in the

first half of

2022, I do think

we will be able

to say that

we're back to

normal."

In another

interview with

NBC, Gates

warned that "the

next four or

five months will

be quite bleak"

due to it being

winter in the

northern

hemisphere.

Serum Institute

of India will be

a Critical

Vaccine Supplier

The factory at

the Serum

Institute of

India, a

manufacturer of

immunobiological

drugs, appears

ready to play a

global role in

the production

of Covid-19

vaccines, once

they are

developed,

because few

manufacturers

can match the

scale of its

facilities.

As a leading

supplier to the

developing

world, it is

also in the

forefront of

efforts to

combat “vaccine

nationalism,” where

wealthy

countries such

as the United

States pay to

secure a massive

number of doses

to help their

citizens first,

while poor

countries wait

at the back of

the line.

“The only choice

the world

community has is

to fire as many

barrels as

possible to try

and get as many

vaccines as

possible so as

to improve our

chances of

dealing with

this disease,”

said Adar

Poonawalla, the

company’s chief

executive.

Normal as it

might seem to

want to stop the

virus at home

before worrying

about the rest

of the world,

health experts

warn that,

absent

international

immunization,

the virus will

continue to

spread.

“Covid anywhere

is Covid

everywhere” said

Melinda Gates of

the Gates

Foundation.

“Even if you

vaccinate the

entire Midwest

of the United

States or every

single person in

our country … if

you still have

Covid raging in

another country,

it’s going to

bounce back to

our borders.”

Since the start

of the pandemic,

which has

infected more

than 50 million

people

worldwide,

governments have

scrambled to

secure supplies

of any future

vaccine.

A study released

this month by

the Duke

University

Global Health

Innovation

Center found

that some rich

countries have

already struck

deals to procure

enough vaccine

to inoculate

their own

populations many

times over

before poorer

countries obtain

any vaccine at

all.

According to the

researchers, the

U.S. “already

has agreements

to purchase

enough doses to

cover 230% of

its population

and could

eventually

control 1.8

billion

doses—about a

quarter of the

world’s

near-term

supply.”

A leading

vaccine

candidate — from

the drug company

Pfizer, which

reported this

week that

initial trials

showed 90

percent efficacy

— is already

tied up in

advance purchase

agreements with

a handful of

countries,

including the

United States,

for 100-million

doses.

With more

vaccines nearing

approval, the

World Health

Organization is

calling for a

more equitable

distribution to

stop the

pandemic.

“The first

priority must be

to vaccinate

some people in

all countries,

rather than all

people in some

countries,” WHO

Director-General

Tedros Adhanom

Ghebreyesus said

in September.

“If people in

low- and

middle-income

countries miss

out on vaccines,

the virus will

continue to

kill, and the

economic

recovery

globally will be

delayed,” Tedros

said.

As the demands

of rich

countries have

already cornered

the market in

future vaccines

from European

and American

manufacturers,

Indian companies

will likely play

a large part in

meeting the

massive

worldwide

demand.

The Serum

Institute has

plans to

manufacture five

Covid-19

vaccines, to be

distributed half

in India and

half to the

developing

world.

The vials

rolling off

conveyor belts

at the institute

are filled with

the Covid-19

vaccine

developed by

Oxford

University and

licensed to

AstraZeneca,

which is in

late-stage

trials around

the world.

A worker at the

Serum Institute

of India was

shown holding a

vial of the

Oxford Covid-19

vaccine

candidate being

produced under

the name

Covishield.

Sheldon Healy /

NBC News

The vaccine has

not yet been

approved for

widespread use,

but Serum is

churning it out

anyway, so that,

if it is proven

effective and

passes

regulatory

hurdles, it will

be ready to

distribute

immediately.

The company has

agreed on a

deal, funded by

the Gates

Foundation, to

sell a combined

200 million

doses of the

Oxford vaccine

and another

candidate from

Noavax to lower-

and

middle-income

countries

through the

World Health

Organization-led

Covax facility.

Covax is a

program that

will pool

resources among

countries to buy

eventual

Covid-19

vaccines and

distribute them

more equally

globally,

avoiding the

bilateral

advance purchase

agreements that

countries have

been making with

pharmaceutical

companies.

So far, Covax

has lined up

deals for 700

million doses of

three vaccine

candidates from

AstraZeneca,

Novavax and

GSK-Sanofi.

The vaccines

Serum has agreed

to supply are

just a fraction

of the 2 billion

doses Covax aims

to distribute by

the end of 2021.

India itself is

desperate for a

vaccine. The

nation of 1.3

billion people —

about 17 percent

of the world’s

population — now

trails only the

United States in

the number of

coronavirus

cases.

Serum plans to

address both the

worldwide crisis

and the one at

home at the same

time by

reserving half

of its vaccines

for India and

exporting the

rest.

“We believe in

protecting the

rest of the

world as well as

India. And I'll

tell you why:

Not only because

of the ethical

question — but

also it's

logical,”

Poonawalla said.

“If other

economies don’t

restart … that

doesn’t help

India” he said.

“We are a global

economy.”

Serum’s plan to

export so much

of the vaccines

it is licensed

to produce is

also a business

decision.

The company,

which expanded

from a small

business

deriving

vaccines from

the serum found

in horse blood

in the 1960s,

has made its

name — and its

profits — from

producing

vaccines for

sale to the

developing

world, mostly

Africa and Asia,

at large scale

and low cost.

The company says

that 65 percent

of children

around the world

receive at least

one vaccine made

by Serum in

their lifetimes.

Dr. Rory Horner,

a development

economist at the

University of

Manchester in

England, who has

been researching

India’s role in

the global

pharmaceutical

industry for

over a decade,

said Indian

companies have

long played a

major role

supplying

vaccines and

medications to

developing

countries.

He described it

as a “win-win”

for the country

that he expects

to continue with

Covid-19

vaccines.

“It’s good for

the industry,

but it’s also

good for

reputation

abroad,” Horner

said. “And we’re

going to see

elements of

vaccine

diplomacy and

not just vaccine

nationalism.”

As the world

fights to end

the Covid-19

pandemic, a

construction

site on the

Serum campus

foreshadows the

challenges of

the future.

It’s what

Poonawalla

called a

“pandemic-level”

manufacturing

facility, “which

basically means

I can make any

kind of product

there up to a

billion doses,”

he said.

“Eventually, I

think every part

of the world

will need a

facility like

this going

forward, because

this is not the

last pandemic. “

Allergens can be

Removed Along

with COVID

According to the

World Health

Organization,

allergies are

now the fourth

most common

chronic

illnesses

worldwide They

are also

exacerbated by

various

particulate

matter and

harmful gases in

the air, which

are at their

highest levels

in larger cities

and industrial

locations. In

general, it is

clear that the

proportion of

people who

suffer from

allergies is

particularly

high in

populous, highly

industrialized

regions.

In South Korea,

59 % of the

population are

treated for

allergy

symptoms, in

Japan that

figure is 44 %,

in the USA 28 %

and in Europe 20

%. In Germany,

35 to 40 % of

residents suffer

from

allergy-related

illnesses,

whereby 86 % of

allergy

sufferers suffer

from

pollen-related

allergies, while

40 % are

allergic to pets

and 14 % to mold

spores – those

figures continue

to rise

In particular,

the number of

those allergic

to pollen is

rising

worldwide. The

cost of treating

these patients

amounts to

approximately

Euro 240 million

annually in

Germany alone.

If pollen,

bacteria, mold

spores and other

tiny particles

make their way

into the

interior of a

vehicle through

the ventilation

ducts, they can

provoke allergic

reactions.

The protection

of vehicle

occupants is

therefore

increasingly a

focal point for

developers:

while the first

cabin filters

aimed to protect

the components

of an

air-conditioning

system against

contamination,

modern variants

protect the

passengers

against harmful

allergens and

germs in the

ambient air.

Common cabin

filters include

a particulate

filter and

frequently also

an activated

carbon layer.

This is also

true for the

cabin filters

from

MANN+HUMMEL. The

particulate

filter layer

almost

completely

separates coarse

particles such

as dust, pollen,

and tire debris

as well as the

smallest,

respirable

particles such

as particulate

matter. The

layer of

activated carbon

adsorbs harmful

gases,

unpleasant

odors, and ozone

almost

completely from

the air flowing

through the

system.

But these cabin

filters also

have a third

layer with a

special

biofunctional

coating

containing

polyphenols. Polyphenols

are natural

products with an

anti-inflammatory

effect and are

perceived to

promote good

health. They are

present in

plants such as

green tea and

pomegranates and

many others and

have the ability

to adsorb

allergens and

make them

harmless. This

mechanism is

exploited by

MANN+HUMMEL and

those suffering

from allergies

can breathe

freely.

Mann + Hummel

Uses Nanofiber

Media in Engine

Air Filters as

Well as Masks

Combustion air

always contains

particles which

should not be

allowed to

penetrate the

inside of the

engine. The

application of a

highly efficient

air filter is

therefore

essential in

order to protect

the engine and

its components

such as the

turbocharger or

mass air flow

sensor against

increased wear

and defects

caused by dirt

particles.

MANN+HUMMEL

develops

nanofiber coated

filter media for

the highly

efficient

separation, also

amongst others,

of fine

particles. These

filter media

from MANN+HUMMEL

are

characterized by

a verifiably

higher

separation

efficiency along

with the high

dust holding

capacity.

A high-tec

nanofiber coated

filter media

from MANN+HUMMEL

is the first

choice for

vehicles which

work in

environments

with a high

level of soot or

fine dust

pollution.

Typical

application

areas here are

dusty

construction

sites, mines,

and car rallies.

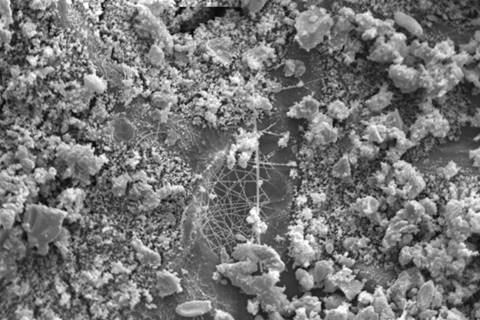

Nanofiber filter

medium before

and after

loading with

dust particles

under real

conditions

(field test).

Good particle

separation

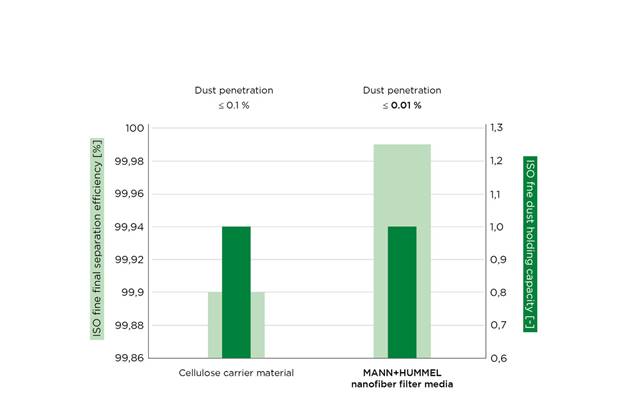

performance

along with low

flow restriction

ISO 5011

separation

performance

tested with ISO

fine test dust

(ISO 12103-01:

A2). Results

from filter

elements with

same size under

typical

conditions for

heavy duty

engine air

intake.

Separation

performance

changes with the

changed test

conditions

(filtration

velocity).

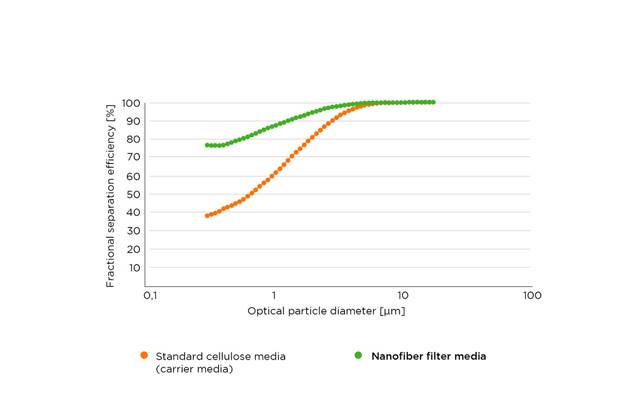

Flat sheet test

with ISO fine

test dust (ISO

12103-01: A2).

Determination of

fractional

separation

efficiency

during the first

60 seconds. The

curves shown are

based on average

values.

Individual

values may

deviate

slightly.

Fractional

separation

efficiency

changes with

changed test

conditions.

MANN+HUMMEL has

successfully

used nanofiber

technology for a

number of years

in series

applications for

the commercial

vehicles sector.

The nanofiber

filter media

consists of a

carrier media

and an extremely

thin layer of

ultra-fine

polymer fibers.

The fibers with

a diameter of

less than one

micrometer are

approximately

200 times

smaller than the

fiber diameter

of the carrier

material. This

leads to a

considerable

improvement in

particle

separation. At

the same time

nanofibers offer

a further

advantage: In

spite of the

high separation

efficiency, the

flow restriction

remains very

low.

A comparison of

the nanofiber

filter media to

the carrier

material on its

own demonstrates

the performance

which nanofiber

technology

offers filters.

In the test of

filter elements

according to ISO

5011, nanofiber

filter media

retained up to

10 times more

dust compared to

the carrier

material on its

own. Standard

media made from

cellulose enable

the separation

of 99.9% of the

total mass of

dust particles

in the air. The

closely meshed

nanofiber layers

allow separation

efficiency to

rise to 99.99%.

The high

separation

performance

ensures that

also smaller

particles are

separated by the

nanofiber layer

of the filter

media. In order

to determine the

separation

efficiency for a

certain particle

size, particles

with a defined

size are counted

in the air flow

upstream and

downstream of

the filter

media. The

results are

shown using

fractional

separation

efficiency

curves. The

nanofiber layer

applied to the

carrier

verifiably

reduces the

passage of fine

particles and

therefore offers

greater

protection for

the engine and

its sensitive

components.

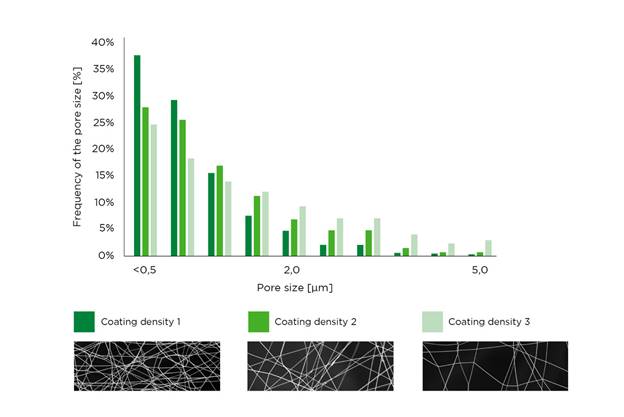

R&D Tools

Control of the

pore size

distribution of

the nanofiber

media by means

of analysis

software for

targeted

separation

performance.

MANN+HUMMEL uses

simulations,

laboratory tests

and special

analysis

software to

improve

nanofiber

coatings for

customized

applications and

combines this

technology with

other media and

materials.

In the

development

process

MANN+HUMMEL uses

analysis

software (with a

patent pending)

which is able to

automatically

determine the

fiber diameter

distribution and

pore size

distribution

from scanning

electron

microscope

images of

nanofibers. This

distribution

substantially

determines the

separation

efficiency and

flow resistance

of the media.