Coronavirus

Technology Solutions

December 14, 2020

Holistic and

Timely Use of

Filtration

Resources Needed

to Fight COVID

Face Masks will

be the Focus on

Wednesday at the

WFI Conference

Researchers at

King Abdullah

University

Develop Membrane

for Face Masks

TTG has

Efficient

Membrane Media

for Masks

ePTFE Membranes

- Application in

High-End Face

Masks

DHA Uses Same

Media for Masks

and Gas Turbine

Inlet Filters

TEFM Provides

ePFTE Membranes

for Masks

Membranes for

Mask Supplied by

Cobetter

BYU Develops

Nanofiber Mask

Nanofiber Media Reduces Face Mask Resistance

____________________________________________________________________________

Holistic and

Timely Use of

Filtration

Resources Needed

to Fight COVID

The filtration

industry can

save hundreds of

thousands of

lives in the

next year

regardless of

how fast

vaccines can be

produced and

delivered. More

efficient masks

and air filters

are needed.

Alternatives are

not nearly as

effective

because

·

Sanitation is

proving to be a

minor solution

because the

virus is

airborne.

·

Social

distancing is as

effective in

avoiding virus

as it is

avoiding perfume

or cigarette

smoke.

·

Partitions cause

turbulence and

can cause

viruses to

remain in

suspension but

do not prevent

the small

particles from

easily flowing

around any

structure.

·

Increasing the

amount of

outside air

flowing through

a room is hugely

expensive as

opposed to

filtration.

The challenge is

to make adequate

numbers of

efficient masks

and filters

available now

but avoid the

cost of

mothballing

newly built

facilities when

the vaccines

become

effective.

There is a

holistic

approach which

will accomplish

this goal. All

air filters are

essentially just

filter media

with a support

structure.

Membranes can be

used in masks

and in gas

turbine intake

filters. There

are very

specialized

facilities to

make the media

but a variety of

sources can be

utilized to make

the structures,.

Many of these

sources can add

second shifts

and produce

filter housings

or masks and

then switch to

some other

products.

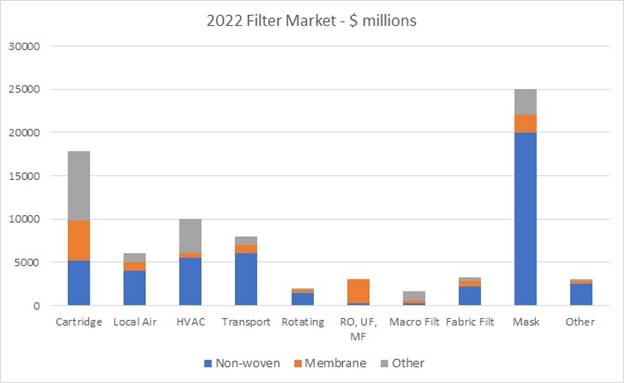

The Mcilvaine

forecast for the

2022 filter

market done last

year is now

outdated but

does show the

use of

membranes, non

wovens and other

media in various

filtration

applications.

By using

a variety of

media types in

masks and air

filters there

will be enough

media for the

short term and

no need to build

facilities which

would only be

used

temporarily. The

fact that there

are a number of

different

types of

vaccines being

produced is

comparable to

using a number

of different

media types.

There is a fast

track program to

expand world

vaccine

production by

orders of

magnitude over

the period of a

year or two and

then scale back.

This is much

more of a

challenge than

scaling up to

produce the

necessary masks.

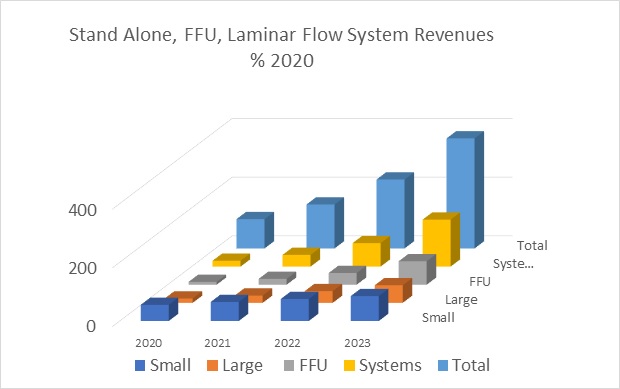

In terms of

filters there

are small air

purifiers,

larger laminar

flow systems,

fan filter

units, and

upgraded

HVAC systems.

All of these

products will

save lives.

However,

none will have

the cost/benefit

ratio of masks.

The

holistic program

should therefore

prioritize

mask

production.

Wildfire health

impairment is

steadily

increasing.

There is growing

evidence that

trace

contaminants

such as lead in

the air are more

prevalent than

previously

known. So even

in a city such

as St Louis it

will be wise to

wear a mask when

the wind is

blowing from the

lead smelter.

For many cities

around the world

air pollution is

the cause of

hundreds of

thousands of

deaths.

Allergies impact

millions. Many

people have

sensitive lungs.

All

of these

factors provide

long term demand

for masks.

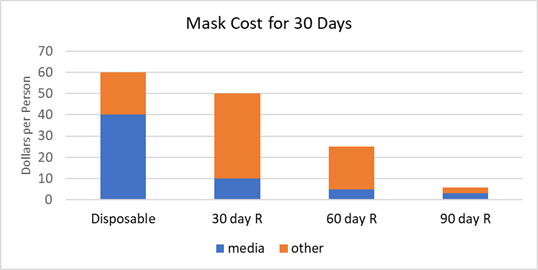

There will be a

mix of

disposable and

reusable masks.

But as shown in

the daily

CATER Mask

Decisions

the CATER Mask

has the comfort,

attractiveness,

tight fit,

efficiency and

reusability

which is needed.

Since a CATER

mask could be

used for 30 days

or even longer

it will require

much less media.

Disposable masks

will use much

more media and

will be less

effective. If

the mask costs

$2 and is used

for one day the

monthly cost

would be $60.

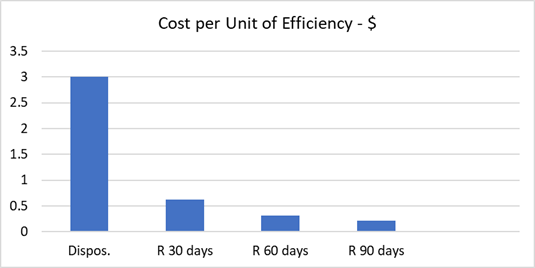

A $50

dollar CATER

mask will have

an 80 percent

net efficiency

or $0.63/ unit

of efficiency vs

disposable masks

at 20 percent

net efficiency

or $3.00/unit of

efficiency.

The disposable

cost per unit of

efficiency is 14

times that of a

reusable mask

with a 90 day

life.

The cost per

unit of

efficiency of

masks and

filters is a

function of the

viral load as

well as the

filtration cost

and efficiency.

|

Source |

Treatment |

Load % |

Cost/Unit Efficiency at 100% Load |

Cost /Unit Efficiency |

|

Emitter |

Mask |

100 |

.0.63 |

0.63 |

|

Recipient |

Mask |

5 |

0.63 |

12.60 |

|

HVAC |

HEPA Filter |

1 |

0.20 |

20.00 |

|

HVAC |

HEPA Filter |

10 |

0.20 |

2.00 |

An emitter of

the virus is

filtering out

100% of the

load.

So the

cost is only

$0.63/ unit of

virus avoided.

He will also be

a recipient. So

even though the

cost as a

recipient is

relatively high

the net

combination is

less than the

0.63/unit

efficiency.

Upgrading an

HVAC system is

likely to

involve less

than 1% of the

viral load

generated by the

individuals in

the building.

The problem is

that recipients

are likely to be

located so that

they are exposed

prior to the

ultimate removal

in the HVAC

system.

Even in

an optimal

setting with

very good

downward laminar

flow air and

exposure to 10%

of the virus

before it

reaches the

recipient the

net unit

efficiency cost

is still higher

than the mask.

Air purifiers in

the rooms of

people in

households with

coronavirus will

come close to

the unit

efficiency cost

of the mask but

air purifiers in

locations where

there is no

known virus are

less cost

effective.

A combination of

masks and

vaccinations can

create herd

immunity

quickly. It will

be a combination

of CATER,

surgical and

medium

efficiency cloth

masks. It will

not include

inefficient

cloth masks.

Because CATER

masks are tight

fitting,

efficient,

comfortable, and

attractive they

will be 93%

effective where

utilized. It was

determined that

only one mask

would be needed

per month and

possibly only

one per quarter

due to

reusability.

This will be the

most

cost-effective

option.

The following

table was

presented last

week in our

Alert. Since

that time there

has been a

change in the

likely number of

people

vaccinated. On

the other hand

we learn that

even with a 94%

effectiveness

most people will

still want

protection in

case they are

part of the 6%.

Other vaccines

with 60%

effectiveness

will result in

no herd immunity

even with 70% of

the people

vaccinated.

Therefore we

still calculate

that it would be

desirable to

spend $98

billion per

month from now

until June and

then $60 billion

per month in the

subsequent

quarter. This

could drop to

under $10

billion per

month

by

February of

2022.

|

Cater Masks Needed to Reach 70% Herd Immunity with 30 Day Life |

|

Date |

Cumulative % Vaccinated |

Add % to Reach 70 |

Mask Inefficiency |

% Needing Masks 1.075 |

People Needing Masks millions |

Monthly Production Rate millions |

Monthly Revenues $ millions at $30/mask |

|

April 2021 |

20 |

50 |

7 |

54 |

3225 |

3225 |

96,750 |

|

June 2021 |

40 |

30 |

7 |

32 |

1920 |

1920 |

57,600 |

|

Sept 2021 |

50 |

20 |

7 |

22 |

1320 |

1320 |

39,600 |

|

Dec 2021 |

60 |

10 |

7 |

11 |

660 |

660 |

19,800 |

|

Feb 2022 |

65 |

5 |

7 |

5.4 |

323 |

323 |

9,690 |

There is a very

large market

potential for

non COVID

applications.

|

Mask Potential in non COVID Applications - billions |

|

|||

|

|

Air Pollution Wildfires units |

Other units |

Total units |

$ billions |

|

2021 |

1 |

.5 |

1.5 |

45 |

|

2022 |

1.1 |

0.55 |

1.65 |

50 |

|

2023 |

1.3 |

0.6 |

1.9 |

57 |

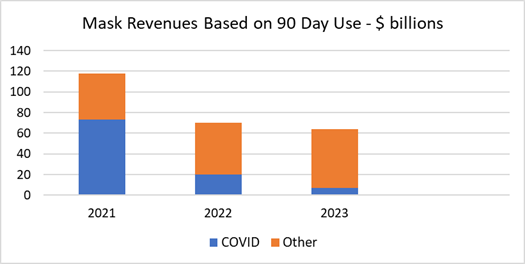

The potential

for the COVID

applications is

much higher than

other

applications

through 2021 but

by 2022 it will

be smaller than

the other

combined

markets. So if

CATER mask

suppliers can

capture a big

share of the non

COVID market

there is not

much of a peak

and valley.

|

|

COVID |

Other |

Total |

|

2021 at 90 day life |

73 |

45 |

118 |

|

2022 at 90 day life |

20 |

50 |

70 |

|

2023 at 90 day life |

7 |

57 |

64 |

It is unlikely

that CATER mask

suppliers can

scale up to $118

billion in

revenues in

2021, but if

they could

capture 70% of

the market there

would be no

downturn in 2022

and only a

slight reduction

in 2023.

The present

revenues for

masks which

truly fit the

CATER criteria

are only around

$200 million.

This

means the 2021

market potential

is 600 times

larger than the

present market.

The long term

market is 300

times the

present market.

The challenge is

to persuade

people in highly

polluted cities,

in an area where

there is

wildfire smoke,

working in meat

processing

plants, or just

riding the

subway that if

they are going

to wear a mask

it should be a

CATER mask.

It would

normally be

impossible to

increase

revenues for a

type of product

by 50 fold let

alone 600 fold.

But the

pandemic creates

a huge

opportunity for

mask suppliers.

If they

do not seize it

many thousands

of people will

die. So it is

not only the

profit motive

which should

drive the mask

suppliers.

CATER Mask

Decisions

will be

providing the

evidence which

will show why

CATER masks are

the best choice

for the wide

range of

applications.

Mask suppliers

can take

advantage of

this free

service to

educate their

prospects.

Face Masks will

be the Focus on

Wednesday at the

WFI Conference

The Conference's

theme is "IAQ

Health and

Safety Solutions

Associated with

COVID-19",

December 15-16,

2020,

8:00 am

-12:00 pm

EST. It

will address the

critical roles

of facemasks and

air filtration

during the

current pandemic

for public

health and

safety. The

virtual

conference will

feature the

following four

sessions:

1. Emerging

Challenges and

Responses

2. IAQ and the

Built

Environment

3. Facemask

Technologies and

Latest

Developments

4. Facemask/Air

Filter Test

Methods and

Standards

Face masks will

be discussed on

Wednesday.

One of

the speakers

will be Wendover

Brown, Her

background is

provided at

https://www.wfinstitute.com/post/fashion-in-efficient-consumer-masks

You can sign up

for one or both

days at

REGISTER NOW!

Researchers at

King Abdullah

University

Develop Membrane

for Face Masks

N95 masks filter

about 85% of

particles

smaller than 300

nm, according to

published

research.

SARS-CoV-2 (the

coronavirus that

causes COVID-19)

is in the size

range of 65–125

nm, so some

virus particles

could slip

through these

coverings. Also,

because of

shortages, many

health care

workers have had

to wear the same

N95 mask

repeatedly, even

though they are

intended for a

single use. To

help overcome

these problems,

Muhammad Mustafa

Hussain and

colleagues

wanted to

develop a

membrane that

more efficiently

filters

particles the

size of

SARS-CoV-2 and

could be

replaced on an

N95 mask after

every use.

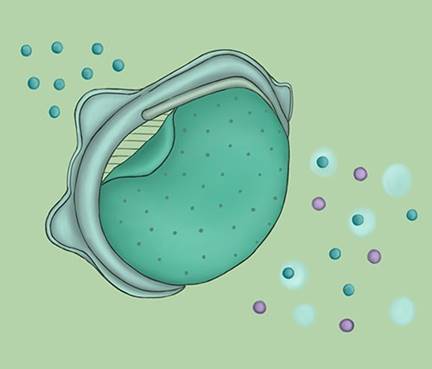

A replaceable

nanoporous

membrane,

illustrated

above, attached

to an N95 mask

filters out

particles the

size of

SARS-CoV-2

(purple

circles),

allowing only

clean air (blue

circles)

through.

Credit: ACS

Nano 2020,

DOI:

10.1021/acsnano.0c0397

To make the

membrane, the

researchers

first developed

a silicon-based,

porous template

using

lithography and

chemical

etching.

They placed the

template over a

polyimide film

and used a

process called

reactive ion

etching to make

pores in the

membrane, with

sizes ranging

from 5-55nm.

Then, they

peeled off the

membrane, which

could be

attached to an

N95 mask. To

ensure that the

nanoporous

membrane was

breathable, the

researchers

measured the

airflow rate

through the

pores.

They found that

for pores tinier

than 60nm (i.e.

smaller than

SARS-CoV-2), the

pores needed to

be placed a

maximum of 330

nm from each

other to achieve

good

breathability.

The hydrophobic

membrane also

cleans itself

because droplets

slide off it,

preventing the

pores from

getting clogged

with viruses and

other particles.

https://pubs.acs.org/doi/abs/10.1021/acsnano.0c03976

TTG has

Efficient

Membrane Media

for Masks

TTG’s

proprietary

membranes have

helped guard

medical

personnel and

medical

equipment for

years. The

latest AIRADIGM™

innovation takes

health care

worker and

patient

protection to

the next level.

Merging

expertise in

filtration and

membrane

engineering with

experience in

performance

fabric design,

TTG has created

a new AIRADIGM

composite

medical face

mask medium that

delivers an

incomparable

value equation

that includes

comfort,

longevity,

durability, and

sustainability.

Three Layers of

Protection

AIRADIGM’s

composite face

mask material is

a proprietary

construction

that features:

- Spun-lace polyester on the outside

- ePTFE membrane in the center

- Spun-bond polypropylene on the inside

- Three layers sonically laminated for integrity and durability

The new AIRADIGM

composite fabric

TG77007 meets

N95 surgical

mask and ASTM

Level 3 criteria

for face mask

media that offer

the highest

levels of

protection

against

particulates,

microbes, and

fluids. *

Comfort and

Performance

Studies have

shown that PPE

comfort is a

must for

compliance and

concentration,

both of which

are absolutely

critical in

healthcare

settings. Just

like in

performance

apparel,

AIRADIGM

membranes keep

fluids out but

allow body heat

and vapor to

escape so that

the wearer stays

comfortable for

the long term.

Also, the

composite

fabric’s

membrane core

supports

breathability

without

compromising

protection.

This unique

AIRADIGM

composite

medical face

mask fabric

provides

filtration

capabilities

that do not

degrade with

humidity the way

that traditional

mask materials

do. Microbe and

particle

protection

levels stay

consistently

high for all-day

protection

without frequent

mask

replacements.

Durable and

Sustainable

In addition to

protecting for

longer periods

of time than

traditional face

masks, masks

made with the

special AIRADIGM

composite

material can be

cleaned in an

autoclave and

safely reused.

That relieves

the stress on

the PPE supply

chain and

improves return

on investment,

not to mention

that

substantially

fewer masks end

up in the

landfill.

AIRADIGM

membranes and

composite

fabrics are

manufactured by

TTG in the

United States in

a clean,

resource

considerate,

state-of-the-art

facility for the

highest quality,

quickest

customer

support, and

most reliable

deliveries.

*Click

here for

AIRADIGM’s

TG77007

composite

medical face

mask material

technical

specification

sheet.

ePTFE Membranes

- Application in

High-End Face

Masks

With the recent

advent of

Covid-19, there

is a significant

strain on

resources

pertaining to

either the

prevention or

containment of

the virus.

One of the key

shortages

highlighted has

been around face

masks, where

some experts

have suggested

that if the

pandemic

continues to

wreak havoc, the

US presently has

only 1% of the

face masks it

would need.

This shortfall

has led to

opportunistic

behavior, such

that the price

of face masks

has more than

quadrupled in

the past three

weeks. As a

result, good

quality masks

are not only

scarce, but are

being sold at an

unimaginable

premium.

Poly Fluoro Ltd

ePTFE membranes

have advantages

as mask media.

While ePTFE

itself is not a

low-cost

material, its

application in

face masks could

be revolutionary

and allow for a

very effective

product in

fighting the

current crisis.

The reasons for

this are as

follows:

- Permeability – ePTFE has a unique property of being impervious to liquids, but permeable to gases. Since Covid-19 is known to be spread by droplets in the air, ePTFE forms an ideal medium to arrest the passage of droplets

- FDA approved – as PTFE is an FDA approved material, it poses no risks to being used in face masks. Indeed, PTFE is one of the few materials that is approved for insertion into the human body, making it completely safe for such an application

- Hydrophobic – not only is ePTFE resistant to droplets, but it is also hydrophobic in nature, meaning that droplets that do reach it are immediately repelled. Hence, there is less risk that an infected droplet would remain on the surface of the material. This allows the face mask to have a longer lift, as there is less chance that the infection stays on the surface of the material.

- Low cost – as mentioned, ePTFE is itself an expensive material. However, when used in a small quantity – such as would be needed in a face mask – the price is negligible when compared with standard face masks

With the current

crisis in play,

it is essential

that newer and

more effective

materials are

brought into

action. ePTFE is

one such

material, as it

can be

manufactured in

bulk and

embedded into a

standard

non-woven

polypropylene

mask to give a

manifold

improvement in

protection,

while adding

very little in

terms of cost.

By the company’s

estimate, a

simple ePTFE

lined face mask

should cost

nothing more

than US$0.2 per

piece – which is

a far cry from

the US$2-3 we

are currently

seeing for

high-end masks

on the market.

Poly Fluoro Ltd

has been at the

forefront of

polymer

innovation,

pioneering the

manufacture and

application of

engineering

plastics since

1985.

Integrating

in-house

processing

techniques with

innovative

machining and

fabrication

capabilities,

they have

developed a

unique range of

products

tailored to suit

numerous

applications.

Poly Fluoro

partners with

over 100

Original

Equipment

Manufacturers

(OEMs),

supplying

value-added

products in

PTFE, PEEK,

Delrin, Nylon,

and a range of

other

high-performance

polymers.

Over the years,

the company’s

specialty

products have

become

synonymous with

the most

reliable and

robust

engineering

plastics for OE

fitment.

Operating out of

a 20,000 square

foot plant, they

are an

accredited ISO

9001 company

that offers

end-to-end

design,

prototype, and

production

services.

The company

manufacturing

facility is

equipped with

the capacity to

mold, extrude,

expand, and

machine polymers

in sizes ranging

from 10mm to

500mm in

diameter.

Specializing in

both virgin and

formulated

grades, they

offer

end-products

ideally suited

for use in

original

equipment and

industrial

maintenance.

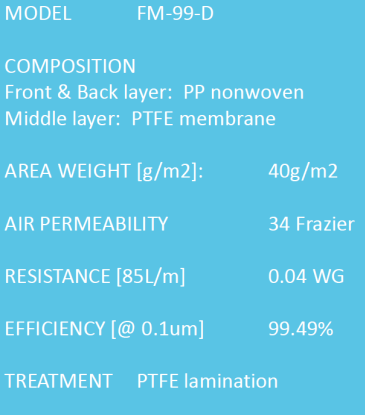

DHA Uses Same

Media for Masks

and Gas Turbine

Inlet Filters

DHA Filter has

been in

industrial

filtration for

more than three

decades.

Like so many

companies, the

Coronavirus

pandemic has had

a dramatic

impact on how it

does business.

As a filtration

media producer,

DHA began

receiving

inquiries as

early as January

by face mask

manufacturers

looking to

procure

meltblown

polypropylene.

Up to this

point, this has

been the

preferred

material for

face mask

construction. As

the volume of

requests rapidly

increased, it

became clear

that the supply

of this material

was going to

fall well short

of global

demand.

DHA began the

search for

alternative

materials that

might yield

similar if not

superior

filtration

properties.

Immediately it

became apparent

that the DHA

proprietary HEPA

grade, low

resistance PTFE

membrane

developed for

gas turbine

inlet filters

would be a

viable option.

DHA reworked the

membrane with

approved base

support

materials to

quickly enter

the PPE arena.

The underlying

technology is an

PTFE face mask

membrane that

acts as the

mask’s

efficiency

layer.

It is

encompassed by a

layer of

spunbond

polypropylene on

either side to

complete the

composite used

to make the

masks. In lab

testing the

material proved

to be 99%

efficient at

filtering

particles 0.1

micron and

larger. This

exceeds the

standard for

materials used

in typical PTFE

face mask. The

material is also

100% hydrophobic

which aids in

creating an

impenetrable

barrier against

droplets and

spray.

FEATURES

- 100% Hydrophobic, preventing transfer of fluids

- Filters 99% of particulate matter

- Breathable, lightweight PTFE membrane for comfort

- Spunbond support layer resists tearing and shredding

- Sonically welded construction for durability

- Flexible metal nose piece ensures secure fit

- Low air resistance allows for uninhibited breathing

- Suitable for all day wear

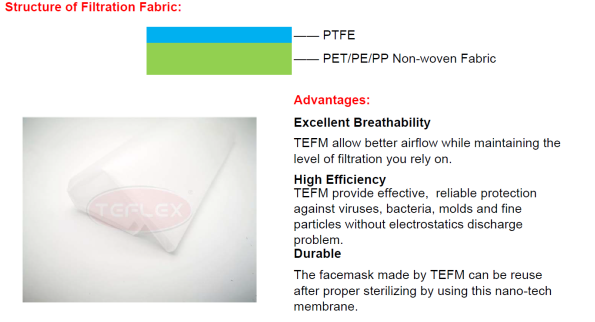

TEFM Provides

ePFTE Membranes

for Masks

TEFM is made of

ePTFE

microporous

material by

unique nano-technology.

The PTFE

membrane has a

micropore

structure with

small pore size,

high porosity

and irregular

permutation. The

efficiency for

diameter 0.3 um

particulate can

be above 95%. It

has excellent

performance to

block PM2.5

particulate,

dust mite, virus

& bacteria. The

PTFE filtration

membrane with a

wide

application,

such as N99,

N95, KF94, FFP3

mask, medical

masks is

reusable.

The masks retain

performance

after repeated

washing,

especially after

laundering with

surfactants and

at high

temperatures,

but performance

may differ from

the laboratory

tests. Hence,

while

antimicrobial

masks can offer

additional

protection

against

microbes, basic

hygiene

practices such

as not touching

the mask surface

and washing of

hands should

still be

observed.

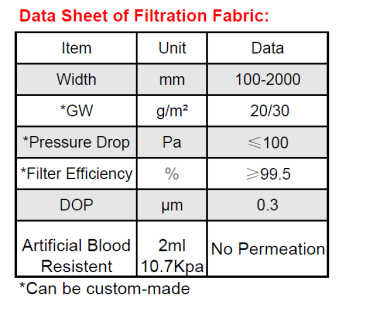

Membranes for

Mask Supplied by

Cobetter

Cobetter is a

Chinese company

supplying PTFE

membranes for

masks. The

advantages are

explained at

https://www.cobetterfiltration.com/Industries/Medical/Mask/mask-membrane-PTFE/

Founded

in 2003,

Cobetter is an

international

company

headquartered in

Hangzhou, China

with over 1500

employees and

nearly 100,000

square feet of

filtration

production area

cleanroom space.

With over 1,200

products and

100-patented

technologies,

Cobetter has

developed a full

product range

composed of core

materials with

unique

performance

capabilities.

Cobetter has

implemented

extensive

quality control

methods

throughout their

entire

manufacturing

process for

their filtration

products. These

measures ensure

the products are

high quality,

stable, and

reliable in

accordance with

ISO 9001, 13485,

14001, and OHSAS

18001 standards.

One of

Cobetter’s core

competencies is

their membrane

technology which

they develop and

manufacture

in-house.

The Cobetter

representative

in the U.S. and

Singapore is

Banner

Industries. It

was founded in

1985 to serve a

rapidly

expanding high

purity market

and to satisfy

the increasing

demand for

high-quality

components with

fast delivery at

competitive

prices.

BYU Develops

Nanofiber Mask

The cloth masks

many are

sporting these

days offer some

protection

against

COVID-19.

However, they

typically

provide much

less than the

professional N95

masks used by

healthcare

workers.

That may soon

change.

Recently,

students from

BYU’s College of

Engineering

teamed up with Nanos

Foundation to

develop a

nanofiber

membrane that

can be

sandwiched

between the

cloth pieces in

a homemade mask.

While today’s

typical cloth

mask might block

fewer than 50%

of virus

particles, the

membrane — which

can be made

using simple,

inexpensive

materials — will

be able to block

90 to 99% of

particles,

increasing

effectiveness

while preserving

breathability.

The membranes

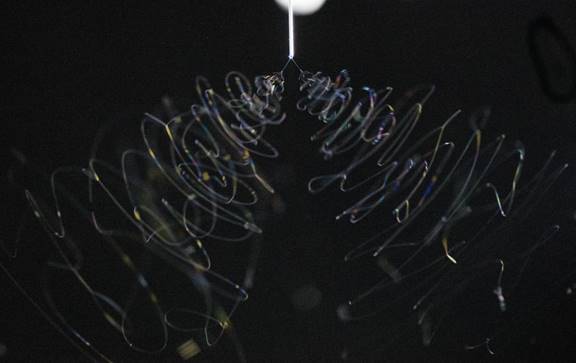

are made through

a process called

“electrospinning,”

which involves

dissolving a

polymer plastic

in a solution

and then using

an electrical

current to move

a droplet of the

polymer downward

through a

needle. As the

droplet

accelerates, it

stretches into a

very small fiber

that retains a

static charge.

“Those

nanofibers

randomly land on

a collector to

create a sort of

non-woven mesh,”

said Katie

Varela, a BYU

mechanical

engineering

senior on the

project team.

The remaining

charge in the

fibers is

beneficial, she

explained,

because virus

particles also

have a static

charge. “When

they come close

to your mask,

they will be

statically

attracted to the

mask and will

not be able to

go through it,

and so it

prevents you

from inhaling

viruses.”

Liquid polymer

is stretched out

to create

nanofibers used

to increase the

efficiency of

cloth masks.

In addition to

the dramatic

improvement in

efficacy,

another key

benefit of the

nanofiber masks

is that unlike

traditional N95

masks, which

have a

reputation for

being hot and

stuffy, they

allow for the

circulation of

(filtered) air,

water, and heat.

“Not only is it

hard to find an

N95 mask these

days, but the

best mask is

useless if you

won’t wear it,”

said Will Vahle,

director at

Nanos

Foundation. “Our

nanofiber

membranes are

six times easier

to breathe

through than

existing N95

masks, making

them cooler,

drier, and more

comfortable.”

The group plans

to make the

instructions for

creating the

membranes open

source. They

hope that

non-profit

organizations

will use the

instructions to

set up local

sites where

people can bring

in their masks

to be fitted

with a membrane.

They also hope

other engineers

will use their

work as a

springboard to

produce more

effective

filters.

“We had our own

proprietary

nanofiber

production

process,” said

Vahle of the

project’s

origins, “but we

realized, hey,

we have some

expertise in

this — why don’t

we get this

together and

release a

version that

anybody can do?”

When Vahle and

his colleagues

approached BYU

to collaborate

on the project,

BYU “jumped at

the

opportunity,”

Vahle said. In

addition to

providing

funding and

facilities, the

university

connected the

company with

“fantastic

students, who’ve

really

demonstrated an

incredible work

ethic and a

drive to help

people in need.”

Using

cutting-edge

science to make

an immediate

positive impact

has also been

highly valuable

for the BYU

students on the

project.

“This experience

makes things

very real,” said

Varela. “I’m

really glad that

I’m able to help

with this fight

against COVID-19

to help people

all around the

world and in my

community.”

Nanofiber Media

Reduces Face

Mask Resistance

This was the

conclusion of

researchers from

Stony Brook

University

Potentially

infected

individuals

(‘source’) are

sometimes

encouraged to

use face masks

to reduce

exposure of

their infectious

aerosols to

others

(‘receiver’). To

improve

compliance with

Respiratory

Source Control

via face mask

and therefore

reduce receiver

exposure, a mask

should be

comfortable and

effective. the

researchers

tested a novel

face mask

designed to

improve

breathability

and filtration

using nanofiber

filtration.

Using

radiolabeled

test aerosols

and a calibrated

exposure chamber

simulating

source to

receiver

interaction,

facepiece

function was

measured with a

life-like

ventilated

manikin model.

Measurements

included mask

airflow

resistance

(pressure

difference

during

breathing),

filtration,

(mask capture of

exhaled

radiolabeled

test aerosols),

and exposure

(the transfer of

‘infectious’

aerosols from

the ‘source’ to

a ‘receiver’).

Polydisperse

aerosols were

measured at the

source with a

mass median

aerodynamic

diameter of 0.95

µm.

Approximately

90% of the

particles were

<2.0 µm. Tested

facepieces

included

nanofiber

prototype

surgical masks,

conventional

surgical masks,

and for

comparison, an

N95-class

filtering

facepiece

respirator

(commonly known

as an ‘N95

respirator’).

Airflow through

and around

conventional

surgical face

mask and

nanofiber

prototype face

mask was

visualized using

Schlieren

optical imaging.

Airflow

resistance [ΔP,

cmH2O]

across sealed

surgical masks

(means: 0.1865

and 0.1791 cmH2O)

approached that

of the N95

(mean: 0.2664

cmH2O).

The airflow

resistance

across the

nanofiber face

mask whether

sealed or not

sealed (0.0504

and 0.0311 cmH2O)

was

significantly

reduced in

comparison. In

addition,

‘infected’

source airflow

filtration and

receiver

exposure levels

for nanofiber

face masks

placed on the

source were

comparable to

that achieved

with N95 placed

on the source;

98.98% versus

82.68% and

0.0194 versus

0.0557,

respectively.

Compared to

deflection

within and

around the

conventional

face masks,

Schlieren

optical imaging

demonstrated

enhanced airflow

through the

nanofiber mask

Substituting

nanofiber for

conventional

filter media

significantly

reduced face

mask airflow

resistance

directing more

airflow through

the face mask

resulting in

enhanced

filtration.

Respiratory

source control

efficacy similar

to that achieved

through the use

of an N95

respirator worn

by the source

and decreased

airflow

resistance using

nanofiber masks

may improve

compliance and

reduce receiver

exposure.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4090760/

Properties of

commercially

available

antimicrobial

masks. Compared.

Anti-microbial

masks were

compared in a

study linked

below. Here is a

summary.

|

Mask Brand |

Classificationa |

Antimicrobial in outer layer |

Antimicrobial in inner layer |

Mask proven biocidal against |

|

Nexera Medical SpectraShieldTM |

N95 (ONT) |

Ag-Cu zeolite |

X |

Bacteria; virus |

|

GlaxoSmithKline Actiprotect® |

N95 (ONT) |

Citric acid |

X |

Virus |

|

Filigent BioFriendTM BiomaskTM |

N95 (ONT) |

Citric acid |

Cu NPs |

Virus |

|

Innonix RespoKareTM |

Surgical (OUK) |

Citric acid |

Cu NPs |

Virus |

|

NBC Meshtec Cufitec® |

Surgical (OUK) |

CuI NPs |

X |

Virus |

|

Anson Nano Silver |

Surgical |

X |

AgNPs |

Bacteria; fungi |

|

Copper Clothing |

Washable KN99 (FFP3) |

CuxO NPs |

X |

Bacteria; virus; fungib |

|

Cupron Inc. |

Washable |

CuxO NPs |

X |

Bacteria; virus; fungi b |

|

Copperline |

Washablec |

CuxO NPs |

X |

Bacteria |

|

Argaman BioBlockXTM |

Reusabled |

Cu2O NPs |

Cu2O NPs |

Bacteria; virus |

|

Sonovia SonomaskTM |

Washable |

X |

ZnO NPs |

Bacteria |

aMedical

and/or FDA

classification.

OUK = FDA

clearance as a

surgical mask

with

antimicrobial/antiviral

agent; ONT = FDA

clearance as an

N95 mask with

antimicrobial/antiviral

agent.

Washable/reusable

masks do not

require any

certification. bAntimicrobial

tests were

performed only

on fabric but

not directly on

the masks. cSingle

HEPA filter

provided with

the mask is not

washable or

reusable. dReusable

but not

recommended to

be laundered.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7429109/