Coronavirus

Technology Solutions

December 8, 2020

New Mexico Converting Only Some Schools From

MERV 10 to 13

Foster Farms Closes Poultry Plant in California

Due to 193 Cases

JBS Protecting Older Workers Due to New Outbreak

Meat Processors Should Consider the Cleanrooms

International FFU Rather Than Partitions

Purar Offers Reusable Mask with Unique Features

M+H Air Purifier Used at Schools

___________________________________________________________________________

New Mexico Converting Only Some Schools From

MERV 10 to 13

Due to COVID-19

New Mexico public health guidelines have changed

the way many systems function; public schools

have changed their entire learning model.

Schools try to keep up with state guidelines,

including air filter regulations which pressure

schools to quickly accommodate.

As with many guidelines for COVID-safe

practices, the air filter requirements changed

over time. Initially, the New Mexico Public

Education Department required a MERV 9 or higher

in all schools. In September, however,

that requirement changed to a MERV 13 to match

advisory from the Centers for Disease Control

and Prevention and the American Society of

Heating, Refrigerating and Air-Conditioning

Engineers.

MERV 13 filters are more effective in removing

viral particles from the air, helping to limit

the spread of the SARS-CoV-2 coronavirus, which

causes the COVID-19 disease.

A MERV 8 or MERV 9 is standard for most public

schools, according to Gabe Jacquez, deputy

superintendent of operations for Las Cruces

Public Schools.

Due to reports that MERV 13 filters wear down

ventilation systems and would cost much more to

schools whose budgets are already tight with

accommodations made for COVID-19 in other areas,

NMPED also allows the highest MERV filter that

the system is compatible with.

Jacquez said the district will be getting a

shipment of MERV 13 air filters in mid-November.

Currently, LCPS has MERV 8 filters installed

districtwide. But MERV 13 — which is a better

filter — is now required by the NMPED.

LCPS ordered MERV 13 filters in mid-September,

when the new requirement was announced by NMPED.

But the delivery date has been pushed back, due

to high demand for the air filtration

systems across the country.

Jacquez explained that the manufacturing of

filters is being slowed by the shortage for the

filtering media that makes up the MERV 13.

“It's affected many districts who run typically

a (MERV 8) or a (MERV 9) like we do, so

everybody's asking for the same thing at the

same time,” Jacquez said. “At first, it was a …

two- to six-week (wait), and then they pushed it

off to eight. There's really no options … pretty

much you have to get in line, and as they get

produced, they will get out to folk

In the meantime, LCPS has been using individual

HEPA air filters, which are individual air

purifiers, and opening windows and doors to

improve air circulation.

The week of Oct. 19, LCPS brought a group of

eight special education students to Picacho

Middle School for in-person instruction to meet

their needs. But the school was shut down on

Oct. 22 after an employee in the school tested

positive for COVID-19.

Vista Middle is currently holding in-person

instruction for special education students as

the district slowly introduces small special

education classes back to in-person learning in

different schools.

Districtwide, Hatch Valley Public Schools has

had MERV 10 filters for three years, according

to Jimmy Martinez, administrative assistant for

HVPS's maintenance department.

Martinez said they looked into purchasing MERV

13 filters for the district, but quickly

realized the filters would not be compatible

with many of the systems in place.

He said their Heating, Ventilation and Air

Conditioning systems range from 5 to 15 years

old or more across the schools in HVPS.

After consulting with its vendor who manages

their HVAC systems, HVPS concluded that they

would not have the funds to replace all their

filters.

Martinez said that not only would that higher

price of the MERV 13 filters be hard to

accommodate, but these filters need to be

replaced more frequently — since they filter out

more particles and fill up more quickly.

Additionally, the filters run down the HVAC

systems, which could potentially require pricey

repairs.

"Quite frankly, we just don't have the funding

to do what Las Cruces Public Schools do,"

Martinez said. "We're really glad to hear that

the (MERV) 10's were okay, and we can continue

using those."

Martinez said HVPS recently made an order to

replace all their air filters, a routine process

that happens around once a quarter. He said

there have not been any shortages for MERV 10

filters.

Martinez said that the national shortage in MERV

13 filters was not the cause for the district

opting to continue using MERV 10 filters. After

talking with vendors, HVPS decided MERV 10

filters were the best option for the district.

HVPS Superintendent Michael Chavez said that the

district is not offering in-person instruction

at this time.

Before the recent spike in COVID-19 cases in Doña

Ana County, HVPS was offering ancillary

one-on-one instruction on a needs-basis,

according to Chavez. That instruction has

stopped, and Chavez said they will not be

offering face-to-face instruction again until

cases come down.

Gadsden Independent School District will

continue to use MERV 8 and MERV 9.

GISD spokesman Luis Villalobos stated that "not

all GISD systems can handle such a restrictive

filter as the MERV 13. This filter, although

more efficient in producing air quality, can

make systems work much harder to get air through

and, in turn, could (cause) wear and tear,

possibly lowering the life expectancy of

systems."

Villalobos said that GISD will be replacing the

air filters more frequently than normal to

ensure the air circulating in school buildings

is clean. GISD will not be holding any in-person

instruction for the remainder of the semester.

Villalobos also stated that, due to the

unavailability of MERV 13 filters because of the

recent spike in demand, GISD has not been able

to purchase them up to now.

Foster Farms Closes Poultry Plant in California

Due to 193 Cases

Meat processor Foster Farms temporarily closed a

poultry processing plant for deep cleaning

following a coronavirus outbreak at the facility

in Fresno, California. In the past two weeks,

193 of the 1,400 employees at the plant tested

positive for COVID-19, reported the Fresno

Bee.

Meanwhile, Merced County officials reported a

COVID-19 outbreak at a Foster Farms plant in

Livingston, 70 miles northwest of Fresno in the

Central Valley. Seven workers at the Livingston

plant tested positive for COVID-19, said the

Bee.

Foster Farms said prevalence of COVID-19 at its

plant on Cherry Street “began ramping up in

early November concurrent with the acceleration

of cases throughout Fresno County,” said the

newspaper. The coronavirus rate at Foster Farms’

plant on Belgravia Avenue in Fresno remained

below 1%, according to the company. At least two

Foster Farms employees in Fresno have died of

coronavirus-related complications.

When the plant on Cherry Street reopens, workers

will be tested twice a week, said Foster Farms.

The Merced

Sun-Star said county

officials added Foster Farms to their list of

workplaces with COVID-19 outbreaks last

Wednesday.

“Foster Farms return to the outbreak list is

notable, as the Livingston plant previously

spent many weeks on the outbreak list,” said the

Sun-Star. “The outbreak resulted in 92 Foster

Farms employees testing positive for COVID-19,

nine of whom died. The workplace outbreak was

the worst in Merced County and one of the

deadliest in the state, according to County

Public Health officials.”

The United

Food and Commercial Workers union

said President-elect Joe Biden’s selection of

Xavier Becerra to serve as U.S. health secretary

“sends a clear message that this administration

is ready to fight for our country’s frontline

workers. Protecting our country’s essential

workers is crucial to taking control of this

pandemic and rebuilding the economy.” The UFCW

represents 1.3 million food and retail workers

At least 339 workers at meat plants, food

processing plants, and farms have died of

COVID-19 and nearly 75,000 co-workers have had

confirmed cases of COVID-19, according to data

collected by FERN as

of Monday at midday.

An Illinois-based meat manufacturer is suing the

state of New Mexico after health officials there

ordered a processing plant to close for two

weeks because of a coronavirus outbreak.

In a complaint filed in U.S. District Court,

Stampede Meat said it will lose millions of

pounds of meat at a plant in Sunland Park, just

across the state line from El Paso, Texas, and

it asked a judge to throw out the order.

In court documents filed Friday, the company

outlined several measures it had taken to halt

the virus's spread, citing President Donald

Trump's executive order April

28 invoking the Defense Production Act.

The order required meat processing plants to

remain open during the pandemic.

In a letter to the company on Nov.

3,

a New Mexico health official cited six positive

coronavirus tests from Oct. 23 to Oct. 27 and

ordered the plant to be closed for two weeks.

The New Mexico Heath Department referred

questions about the suit to a spokeswoman for

the state's Environment Department. The

spokeswoman, Maddy Hayden, declined to discuss

the suit, but she said courts have repeatedly

upheld the state's authority to protect the

public's health and safety.

Stampede Meat employs more than 500 workers at

its Sunland Park plant. Hayden said more than

100 workers there have tested positive since the

pandemic began.

Stampede did not immediately respond to a

request for a comment.

The United States is having its highest

single-day tallies of coronavirus

infections. More than 120,000 people tested

positive for the virus Thursday, according to an

NBC News tally.

The Midwest and the Southwest have been hit

hard. In New Mexico, the number of cases

steadily rose over the last two weeks, jumping

from just over 700 on Oct. 8 to 1,210 on Sunday,

according to the Johns Hopkins University

Coronavirus Resource Center.

Nearby El Paso has also had a surge in

infections, with the number of cases nearly

doubling in the last month, according to Johns

Hopkins. So many people are

dying in the county that six mobile morgues have

been set up, with four more on the way,

officials said Monday.

JBS Protecting Older Workers Due to New Outbreak

JBS USA voluntarily removed 202 workers,

including those who are 60 and older, from its

Greeley, Colorado, beef facility as part of its

vulnerable population policy, a company

spokesperson said in an email. The workers are

getting full pay and benefits.

The plant is one of the largest in the country

with about 3,500 workers. The spokesman said

there have been 32 cases among its Greeley plant

workforce in the most

recent wave of community outbreak in

Weld County, where the plant is located. In

recent weeks, the company said, Weld County has

had more than 4,450 cases and Colorado has had

more than 69,120 cases.

Across all of JBS's U.S. facilities, the

spokesperson said the company has removed more

than 5,000 people — roughly 8% of its workforce

— with pay and benefits during the most recent

wave of infections spreading across the country.

To accommodate for staff reduction, JBS said it

may simplify the mix of products in a plant.

As the meat industry continues to fight off

coronavirus surges in communities across the

country, JBS is ramping up its defensive

strategy to protect the more at-risk members of

its workforce.

Early in the pandemic, meat plants became hot

spots for outbreaks and many criticized the

industry for responding too slowly. During the

course of the pandemic, many meatpackers —

including JBS, Tyson and Smithfield — have

implemented precautions in plants, including

temperature checks, staggered start times,

required use of masks, physical barriers, UV

germicidal air sanitation and plasma bipolar

ionization technologies. But even with

precautions, coronavirus has continued to

spread.

The original outbreak at the Greeley plant was

among the worst in the industry, with six deaths

and more than 290 cases as of October, according

to the Greeley Tribune. In September, the

Occupational Safety and Health Administration

cited the plant with a proposed $15,615 fine for

"failing to protect employees" from the

coronavirus.

JBS said it first removed vulnerable workers at

the Greeley plant in late March. Some returned

in August as case numbers subsided in the

community. Many beef, poultry and pork plants

across the country temporarily

closed to

stop the spread of the virus early on in the

pandemic. The

Greeley plant temporarily

shuttered in April after urging from

the local union.

Since March, the

largest meat companies in

the country have spent hundreds of millions on

COVID-19 precautions and tens of thousands of

workers have been infected. JBS USA has invested

more than $415 million into COVID-19

precautions, support and bonuses. Executives

have expressed more confidence since precautions

have been in place, even as the virus has surged

across the country.

"I’m pretty confident we are not going to have

the size of the disruption we saw in April and

May," JBS CEO

Andre Nogueira said at

The Wall Street Journal’s Global Food Forum in

October.

As cases surged around Colorado, JBS said it

partnered with the state to offer testing to its

workers at a location near the Greeley plant.

Many say testing has helped

to slow the

spread of the virus in processing plants.

"We are optimistic that this, coupled with our

weekly surveillance testing and contact tracing

protocols, has contributed to the low number of

positive cases at our facility despite the high

rate of spread in the surrounding community,"

the spokesman said.

Last month, JBS

USA also announced it would cover 100% of

employee costs associated with COVID-19

diagnosis and treatment. That move came in

addition to free COVID-19 testing, which has

been available for the company’s workers since

March. To date, JBS has conducted more than

20,000 random surveillance tests of asymptomatic

team members, the company said.

Amid the continued spread of the virus, the food

industry is pushing

for workers to be prioritized for

vaccinations. Last week, the North American Meat

Institute urged

officials to

place meat and poultry workers at the front of

the line to receive the COVID-19 vaccine. JBS

said the company is actively working with state

and local health departments to coordinate

vaccination of its workforce as soon as it

becomes available.

"The meat and poultry industry was among the

first sectors to be challenged with the

pandemic, and since March the industry has

implemented effective programs and controls to

stop the spread of COVID," NAMI CEO Julie Anna

Potts said in an emailed statement. "Our efforts

are working, but access to vaccines remains the

most critical tool to protect this critical

infrastructure workforce."

Meat Processors Should Consider the Cleanrooms

International FFU Rather Than Partitions

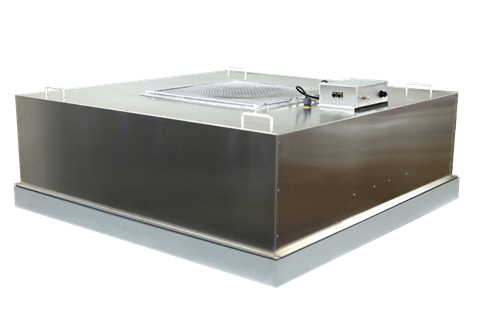

This new fan filter unit from Cleanrooms

International is just what meat processors

should be installing instead of partitions.

Features of the SAM44 Fan Filter Units

include:

-

HEPA filter 99.99% eff. @ 0.3

micron

-

Modbus interface card for speed

control through BMS

-

200-277V 50/60 Hz EC motor

-

CAT5 connection

-

On/Off switch

-

Handles

-

Protective inlet screen

-

Aluminum construction, mill

finish

Final filter is protected with a white epoxy

diamond pattern grille and are tested according

to accepted procedures as described by the

Institute of Environmental Sciences (IEST)

and/or ISO standards.

Optional Features

-

ULPA filter 99.9995% eff. @ MPPS

-

BACnet MSTP or BACnet IP control

via BMS

-

Local control via potentiometer

Purar Offers Reusable Mask with Unique Features

Your air, your style, and you. Breathe in

healthy and clean air with Purar, where the

useful is separated from the harmful particles

by providing all with comfortable, highly

functional, and appealing face masks, while

never compromising on personal style.

Having experienced Shanghai China’s long season

of air pollution first hand, Purar’s co-founder,

Jasmine/Xiaohua Meng, found that wearing a mask

was the only way to protect yourself. As a daily

mask user, she experienced the discomfort of

wearing standard surgical facemasks, which make

breathing harder from increased humidity, fogs

up glasses, and can irritate the wearer.

With the question in mind of finding a highly

protective, comfortable, and stylish

alternative, Jasmine delivered the pitch to her

employer, Mann+Hummel, which makes most of its

billions annually from industrial air filter

manufacturing; conventional car filters, to be

specific. Headquartered near Stuttgart, Germany,

Mann+Hummel has been looking for alternative

directions to pivot into, given that the

conventional car market is changing

dramatically. So a few years ago, Mann+Hummel

launched a startup contest called InCube, the

winning idea gets you six months at a startup

incubator, Plug and Play Tech Center, in

California.

Purar emerged as a winning product for the 2019

contest and was formally launched in the Plug

and Play’s Acceleration program in Silicon

Valley, with a global team of developers working

to create a mask that not only works well, but

also feels like a seamless part of our wearers.

Derived from the words “Pure Air”, the facemasks

are engineered by the filtration experts at

Mann+Hummel to achieve the KN95’s filtration

level, giving it the ability to filter more than

95% of the 0.3 micron particles. Besides being

certified for KN95 standards, Purar facemasks

has also passed the leakage test according to

GB2626-2019.

In terms of the design, the reusable facemask

includes a filter that can be replaced and a

sustainable outer shell which is washable. The

washable shell is crafted with an ergonomic

design that is configured carefully with

polygons for fitting comfortably according to

your face shape. An additional feature of the

mask is the neck grip that does not hurt your

ears as much as ear-looped mask. This neck grip

provides more convenience for wearers who use

wire or wireless audio device such as headphone

or AirPods or even female wearers who

accessorize their ears with large chunky

earrings. For those who wear glasses, the mask

comes with a pre-formed nose support that helps

prevent glass-fogging issues.

Each mask is available in 2 sizes (size S and L)

and includes 6 stylish colors: Blue, Black,

Burgundy, Grey, Pink and Mauve. A box of mask

retails at USD49 and comprises of a mask shell,

2 replaceable filters (Protect Plus and Lite

Comfort) and a travel pouch. Protect Plus filter

is tested and certified for standard that

similar to American N95 (GB2626-2019,

certification KN95) to provide full protection.

Whilst Lite Comfort filter provides higher air

permeability than Protect Plus to provide more

comfort and breathability.

Purar mask is available in 6 stylish colors:

Blue, Black, Burgundy, Grey, Pink and Mauve

Purar does not stop at just offering a highly

fashionable facemask to end-consumers, it goes

beyond this by also offering customizable mask

for B2B corporate needs.

After all, Purar’s mission is to provide

people with a comfortable and fashionable

accessory by leveraging the creativity of young

designers to enable them to breathe cleaner air.

Customizable facemask for corporate needs

M+H Air Purifier Used at Schools

There are systems and areas within buildings

where the upgrade of filtration is simply not

practical. One possible solution is a portable

air cleaner like the TRI-KLEEN 500UV that

utilizes HEPA filtration and UV lights. These

units allow for increased filtration as well as

more air changes to provide a cleaner space.

Place the device as close as possible to the

occupants location, so they breathe the actual

filtered air. The larger the distance to the

unit, the higher the chance to inhale swirling

contaminants which could include viruses. In

addition the TRI-KLEEN 500UV has an optional

exhaust grille that will allow for a flex duct

to be attached and allow for the air to be

exhausted to create a negative pressure in a

space to allow for containment in a specific

space.

Everyone from policymakers to parents wants to

get students back to school, college or

university. While virtual learning has

temporarily filled the void left by school

closures, it can't replace classroom teaching –

or the mental and emotional benefits that being

in school brings. But all these stakeholders

also agree that schools can only be reopened

safely. Parents will look to school

administrators to protect their children.

Educators will trust that they will be provided

with a safe place to work.