Coronavirus

Technology Solutions

November 30, 2020

Face Mask Risk Rating System Launched

Triumvirate Environmental Provides Fit-Testing and Respiratory Protection Expertise

SWM Expanding Electrostatic Media Production in

NC

Cognex

Machine Vision Detects Flaws

in

Masks

Aim Checks Quality of Vietnamese Masks

Vogmask has Spent Nine Years to Achieve Maximum

Comfort, Attractiveness, Tight Fit and

Efficiency of Its Masks

California Wild Fires Can Do Lasting Damage to

Health of Children

Brazilian Jet Manufacture Installing HEPA

Filters in Older Planes As Well As the Newer

Ones

Membrane Media Used in Mask Developed at

University of Kentucky

New Replaceable Membrane Filter for N95 Masks Developed in Saudi Arabia

______________________________________________________________________________

Face Mask Risk Rating

System Launched

A new face mask risk rating system will allow regulators to specify masks that minimize the risk of virus infection. The Face Mask Risk Rating System takes into account penetration and leaks, filter media resistance and estimated defects.

The rating system

has a simple numerical formula which will

be easy to use. The mask rated 19 will provide 6

times more protection than the one rated 115.

|

Inefficiency % |

Leaks % |

Resistance mm H20 |

% Defect |

Total |

|

|

CATER mask 99 |

1 |

4 |

14 |

1 |

19 |

|

CATER mask 95 |

5 |

4 |

9 |

1 |

19 |

|

CATER mask 93 |

7 |

4 |

8 |

1 |

20 |

|

Cloth Mask |

40 |

40 |

15 |

20 |

115 |

|

Surgical Mask |

5 |

40 |

8 |

1 |

54 |

|

LF N95 |

5 |

30 |

14 |

1 |

50 |

|

TF N95 |

5 |

4 |

12 |

1 |

21 |

Many people are wearing cloth masks with risk ratings in excess of 100. Regulators have issued warnings that some masks may be worse than none at all. Duke University research showed that some masks create small droplets after temporarily stopping large droplets. It is therefore very important that the correct risk rating be applied.

From a risk reduction standpoint if 20% of the people wear masks that are five times as effective as inefficient masks the other 80% can avoid masks and still reach the risk level of everyone having an inefficient mask.

Can you imagine a regulation which says if you

have an efficient mask you only have to wear it

20% of the time?

Valved masks are routinely prohibited because of

the 33% leakage of exhaled air. But they can be

very efficient on inhaled air.

|

Mask |

Inefficiency % |

Leaks % |

Resistance mm H20 |

% Defect |

Total |

|

CATER mask 95 |

5 |

4 |

9 |

1 |

19 |

|

Cloth Mask |

40 |

40 |

15 |

20 |

115 |

|

Surgical Mask |

5 |

40 |

8 |

1 |

54 |

|

Valved CATER 95 |

5 |

(33+4)/2 =19 |

9 |

1 |

34 |

When both transmitter and recipient are wearing

the same masks the average of the two remains

the same except in the case of valved masks. The

combined average is 34 when both transmitter and

recipient are wearing valved masks.

This is much better than surgical masks

or cloth masks.

If regulators are so concerned about mask

efficiency that a 34 risk rating is unacceptable

then so are all the other masks except CATER

masks and tight fitting N95 masks.

These examples show the importance of

establishing a Face Mask Risk Rating system such

as now being launched. It is associated with but

partially separate from CATER Mask Decisions.

Triumvirate Environmental Provides Fit-Testing

and Respiratory Protection Expertise

Per OSHA regulations, if employees are required to wear respirators in the workplace, the employer must develop a Respiratory Protection Program (RPP). A major component of a compliant RPP is fit-testing, a protocol that determines whether the respirator forms a proper tight seal around the employee’s mouth and nose. Without a documented fit-test from a trained professional, there is no way to know whether the respirator is actually filtering air to remove dangerous particles, or simply allowing the outside air in through small gaps—which are often invisible.

Beyond proper, documented fit-testing, a truly

protective respiratory program also includes

exposure risk assessments, medical evaluations,

training, and documentation. Triumvirate

Environmental’s professionals are well-prepared

to assist with these required components, as

well as provide higher-level guidance on the

selection of appropriate respirators, HR

policies, and OSHA enforcement during the

COVID-19 pandemic.

Keys to safely operating HVAC systems and

maintaining healthy spaces include:

·

Before HVAC operation:

§

Review records for air quality issues, if any,

at your organization in the past year;

§

Inspect systems and conduct required

preventative maintenance such as coil cleaning

and filter replacement; and

§

Disinfect rooms appropriately in accordance with

CDC guidance.

·

During HVAC operation:

§

A week prior to occupancy, run the HVAC system

in “occupied” mode;

§

Disable occupancy sensors and the demand control

ventilation system;

§

Maintain the air temperature between 68 to 78

degrees Fahrenheit;

§

For mechanical equipment, make sure all the

filters are properly installed and establish a

routine for replacement. The filtration should

be maximized and within the capabilities of the

equipment. Consider upgrading filters; HEPA

filters may not be an appropriate option due to

high pressure drops and the likelihood that

systems will need new filtration; and

§

Perform an air flush before the building is

occupied.

Ventilation Studies • Laboratory, pilot scale, &

manufacturing operations • Control banding for

exposure control • Fugitive emission control •

Dust explosion assessment & control Audits and

Inspections • Laboratory safety, biosafety, &

radiation safety program evaluations • BSL 1, 2,

& 3 laboratory operations • ABSL 1, 2, & 3

animal facility (vivarium) operations

Respiratory Protection • Written programs •

Training • Qualitative & quantitative fit

testing

SWM Expanding Electrostatic Media Production in

NC

In response to customer demand that has more

than doubled over the past year, SWM

International, is ramping up production of its

Alphastar™ Electrostatic Media product at its

Wilson, North Carolina manufacturing facility.

Alphastar Electrostatic Media is a primary

component in HVAC air filtration products,

including MERV 13 rated air filters.

“We began to see demand rising in April due to

the COVID-19 pandemic, and quickly developed

ongoing plans to support our customers.

Expanding our output was critical, as we are an

essential supplier to many of the largest air

filtration companies in the U.S. SWM is

determined to do everything we can to help our

customers deliver the air filters and medical

respirators that are vital tools in stopping

infection spread and improving indoor air

quality,” said Bart Sistrunk, Commercial

Director of Filtration for SWM.

The company is expanding the workforce at the

facility to support the higher production level

and is continuing to evaluate further actions to

increase output. This follows efficiency

projects earlier in 2020 to increase capacity on

the existing production lines. SWM anticipates

ongoing demand for Alphastar media as commercial

and residential customers respond to

recommendations from the Centers for Disease

Control (CDC) and ASHRAE (American Society of

Heating, Refrigeration and Air-Conditioning

Engineers) to upgrade building filtration to a

minimum of MERV 13, which requires more frequent

changes compared to lower level filters such as

MERV 8.

The proprietary fiber blend in SWM’s Alphastar

media is carded and needled into a fully

homogenous material, making it a highly

effective nonwoven for a variety of air

filtration applications, including emergency

respirators, N95 masks, CPAP (continuous

positive airway pressure) machines, and

ventilators.

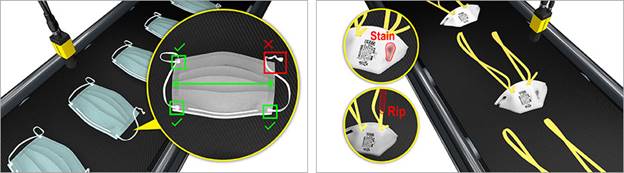

Cognex Machine Vision Detects Flaws in Masks

There are different types of face masks that

help prevent the spread of disease, from a

typical surgical mask to an N95 respirator. This

equipment is crucial to help keep workers safe.

However, these masks only protect users if they

are defect free and pass stringent ISO

standards, which is challenging when demand far

exceeds existing supply. The quality of masks

should be rigorously checked to prevent

defective products from making it to the market,

including checking for flaws such as embedded

hair or stains, measuring the width of the mask,

checking for the presence of straps, and

determining that the straps are correctly

attached to the mask.

By leveraging both machine vision and deep

learning technology manufacturers can ensure

masks are produced in compliance with ISO

standards and catch defective masks before they

are shipped. Cognex In-Sight 8402 vision system

detects the presence of facemask components such

as ear bands and strap welds, while also

measuring the width of the masks to ensures they

are manufactured to the correct size. Many

defects, however, are difficult to predict and

program with traditional machine vision

algorithms. Cognex Deep Learning is trained with

as few as 50 sample images to easily locate and

classify random defects, such as rips, stains,

and stitching errors.

Aim Checks Quality of Vietnamese Masks

Aim is a Vietnamese Company with decades of

experience in quality control. The name stands

for Agriculture, Industry and Marine.

Purchasers can hire the company to visit

Vietnamese media and mask suppliers and check

various quality control procedures. It will also

take samples and perform efficiency tests. It

will determine potential damage to masks during

packaging and check the operations.

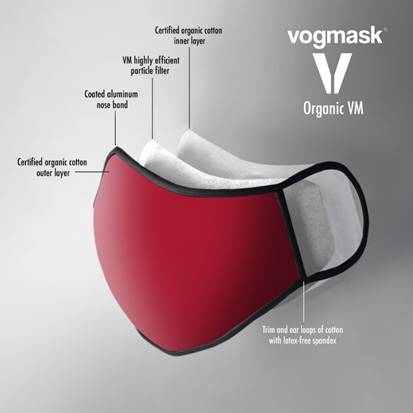

Vogmask has Spent Nine Years to Achieve Maximum

Comfort, Attractiveness, Tight Fit and

Efficiency of Its Masks

Vogmask lists the following attributes that it

strives to achieve in all its masks.

Comfortable:

Suitable constituent materials safe for

respirators (including textiles, filter media,

inks and dyes, packaging) [see folowing design

diagrams]

Designed to facilitate correct positioning on

the user and remain in place

Adequate adjustment options such as no charge

wrong size replacement, head strap accessory and

noseband

No restriction of the user's field of vision

Easy breathing established by inhalation and

exhalation resistance tests

Comfort as important factor in compliance

Attractiveness:

Aesthetics of product appearance on face

Several designs and colors

Encourages compliance in mask wearing

Encourages mask use in all environments

Tight-Fitting:

Manufacturer to supply correct donning, doffing,

and noseband instructions

Product support to ensure correct size

Practical performance testing on test subjects

to determine leakage under normal activities

Efficient:

3rd Party Testing on all design and engineering

changes

NaCl Particle Filtering Efficiency at mean

diameter .3-microns

Continuous flow rate at 85 L/min

Quality plan in manufacturing to include Quality

Checkpoints and Inbound Quality Inspection

Clear communications for consumer on reason for

various particle size testing (most penetrating

particle size)

Relationship of filtering efficiency to

breathing resistance (circles back to comfort)

Vogmask also has

the Organic cotton (GOTS Certified) material as

an alternative to synthetics

to serve highly allergic and

environmentally conscious populations which

are either sensitive to manmade textiles

or prefer natural fabrics.

Both the outer and inner layer of the Organic VM

are organic cotton. The trim is 94% cotton with

6% latex-free spandex, so for highly allergic

mask wearers, these are most agreeable. Note

there is no carbon filter layer. Customers

concerned about synthetic textiles are often

also concerned about coconut-shell derived

carbon ash bonded to textile, so Vogmask has

left it out of the

purest Vogmask VM.

California Wild Fires Can Do Lasting Damage to

Health of Children

A recent article in the New York Times

explained the fires sweeping across millions

of acres in California aren’t just incinerating

trees and houses. They’re also filling the lungs

of California’s children with smoke, with

potentially grave effects over the course of

their lives.

The effects are not evenly felt. While

California as a whole has seen a steady uptick

in smoke days in recent years, counties in the

state’s Central Valley, which is already cursed

with some of the most polluted air, were

particularly hard hit by wildfire smoke this

year.

So for a child, it matters where you live. It

matters how much foul air you breathe in on days

when there are no fires at all. It matters

whether your family can afford an air purifier

at home or whether they can whisk you away when

ash rains down from the sky.

Dr. Kari Nadeau, a professor of medicine at

Stanford who specializes in pediatric allergies

and asthma, said she worried that the damage to

children might last a very long time. It is

well-established that long-term exposure to fine

particulate matter pollution, the kind that

comes out of the tail pipes of cars and trucks,

increases the risk of asthma in children and

compromises their immune systems.

Her latest research suggests that exposure to

wildfire smoke, which contains the same

particulate pollution and more, is associated

with genetic changes in children’s immune cells.

“It could,” she said, “have irreversible

consequences.”

Already, an

estimated 7.6 million children are

exposed to wildfire smoke every year in the

United States, and with climate change making

the American West hotter and drier, many more

children stand to be at risk. “This is a problem

that’s not going to go away,” Dr. Nadeau said.

“We are going to see these very extreme weather

conditions and we should be prepared.”

Patricio, a 7th grader, lives with his parents

and his two younger siblings in a neighborhood

flanked by several busy roads, an airport and

agricultural fields that fill the air with dust.

Patricio has asthma. Even when there are no

fires, there have been times when the air in

California’s Central Valley is so thick with

pollutants that he wheezes and struggles for air

or suffers from a rash of respiratory

infections. The fires are an additional assault

Everything about this area screams bad air

quality,” Patricio said. “If you had a child

with asthma or any person in your household with

asthma and you wanted to move into this area,

it’s not a good idea. I don’t recommend it.”

It’s been a rough year. First, remote schooling

because of the pandemic. Then, a heat wave with

temperatures peaking past 100 degrees. Then, in

mid-August, fires burning to the north and east,

pouring smoke into the valley.

Ash settled over every tree. The air smelled

like charcoal. Patricio looked outside and told

his mother, Gilda Zarate-Gonzalez, that he felt

an “impending sense of doom.”

Even by mid-October, when the smoke had subsided

enough for Ms. Zarate-Gonzalez to propose a

family bike ride, it looked as though someone

had taken a giant gray crayon and smeared it

across the horizon.

Fresno and its neighboring counties in the

Central Valley rank first

in the country for particulate matter pollution,

according to the American Lung Association. Its

childhood asthma

rates are far higher than

the statewide

average.

Several busy highways pass through Fresno. Dust

and chemicals swirl up from the fields. Smoke

gets stuck for long stretches of time until the

winds can blow it westward to the Pacific.

One afternoon in August, a few days after a ring

of lightning fires had turned the skies around

San Francisco orange, Robin Fletcher, 16, took

her dog for a walk.

Within 10 minutes, her face turned red. Her arms

broke out in hives, then her stomach. Her chest

tightened. “It was stressful and scary, so I

started crying,” Robin said. “Not

hyperventilating. But freaking out, kind of.”

Robin has had allergies since she was little,

which also makes her prone to asthma. That

afternoon, her inhaler didn’t help, nor her

EpiPen. Only steroids, administered in an

emergency room, could temper her severe

anaphylactic reaction.

To this day, neither her family nor her doctors

know what brought it on. Resin from a burning

tree? Cars that had gone up in flames? Other

chemicals? Wildfire pollution can contain toxic

metals, petroleum products, plastics and

carcinogens.

“That’s what’s so terrifying,” her father,

Arthur, said. “It looked beautiful. But there’s

stuff out there, floating.”

Unlike the Central Valley, the air in the San

Francisco Bay Area is gloriously clean for much

of the year, and Robin can usually keep her

asthma in check. She plays lacrosse and soccer.

Her private school shuts down for a few days at

a time when wildfire smoke is bad. She is in a

clinical trial, supervised by Dr. Nadeau, to

overcome her allergies.

At home, too, she is well protected. Her mother

is a doctor. Her father has installed an

electrostatic air filter in the ventilation

system, which cleans and humidifies the air as

it circulates through the house. There’s a stash

of N-95 masks in the basement.

And since the day of the anaphylactic attack,

Robin has acquired two new tools: an air quality

app on her phone, and a tube-shaped device to

check her lung capacity. She uses them both to

assess whether it’s safe to go outside.

“I know I can keep myself safe,” Robin said,

“but it’s something on my mind.”

On Dr. Nadeau’s mind is what happens next. Even

after the smoke clears, she wants to know, how

long might the damage last in children exposed

to these sharp spikes in pollution?

There are clues in a robust body of research on

the health effects of conventional particulate

matter pollution. Exposure to that kind of air

pollution is associated with a greater risk of

preterm births among pregnant women, more severe

asthma symptoms among children and, as Dr.

Nadeau concluded in an earlier study, changes in

children’s immune system cells.

Her more recent research, with her Stanford

colleague, Dr. Mary Prunicki, suggests that

children like Robin, exposed

to even short bursts of

wildfire smoke,

show changes in their immune system genes — in

particular those genes that can help the body

respond to allergens further down the road.

What is not yet known, and what Dr. Nadeau seeks

to examine in the months ahead, is how children

exposed to chronic air pollution and then to

acute episodes of wildfire smoke, like Patricio

in Fresno, might be affected differently. “Most

likely, the wildfires are another hammer on

their systems,” Dr. Nadeau said. “That hammer is

a dangerous hammer

https://www.nytimes.com/interactive/2020/11/26/climate/california-smoke-children-health.html

Brazilian Jet Manufacture Installing HEPA

Filters in Older Planes As Well As the Newer

Ones

Embraer has issued a service bulletin allowing

operators of its 50-seat ERJ-145 regional jet to

install high-efficiency particulate air (HEPA)

filters, with the first kits to be delivered by

next month.

The Brazilian airframer, which took five and a

half months to develop the kit, adds that it is

completing work for HEPA filter kits for the

ERJ-140 and ERJ-135 “very soon”.

Source: Embraer

There are more than 250 in-service commercial

ERJ-145s now.

It adds: “The kits for the first 70 aircraft are

already being assembled and should be delivered

by mid-December.”

“Given the moment we are living, developing a

HEPA filter service bulletin for the ERJ-145 is

a must-have solution Embraer developed for

making cabin conditions even safer for

passengers,” says Johann Bordais, president and

chief executive, Embraer Services & Support.

HEPA filters have been in the spotlight recently

amid the global coronavirus pandemic, as

airframers and airlines tout their ability to

trap most bacteria, viruses and fungi.

HEPA filters are already a standard feature on

Embraer’s later generation of aircraft, such as

the E-jet family, and on Embraer Executive Jets.

There are more than 250 ERJ-145s in commercial

service globally, with another 261 jets in

storage.

Membrane Media Used in Mask Developed at

University of Kentucky

With funding and support from Kentucky's

National Science Foundation (NSF)-sponsored

Established Program to Stimulate Competitive

Research (EPSCoR), a team from UK and Somerset

Community College (SCC) is creating 3D-printed,

membrane-filtered face masks that can inactivate

the coronavirus. The goal, through passive

decontamination, is to not only protect people

from breathing in viruses, but to eliminate them

on contact.

Isabel Escobar, professor of chemical and

materials engineering in the UK College of

Engineering and associate director of UK’s

Center of Membrane Sciences, is working to

perfect the central component of the masks — the

filter. This filter will contain a unique

membrane composed of a polymer dissolved in a

nontoxic, bio-derived solvent, which will then

be chemically bound to medical-grade silver

nanoparticles, known for their antiviral

efficiency.

“The virus is about 120 nanometers in size — in

the world of membranes, that's large,” Escobar

said. “Even more so, it's not going to come as a

virus by itself, flying in the air. It's going

to come in the saliva, so it's going to be a

much larger particle. A large particle is just

not going through (this filter).”

But Escobar’s research takes it a step further,

adding the silver nanoparticles for the passive

disinfection.

“(The silver nanoparticles) prevent the virus

from binding and attaching, and it inactivates,”

she said.

Eric Wooldridge, professor of additive

manufacturing at SCC, and his team will be

providing the substrates, or the structure, of

the masks. These substrates, made of

polypropylene, will be 3D-printed in a honeycomb

pattern to allow for a strong, breathable

structure. The antiseptic membranes from

Escobar’s team will then line the insides,

ultimately creating a safer, cost-effective and

environmentally sustainable PPE that would match

or exceed N95 mask requirements.

“Utilizing SCC’s additive manufacturing

capabilities to produce the base components

combined with UK’s groundbreaking nanotechnology

to provide the coatings, our goal is to not only

demonstrate that it can be done, but that we can

rapidly scale production through our KCTCS

additive manufacturing network,” Wooldridge

said. “This collaboration represents one of the

primary goals of the KY NSF EPSCoR program:

bridging the gap between theoretical research

and practical application to rapidly respond to

a need and create solutions that truly matter to

the Commonwealth.”

New Replaceable Membrane Filter for N95 Masks

Developed in Saudi Arabia

The filter has a smaller pore size than normal N95 masks, potentially blocking more virus particles, according the researchers from King Abdullah University of Science and Technology in Saudi Arabia.

Researchers have developed a more efficient membrane filter that can be attached to a regular N95 mask and replaced when needed.

The filter has a smaller pore size than normal N95 masks, potentially blocking more virus particles, according the researchers from King Abdullah University of Science and Technology (KAUST) in Saudi Arabia.

Since the outbreak of COVID-19, there's been a worldwide shortage of face masks -- particularly the N95 ones worn by health care workers, they said. Although these coverings provide the highest level of protection currently available, they have limitations, the researchers noted in the journal ACS Nano.

N95 masks filter about 85% of particles smaller than 300 nm, they said. The researchers noted that SARS-CoV-2, the coronavirus that causes COVID-19 is in the size range of 65-125 nanometres (nm), so some virus particles could slip through these coverings.

Due to shortages, many health care workers have

had to wear the same N95 mask repeatedly, even

though they are intended for a single use. To

help overcome these problems, Muhammad Mustafa

Hussain and colleagues wanted to develop a

membrane that more efficiently filters particles

the size of SARS-CoV-2 and could be replaced on

an N95 mask after every use.

The researchers first developed a silicon-based,

porous template using lithography and chemical

etching. They placed the template over a

polyimide film and used a process called

reactive ion etching to make pores in the

membrane, with sizes ranging from 5-55 nm. The

researchers then peeled off the membrane, which

could be attached to an N95 mask.

To ensure that the nanoporous membrane was

breathable, the researchers measured the airflow

rate through the pores. They found that for

pores tinier than 60 nm, the pores needed to be

placed a maximum of 330 nm from each other to

achieve good breathability.

The hydrophobic membrane also cleans itself

because droplets slide off it, preventing the

pores from getting clogged with viruses and

other particles, according to the researchers.