Coronavirus

Technology Solutions

November 24, 2020

Millions of Lives Saved with Intelligent Mask

Program

Millions of Lives at Risk

Billions of Masks Needed to Achieve Herd

Immunity

Electrospun Nanofibers Available for CATE Masks

4C Air Supplies Nanofiber Based Masks for $3

Each

Dipole Providing Nanofiber Media for Military

Protection

Dipole Teaming with Gemstone Bio on Nanofiber

Media for Masks

Bionicia Supplies Electrospinning Equipment and

Does Contract Manufacturing

______________________________________________________________________________

Millions of Lives Saved with Intelligent Mask

Program

More than 55 million people have contracted

COVID-19 globally and 1.3 million have died.

More than 3 million more people will die in the

next 13 months unless policies change.

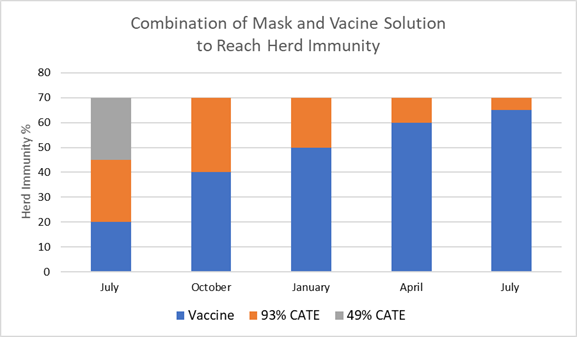

Many of these of lives can be saved by an

intelligent mask program. Acceleration of the

use of 93% rated CATE masks combined with

decreasing use of 49% rated CATE masks and

restrictions against 20% rated CATE masks are

what is needed. A combination of vaccines and

masks can provide the equivalent of herd

immunity (70%) by July of next year.

Experts are unanimous in their belief that masks

can save millions of lives in the next 13

months. But this is like saying that drugs can

save millions of lives. This statement may be

true but only if the right masks are worn. Some

masks provide no protection. The belief that

these masks capture large cough and sneeze

droplets is valid but there are two big

problems.

·

Most virus is

transmitted in small droplets through breathing

and talking

·

Large droplets

temporarily captured evaporate and transmit the

virus on a delayed basis

The idea that all masks are created equal has

been as responsible for infections as the idea

that masks are not important or that mandates

unfairly violate civil rights. It is therefore

imperative that the public understand

differences between masks and wear ones which

provide protection as well as reduce

transmission.

There are four aspects of masks which are

important.

·

Comfort: People

will not wear masks all day if they are not

comfortable.

·

Attractiveness:

As a major article of clothing an

attractive mask will be used more than an

unattractive one.

·

Tight Fit:

It is very difficult to achieve a tight.

But if 50% of the air leaks around the mask 50%

of the virus will as well.

·

Efficiency: Many

masks claim high removal efficiency on viruses

which are the size of perfume or smoke. But

unless valid performance tests are available the

efficiency is questionable.

These four important aspects form an acronym.

CATE masks are what every person will want to

have. There are many reusable versions of CATE

masks which make them affordable even it the

initial price is 30 times that of a disposable

mask.

If everyone were to start wearing masks with a

93% CATE rating tomorrow most of the

transmission would stop and millions of lives

would be saved. This may not be possible

immediately. But within six months everyone

could have 93% rated CATE masks.

In the meantime there are sufficient 49%

rated CATE masks to be used where the 93% rated

masks are not available. It will be equally

important to warn people against using masks

with a rating below 20%. They provide access to

restricted areas and therefore result in more

infections than if they were not available

So governments who are already mandating masks

have to clarify

their policies. They should provide

guidance which minimizes restrictions for those

with 93% rated masks. The guidance should

provide more limited access to those with 49%

rated CATE masks. They should prohibit access to

those with 20% rated CATE masks as they now do

for people with no masks.

Since CATE masks are reusable the cost per

wearing is low. The fastest and best way to

implement this program is not through government

purchases but just through guidance and

stipulations regarding mask use. The funding can

be part of the general support programs already

available in most countries.

The private sector has the capability to quickly

ramp up production. This can be done cost

effectively even though the market will surge

and then shrink in 2022. The key is use of

materials and resources already supplied in

other markets. So this becomes just one more

application for a product rather than the sole

market. Even with billions of people wearing

reusable masks the weight of non wovens

being consumed will be tiny compared to diapers,

wipes, or other high volume products.

The technology is also highly developed.

93% CATE masks have been used for years

for air pollution protection, wildfires, pollen

and immune depressed conditions

Millions of Lives at Risk

The death toll in the United States, currently

at 244,250, could nearly double by March 1 to

438,971, the Institute

for Health Metrics and Evaluation (IMHE) at

the University of Washington’s School of

Medicine forecasted in its latest projection.

Add Europe, which is in the midst of a second

wave of infections, and the rest of the world,

and the global death toll could reach a

staggering 2.8 million by March 1, the

IMHE projected.

“When

you see that Europe is already up to 4,000-plus

deaths a day, and it just keeps growing. We’re

on a similar trajectory,” Dr. Christopher

Murray, a professor of health metrics sciences

at the University of Washington and director of

the IHME, told NBC News. “We’re just about four

weeks behind."

More than a half million

lives could be lost to COVID-19 by 28 February

2021 in the USA, suggests a modeling study

published in Nature Medicine. The paper

also estimates that universal mask use could

prevent the worst effects of epidemic

resurgences in many states and could save nearly

130,000 of those half million lives.

The first major impact of

vaccines will be in the second quarter 2020. So

by July 1, 2021 twenty percent of the world

could be vaccinated.

This could reach 50% by the end of 2021.

By that point in time the U.S. deaths

could reach 800,000 or more. World death tolls

could reach 5 million people.

Billions of Masks Needed to Achieve Herd

Immunity

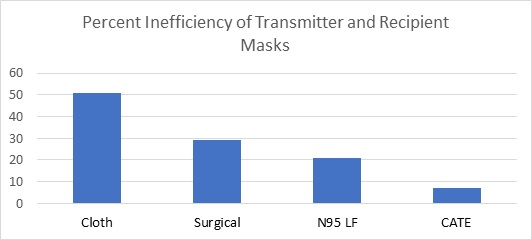

CATE is an acronym for Comfortable, Attractive,

Tight Fitting, Efficient. These masks have been

available for many years to combat air

pollution, wildfires and pollen. they are the

ideal selection for the general public in the

fight against COVID. Here are the numbers.

In

a room where people are social distancing at six

feet and MERV 8 filters are used in an HVAC

system with three air changes per hour unmasked

individuals will be generating a cloud of virus

particles similar to perfume or cigarette smoke.

If masks are worn by transmitters as well as

recipients, the net protection is a combination

of the performance of both masks.

The net effectiveness is a function of the

potential capability of the mask minus failure

to achieve a tight fit and periods where the

mask is discarded due to discomfort or social

drivers. When all is considered the CATE mask

combination is 93% effective compared to only

49% for the cloth mask.

Mask type: CATE masks are generally reusable and

have various features to make them

attractive, tight fitting and comfortable as

well as efficient. Surgical masks are efficient

but not tight fitting. N95 masks can be

fitted for a tight seal but when worn by general

public they are often not used properly.

Cloth masks can excel in comfort and

attractiveness but are loose fitting and

inefficient.

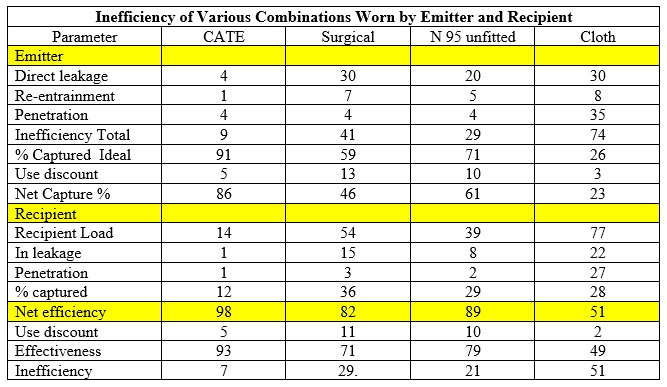

Direct Leakage: This is the amount of air which

is exhaled around the mask directly.

Re-entrainment: Droplets initially captured on

masks evaporate and split causing virus to

escape.

Penetration: This relates to the efficiency of

the filter media.

Use Discount: Masks should be worn as

appropriate. Cloth and CAT masks are more

comfortable than the others and are more likely

to be used in borderline situations.

Recipient Load: This is the virus escaping the

transmitter mask.

In

Leakage: This is the amount inhaled around the

mask seals.

There is no question that tight fitting

efficient masks are the most effective weapon

against COVID. These masks prevented any

U.S. medical staff fighting Ebola to become

infected. The COVID incidence among medical

personnel in high COVID environments is very

low. In cases where these personnel had no

choice but loose fitting surgical masks the

infection rate was high. If a comfortable,

attractive version is available to the general

public the battle can be easily won.

A combination of masks and vaccinations can

create herd immunity quickly. It will be a

combination of CATE, surgical and medium

efficiency cloth masks. It will not include

inefficient cloth masks.

Because CATE masks are tight flitting,

efficient, comfortable and attractive they will

be 93% effective where utilized. It was

determined that only 1 mask would be needed per

quarter due to reusability.

This will be the most cost effective

option.

|

Quarterly CATE Masks Needed to Reach 70% Herd Immunity |

||||||

|

Date |

Cumulative % Vaccinated |

Add % to Reach 70 |

Mask Inefficiency |

% Needing Masks |

People Needing Masks Millions |

Masks Millions 1/person |

|

July 1, 2021 |

20 |

50 |

7 |

54 |

3,225 |

3,225 |

|

Oct. 1, 2021 |

40 |

30 |

7 |

32 |

1,920 |

1,920 |

|

Jan. 1, 2022 |

50 |

20 |

7 |

22 |

1,320 |

1,320 |

|

April 1, 2022 |

60 |

10 |

7 |

11 |

660 |

660 |

|

July 1, 2022 |

65 |

5 |

7 |

5.4 |

323 |

323 |

The surgical masks have high filtration

efficiency but lots of leakage. The assumption

is that the usage will be just one per day or 90

per quarter. To meet the needs of the world on

July 1 2021 with 20% of the 6 billion active

people vaccinated there would be a demand for

378 billion masks per quarter. This reduces to

just under 38 billion by July of 2022. Since

meltblowns are typically used in surgical masks

and there is a big investment and delay in

building new melt blown lines it is very

unlikely that the suppliers would or could gear

up for a market which will peak in the next year

and then shrink substantially.

|

Quarterly Surgical Masks Needed to Achieve 70% Herd Immunity |

||||||

|

Date |

Cumulative % Vaccinated |

Add % to Reach 70 |

Mask Inefficiency |

% Needing Masks |

People Needing Masks millions |

Masks Millions 90/person |

|

July 1, 2021 |

20 |

50 |

29 |

70 |

4,200 |

378,000 |

|

Oct. 1, 2021 |

40 |

30 |

29 |

42 |

2,520 |

226,800 |

|

Jan. 1, 2022 |

50 |

20 |

29 |

28 |

1,680 |

151,200 |

|

April 1, 2022 |

60 |

10 |

29 |

14 |

840 |

75,600 |

|

July 1, 2022 |

65 |

5 |

29 |

7 |

420 |

37,800 |

The cloth masks range in efficiency. In the

example below we have selected relatively

efficient designs. Many would have a 90%

inefficiency rating. We have selected reusable

masks in the $15-30 price range.

Even with a 51% inefficiency rating it

would not be possible to achieve herd immunity

with only 20% of the people vaccinated. You

would need to mask 102% of the active

population.

|

Quarterly Cloth Masks Needed to Achieve 70% Herd Immunity |

||||||

|

Date |

Cumulative % Vaccinated |

Add % to Reach 70% |

Mask Inefficiency |

% Needing Masks |

People Needing Masks millions |

Masks Millions 1/person |

|

July 1, 2021 |

20 |

50 |

51 |

102 |

6,120 |

6,120 |

|

Oct. 1, 2021 |

40 |

30 |

51 |

61 |

3,660 |

3,660 |

|

Jan. 1, 2022 |

50 |

20 |

51 |

41 |

2,460 |

2,460 |

|

April 1, 2022 |

60 |

10 |

51 |

20 |

1,200 |

1,200 |

|

July 1, 2022 |

65 |

5 |

51 |

10 |

612 |

612 |

Herd immunity could be achieved by July 2022 if

10% of the active people are wearing cloth masks

and 65% are protected through vaccinations.

However of the 5% who are not vaccinated,

probably half are in fear of side effects. These

people will be ones who will want CATE masks

rather than cloth masks because of the higher

protection.

Because of the huge immediate needs quick herd

immunity will only take place with some mix of

CATE, Surgical, and Cloth masks. But it is

achievable. The Biden Administration is

considering a mask mandate. Many countries

already have them. The problem is that without

specifying effectiveness some people are wearing

masks which provide almost no protection.

One way to achieve herd immunity would be to

specify CATE masks for those who are at most

risk and allow surgical and cloth masks for

others. However, for those masks with lower

effectiveness some specification must be set. It

should be some combination of maximum

penetration plus leakage. Europe has some

community mask specifications set around 80%

efficient media. However without fit being

included the specifications are inadequate.

The requirements can be based on expected load

factors. CATE masks could be required in subways

and theaters. Lower efficiency levels could be

allowed for walking suburban streets or in

grocery stores which have HEPA filtration and

laminar air flow at checkout counters. This

means that people may carry several masks and

use the one appropriate for the setting.

The requirements can be synchronized with the

production capabilities of suppliers. If the

guidelines are set appropriately, we could have

herd immunity in six months and save many

hundreds of thousands of lives.

Electrospun Nanofibers Available for CATE Masks

Fernando Gomollón-Bel, a freelance writer based

in Cambridge, England interviewed some nanofiber

producers for an article in Chemical and

Engineering News. Excerpts are show below.

Subsequent articles provide more information on

the companies interviewed based on McIlvaine

research. The Alerts have many articles on a

number of producers but some of the producers

quoted in this article have not been previously

analyzed

“Electrospinning is like making spaghetti but

using electricity to help us pull,” says Yi Cui,

a professor of materials science at Stanford

University and cofounder of 4C Air, a start-up

that manufactures air filtration systems based

on nanomaterials. The technology is not new.

Electrospinning was discovered in the 1930s, and

“it has been used to make nanofibers for

decades,” Cui says. But the pandemic has created

a new market.

4C Air was originally formed to develop a

material to tackle air pollution. “Fine

particles are extremely dangerous, even more

than officially recognized,” says Steven Chu, a

cofounder of the firm and a Nobel laureate in

physics. Chu and Cui say the firm’s

nanomaterials filter these fine particles

exceptionally well. And since the aerosol

droplets that disperse the novel coronavirus are

similar in size, they saw a new opportunity.

Maryland-based DiPole

Materials also specializes in making custom

nanofibers. When the pandemic struck the US, the

firm redesigned most of its processes. “We soon

started working hand in hand with people that

needed our help,” DiPole CEO Ken Malone says.

“Had it not been for COVID, we probably wouldn’t

be in the filter business.”

Nanofibers make good filters

mostly because of two factors: mechanical and

electrostatic interactions with aerosol

particles. Richard L. Corsi, an expert in indoor

air quality at Portland State University,

compares mechanical filtration to spaceships

flying chaotically through a forest.

“It is like those epic

battles in Star Wars,” he says. “If there are

many trees along the way, the ships are more

likely to crash.” And if the trees are

disorganized and entangled with branches, they

are harder to dodge.

For this reason, nonwoven

fabrics—such as those obtained by

electrospinning—are more efficient at

intercepting small particles. On top of that,

nanofibers have higher adsorption surface areas,

giving them a greater ability to capture

droplets and particles.

The electrostatic

charge imparted by electrospinning also

plays a role in how nanofibers filter aerosols.

“These interactions give the extra boost to

remove additional particles,” Corsi says.

Traditional N95 masks also rely partly on

electrostatics. They are made with dielectric

microfibers that maintain a surface charge for

long periods of time, and aerosol droplets stick

to them like pieces of paper to a balloon. But

Cui argues that this effect is more pronounced

with electrospun nanofibers.

“When you go to small particles and small

fibers, the [electrostatic] effect begins to

play an increasingly important role,” he says.

Cui points to independent testing that shows

that the firm’s products effectively filter the

most penetrating aerosol particles. 4C Air says

all its nanofiber masks have been tested by the

US National Institute for Occupational Safety

and Health and received the N95

certification—meaning they filter at least 95%

of airborne particles.

Nanofibers also make masks more comfortable.

“They allow more air to pass with the same

filtration efficiency,” says Scott R. Gaboury,

chief operating officer of DiPole. The main

reason for this is physics—specifically, the

resistance that the air meets when flowing

through the mask, commonly known as pressure

drop.

Usually, the higher the filtration efficiency,

the higher the pressure drop, which makes the

most secure masks, such as N95s, less

breathable. However, pressure drop is inversely

proportional to the surface area of filter

fibers, which is a plus for nanofibers. “We have

measured many brands, and usually the pressure

drop is over 100 pascals,” Cui says. 4C Air’s

masks reduce that resistance by up to 60%. “The

breathability is just incredible,” he says.

The Spanish start-up Bioinicia, which also makes

masks using electrospinning, has similar claims

on its website. Apart from enhanced

breathability, its nanofibers dissipate humidity

and heat better than traditional fabrics, the

firm says. Water droplets created by

condensation can dissipate the static charges on

the nanofibers and make them less effective

filters. Long-lasting charge makes for

long-lasting masks, Cui says. “For regular use,

you can probably wear our masks for two weeks

without losing any efficiency,” he says.

Beyond masks, the electrospinning firms are

developing other types of protective equipment.

4C Air’s original business is making window

screens to filter fine particles, including

pollen and pollution.

DiPole Materials is creating a variety of custom-made

products for local groups and businesses.

Rather than masks, the firm manufactures pieces

of fabric that snap into 3-D printed plastic

mask frames or can be inserted into cloth

masks. It’s working with the University of

Maryland Medical Center to develop a specialty

mask designed by doctors. And it recently signed

an agreement with the US Army to create new

nanofiber composites for air filtration.

So far, these companies operate on a small

scale, particularly DiPole, which has limited

production capacity and has fabricated enough

material for only around half a million masks.

“Technically, scaling up electrospinning is not

difficult, but we prefer to focus on creating

specialty products and synthesizing unique

nanofibers on demand,” Gaboury says. Although

big multibillion-dollar companies have knocked

on DiPole’s door, the firm kept filter supply

local, he says.

4C Air runs a pilot line in the US and two

production lines in China. “We can afford a

small production of 2 million masks per month,”

Cui says. Bioinicia said in July that it hoped

to be making 11 million masks per week by now

and expanding beyond Europe. The firm didn’t

respond to interview requests.

Big mask makers like 3M have not embraced

electrospinning; their established techniques

are well entrenched and investing in new

technologies is risky. In terms of air

filtration, it’s safe to stick to proven

technologies, Corsi points out. “It is amazing

how even very simple masks can help us prevent

the spread of the virus.”

Executives at electrospun-fiber firms are aware

that masks based on their materials will remain

niche items during the COVID-19 pandemic. But

they are watching a longer time horizon. “This

is unlikely to be the last pandemic,” Chu says,

and nanofibers could bring masks with “much

better protection and much more comfort.”

4C Air Supplies Nanofiber Based Masks for $3

Each

Air 4C Air has collaborated with AireTech Clean

Technology to produce the Nano-Media KN95

Particulate Mask with 4C Air's BreSafe nanofiber

filtration media and filtration technology: a

nanofiber-based particulate mask that can filter

out 95% of dangerous particles, including fine

particulate matter from wildfires and harmful

germs. It is designed for ergonomic comfort

while meeting the high-quality needs of everyday

personal protection.

Effective against harmful smog from fires and

pollution, unlike cloth and medical masks

Five-layered mask for multiple particle blocking

sizes and comfort

High filtration efficiency (>95%) for 0.3

microns particles

Low breathing resistance compared to competitors

Certified KN95 (GB2626-2006, equivalent to NIOSH

N95)

Masks are sold on the 4C Air website at $3 per

mask in boxes of 25.

Dipole Providing Nanofiber Media for Military

Protection

DiPole Materials, an electrospinning company

that specializes in custom nanofiber

manufacturing, has entered into a Cooperative

Research and Development Agreement (CRADA) with

the US

Army Combat Capabilities Development Command

Chemical Biological Center (CCDC

Chemical Biological Center).

“The CCDC Chemical Biological Center technology

developments are very impressive, and we are

excited to collaborate with them to utilize

Dipole Materials’ capabilities in nanocomposites

fabrication for enhanced protection systems to

be used by US military personnel,” said Scott

Gaboury, CSO with DiPole Materials.

Under the terms of the CRADA, DiPole Materials

will utilize its expertise in nanofiber design

and manufacturing to develop composite fibers

from blends of polymers and inorganic materials

capable of abating various toxic chemicals.

These DiPole-manufactured composite fibers will

have the potential for use in a range of textile

materials that can provide enhanced chemical and

biological warfare protection for US Army

soldiers.

“Last year, when we partnered with the Maryland

Department of Commerce to form the Maryland

Defense Technology Commercialization Center (DefTech),

we wanted to help unlock the economic value of

the brilliant work going on in our state’s

military research facilities,” said Ken Malone,

CEO with DiPole Materials. “This CRADA is

another step in that direction and couldn’t have

happened without the help of DefTech.”

The CCDC Chemical Biological Center is the

nation’s principal R&D resource for chemical and

biological protection to US soldiers. The CCDC

Chemical Biological Center’s activities span the

life cycle of chemical and biological defense

research and product development.

Dipole Teaming with Gemstone Bio on Nanofiber

Media for Masks

DiPole Materials, an electrospinning company that specializes in custom nanofiber manufacturing, is teaming up with Gemstone Biotherapeutics, a biotech company developing novel, bioengineered products for scar-free skin regeneration, to rapidly accelerate production of filters to meet emergency demand for medical masks.

DiPole Materials’ and Gemstone Bio’s teams are

collaborating to manufacture cuts of continuous

roll-to-roll production of nanofiber filters.

This material then gets cut into small,

mouth-sized squares which are then mounted into

medical masks. Gemstone Bio’s expert team brings

its practical knowledge of Good Manufacturing

Practices and wet lab skills to help ensure and

maintain manufacturing quality controls.

“Our team is eager to contribute to the

production of materials needed now for rapidly

scaled medical mask manufacturing,” said Emily

English, PhD, CEO of Gemstone Bio. “Partnering

with DiPole Materials is seamless and

demonstrates the depth of Baltimore’s biotech

and advanced materials’ prowess. As a team, we

embraced the opportunity to help our region and

the nation during the crisis.”

DiPole Materials’ nanofiber filters are the type used in N95 respirators, which provide high end protection for critical medical needs. The combined teams are working with cut and sew shops, makers spaces and engineering companies in Maryland to integrate newly produced filters into their masks to increase the protection provided to healthcare workers and first responders.

“We couldn’t ask for better partners with Emily

and the Gemstone Bio team,” said Ken Malone,

Chairman of DiPole Materials. “Time is of the

essence in this crisis. With Gemstone Bio and

our other Baltimore partners, we’re able to ramp

up mask filter production and speed

manufacturing to get masks in the hands of

medical personnel.

“We’re seeing tremendous partnering among

manufacturers and maker communities in our

region to address the COVID-19 epidemic,” said

Ken Malone, Chairman of DiPole Materials. “We’re

eager to deploy our electrospinning

manufacturing capabilities to join in

accelerating production of critically needed

medical masks.”

Bionicia Supplies Electrospinning Equipment and

Does Contract Manufacturing

The company supplies electrospinning equipment

for a range of industries. This raises the

question whether some of the users could

temporarily switch to making mask materials.

The Fluidnatek LE-500 is an electrospinning

machine conceived to be a pilot-line production

tool that provides all of the capability needed

to develop a product from initial concept to

pilot-scale manufacture. With roll-to-roll

collection, large-volume solution reservoirs,

and high-throughput multi-emitter spinning

heads, the LE-500 is the ideal electrospinning

equipment for fabrication of pre-production

volumes of production-quality materials.

However, the LE-500 can be run either in R&D

mode or in manufacturing mode, that way being a

flexible electrospinning device as well.