Coronavirus

Technology Solutions

November 18, 2020

COVID is a Lottery

Where You Want to Minimize the Number of Tickets

Lonza to Make Moderna

Vaccine in the U.S. and Switzerland

EU Approves 4th

Contract with Pfizer

Sonovia Mask Relies on Anti-Microbials Rather

than Sub-Micron Filtration

U.S. Death Toll Passes 250,000

_________________________________________________________________________

COVID is a Lottery

Where You Want to Minimize the Number of Tickets

Covid is a lottery

you want to lose. If you live in the U.S. you

presently hold about 3% of the winning tickets

to win a prize and about 0.5% of the tickets for

the grand prize (death). These are not good

odds. As a driver or passenger in a country with

a 65 mph speed limit you hold 0.5% of the

tickets to win the grand prize. But this is over

an entire life time and not just six months.

We are willing to

take the risks associated with automobiles

because of the benefits. If we cut the speed

limit back to 55 mph we would increase life

expectancy by only a few months. So this is an

acceptable risk. Our COVID strategy should be to

reduce the number of winning tickets until they

are comparable to automobile travel.

Relative

to masks the percent of winning tickets depends

on

·

virus load

·

mask performance

·

mask use (in part a

function of comfort and attractiveness)

McIlvaine has

compared the combination of fit and efficiency

to determine mask performance of CATE masks

(Comfortable, Attractive, Tight fitting,

Efficient) to cloth masks, surgical masks and

loose fitting

N95 masks. CATE masks reduce the number

of lottery tickets by seven fold vs the others

if worn for identical times. If due to comfort

and attractiveness CATE masks are used

more frequently this further reduces the

number of tickets.

CATE masks can be

supplied with various levels of efficiency.

Normal leakage is 2% to 8%.

Media efficiency can be 90%, 95% or 99%.

So with the highest efficiency and highest

leakage you are equivalent to the lowest

efficiency and lowest leakage.

Mask use is the other

variable. When the virus load is high e.g.

equivalent to the risk of traveling routinely at

100 mph everyone will want to wear a mask. But

in a situation where the viral load risk is

equivalent to traveling at 65 mph many people

will discard their masks. If they are wearing

comfortable and attractive masks they will be

more inclined to wear masks at this risk level.

Mask selection needs to be made on this holistic

basis with load, performance and use all

considered. It is likely that most people will

want multiple mask designs which are appropriate

for different levels of risk.

The goal will be to match the mask

selection with a risk level equivalent to the 65

mph speed limit.

Lonza to Make Moderna Vaccine in the U.S. and

Switzerland

Swiss drug maker Lonza has

partnered with Moderna and says it aims to

produce 400 million doses of the vaccine

annually. The U.S. firm is aiming for 500

million to 1 billion doses in total for 2021.

Anyone receiving the vaccine will require two

doses, as with Pfizer’s shot, showing how long

it could take, with the current manufacturing

capacity, to vaccinate internationally.

Lonza will produce ingredients within Moderna’s

vaccine, formally called mRNA-1273, in

facilities in the U.S. and Switzerland, where it

is headquartered. Company Chairman Albert Baehny

told CNBC about the “big challenges” facing drug

makers like his when it comes to scaling up

production.

“We can only produce more than 500 million doses

a year if we install additional manufacturing

lines, so it is clear that we need additional

investments in installation if we want to

produce more than 500 million (per year) in the

future,” he told CNBC’s “Squawk Box Europe” on

Wednesday.

Baehny identified more challenges to vaccine

production that the company had had to confront

since embarking on its partnership with Moderna.

“There are a few issues, the first is speed. We

only started 10, 11 months ago and now we are

producing the first commercial batches of the

drug substance in North America, and we are

planning the first batch of commercial volume in

one or two weeks in Switzerland, so the speed

has been a challenge.”

“The second challenge is to find the people. For

each manufacturing line you need 60-70 educated

persons. We’ve installed four manufacturing

lines so you have to identify and train these

people,” he said.

“Then linked to the speed (issue), you have to

have access to the equipment, install the

equipment, and then test your manufacturing

facility, so (these are) big challenges,

resolved, or almost resolved, in less than one

year.”

Temperature, and keeping the vaccines cold

enough during transportation, is another big

challenge.

Pfizer’s vaccine requires a storage temperature

of minus 94 degrees Fahrenheit, or -70 degrees

Celsius. By comparison, Moderna said on Monday

that its vaccine remains stable at 36 to 46

degrees Fahrenheit — the temperature of a

standard home or medical refrigerator — for up

to 30 days. It can be stored for up to six

months at minus 4 degrees Fahrenheit.

“Those are standard conditions in the

pharmaceutical industry,” Baehny said. “So I

don’t see many problems for the distribution,

for the shipping and for the storage of

Moderna’s vaccine,” he said.

Lonza Biologics in Portsmouth NH has ramped up

its production of the vaccine in anticipation of

final approval for worldwide distribution.

"The Lonza Portsmouth site commenced production

in July and began large-scale production at the

end of September,” Lonza spokesman Glenn Myers

said Monday.

“We can't say how much vaccine has been

produced; however, our goal is to produce drug

substance from our Portsmouth manufacturing

suites for 100 million doses per year,” he

added.

Lonza is also bulking up its workforce. “We have

scaled up our production workforce with 70

dedicated employees with a plan to scale to 100

employees as quickly as possible," said Myers.

Lonza CEO Pierre-Alain Ruffieux offered his

congratulations on Moderna’s phase 3 clinical

trial data of its vaccine, called mRNA-1273.We

are proud to support Moderna in the production

of mRNA-1273. Our collaboration will allow for

the manufacture of material equivalent to 400

million doses per year from Lonza’s facilities.

Large-scale production began at our Portsmouth,

U.S., site at the end of September and we are on

track to begin production at our Visp,

Switzerland, site before the end of the year,”

Ruffieux said.

“With positive interim results from both

Moderna’s and Pfizer’s mRNA vaccine candidates,

we are witnessing a major step forward in the

evolution of vaccine technology, with the

potential to change the way we manage infection

and disease in the future,” he added.

EU Approves 4th Contract with Pfizer

The European Commission approved a fourth

contract with pharmaceutical companies BioNTech

and Pfizer, which provides for the initial

purchase of 200 million doses on behalf of all

EU Member States, plus an option to request up

to a further 100 million doses, to be supplied

once a vaccine has proven to be safe and

effective against COVID-19. Member States can

decide to donate the vaccine to lower and

middle-income countries or to re-direct it to

other European countries.

Today's contract with the BioNTech-Pfizer

alliance builds upon the broad portfolio of

vaccines to be produced in Europe, including the

already signed a contracts with AstraZeneca, Sanofi-GSK and Janssen

Pharmaceutica NV, and

the concluded successful exploratory talks with CureVac and Moderna.

This diversified vaccines portfolio will ensure

Europe is well prepared for vaccination, once

the vaccines have been proven to be safe and

effective.

President of the European Commission, Ursula von

der Leyen, said: “In the wake of

Monday's promising announcement by BioNTech and

Pfizer on the prospects for their vaccine, I'm

very happy to announce today's agreement with

the European company BioNTech and Pfizer to

purchase 300 million doses of the vaccine. With

this fourth contract we are now consolidating an

extremely solid vaccine candidate portfolio,

most of them in advanced trials phase. Once

authorized, they will be quickly deployed and

bring us closer to a sustainable solution of the

pandemic.”

Stella Kyriakides,

Commissioner for Health and Food Safety, said: “A

safe and effective vaccine is the only lasting

exit strategy from the pandemic, and is at the

centre of our European Vaccine Strategy. Today's

agreement follows the encouraging first

indications from the clinical trial results and

is further evidence of our commitment to putting

more Europe in the area of health. It is a very

telling example of what the EU can achieve when

working together, as a Union, and a case in

point of what a future European Health Union

will be able to deliver.”

BioNTech is a German company working with

US-based Pfizer to develop a new vaccine based

on messenger RNA (mRNA). mRNA plays a

fundamental role in biology, transferring

instructions from DNA to cells' protein making

machinery. In an mRNA vaccine, these

instructions make harmless fragments of the

virus which the human body uses to build an

immune response to prevent or fight disease.

The Commission has taken a decision to support

this vaccine based on a sound scientific

assessment, the technology used, the companies'

experience in vaccine development and their

production capacity to supply the whole of the

EU.

Vaccine doses for Europe will be produced in

BioNTech’s German manufacturing sites, as well

as in Pfizer’s manufacturing site in Belgium. If

the BNT162b2 vaccine candidate receives approval

from the European Medicines Agency (EMA),

then doses will be ordered by the EU Member

States who have elected to receive the vaccine

as part of this agreement.

Pfizer’s manufacturing plant in Portage played

a big role in the development of the vaccine but

so far production is being limited to the

Belgian site. Pfizer is headquartered in

Manhattan. The company went through several

hands going back to its roots as the Upjohn

Company in Kalamazoo. The company reached a

massive $2 billion deal with the U.S. government

earlier this year, along with its joint venture

partner in the vaccine, BioNTech. Pfizer is

planning to produce as many as 100 million doses

of the vaccine this year. Next year – that

skyrockets to 1.3 billion doses. It is a

two-dose vaccine. That makes production,

distribution, and keeping track of jabs all the

more important.

Sonovia Mask Relies on Anti-Microbials Rather

than Sub-Micron Filtration

The SonoMask is made of a fabric impregnation of

zinc oxide nano particles, which has proven to

have a strong anti-viral effect in laboratory

testing. The fabric has also been tested to

successfully last throughout 55 wash-cycles,

with a filtration rate of 5μm, in accordance

with WHO guidelines. Tests by Taryag

Laboratories showed more than 98% efficiency on

5 micron particles.

It should be noted that N95 masks are

tested using 0.1 micron particles with

efficiency rating being based on 0.3 micron

particles. So the efficiency test method is not

comparable. It claims high overall protection

but this must be based on anti-microbial

features rather than particle removal.

The Wall St. Journal

wrote in May “Sonovia had been working toward

selling machines and chemicals used to add

antibacterial and antiviral properties to

fabric, and it began manufacturing masks using

the technology two months ago, said Liat

Goldhammer, the company’s chief technology

officer. The fabric used in the masks has been

tested successfully on other coronaviruses, and

Sonovia is awaiting the results of recent tests

on the novel coronavirus. They have sold

thousands of masks to consumers in the U.S. and

have also donated thousands to hospitals in

South Africa, Israel and Germany.

The sono-chemical coating methodology was

developed in 2013 at the

Bar Ilan University in Israel. Sonovia’s

team, which includes Chemistry

Nobel Prize Winner Prof. Sidney Altman,

and has used the company’s proprietary formula

to significantly decrease the transmission and

impact of hospital acquired infections globally.

The question is what impact the anti-viral nano

particles have on small virus particles which

pass through the mask. It would seem that there

would be no contact or if there were contact it

would be so brief as to not be meaningful. On

the other hand the material could be effective

on viruses captured by the mask. This could

reduce surface transmission from the mask.

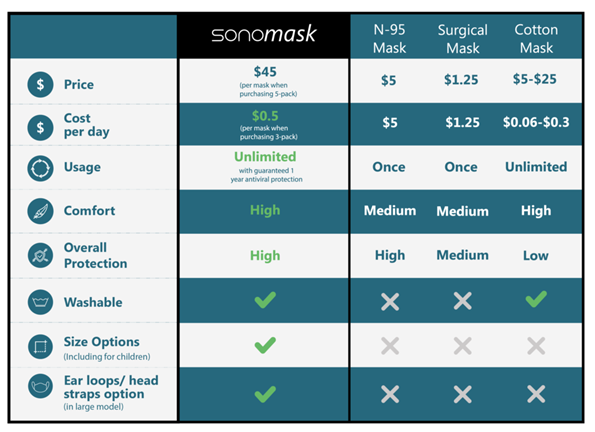

Here is the comparison with other masks prepared

by Sonovia.

Besides the efficiency concern another area of

investigation is health impacts related to

nanoparticles.

One researcher believes that this is an

area where more study is needed.

U.S. Death Toll Passes 250,000

The United States passed a grim milestone on

Wednesday, hitting 250,000 coronavirus-related

deaths, with the number expected to keep

climbing steeply as infections surge nationwide.

Experts predict that the country could soon be

reporting 2,000 deaths a day or more, matching

or exceeding the spring peak, and that 100,000

to 200,000 more Americans could die in the

coming months.

Just how bad it gets will depend on a variety of

factors, including how well preventive measures

are followed and when a vaccine is introduced.

“It all depends on what we do and how we address

this outbreak,” said Jeffrey Shaman, a Columbia

University professor of environmental health

sciences who has modeled the spread of the

disease. “That is going to determine how much it

runs through us.”

Back in March, when the virus was still

relatively new and limited mainly to a few

significant pockets like New York, Dr. Anthony

S. Fauci, the top infectious disease expert in

the country, predicted that it might kill up to

240,000 Americans.

It has now passed that mark, with no end in

sight.

Since the very beginning, preventive measures

like wearing masks have been caught up in a

political divide, and that remains the case

today, as the Trump administration resists

beginning a transition of power to

President-elect Joseph R. Biden Jr. and

cooperating on a pandemic strategy.

New vaccines may begin to have an impact next

year, experts said, and for now, developments in

treating the disease as well as a younger

population getting infected mean that far fewer

people who are admitted to hospitals are dying.

Infections are also being diagnosed

earlier, which helps combat it.

The deadliest day of the pandemic in the United

States was April 15, when the reported daily

toll hit 2,752.

There is always a lag in deaths, compared with

the rate of infection and hospitalizations, and

with the latter measure now hitting records

every day — 76,830 Americans were hospitalized

on Tuesday, according to the Covid

Tracking Project — the death toll is certain to

go on rising.

Covid-19 deaths have continued their bleak march

with little respite throughout the year.

By March 24, a little over a month into the

pandemic, 50,000 people had died. That number

doubled to 100,000 by May 27 and added another

50,000 within two months, by July 29. Two months

later, on Sept. 22, the total reached 200,000.

Toward the end of the summer, the number of

cases being reported daily in the United States

eased, after a brief spike in July. But they

have been soaring again since the beginning of

November.

On Sept. 22, there had been somewhat more than

6.9 million total cases in the United States,

according to

a New York Times database.

As of today, there have been more than 11.5

million.

The combination of the onset of winter, fatigue

with preventive measures, holiday travel and

gatherings as well as the patchwork of responses

across all 50 states is expected to drive that

number still higher.

“We have a lot of people who have not been

infected with this yet,” said Dr. Shaman. “If

you get complacent, the virus does not care. It

is just going to come back.”