Coronavirus

Technology Solutions

November 17, 2020

Avoiding Economic Nationalism in the Pandemic

Era

Demand for Air Purifiers in India Soars

Scottish Meat Processors Dealing with Many COVID

Cases

Automation is the Meat Processing Solution to

COVID

Chinese City Claims Imported Beef Tainted with

COVID

_____________________________________________________________________________

Avoiding Economic Nationalism in the Pandemic

Era

Economic nationalism is not sustainable

according to Gary

Gereffi,

director of the Duke

University Center on Globalization, Governance &

Competitiveness.

“National economies can’t be self-contained

industries. They have to tie in to other parts

of the world. We can re-think relationships, but

we need to find a partnership model,” he said

back in 2017.

“Frequently a US company is dealing with

international production networks where the

assembly of finished goods is moved offshore,

while key components or subassemblies are

provided from the US,” said Gereffi. “Running a

company like that means knowing how to manage

global supply chains involving a variety of

firms. Many US companies that initially focused

on making everything at home have no idea how to

manage this form of coordinated production where

cross-border logistics need to be very precise

and the financing is decentralized. Also, even

if the same companies that left the US now

return, they are likely to bring back far fewer

jobs than before because production was probably

more labor-intensive in the earlier period.”

Raising tariffs on imports could have negative

ramifications on the US (as well as the

exporting country). Many companies have set up

regional and global production networks to make

finished products using a large proportion of

imported parts. Case in point: a car has about

30,000 distinct parts and an iPhone has hundreds

of parts, many of which are not available in the

US supply chain.

“If you try to raise taxes on all the inputs

that are made in different countries, you’re not

only affecting the parts producers abroad, but

also the final goods producers in the US,”

explained Gereffi. This is true for the US

automobile industry, where 40 percent of the $20

billion in auto parts imported from Mexico are

US-made parts and components.

While economic nationalism is not sustainable,

Gereffi believes that actions need to be taken

to support those who might view themselves as

impacted negatively by globalization. In

industrialized nations, the most vulnerable

groups often are workers whose skills and

experience are rendered obsolete by new

technology at home or low-cost imports from

abroad.

“Globalization creates winners and losers and in

the United States we don’t have a strategy for

the losers,” he said. “How do we re-build

workforces among certain industries? We haven’t

paid enough attention to this.”

Gary has recently addressed the question as to

whether the specific circumstances of the COVID

19 crisis change the views about economic

nationalism. In a phone call today with

McIlvaine he pointed to the fact that China is

again a

major exporter of meltblown media and

masks to the U.S. He is asking whether in the

future a reshoring policy for critical items

such as meltblown media and masks will be

necessary for national security reasons.

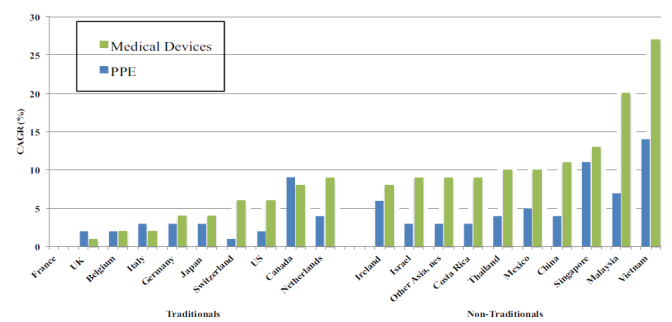

In an article appearing in the Journal

of International Business Policy Gary

analyzed the exports of various countries prior

to the

pandemic.

The market shares in exports had changed in the

2008-2018 period. Traditional exporters such as

the U.S. were surpassed by nontraditional

players such as Vietnam.

Gary points to the spectacular production

expansion of meltblowns in China in the first

few months of the pandemic. He asks why the U.S.

could not have acted similarly. Sinopec was the

company responsible for the biggest increase in

meltblown production. They are one of the

world’s largest energy and petrochemical

companies and were therefor capable of quickly

building melt blown lines to produce 12

million tons per day of media. Without

government funding no company in the U.S. would

take the risk of such a large increase in

capacity without assurance of a long term need.

McIlvaine answered Gary’s question about a

future solution and with the following. The U.S.

could quickly ramp up to produce large

quantities of masks but not to produce large

quantities of meltblown media.

Fortunately meltblown is only one medium for

masks. Membranes and nanofibers can also be

utilized. The present U.S. production of media

which could be used in masks is very large

compared to what is needed in masks. The

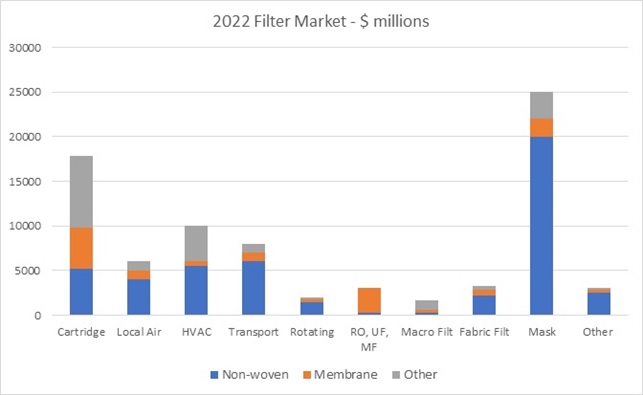

following chart shows the type of media by end

use. Even

with a huge increase in mask production in 2022

to $25 billion worldwide the media use would not

equal that of the other industries combined.

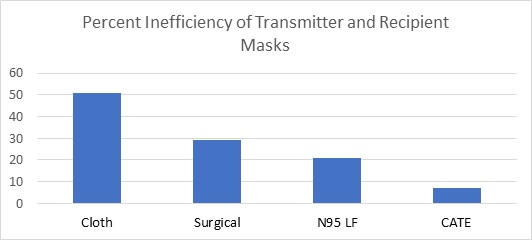

This is not the full story. In fact if the U.S.

and other nations used Comfortable, Attractive,

Tight Fitting, Efficient (CATE) reusable masks

each square meter of media would be 90 times as

effective as if used in a disposable mask. One

reason is that it would be used 30 times instead

of once. Also because of the tight fit it is

three times more effective than a loose fitting

N95 mask.

The CATE mask advantages can be

summarized

·

Much more effective in fighting COVID

·

Can use membrane, nanofiber, or meltblown media

·

Can be reused 30 times

·

Provides much tighter fit

·

Production can quickly be ramped up to provide

the needs in each country

·

Cost per use is no greater than for disposable

masks

McIlvaine has asked Gary to keep us informed of his activities in this area so that we can report them. You can see his complete COVID analysis at:

Demand for Air Purifiers in India Soars

Sales of air purifiers in many Indian cities

such as new Delhi are rising rapidly. Panasonic

has

seen a fivefold increase. Sales are rising for

low priced units at around 10,000 Rs and also

the high priced Dyson units at 50,000 Rs. Sales

at Samsung and Xiaomi are also up substantially.

Scottish Meat Processors Dealing

with Many COVID Cases

Operations were paused at one of

Scotland’s main meat processing

plants earlier this week after a

number of its staff tested

positive for Covid-19, Scotbeef

confirmed the cases at its

Bridge of Allan plant and said a

phased return to getting the

facility up and running was

already under way

In a statement, the company

said: “In the last few days a

number of colleagues working at

our Bridge of Allan plant have

tested positive for coronavirus

and are now self-isolating in

line with national guidance.

“We take the welfare of our

colleagues very seriously and

are working with the relevant

authorities to ensure everyone’s

safety.

“All appropriate action has been

taken and activity was paused on

a temporary basis whilst all

colleagues were tested.

“We continue to work closely

with NHS Forth Valley’s public

health team who are providing

advice and support to assist

with a phased return to full

operation over the coming days.”

Scotbeef said since the

beginning of the pandemic a

range of comprehensive

protection measures had been put

in place including physical

distancing and the use of

personal protective equipment

(PPE).

The company added: “Frequent

inspections of our plants by the

relevant authorities confirmed

that we have taken all necessary

precautions however, given the

size of our workforce and the

rising levels in the wider local

community, it is not unexpected

that we would experience some

positive cases during the

ongoing pandemic.”

The Scotbeef outbreak follows news that a number

of employees at another meat plant – Kepak

McIntosh Donald in Portlethen, near Aberdeen –

had tested positive for Covid-19.

A spokeswoman for NHS Grampian said the health

board was working with Kepak McIntosh Donald and

other partners to ensure all appropriate control

measures are in place within its workforce.

Meat processors trade body, SAMW, declined to

comment on the cases but said all of its members

had installed extra safeguards to observe

Covid-19 rules.

Automation is the Meat Processing Solution to

COVID

The spread of coronavirus throughout the

meatpacking industry, where tens of thousands of

workers have been infected in the United States

alone, is greatly accelerating plans by major

meatpacking companies to introduce automation

and robotics into the plants.

Nationwide, at least 48,000 meatpacking workers

have been infected and 245 have died. The major

meatpacking companies are framing their

investments in automation as a humane response

to outbreaks in their workforces. Management at

JBS’ beef plant in Greeley, Colorado were

revealed by two whistleblowers to have

deliberately allowed potentially infected

workers into the plant and threatened health

care screeners who sent symptomatic workers home

to quarantine. Even before the pandemic, the

meatpacking industry was among the most unsafe,

with massive rates of carpal tunnel and other

repetitive motion injuries.

Workers in a Hog Slaughter and Processing Plant

(Wikimedia Commons)

Instead, the coronavirus is being seized upon to

implement an “Amazonization” of the workforce,

using advances in robotics, in the manner

pioneered by the online retail giant, to greatly

intensify the exploitation of an already

low-wage workforce. No doubt a crucial aim is to

“thin out” the ranks of increasingly restive

meatpacking workers, who have carried out

wildcat strikes and protests at several

facilities in opposition to the companies’ “herd

immunity” policies.

Tyson Foods, the poultry titan of the meat

industry, has rapidly increased its investments

in automation. Over the past three years, Tyson

Foods has invested over $500 million, including

the founding in August 2019 of the Tyson

Manufacturing Automation Center (TMAC) in

Springdale, Arkansas, near its headquarters.

TMAC has been focused on developing automation

and robotics for the company production line in

order to help improve efficiency. This summer,

they tested a robot to perform such tasks as

moving chicken breasts from a conveyor belt into

tray packs for sale in grocery stores. TMAC’s

main focus is the development of an automated

deboning system for poultry. The efforts to

create and implement “robot butchers” is being

sped up, according to Tyson Chief Executive Noel

White.

Like Tyson Foods, Canada’s Lesters Foods was

forced to close many of its meat-processing

facilities early on in the pandemic. Lesters

Foods’ president, Henry Mizrahi, sought

automation as an alternative to maintain

production. Lesters Foods has invested millions

in a five-year plan to increase automation,

including an initial plan to install robotic

arms in one of its facilities capable of moving

packages into larger containers for shipping, to

reduce the rate at which workers remain in close

proximity to one another.

Mizrahi, capitalizing upon the pandemic’s

displacement of workers, is certain automation

is “worth the expense,” adding, “When we started

to see [COVID-19 affect other plants], I saw how

tragic the impact was on human health. The

pandemic has certainly accelerated our strategy

of planning for more robotic equipment.”

Automation, Mizrahi says, will allow “increase

food security and improve plant safety.” But in

reality, workers are being replaced, not

protected. The drive for automation no doubt has

the potential to free workers from laborious and

life-threatening tasks, particularly during a

pandemic, but the result of automation under

capitalism is to increase the exploitation of

workers through layoffs, speedup and wage cuts.

Meat plants account for $1 billion in global

annual sales of automation supplies and

services. Georgia-based Cantrell-Gainco, which

sells chicken deboning equipment manufactured in

Japan’s Mayekawa plant, has fielded double the

usual number of inquiries since the coronavirus

pandemic hit North America.

Mayekawa, which has manufacturing plants in

Brazil, Europe, India, Mexico, Serbia, South

Korea, and the United States, issued a statement

on global sales stating its chicken deboning

robot parts sales are set to rise by more than

$28 million from $32 million in 2019 to $45

million this year and $60 million in 2021. This

includes North American sales regarding

affecting Tyson Foods, Sanderson Farms, and Peco

Foods.

In

Brazil, the country’s fourth-largest pork

processor, Frimesa, has intensified its

automation efforts as COVID-19 sweeps the

nation, spending R$20 million, or $3.53 million

USD, annually. Claudecir dos Santos, Frimesa’s

research manager, said that the automation will

receive a 5 percent annual increase in funding.

Frimesa’s Assis Chateaubriand plant under

construction in the state of Parana will include

five robots, costing approximately €500,000, or

$586,000, each.

Olymel LP, one of Canada’s largest pork and

poultry processors, had a plan for automation

before the pandemic forced the company to

temporarily close its Yamachiche plant for more

than two weeks in late March, after nine out of

the more than 1,000 workers tested positive for

the disease. Upon the facility’s reopening, the

company decided to accelerate the plan, which

entails the use of robots to sort meat cuts,

pick and pack shipments, and stack crates.

Pilgrim’s Pride, a multi-national food company

mostly owned by JBS SA, is currently one of the

largest poultry producers in the United States

and Puerto Rico, and the second-largest chicken

producer in Mexico. After exiting bankruptcy in

December 2009, it moved its US headquarters to

Greeley, Colorado in 2011. The company said in

July it will use automation to double capacity

of a Minnesota plant to produce chicken sold in

tray packs.

Chief commercial officer Henrik Andersen of

Denmark’s automation manufacturer Frontmatec

said, “The outbreaks of [COVID-19] will put

extra spice into the need for automation because

the fewer people you have, the less likely you

are to suffer from these outbreaks.”

In

2018, the global meat sector was valued at

$945.7 billion. It is forecast to increase to

$1,142.9 billion by 2023. Production of meat

worldwide saw an increase between 2016 and 2018,

from 317.2 million metric tons to around 330.5

million metric tons. The world is projected to

produce 60.8 million metric tons of beef in

2020, down 922K metric tons from 2019 due to the

coronavirus pandemic.

Chinese City Claims Imported Beef Tainted with

COVID

Authorities from the Chinese city of Jinan say

they have found traces of Covid-19 on beef,

tripe and packaging from New Zealand and a

handful of other countries, Reuters reported.

However, Prime Minister Jacinda Ardern says she

has been advised it was not a product from New

Zealand and officials were investigating

further.

Officials say the products and packaging that

have been found to have had Covid-19 have come

from New Zealand, Brazil and Bolivia, while two

other provincial capitals detected it on

packaging on pork from Argentina.

Ardern told TVNZ today she is "being advised

it's not our beef".

"We've been advised that's Argentinean beef, so

just trying to get to the bottom of what's been

reported there as we speak but rest assured

we'll keep doing that," she told Breakfast.

"But to this point I've been advised it's not

our beef but we'll keep working away on that."

A spokesperson for the Ministry of Foreign

Affairs and Trade told the Herald they have not

been informed officially of any coronavirus on

New Zealand products.

"There are media reports that the city of Jinan,

in China's Shandong province, has detected

coronavirus on beef products imported from New

Zealand.

"New Zealand has not been informed of this

officially by the Chinese authorities.

The packages entered through ports in Shanghai,

the city's municipal health commission said.

More than 7500 people who may have been exposed

tested negative for coronavirus, it said.

China is ramping up testing on frozen foods

after frequently detecting Covid-19 on imported

products.

It is not known how Covid-19 got onto the

products that came from New Zealand, with a

number of procedures taking place before it

leaves the country.

Frozen pork cases were also reported in the city

of Zhengzhou and Xian. It's not clear if the

cases are related.

The World Health Organization has consistently

said the risk of contracting Covid-19 from

frozen packaging is low.

The role of frozen food and cold temperatures in

potentially transmitting the virus was in the

spotlight in New Zealand when officials probed

the source of a mystery outbreak in August that

began with a worker in a cold store facility.

"We do know from studies overseas, that

actually, the virus can survive in some

refrigerated environments for quite some time,"

director general of health, Ashley Bloomfield,

told reporters at the time.

But how concerned should we actually be?

Having previously stated it's "highly unlikely

that people can contract Covid-19 from food or

food packaging", the World Health Organization

(WHO) reiterated its stance earlier this year.

"People should not fear food, or food packaging

or processing or delivery of food," WHO's head

of emergencies programme Mike Ryan told a

briefing in Geneva in August.

"I would hate to think that we would create an

impression that there's a problem with our food

or there's a problem with our food chains.

"There is no evidence that food or the food

chain is participating in transmission of this

virus. And people should feel comfortable and

safe."

Meat Industry Association chief executive Sirma

Karapeeva said the risk of Covid-19 transmission

by food or food packaging was "negligible".

"Advice from the World Health Organization is

that transmission by airborne droplets and

aerosols is the dominant pathway for Coivd-19

infection," she said.

"We are closely watching and reviewing

international developments about transmission

and taking advice from the Ministry for Primary

Industries and experts at the New Zealand Food

Safety Science Research Centre about how we

respond to these emerging risks as our knowledge

about the virus grows," Karapeeva said in a

statement.

Since the early days of the response to

Covid-19, the industry had been working to

strict protocols that were developed with the

Ministry for Primary Industries and provided

guidance and a minimum standard for processors

for operating.

"The protocol, which is consistent with other

industries and guidance from the World Health

Organisation, means we have a robust first line

of defense against the transmission of the

virus," Karaveeva said.

Under the protocol, employees observe physical

distancing. In situations where this is not

practicable, extra controls are put in place

including personal protective equipment, she

said. Employees also undergo temperature checks.

Karapeeva said companies are also recording who

is working at each site and in which team or

bubble they are operating in.