Coronavirus

Technology Solutions

October 29, 2020

Respro® UK Ltd has been Making Masks for 23

Years

idMask has Sold 50,000 Masks

Cambridge has Warehouses in UK and U.S.

RZ Mask Focuses on Masks for Workers

Saginaw Public Schools will Install 400 Air

Purifiers

Valmet to Build Filter Fabric Plant in India

Lydall Sales up Slightly in Third Quarter

Hollingsworth & Vose Expanding the Capacity of

Technostat

The Fallon Company and Shawmut

Corporation

Investing in Manufacturing Operation to Produce

N95 Respirators

________________________________________________________________________

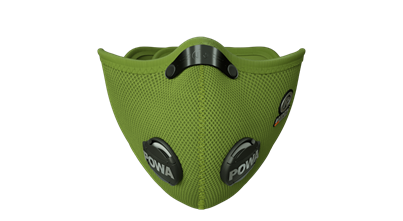

Respro® UK Ltd has been Making Masks for 23

Years

The company says Viral protection is best

attended to by using

a

respiratory mask that incorporates an Activated

Charcoal Cloth layer together with a sub-micron

particle filter layer (combination

filter) as it has the ability to adsorb

viral matter in both the micro and the nano

range of sizes by means of entrapment and

adsorption. Whilst a P2/P3 industry face mask

will trap particulates which may well carry

viral matter, they generally come in one size.

This increases the chance of a misfit by the

user, especially if used by children or if they

are not shown how to fit a mask properly or

undergo a fit test. This means that a percentage

of unfiltered air will bypass the filter

completely. So whether that rated mask is P1/2

or 3, is not a significant factor. The

correct fit and the seal are!

The combination of HEPA-type filter layer and

DACC in one single filter provides sub-micron

(smaller than PM2.5) dust filtering capability,

together with DACC capability for filtering

gases (VOCs/Acid gases), vapors and viral matter

in the nano range of sizes by means of

adsorption.

The following valved mask sells for £47.

You can view past articles on Respro through the

following links

1. McIlvaine

Coronavirus Market Alert

... Canada

has Efficient Mask with Insertable Filters

Totobobo has Reusable Mask with

Electrostatically Enhanced Filters Respro®

Mask has High Efficiency Valved Masks and Lower

Efficiency Scarves ____ The Coronavirus ...

Terms matched: 1 - Score: 21 - 30

Jun 2020 - URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-06-29/Alert_20200629.html

2. McIlvaine

Coronavirus Market Alert

... Vogmask

performed fairly well, capturing 95% of

pollutants. Big-name masks like the Respro and

Totobobo masks both captured less than 85% of

pollutants. It's important to ...

Terms matched: 1 - Score: 11 - 16

Oct 2020 - URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-10-15/Alert_20201015.html

3. McIlvaine

Coronavirus Market Alert

... the

market with its brightly colored designs. And

abroad, companies like Airpop and Respro are

entering the fold, hoping to provide an

attractive alternative to the standard white ...

Terms matched: 1 - Score: 6 - 27

Oct 2020 - URL: http://www.mcilvainecompany.c

idMask has Sold 50,000 Masks

The company has sold 50,000 masks since 2013

when it was founded in Shanghai.

The

price is $60.

A replacement pack of three filters is

$20.

idMASK 2.0 is designed to be 99.99% airtight,

eliminating the leakage of contaminated air

while filtering over 90% of dangerous particles

such as viruses and smoke.

The company says “We spared no expense on the

use of premium material. Typical N95 masks have

a paper layer sandwiched in the filter that

slows down breathing so their thinner layer of

expensive electrostatic material can do its job.

We don't have this. With idMASK 2.0 we just used

more of the good stuff so you can

breathe normally during workouts and as you go

about your day.”

Cambridge has Warehouses in UK and U.S.

Soon after its founding, Cambridge

gained early investment from Y Combinator

(YC) via their Fellowship program . It is also

backed by the Martlet Fund.

Cambridge Mask Co® has grown fast, and now has

offices in the UK and Hong Kong and a client

list that includes schools, hospitals and

embassies worldwide.

Together with investors, the company is working

on technological developments to change the way

we think about clean air.

The company has two warehouses: one in

Northampton, UK, and one in Ohio, USA.

It retails masks in over 100 countries globally.

It sells online via the main site :

cambridgemask.com and us.cambridgemask.com.

Cambridge Mask Co also sells on other e-commerce

platforms such as Amazon and

has distributors across North and South East

Asia, Europe, US, Australia, and Canada.

Cambridge Mask Co controls every aspect of the

manufacturing process, which means it is

able to

create custom designed masks with client

branding. The minimum order quantity the PRO

Mask with custom designed patterns is 512 units.

Cambridge Mask Co sells in over 70 countries and

partners with corporations such as Deliveroo,

British Airways and Aviva.

It has also supplied the German, Swedish and

Australian foreign services as well as the Nepal

Police and the Dutch Army. On the medical side,

Cambridge Masks are offered in Mayo Clinic in

the USA as well as United Family Hospitals.

DELIVEROO

United Kingdom:

Half of all Deliveroo’s 25,000 UK self-employed

riders use bicycles to make deliveries and the

company is determined to play its part in

tackling the challenges of pollution and poor

air quality in areas where they operate. Deliveroo’s

eponymous logo looks fantastic on the masks and

will help their riders tackle air pollution.

AVIVA AIRRUN

Poland:

Cambridge Mask Co partnered with Aviva to

support their 5km AirRun campaign for the fight

for clean air in Poland! This was a great

initiative that gathered thousands of people in

the center of Krakow to increase awareness of

air pollution!

Here are links to additional articles on

Cambridge Mask in CTS

1. McIlvaine

Coronavirus Market Alert

... on

June 18 to Launch Debate on Protecting Wearer as

Well as Those at Risk Cambridge has

an Efficient and Comfortable Mask but with Valve

Armbrust American Gearing Up to Manufacture ...

Terms matched: 1 - Score: 26 - 27

May 2020 - URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-05-26/Alert_202005026.html

2. McIlvaine

Coronavirus Market Alert

... Develop

Nanofibers for Masks O2 Nano Mask is Low

Pressure Drop, Efficient and Reusable Cambridge has

an Efficient and Comfortable Mask but with Valve

Masks are Part of a Combined ...

Terms matched: 1 - Score: 22 - 10

Jun 2020 - URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-06-10/Alert_20200610.html

6. Coronavirus

Alerts Table of Contents

... Develop

Nanofibers for Masks O2 Nano Mask is Low

Pressure Drop, Efficient and Reusable Cambridge has

an Efficient and Comfortable Mask but with Valve

Masks are Part of a Combined ...

Terms matched: 1 - Score: 8 - 29

Oct 2020 - URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/TofC.html

7.

8. McIlvaine

Coronavirus Market Alert

... Nexera

N95 polyester With Agion anti-microbial Kuban

state U N95 nanofiber Developed by Russian

researchers Cambridge N95

spunbond Small carbon fibers IQ Air N99

microglass Originally designed for air pollution

Moden ...

Terms matched: 1 - Score: 5 - 4

Aug 2020 - URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-08-03/Alert_20200803.html

9. McIlvaine

Coronavirus Market Alert

... trying

Vogmask is that the mask is very light. It is

lighter than the Cambridge Pro

Mask that I Brooke usually uses, and it also

feels significantly lighter than ...

Terms matched: 1 - Score: 5 - 16

Oct 2020 - URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-10-15/Alert_20201015.html

RZ Mask Focuses on Masks for Workers

The company was founded in 2010.

This year it made the Inc.

5000 list for 2020!

This list features the 5000 fastest-growing

private companies in the US.

RZ

Industries® ranked

#831 overall,

and #74 in the category Consumer Products and

Services.

Uses include woodworking, power sports,

agriculture, construction, landscaping and

public safety.

Any given day on the farm can expose

lungs to dangerous dust, mold, chemicals

and more. With

the RZ

agriculture respirator mask in a

pocket

it can be quickly donned to protect from dust,

mold, chemicals, animal hair and more.

KEY RZ MASK FEATURES:

·

Filtration rate of 99.9% (according to the latex

particle challenge performed by world renowned

Nelson Laboratories)

·

Adjustable metal Nose Clip

·

Four options of comfortable, facial contouring

fabric

·

Adjustable stretch bands for comfort and ease

·

Reusable outer shell design to decrease cost and

waste

·

One-way exhalation valves to keep you cool and

dry. Valve cap is now available

·

Low profile shape to fit seamlessly with other

personal protective gear

Partners include Ace Hardware, Lowes, and

Northern Tool.

This mask is $37.

The three filter pack is $9.

Saginaw Public Schools will Install 400 Air

Purifiers

Saginaw Public Schools will install 400 air

purifiers

throughout the district as part of an effort to

keep classrooms as safe as possible when

students return to hybrid learning in November.

At a special Board of Education meeting on

Wednesday, Oct. 28, the board voted unanimously

to accept a bid from Goodyear HVAC Sales for 400

air purifiers and 400 filter replacements at a

total cost of $274,000. The district will pay

for the equipment with Cares Act coronavirus

relief funds, according to the purchase

recommendation from Superintendent Ramont

Roberts read during the meeting.

The purifiers have a five-year warranty and the

filter replacements should allow them to last

for another five, said Tamara Johnson, the

district’s executive director for fiscal

services. The company will deliver the equipment

directly to each site and they can be installed

almost immediately, she said.

Valmet to Build Filter Fabric Plant in India

Valmet has

decided to invest in filter fabric manufacturing

in Pune, India, in order to better serve its

customers and improve delivery times of filter

fabrics to the Asia Pacific and Middle East

areas.

The investment includes manufacturing equipment

for filter fabric production. The new unit will

start operation in the second quarter of 2021.

“This investment gives us the necessary assets

to further develop our services close to

customers and strengthen our position in the

market. It also ensures our capacity for the

coming years to deliver filter fabrics that

respond to customer needs for maximized

reliability and optimized performance of their

production process,” says Tero Kokko, vice

president, Fabrics Business Unit, Valmet.

Valmet is one of the leading suppliers of filter

fabrics and industrial textiles globally.

Valmet’s filtration offering covers filter

fabrics and felts for the mining and chemical,

pulp and paper, dry filtration and laundry

industries.

Lydall Sales up Slightly in Third Quarter

Lydall’s net

sales of $207.1 million increased by $1.8

million, or 0.9% compared to the third quarter

of 2019. Organically, sales were up 0.3%, led by

11.4% organic growth in Performance Materials

(PM), offset by softer demand in the Technical

Nonwovens (TNW) segment and a modest year over

year decline in Thermal Acoustical Solutions

(TAS).

“Robust demand for specialty filtration products

continued, with sales in Performance Materials’

Filtration sub-segment up 38% compared to prior

year, driving an adjusted EBITDA margin of

almost 21% in the segment,” says Sara A.

Greenstein, president and chief executive

officer. “Our global meltblown assets are at

full capacity, and we are on schedule to be

fully operational early next year on the first

of two new domestic meltblown assets. This is

expected to be a strong and immediate

contributor to 2021 EBITDA as its capacity has

been fully committed under long term contracts.”

Greenstein also reports that global auto demand

rebounded sharply in the third quarter driving a

surge in Lydall’s Thermal Acoustical Solutions

business, which more than doubled sales from the

second quarter. “Volumes in North America were

up over 150% sequentially as a result of

Lydall’s exposure to light truck and SUV

platforms,” she says.

At the same time, she added, the company began

to experience an increase in Covid-19 cases,

particularly at its North American operation,

resulting in workforce shortages and other

operational inefficiencies causing higher

overtime, outsourcing costs, and logistics

costs, some of which will continue through the

fourth quarter. “We continue to be vigilant in

protecting the health, safety and well-being of

our entire workforce while balancing the

increasing demands of our automotive customers,”

Greenstein says.

Hollingsworth & Vose Expanding the Capacity of

Technostat

Hollingsworth & Vose is significantly expanding

the capacity of its Technostat electret

filtration media products. This new capacity

will be installed at the company's Hatzfeld

Germany location and will begin operation in the

second half of 2021. Technostat is the highest

performing electret filter media for cabin air,

HVAC, air purifier and other indoor air quality

(IAQ) applications requiring high filtration

efficiency and low pressure drop according to

the company.

H&V’s unique and proprietary Technostat products

play a direct role in fighting the COVID-19

pandemic in ventilator, respirator and other

critical medical applications. With the latest

Hatzfeld investment, H&V is further improving

its global Technostat manufacturing footprint,

which already includes Kentmere, U.K. and Floyd,

VA.

“This expansion will allow H&V to further

support the growth of our key customers and

strategic growth markets, globally. We are

especially proud of the impact Technostat® has

made in the fight against COVID-19,” says

Patrick Demchko, global director of product line

management at H&V.

“People are really starting to pay attention to

indoor air quality, and how that air quality

impacts their health. Whether in your home, your

car, or within any commercial building,

including schools and hospitals, Technostat®

offers a unique solution to the market in that

it has the highest efficiency at the lowest air

flow resistance available."

The Fallon Company and Shawmut

Corporation

Investing in Manufacturing Operation to Produce

N95 Respirators

The Fallon Company and Shawmut

Corporation announced the creation of a new

domestic manufacturing operation to produce N95

respirators. State of the art manufacturing

equipment installed in an expanded facility

based in West Bridgewater, MA, will enable

end-to-end production of up to 180 million masks

per year. Additionally, the operation is

expected to create as many as 300 new jobs in

Massachusetts.

The new effort will also be supported with a

$2.7 million grant from the Commonwealth’s

Manufacturing Emergency Response Team (MERT), a

state-led initiative that has facilitated the

production of more than 11 million pieces of

personal protective equipment (PPE) and other

critical items by manufacturers that pivoted

operations to address Covid-19 at the onset of

the public health crisis. Announced on Oct. 15,

this is one of 13 grants totaling $6.5 million

being distributed to multiple organizations

during October, or “Manufacturing Month,” to

support the production of PPE in Massachusetts.

“The MERT program continues to identify and

support successful ‘Made in Massachusetts’

manufacturers like the Fallon Company and

Shawmut Corporation, that will produce N95 masks

and other PPE equipment locally, for

Massachusetts front-line responders, business

owners, and residents,” says Governor Charlie

Baker. “We are pleased to welcome the expansion

of this manufacturing facility in Massachusetts

and appreciate the role these companies are

playing in the Commonwealth’s fight against

Covid-19.”

The operation brings together two

well-established, successful family businesses

to serve as one of only a handful of

high-quality mask manufacturers in the U.S. The

West Bridgewater facility will extend existing

Shawmut manufacturing capabilities, which

include medical gowns, to add polypropylene

meltblown extrusion and mask conversion

capabilities to create respirators, shoring up

the U.S. healthcare supply chain with domestic

production. The 60 tons of machinery was

fast-tracked from Reifenhauser REICOFIL GmbH &

Co of Germany on an expedited timeline and, last

week, landed in the Port of Boston.

In addition to a financial investment by Joseph

Fallon, CEO of the Fallon Company, the effort

will be supported by President Michael Fallon

and the company’s development, legal, and

construction teams. Funds will support

infrastructure upgrades, utility improvements,

and capital investment to Shawmut Corporation’s

manufacturing facility in West Bridgewater.

Widely recognized as the leader in meltblown

polypropylene production equipment, the

Reifenhauser production line will enable the

conversion of nonwoven materials into N95

respirators in Massachusetts.

“With all that’s at stake right now, we must

shore up domestic manufacturing of lifesaving

personal protective equipment for the people

whose lives are at risk,” says Joe Fallon, the

initial investor in the new facilities. “So this

isn’t just about making masks here in the U.S.,

it’s about ensuring we have the equipment needed

to keep our frontline workers safe and in a

position to take care of people over the long

term.”

In addition to having full control of the

manufacturing process to ensure ongoing quality

and safety and eliminate potential price

gouging, domestic production will allow first

responders and medical personnel to conduct fit

testing in the factory, as well as allow for

rapid prototyping and testing of future PPE

products.

Shawmut, which has decades of experience in the

healthcare sector, is currently producing

isolation gowns and surgical barrier fabrics,

and will now be producing high-quality FDA- and

NIOSH-approved N95 masks made of meltblown nano

fiber material. The company plans to start with

an initial run rate of 5 million masks per

month, gradually building up to producing 15

million masks per month.

“These health risks are not going away. We need

to plan ahead to ensure our state and country

never run out of N95 masks again,” says Shawmut

CEO James Wyner. “Shawmut is proud to be

partnered with Joe and others at the Fallon

Company to bring this advanced PPE manufacturing

investment to Massachusetts."

“We have a 104-year history of manufacturing in

the state,” adds Shawmut’s 95-year-old chairman

Justin Wyner. “We are honored to have been

chosen for this important grant from MERT, and

grateful for the opportunity to bring these

vital manufacturing capabilities home to the

Commonwealth.”

A fourth-generation, family-run company with

locations across the country and around the

world, specializing in high performance

materials for automotive and medical

applications, Shawmut has been working with

Massachusetts MERT and federal officials,

including members of FEMA, to support the

production of as many as 4M isolation gowns per

month.

The Fallon Company is rooted in family values,

sustaining strong partnerships and helping

others, which is fundamental to the Fallon

Company’s identity. With a long history of

“quiet generosity,” the family has received

notable recognition for helping those in need,

including military families and single parents,

along with children’s healthcare and youth

enrichment organizations, among others.