Coronavirus

Technology Solutions

October 26, 2020

CATE Masks are the Future

Midwest Filter Cost Evaluations are Useful but

Need Interpretation in the Pandemic

HALO Life Inc Provides Tight Fitting Efficient,

Comfortable and Attractive Masks

Revolution Fibres Makes Rolls of Electrospun

Media

Rosmerta Group Produces 15 Million Masks per

Month in India

______________________________________________________________________________

CATE Masks are the Future

Comfortable-attractive-tight fitting - efficient

(CATE) masks are the future not only for

the wealthy but for all the citizens of the

world. Tight fitting-Efficient

(TE) which are not comfortable or

attractive are worn by healthcare personnel. And

yet they walk through hospital waiting rooms and

offices which are anything but antiseptic. The

local hospital now has a player piano and floor

to ceiling drapes in the lobby. If hospitals see

the need for investments in attractiveness why

subject patients to skimpy surgical gowns and

hospital personnel to garments which are just as

unattractive.

It will be harder to make the argument for

comfort and attractiveness in hospital apparel

than it will be for the average citizen just

trying to protect himself from COVID.

Northern winters can be deadly. The

choice of ski hat is potentially a life or death

decision. However, the purchase decisions not

only take health into account but also

attractiveness and comfort.

Most available masks are not TE. Those that are

TE are generally

not CA. Previous Alerts by McIlvaine have

documented the need for TE masks. But unless you

add the CA, people will not wear them as much as

they should.

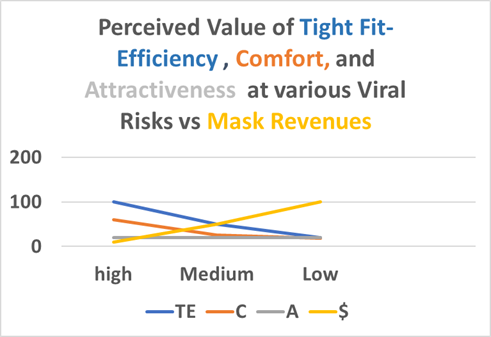

Efficiency and a tight fit are critical at high

viral risk. Comfort is important at all loads

but at high viral risk which is load times hours

it is more important than at lower risk levels.

Attractiveness is independent of virus

risk.

Most people will spend nearly all their time in

lower risk environments where the value assigned

to attractiveness and comfort is equal to that

of the tight fit and efficiency. McIlvaine is

forecasting a mask market of hundreds of

billions of dollars per year with most of it in

the low risk category where attractiveness will

be a major influence in the selection.

This assertion can be supported by the common

metric which measures all harm and good called

Quality Enhanced Life Days (QELD).

It is not an artificial mathematical

formula it is simply the

measurement of individual desires. the

average individual would rather live to 80,

socialize

and eat ice cream than live to 100 in

solitary confinement. McIlvaine introduced the

concept nine years ago to evaluate the choice of

single use vs reusable surgical gowns.

The selection of an attractive mask is

equivalent to eating ice cream, wearing $200 gym

shoes or

a hoodie. It adds QELD with no additional

health benefit. On the other hand if the

individual wears the mask more frequently

because it is attractive there is a health

benefit.

The CATE segment of the market will be far

larger than the TE market pre-COVID. When

considerations of air pollution, allergies, and

wild fires are added to the analysis it is

likely that the market will not spike and

retreat to previous lows but instead continue to

be very substantial.

Analysis of the technology is covered in Daily

Alerts and webinars which are part of

Coronavirus Technology Solutions

Click here for more information

Forecasts for the CATE mask market are included

in the High Efficiency Mask Market and Supplier

program Click

here to

view a video description or Click

here for

the power point display

Bob McIlvaine can answer your questions at 847

226 2391 or

rmcilvaine@mcilvainecompany.com

Midwest Filter Cost Evaluations are Useful but

Need Interpretation in the Pandemic

Founded in 1950, Midwest Air Filter, Inc. has

provided air filtration products to the

commercial, industrial, institutional and

residential HVAC marketplace for over 60

continuous years.

It stocks filters in three locations throughout

Michigan and fabricates special size products to

assure prompt delivery at competitive prices. It

has developed a Total Filtration Management Team

(TFM)

tailored to the customers’ specifications

while utilizing employee’s areas of expertise.

This allows a multi-disciplinary approach. It

does provide filters for COVID related

applications. It works

with facility

managers to help provide clean air solutions in

hospitals, assisted living facilities, nursing

homes, dentist offices, and operating rooms.

Midwest sells Filtration Group products. It also

sells niche products from a few other

manufacturers. This includes paint booth filters

and high temperature stainless steel filters.

The following analysis by Midwest was prepared

last year and needs to be interpreted for the

pandemic environment.

But the main theme is important which is

you have to balance pressure drop and dust

holding capacity to provide the optimum

combination of filter investment and energy

cost. In the COVID environment this means more

efficient filters but dust holding capacity can

be extended with the right pre-filter.

When evaluating multiple filters against each

other, it is very common to focus on the initial

DP as the primary indicator of Total Cost of

Ownership (TCO) of a given product. However,

that is only one part of the story. As it turns

out, the Dust Holding Capacity (DHC), or more

generically, the amount of dirt and other

particulates a filter can hold until it reaches

its maximum recommended operating pressure is

just as important.

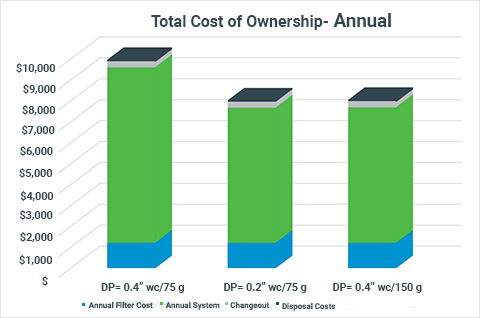

In the chart below, they show three products

with three different performance levels – the

first is a pleat with an initial DP of 0.4” w.c.

and a DHC of 75g. The second pleat has ½ the

initial DP but the same DHC, and the third

product has double the DHC but the same initial

DP as the first pleat. In this scenario, they

find that products two and three have

essentially the exact same TCO, both saving 19%

compared to the first product when changed out

on the same interval.

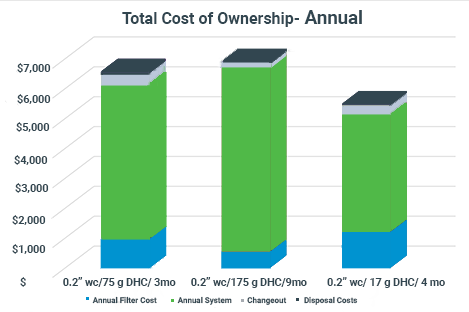

Just because a filter lasts a long time, doesn’t

mean it should – change it out early.

Energy provider PG&E recommends regular filter

maintenance as the #1 way to save energy on

commercial and industrial buildings. Despite

that, there are products out there that

advertise a longer life than standard products,

which is driven by a higher than average DHC.

The best way to take advantage of that

performance is not to change it out at its final

life, but instead to change it out early. While

you could save around 45% on your filters

annually by using the better filter longer, it

actually drives up the TCO by around 5% in this

example because of increased energy usage.

Changing the same filter out at four months

instead allows for TCO savings of 17%.

Look at the whole system, not just each filter

individually.

Always remember the filters are a part of a

system and each filter should not be looked at

individually. Just because you have a spot for a

prefilter does not mean you need one. Products

with high amounts of media like 4-V bank

minipleats in low dust applications are probably

better without a prefilter to reduce the overall

system pressure drop. On the other hand, high

dust applications should have a higher MERV

(11-13) pre or secondary filter to protect the

more expensive efficiency filter to make it

last. Naturally, there are many “in-between”

installations that require a MERV 8-10 prefilter.

HALO Life Inc Provides

Tight Fitting Efficient, Comfortable and

Attractive Masks

HALO Life Inc is a mask provider headquartered

in Santa Rosa CA.

Keith N Anderson is CEO. Until recently

he is chief marketing officer at Penny Inc. The

concept of the HALOmask was conceived four years

ago in New Zealand, When volcanoes erupted in

Indonesia, its masks protected many from toxic

silica ash. Wild fires and polluted air in Asian

cities are other common uses.

With the global outbreak of coronavirus, the

mission has become laser-focused to protect as

many people as possible with the most

comfortable, stylish and efficient mask on the

face of the Earth.

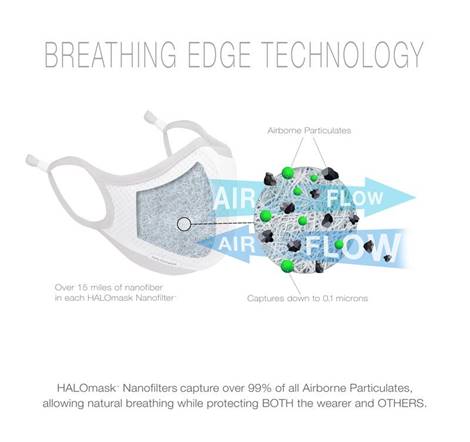

The company makes the following claims about its

masks

1.

Superior Nano-filtration that protects from a

wide range of airborne pathogens, pollens &

pollutants

2.

Superior

Design and ultra-comfortable contour-fit that

prevents air-leaks and can be worn for HOURS at

a time

3.

Superior Style that reflects

personal fashion sense

The HALOmask uses proprietary SETA™ Nanofiber

filters

HALOmask filters have been laboratory tested to

capture 99.99% of all airborne pollutants and

contaminants at PM2.5 microns, and 97.9% at 0.3

microns – which exceeds N95 filter standards.

Tests have been conducted by Nelson Labs.

The mask’s engineered contour-fit

design provides a tight seal and prevents air

leaks, the ultra-thin SETA nanofiber filter

allows maximum breathability and protection.

Four sizes are available.

HALOmasks are durable, reusable with replaceable

filters and fully adjustable to any face.

The mask sells for around $35 and a set of three

replaceable filters with a recommended life of

200 hours each can be purchased for about $15.

The company has responded to the global pandemic

by rapidly scaling manufacturing capacity to

produce millions of HALOmasks for use worldwide.

The immediate goal is to provide a safe,

comfortable and stylish alternative to cheap

paper and ineffective fabric masks.

The

proprietary filters are made in New Zealand, the

company is currently working with a third

generation garment manufacturer in Hong Kong

that manages manufacturing in China and in

Cambodia. It is also evaluating factories in the

United States, Mexico, Turkey, and elsewhere. It

ships from warehouses in Nevada and

Pennsylvania.

As the coronavirus recedes there are still

compelling reasons to wear a protective

facemask. Whether commuting, walking or biking

in traffic, being exposed to dust, ash or smoke,

suffering allergies or chemical sensitivity,

or living in industrial or agricultural regions,

wearing an effective facemask makes a WORLD of

difference, physically, emotionally and

psychologically! the company

predicts

that wearing a stylish facemask will become an

accepted part of fashion-forward society for

years to come.

Revolution

Fibres Makes Rolls of Electrospun Media

This New Zealand Company was focused on air

filters in 2009 when it started developing sonic

electrospun nanofibers.

Today these are used in many applications

from fishing rods to filters. Known as SETA

nanofiber material it is used in products such

as the HALO mask.

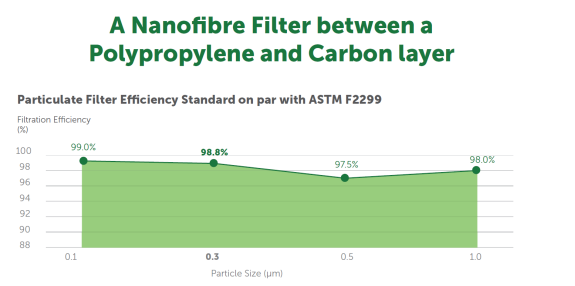

Dr. Fabrice Karabulut RD & Implementation

Scientist has provided details on the

performance.

Most toxic particulate compounds are smaller

than 1 micrometer in diameter. Conventional

mechanical fibrous filters (such as MB filters)

remove micrometer-sized particles with high

efficiency. However, for particles in the

submicron range, ES NF are considered better as

they offer enhanced filtration performance. This

is due to their high surface area and small pore

diameter. Electrospun nanofibre are

characterized by a very large surface area,

which significantly increases the probability of

the particles depositing on the fibre surface -

thereby improving the filter efficiency. In

addition, ES NFs have low basis weight, high

permeability, and tight pore size that make them

appropriate for a wide range of filtration

applications. ES NF filters have a thinner fibre

diameter (10 - 300 nm), and a smaller and more

uniform pore size than common MB N95 face masks,

which are made of PP fibres with diameters in

the range of

∼

500 - 1000 nm.

Some particles in the nano range (∼

100 - 500 nm) are difficult to filter as they do

not behave entirely according to one capture

mechanism. Filtration of MPPS particles require

uniform multiple nanofibre layers, which defer

the particles so that they obey one of the

mechanisms. Multilayer filters are often

hindered by poor breathability and high pressure

drop, which is undesirable for filters. However,

electrospinning enables control of the porosity,

packing density, fibre diameter and surface area

of the nanofibers.

Breathing comfort is commonly associated with

pressure drop. However, moisture transportation

is another important factor to consider. A

recent study conducted breathability tests

through N95 MB and ES NF masks to evaluate their

water vapor transmission rates (WVTR). It was

observed that the WVTR of ES NF filters was

superior. MB filters have sponge-like structures

which resist moisture. Therefore, moisture takes

longer to pass through the filter.

A study was performed on the reusability of MB

and ES NF filters when cleaned with ethanol

(sprayed and dipped). The results showed that MB

filters are only effective for single use due to

the steep reduction of filtration efficiency

after ethanol cleaning (to

∼

64%). This is because the electrostatic charge

of MB filter is lost when cleaned, leading to a

dramatic drop in performance. MB filters lose

static electricity when exposed to water and

moisture, diminishing their filtering effect to

almost half the original performance. In stark

contrast, it was found that ES NF filters can be

successfully reused multiple times after

cleaning with ethanol as the filtration

efficiency remains constant.

https://www.revolutionfibres.com/wp-content/uploads/2020/08/MB-vs.-NF-White-Paper.pdf

Rosmerta Group Produces 15 Million Masks per

Month in India

The Rosmerta Group has been entrenched in the

transport sector of India for the last 20 years

through products like Smart Card Driving

License/ Vehicle Registration Cards, Speed

Limiting Devices, Vehicle Tracking Systems

(VTS/ITS), Inspection & Certification (I&C) Test

Lanes, Automated Driving Test Tracks and High

Security Registration Number Plates (HSRP). It

has a Pan-India reach with over 4,000 employees

spread across 300 offices in 20 states of India.

It serves

a diverse range of customers ranging from

Central & State Governments, Automobile OEMs,

State Transport Corporations and Private

Institutions.

Having felt the need to support clients and

employees during the ongoing COVID 19 pandemic,

it set up a state of the art manufacturing

facility for Surgical Masks as well as Filtering

Face Piece Respirators.

What started out as an experiment to use their

established distribution chain set up to help

OEM’s and dealerships with PPE like masks,

respirators and sanitizers led Rosemerta to

realize the huge gap in the market for quality

products at affordable prices.

HALO was conceptualized by the idea of introducing internationally certified products to the masses at value for money price points. Each HALO product meets international standards. And the facility is slated to be one of the best in the country with one of the highest production capacity of over 15 million masks a month.

Rosemerta has evaluated the three different

kinds of masks available in India:

Cotton masks, surgical masks and FFPRs,

commonly known as an N95.

According to the company cotton

masks are nothing but cotton fabrics

woven into a mask. These are readily available

and can also be made at home. However, they

aren’t very effective as they absorb any

droplets they come into contact with. They are

mostly very thin masks and are highly

susceptible to the virus. They can get

penetrated by up to 97% of the viral particles

from the air.

The other alarming concern with cotton masks is

its loose fit which makes it insufficient to be

a protective barrier.

Surgical masks (3-ply)

are effective in blocking splashes,

large-particle droplets and even particles as

small as the size of 0.3 micron. They have a

strong barrier which can have a

Bacterial Filtration Efficiency (BFE) of

>99.8%. However, much like cotton masks, the

loose fit of surgical masks don't provide

complete protection from germs and other

contaminants. These masks are best used when one

is present in a controlled environment, which is

why health workers use them.

A surgical mask can be worn when visiting family

members, entertaining guests at home or at the

workplace with fewer employees.

Lastly, a

Filtering Face-Piece Respirator

(commonly referred to as FFPR) which is commonly

known as an N95 in India is a protective

respiratory device which is specially designed

to attain a very close facial fit and is

extremely coherent in filtering airborne

particles, viruses, bacteria, pollution making

N95 as the best protection against COVID-19 when

you are in a public space.

One must note that not all masks available in

the market follow the best in industry

practices. However,

HALO ensures that the quality of its

masks exceed both domestic as well as

international testing standards.

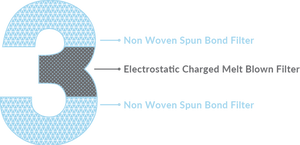

The surgical marks by HALO have three layered

filters.

The first & third layer is the

Non-Woven Spun Bond Fabric while the

middle layer is the

Virgin(Master Batch) Non-Woven Melt Blown Fabric.

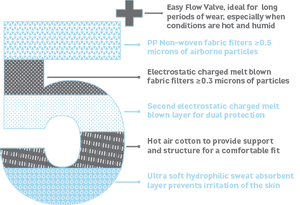

The FFPRs produced by HALO have five layered

filters.

The top most exterior layer is Non-Woven Spun

Bond Fabric, followed by two layers of Virgin (MasterBatch)

Non-Woven Melt Blown Fabric. The next layer is

the Needle Punch Fabric, also commonly known as

the Hot Air Cotton. And the innermost layer is

the Hydrophilic Spun Bond Fabric. It is an

absorbent material, and as such soaks up sweat

and removes irritation of the skin (last/skin

layer). This ensures easy breathability and one

can wear the mask for a longer duration.