Coronavirus

Technology Solutions

October 15, 2020

Experts say Masks are More Important Now than

Vaccines but Fail to Qualify the Term to Mean

“Efficient and Tight Fitting”

FDA will No Longer Review Chinese Masks for

Addition to the Approved List

Qualitative vs Quantitative Fit Tests

Polymer Face Masks Developed at Ag School and

Being Tested at Meat-Processing Plants

How Efficient are Masks Once Leakage is

Included?

OSHA will Levy Fines for Failure to Have

Appropriate Mask Fit Testing

Vogmask is a Lightweight Mask with a Good Fit

______________________________________________________________________________

Experts say Masks are More Important Now than

Vaccines but Fail to Qualify the Term to Mean

“Efficient and Tight Fitting”

McIlvaine agrees with the recent comments that

masks are the most important weapon in the fight

against COVID.

But using the term “mask” is

like using the term “pill”.

If you have malaria the quinine pill is a

solution but aspirin is not. A squirt gun is

nominally a gun but not the weapon of choice

against a deadly enemy.

To fight COVID the tight fitting efficient mask

is the solution. A loose fitting cloth mask is

no better a solution than an aspirin.

Some are expressing concern that people

over estimate the protection given by poorly

fitting inefficient masks. Here are recent

comments by those who do not define the term

“mask”

While there has been a lot of talk and hope that

an effective Covid-19 vaccine will be available

soon, top experts say an affordable tool that

already exists is just as important in the fight

against the pandemic: masks.

Dr. Christina Brennan, vice president of

clinical research at Northwell Health’s

Feinstein Institutes for Medical Research,

told “60 Minutes” on Sunday that if she had to

choose between a mask or a vaccine, a mask is

more important.

“With our social distancing, wearing of the

mask, the data’s already showing that it’s been

effective. It’s, you know, cost savings, and

it’s effective. And it can go a long way,” said

Brennan, who oversees multiple clinical trials

using drugs such as Remdesivir, which President

Donald Trump received on Oct. 2, to treat

Covid-19.

Dr. David Ho, a world renowned

virologist working on developing monoclonal

antibody therapies for Covid-19 at Columbia

University, who also appeared on “60 Minutes,”

emphasizes the importance of masks too. He

tells CNBC Make It that “masks are key right

now.” But “we need as many tools in our tool box

as we can have in dealing with this pandemic,”

says Ho, and “vaccines and therapies would make

a huge difference as well.”

Dr. Kevin Tracey, who spoke to “60 Minutes” and

heads the Feinstein Institutes for Medical

Research at Northwell Health, says masks are key

in tackling Covid-19 now.

“The reality is we know the masks work,” Tracey,

who is doing clinical trials and research around

Covid-19 treatments, tells Make It. But also,

“we know we need to make therapies and

vaccines.”

It is puzzling that so little information is

being published about mask leakage and mask

efficiency. Distinguished professionals are

using the term mask to indicate some product

much more specific than just a “pill” but the

public needs to be made aware of the big

differences in mask quality.

FDA will No Longer Review Chinese Masks for

Addition to the Approved List

Today, October 15, the U.S. Food and Drug

Administration (FDA) reissued the Emergency

Use Authorization (EUA)

for certain filtering face-piece respirators (FFRs)

that are manufactured in China and are not

approved by the Centers for Disease Control and

Prevention’s (CDC) National Institute for

Occupational Safety and Health (NIOSH).

Under the June 6, 2020 version of this EUA, a

respirator was authorized if it met any of three

predetermined eligibility criteria. Effective

immediately, the reissued EUA no longer includes

the three eligibility criteria, meaning the FDA

will no longer review requests nor add to the

list of authorized respirators–known as Appendix

A—of this EUA based on those criteria.

The FDA recognizes there is still a shortage of

FFRs, and to provide additional capacity as

needed, the agency is continuing the emergency

use authorization of respirator models that are

already included in Appendix A of this reissued

EUA.

“Since the beginning of the COVID-19 public

health emergency, we have taken appropriate

actions to support the personal protective

equipment needs of our health care personnel by

issuing EUAs. As part of our continuing work to

meet the demands of this public health

emergency, we undertook and completed a shortage

assessment and concluded that reissuing this EUA

was appropriate to reflect the current U.S.

demand for these products,” said Suzanne

Schwartz, M.D. M.B.A., Director of the FDA’s

Office of Strategic Partnerships and Technology

Innovation in the Center for Devices and

Radiological Health.

To further inform the EUAs, the FDA completed a

respirator shortage assessment to understand

current product availability for both

NIOSH-approved N95s and KN95 respirators and use

practices for each. The assessment shows that

the KN95 respirator models authorized by this

EUA meet the demand for these respirators. As

part of this assessment, the agency heard

directly from health care personnel that the

KN95 design has limited adoption in health care

settings; from distributors that imported,

non-NIOSH-approved product from China is sitting

in warehouses unused; and from manufacturers

that NIOSH-approved N95 production is

increasing. Additionally, CDC/NIOSH continues to

issue more N95 approvals.

The FDA is reissuing this EUA to authorize only

those respirators the FDA had already authorized

and that are presently listed in Appendix A. As

outlined in the reissued EUA, FDA has removed

the previous eligibility criteria and,

therefore, no additional respirator models will

be added to Appendix A under those criteria. As

such, the FDA is no longer reviewing requests

submitted based on the June 6, 2020 EUA’s

criteria.

As a result of this EUA’s reissuance, FDA

expects that staff and agency resources that

were devoted to reviewing those submissions can

instead focus on other critical needs during the

COVID-19 public health emergency, including

continuing to work with CDC/NIOSH to help

facilitate the availability of respiratory

protection that meets the applicable standards

and demands of health care personnel. The FDA is

committed to refining our policies and

approaches as appropriate to further facilitate

the development and availability of these

devices for health care personnel.

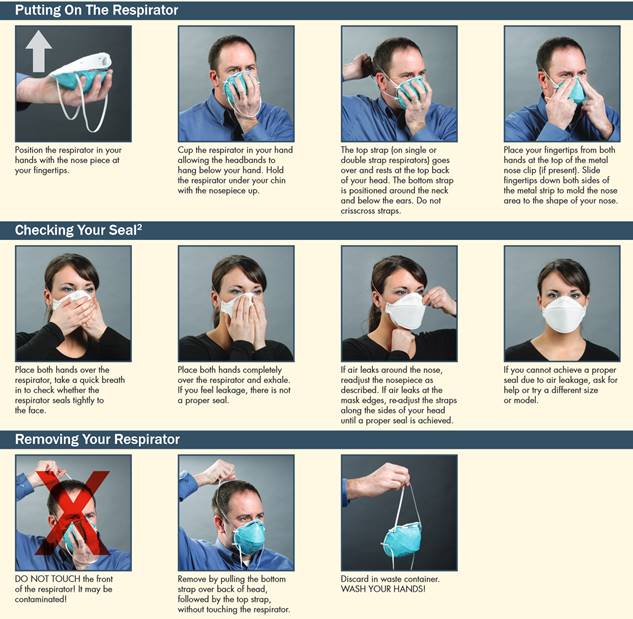

Qualitative vs Quantitative Fit Tests

According to OSHA, “a ‘fit test’ tests the seal

between the N95 mask’s, or respirator's,

facepiece and your face.” It typically takes

15-20 minutes to complete and should be

performed when this type of mask is first used

and then at least annually. The purpose of the

fit test is to assure that the mask fits and

seals properly so potentially contaminated air

cannot leak into the mask and so hazardous

substances are kept out. The fit test must be

conducted using the same make, model and size of

mask that the worker will use on the job. Fit

testing with a different type of mask than the

one that will be used does not assure proper

protection. If the model of mask used for the

fit test does not properly fit, another make,

model, style, or size of mask must be tested

until one that fits properly has been

identified. Employers need to provide staff with

a reasonable selection of sizes and models to

try. Once the fit test is completed and the

wearer knows which mask fits best, he/she should

always use the one shown to be the right ‘fit’

or ‘size.’ That way, it can be replaced with

another mask with appropriate fit. Fit tests can

be qualitative or quantitative. In dentistry,

the qualitative test is most often used.

Qualitative fit testing is normally used for

half-mask respirators like the N95, which cover

only the user’s mouth and nose. Qualitative fit

tests operate on a pass/fail method and do not

measure the actual amount of leakage. They rely

on the user’s sense of taste or smell, or the

person’s reaction to an irritant, to detect

leakage. The mask fails the test if the wearer

can detect any leakage of the test substance.

OSHA has accepted four qualitative fit test

methods:

1. Isoamyl acetate, which smells like bananas;

2. Saccharin, which leaves a sweet taste in your

mouth;

3. Bitrex, which leaves a bitter taste in your

mouth;

4. Irritant smoke, which causes coughing.

Information on quantitative fit testing can be

found on OSHA’s website. The agency’s resource,

Appendix A to §1910.134—Fit Testing Procedures

(Mandatory): Part I. OSHA-Accepted Fit Test

Protocols: A. Fit Testing Procedures—General

Requirements, offers helpful guidance. Mask fit

should be reevaluated any time the wearer

experiences changes in his/her physical

condition that could affect the fit. These

include: a significant change in weight (either

loss or gain); major dental work, such as new

dentures; facial surgery that changes the shape

of the face; or significant scarring in the area

around the seal. Employers must ensure that the

fit testing and recordkeeping requirements of

OSHA's respiratory protection standard are met

before staff can use a N95 mask for protection

against hazardous exposures at work. Employers

may allow personnel to use their own respirators

but cannot require them to do so.

Polymer Face Masks Developed at Ag School and

Being Tested at Meat-Processing Plants

While many people are encouraged and even

mandated to wear face masks to prevent the

spread of COVID-19, some complaints have become

common: The mask doesn’t fit correctly. It’s

uncomfortable. It’s too hot, or it’s hard to

breathe through.

A material scientist at The Ohio State

University (OSU) College of Food, Agricultural,

and Environmental Sciences (CFAES) is working to

change that.

Judit Puskas is in the final stages of

developing a polymer face mask she expects will

be more effective in the fight against COVID-19.

Puskas, who is a distinguished professor in

polymer science in the CFAES Department of Food,

Agricultural and Biological Engineering, has a

provisional patent application pending for the

mask she is developing.

She’s working with the Mayo Clinic to create and

test the mask to meet the same safety and

efficacy standards of an N95 mask, but with more

comfort and usability for the wearers. Puskas’

mask is made of a nonwoven fabric composed of

biocompatible rubber composite formed into a

fiber mat that can be used to create personal

protective equipment, including face masks.

The goal, she says, is to offer alternatives to

the current market of N95 masks that can be used

by workers in a wider variety of conditions and

situations.

“The current N95 masks protect against the

virus, but most people say the masks aren’t

comfortable and aren’t easily breathable,”

Puskas says. “There are other polymer fiber mats

used in N95-equivalent masks, but they are based

on rigid plastics and don’t offer much

flexibility.

“The material I’ve developed is a flexible,

breathable rubber, that can be made into

comfortable-fitting masks. Additionally, it’s

water-repellant, doesn’t allow sneeze particles

through, nor will it let moisture build up on

the mask from breathing. This rubber can also be

used in hot, humid conditions as well as in a

freezer, can be easily sterilized in water-based

solutions, and is recyclable for multiple

reuse.”

It’s for those reasons that Puskas’ masks, once

completed, will be tested by more than 100

workers in five meat-processing plants across

Ohio to gauge the masks’ effectiveness for ag

workers in hot, humid conditions.

CFAES researchers, including Lyda Garcia, an

assistant professor of meat science; Mary

Rodriguez, assistant professor of community

leadership; and Joy Rumble, assistant professor

of agricultural communication, are working with

meat processors statewide to determine the

barriers workers face when considering masks as

personal protective equipment to reduce the

potential spread of COVID-19.

The team is also researching workers’

perceptions about wearing personal protective

equipment to better understand why some choose

not to wear it. The team’s goal is to develop

strategies to get more workers to change their

perception of masks and to choose to wear them,

Rodriguez says.

According to the Centers for Disease Control and

Prevention (CDC), the meat and poultry

processing industry, which is an essential

component of the U.S. food infrastructure,

employs approximately 500,000 people nationwide,

many of whom work in close proximity to other

workers, often in hot, humid conditions.

Ohio meat processors reached out to Garcia, who

is also an Ohio State University Extension meat

science specialist, and her team for help in

determining solutions for personal protective

equipment, including understanding what works

and how to encourage workers to wear personal

protective equipment such as face masks, Garcia

says. OSU Extension is the outreach arm of

CFAES.

Garcia says the conversations with meat

processors helped her team realize that

understanding employee behavior and attitudes

about wearing personal protective equipment such

as masks would be valuable in helping Puskas

modify and adjust her mask design.

“Understanding employee behavior, attitudes and

leadership is critical when designing personal

protective equipment,” she says. “The most

common complaint among workers is that masks are

uncomfortable, tend to move and slip off, and

they have to keep adjusting them.

“Another drawback is that workers say it’s

difficult to breathe in masks in hot, humid

conditions while constantly moving, and they

don’t like breathing in their own carbon dioxide

that is trapped in the masks in those

conditions.”

Additionally, Garcia says, with the fans and the

air conditioning noise in the plants, workers

say wearing masks makes it harder to communicate

with each other, which could be a safety issue

considering the sharp knives and tools they use.

“Also, these workers are on their feet 8 hours a

day, wearing hair nets, safety glasses, with

some men having long beards, then you add a mask

and you can see where things can become more

complicated fast on top of just wearing the

mask,” she says. “At the end of the day, it’s

about working with employees to encourage them

to wear personal protective equipment.

“Not only will it serve to protect the food, but

it will help keep the employees safe and

healthy, and, in turn, will keep them working to

provide a wholesome, sound, high-quality

product.”

That’s one of many reasons why Puskas was

compelled to develop a mask using the

biocompatible rubber composite fiber mat she

created as a way to add comfort, flexibility and

breathability to the N95 mask market.

http://www.angusbeefbulletin.com/extra/2020/08aug20/0820fp_B_FaceMasks.html

How Efficient are Masks Once Leakage is

Included?

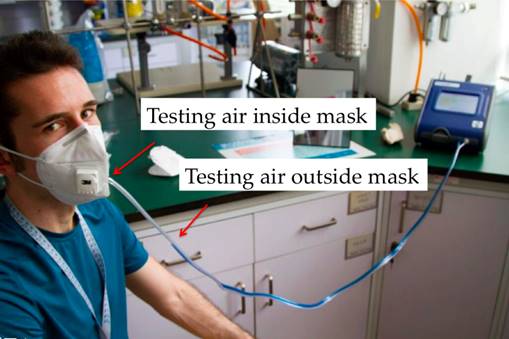

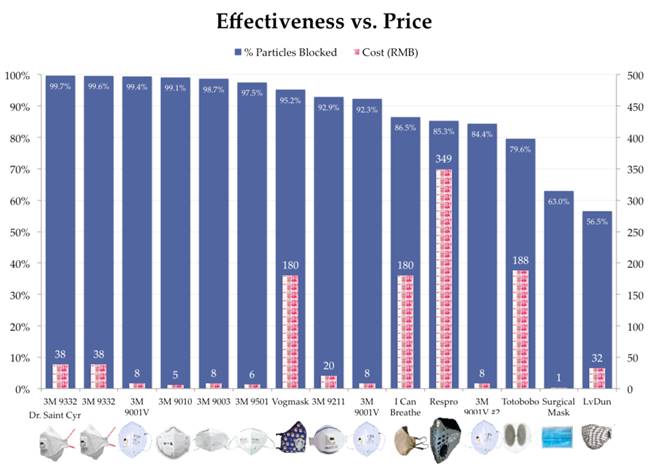

It is interesting that McIlvaine found better

information on leakage for masks worn by the

public in air pollution

research rather than COVID. There is a

good analysis on the Smart Air website dating

back three years.

Thomas is an Associate Professor of Behavior

Science at the University of Chicago Booth

School of Business and the founder of Smart Air,

a social enterprise to help people across the

world breathe clean air without shelling out

thousands of dollars for expensive purifiers.

In addressing the mask leakage Talhelm said

“This question is tougher to answer because you

have to measure the mask while you’re actually

wearing it. For that, you need a really

expensive fit

test machine.

Fortunately, I begged and begged 3M until they

let me use their lab in Beijing.

The blue tube is sampling air outside the mask,

while the white tube is sampling air from inside

the mask.

Smart Air co-founder Anna Guo and Beijing-based

Dr. Richard Saint Cyr also

tested masks,

so I combined all of our data.

The 3M masks consistently performed the best in

these tests. The Vogmask performed fairly well,

capturing 95% of pollutants. Big-name masks like

the Respro and Totobobo masks both captured less

than 85% of pollutants.

It’s important to make clear: masks that fit my

face well might not fit other people’s faces

well. However, there is evidence from a broader

population that masks fit most people well. A

scientific study of 3M models on 22 Chinese

people found a median fit score of

99.5%–essentially the same as the top results

from Dr. Saint Cyr and me.

Best yet, effective masks don’t cost a lot of

money.

The branded masks – Vogmask, Respro, I Can

Breathe and Totobobo – all cost the most.

However these masks consistently performed worse

than cheaper 3M masks. Only the Vogmask was able

to capture over 95% of particulates (meeting the

N95 criteria).

OSHA will Levy Fines for Failure to Have

Appropriate Mask Fit Testing

Guy Burdick asks and answers the following

question.

Will workplace safety and health inspectors show

up at your facility if workers contract

coronavirus disease 2019 (COVID-19) and one of

them files a complaint? Yes; in fact, it’s

already happened.

Although there are no federal standards for

coronavirus exposure or airborne infectious

disease, COVID-19 has become a recognized

workplace health hazard since the pandemic was

declared in March. You can be cited for failing

to protect your employees from the coronavirus

under the General Duty Clause of the

Occupational Safety and Health (OSH) Act of

1970.

Section 5(a)(1) of the OSH Act reads: “Each

employer shall furnish to each of his employees

employment and a place of employment which are

free from recognized hazards that are causing or

are likely to cause death or serious physical

harm to his employees.”

The federal Occupational Safety and Health

Administration (OSHA) has cited several

employers under the General Duty Clause for

failing to protect their employees from the

coronavirus.

OSHA cited JBS Foods Inc. of Greeley,

Colorado—operating as the Swift Beef Company—for

failing to protect employees from exposure to

the coronavirus. The agency cited JBS Foods with

a violation of the General Duty Clause for

failing to provide a workplace free from

recognized hazards that can cause death or

serious harm and proposed penalties of $15,615,

the maximum allowed by law.

The agency conducted a coronavirus-related

inspection and also cited the company for

failing to provide an authorized employee

representative with injury and illness logs in a

timely manner following OSHA’s inspection.

The agency cited Smithfield Packaged Meats Corp.

in Sioux Falls, South Dakota, for a General Duty

Clause violation for failing to protect

employees from exposure to the coronavirus. OSHA

proposed a penalty of $13,494. At least 1,294

Smithfield workers contracted the coronavirus,

according to the agency, and 4 employees died

from the virus in spring 2020.

In addition to the General Duty Clause, the

agency also is enforcing all federal standards,

including the respiratory protection standard

despite ongoing shortages of N95 filtering

facepiece respirators.

OSHA cited Bergen New Bridge Medical Center for

respiratory protection violations at its

Paramus, New Jersey, location. The hospital

failed to fit test tight-fitting facepiece

respirators on employees who were required to

use them, train employees on proper respirator

use, and ensure employees understood when to

wear a respirator, according to OSHA. The agency

proposed penalties of $9,639.

OSHA cited Georgetown Dental LLC in Georgetown,

Massachusetts, for respiratory protection

violations, proposing penalties of $9,500. The

agency cited the dental practice for failing to

provide medical evaluations and initial fit

testing for employees required to wear N95

respirators as protection against the

coronavirus; a lack of written programs for

bloodborne pathogens (BBP), hazard

communication, and respiratory protection; and

insufficient bloodborne pathogen training and

controls and inadequate eyewash stations.

OSHA cited Hackensack Meridian Health for a

serious violation for failure to provide

respirators to resident-care employees at its

North Bergen, New Jersey, location in March.

Employees without respirators were caring for

residents who were exhibiting symptoms of

coronavirus infection, according to the agency.

OSHA proposed penalties totaling $28,070. Other

violations included failure to conduct

respirator fit testing, effective training, and

compliant medical evaluations for the period

after the employer began providing respirators

to the employees and requiring their use.

The agency cited Ohio-based healthcare provider

OHNH EMP LLC for violations of the respiratory

protection standard after the company reported

the coronavirus-related hospitalization of seven

employees. The agency proposed penalties

totaling $40,482. The agency also issued the

company a Hazard Alert Letter regarding the

company’s practice of allowing N95 respirator

use for up to seven days or until damaged or

soiled. The company also had instructed

employees to wear surgical masks issued each day

over their respirators. Wearing a surgical mask

over a respirator could interfere with the

respirator’s inhalation and exhalation

resistance—factors the National Institute for

Occupational Safety and Health (NIOSH) tests

respirators for in addition to particle

filtration when certifying respirators.

The agency cited three of the company’s

locations for serious violations of the

respiratory protection standard’s requirements,

including lack of a comprehensive written

respiratory protection program and medical

evaluations of employees provided with and

instructed to wear respirators.

State workplace safety and health agencies also

have cited employers for inadequate COVID-19

protections. Governors in Nevada and Oregon have

ordered their workplace safety agencies to

ensure employers’ compliance with their states’

COVID-19 restrictions in addition to enforcing

their states’ occupational safety and health

laws. California and Michigan have cited several

employers for coronavirus-related violations.

The California Division of Occupational Safety

and Health (Cal/OSHA) announced it had cited 11

employers in agriculture, food processing,

health care, meatpacking, and retail for not

protecting employees from coronavirus exposure.

Cal/OSHA conducted a complaint-initiated

inspection of DL Poultry, Inc., of Monterey Park

and proposed penalties of $51,190 for COVID-19

and other violations. The agency proposed

penalties of $9,000 following a

complaint-initiated inspection of Olson Meat

Company, a meatpacking facility in Orland,

finding the employer did not physically distance

employees at least 6 feet apart in processing

areas or install plexiglass or other barriers

between workers.

The agency cited a frozen food manufacturer and

a temporary employment agency for failing to

protect hundreds of employees from COVID-19 at

two frozen food plants. The employers did not

implement procedures to have employees work at

least 6 feet away from each other or install

barriers and did not investigate employees’

COVID-19 infections that included more than 20

illnesses and 1 death.

The agency has cited agricultural labor firms

with COVID-19 and other violations, including:

-

Michel Labor Services Inc. for

COVID-19 and heat illness

prevention violations and

proposed penalties of $11,700

following an inspection of a

Dixon worksite; and

-

Serve Max Farm Labor Contractor

with both COVID-19 and heat

illness prevention violations

after an enforcement task force

inspection of a Vacaville

agricultural worksite, seeking

penalties of $11,250.

California also has an airborne transmissible

disease (ATD) standard that applies to

healthcare facilities, as well as correctional

facilities, diagnostic laboratories, and police

and public health services. Under the ATD

standard, California employers must protect

workers at healthcare facilities and other

services and operations from airborne diseases

like COVID-19 and tuberculosis (TB), influenza,

and pertussis (whooping cough).

Since the pandemic began, Cal/OSHA has cited

several employers under the ATD standard,

including:

-

Gateway Care & Rehabilitation

Center, a skilled nursing

facility in Hayward, for

exposing nurses and housekeeping

workers to COVID-19 when it

failed to provide necessary

personal protective equipment

(PPE);

-

Santa Rosa Police Department for

failing to implement required

screening and referral

procedures for persons

exhibiting COVID-19 symptoms and

failing to report to Cal/OSHA

multiple serious illnesses

suffered by employees who

contracted COVID-19; and

-

Sutter Bay Hospitals’ CPMC

Davies Campus for not ensuring

its healthcare workers in

administrative medical offices

and security guards in the

emergency department wore

respiratory protection, as well

as medical staff without N95

masks or other proper protection

while performing a medical

procedure in the operating room

on a suspected COVID-19 patient.

The Michigan Occupational Safety and Health

Administration (MIOSHA) cited 19 businesses with

serious “general duty” violations for failing to

protect employees from coronavirus exposures.

Violations cited under the state’s reopening

guidelines included:

-

Lack of a preparedness and

response plan and failure to

designate a COVID-19 workplace

supervisor;

-

Failure to require face

coverings when social distance

could not be maintained;

-

Failure to train employees on

COVID-19 guidelines;

-

Failure to conduct a daily

health screening protocol and

maintain/retain documentation

for training, entry screening,

and contact tracing; and

-

Failure to post signs, markings,

and barriers at the time clock

and provide cleaning supplies

for high-touch surfaces.

https://ehsdailyadvisor.blr.com/2020/10/covid-19-enforcement-a-guide-for-ehs-professionals/

Vogmask is a Lightweight Mask with a Good Fit

Ethan Brooke is the person behind

BreatheSafeAir.com. He has addressed mask fit in

his blog and had the following observations

about the fit with Vogmask

It’s important to note that the filter

standards (N95, KF94, KN95, etc.) are irrelevant

if the mask isn’t fitted correctly. If there are

gaps in the seal, particles can simply enter

through these gaps rather than through the

filter.

For this reason, the fit of a mask is vital. For

the best fit, professional fit testing is

required. However, this is not accessible for

most people.

3M recently found that even without professional

fit testing that some level of protection can be

achieved if methods are followed to create a

good fit (3M).

If you are wondering how to don a respirator

properly, please refer to this guide by

the CCOHS.

It is vital that a mask fits as well as possible

and that a seal can be made between your mask

and your face.

Vogmask offers five different sizes, each meant

for different people. The mask sizing is meant

to be easily accessible and is therefore based

on the height of the wearer. However, if you

have strong facial features, you may find

achieving a fit hard. This is especially true if

you have a big or small nose.

Vogmask uses ear-straps, and although common on

respirators, this is one of Brooke’s biggest

issues with the product. Ear-straps are less

sturdy than a head-band style of strap and mean

that the mask is more loosely fitting. Further,

these ear straps (as with all ear-straps) become

very painful after long periods.

Luckily, a headband accessory is available. If

you are purchasing a Vogmask and expect to be

wearing it for long periods of time, Brooke

can’t recommend this headband enough. Your ears

will thank you for it!

The mask features a wire-nosepiece for

adjustments around the nose. Although easily

adjustable, it’s important to try to retain the

structural integrity of the product when storing

it. This means, if possible, don’t share the

mask and don’t store it in the sun, or somewhere

where it can be crushed.

Another aspect that I noticed when first trying

Vogmask is that the mask is very light. It is

lighter than the Cambridge Pro Mask that I

Brooke usually uses, and it also feels

significantly lighter than most other reusable

masks that I use.

This is great for long-term wear. Although the

weight doesn’t seem to make a big difference

initially or in theory, in practice after long

periods of wear it will be a lot more

comfortable.