Coronavirus

Technology Solutions

October 14, 2020

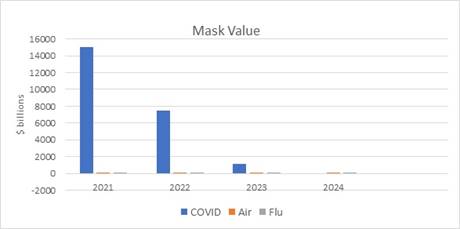

Filter Media Market will be Large but Volatile

Acoustical Wall Coverings with Anti-Microbials

Available from National Wall Covering

Effectiveness of Antimicrobials Analyzed by

Singapore Researchers

Cummins is in Mask Manufacture for the Long Haul

_____________________________________________________________________________

Filter Media Market will be Large but Volatile

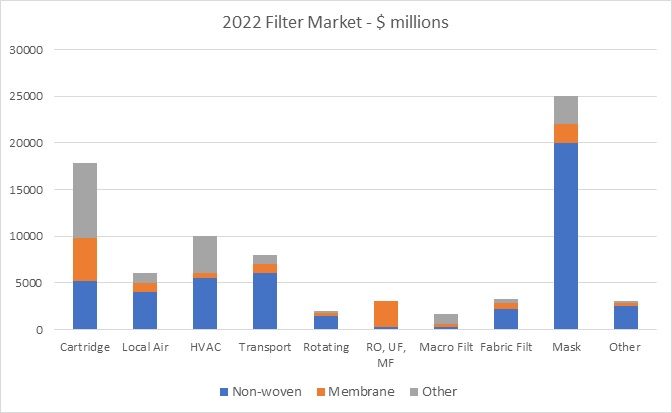

The segments of the

filtration industry which use non-woven and

membrane filters were $60 billion in 2019. If

the lowest true cost choices relative to the

coronavirus are selected the market will grow to

$80 billion in 2022. This represents an increase

of 33 percent over the 2019 revenues.

Coronavirus variables

have the biggest effect on the mask, local air

and HVAC purchases. Given the lowest true cost

path the media purchases for masks would be over

$5 billion. The media purchases for local air

and HVAC would be $4 billion. Media purchases

for other filtration applications would be over

$21 billion.

The lowest true cost

analysis recognizes the fact that most virus

transmission is through small aerosols. As a

result highly efficient masks and filters

represent the lowest true cost.

Media suppliers are

investing in production lines which will be

depreciated over many years. So the market past

2022 is of high interest. The future markets are

dependent upon

·

choice of the lowest

true cost program or the choice the U.S. and

Brazil have taken

·

the timing and impact

of vaccines and therapies

·

the impact of the

next pandemic, influenza and air pollution

·

the development of

new media with higher performance attributes

·

existing capacity

versus demand at any point in time.

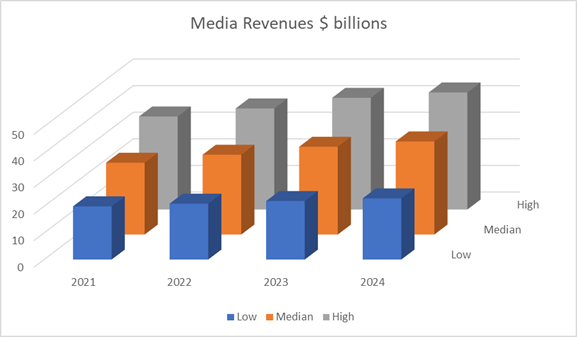

The filtration media

suppliers are facing the challenge of a very

volatile market. The 2021 market could vary from

$20 to $35 billion. By 2024 the market could

vary from $23 billion to $44 billion.

Media suppliers will

be well advised to continually adjust forecasts

in each application and geography.

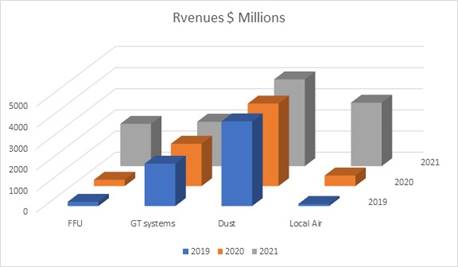

Some applications such as rotating

equipment have much more certainty than masks.

The same media which

can be used in masks and HVAC filters has

applicability in gas turbine intake filters,

dust collectors, and liquid cartridges.

Growth in gas turbine inlet filters and dust

collection will be much more predictable than

media for fan filter units and local air

systems.

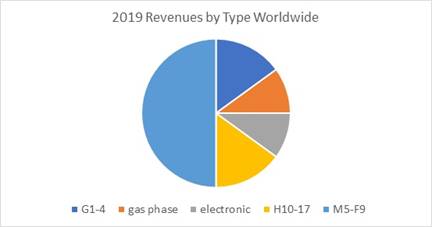

Media efficiencies will change substantially

from this 2019 split.

the

i

the

i

The COVID impact will likely lessen but air

pollution and influenza concerns will insure a

continuing market.

The Mcilvaine Company has custom reports on

filter media and multi client reports on each

filtration application. Details are found at

www.mcilvainecompany.com

Bob McIlvaine can answer any questions at

rmcilvaine@mcilvainecompany.com

or 847 226 2391.

Acoustical Wall Coverings with Anti-Microbials

Available from National Wall Covering

National Wall Covering is a distributor

operating in 30 States in the U.S. Standard

Repeat Acoustical Wallcoverings are a curated

selection of repeat-pattern designs printed via

dye-sublimation on Sibilance® High Performance

Acoustical Felt.

·

Derived from 100% postindustrial recycled

polyester

·

Provides an acoustically rated noise coefficient

(NRC) of .20.

·

Highly resistant to shrinking and stretching.

·

Coated for maximum stain resistance and

lightfastness (has a lightfastness rating of 5).

·

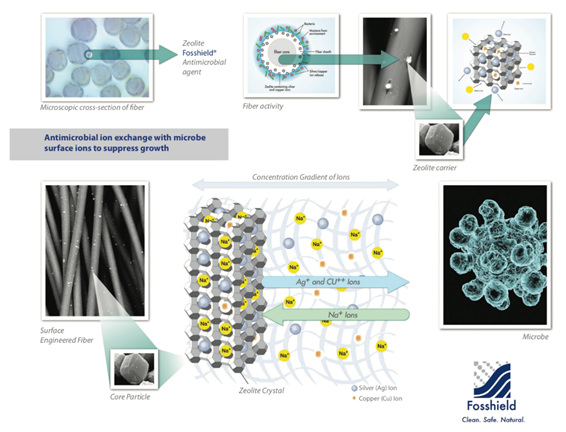

Fosshield Antimicrobial Technology: Silver &

copper ions incorporated into the polyester

fiber naturally attack microbes.

·

Does not absorb moisture making it a durable and

long-lasting solution.

·

Easily installed using traditional wallcovering

paste and butt seams leaving no visible overlap.

Fossheild®, an FDA cleared

antimicrobial technology incorporating silver

and copper ions into the fiber which naturally

attack microbes thus delivering surface

protection in addition to odor, mold, and

bacteria resistance.

Fosshield is the technology incorporated

into the SpectraShield™ 9500 N95 surgical

respirator mask. In the FDA testing, Fosshield began

microbe prevention immediately and eliminated

99.99% of certain odor-causing bacteria after

one hour of contact with the respirator surface.

This antimicrobial technology

is a solution for healthcare, living, and

workspaces with the added benefit of noise

mitigation and visual beauty.

“ The fiber

technology featured in Fosshield® works against

the types of airborne bacteria we are most

concerned about. This type of ‘capture and kill’

technology is ideal.

It’s the silver bullet against bacteria.” –

Dr. Charles Gerba

Effectiveness of Antimicrobials Analyzed by

Singapore Researchers

The Institute of Materials Research in Singapore

has just published an extensive analysis of

masks. We have excerpted some relevant

paragraphs on antimicrobials.

Apart from natural herbal extracts, metals and

their compounds have also been extensively

studied for their antimicrobial application.

Nanoparticles of metal and their compounds have

garnered huge attention as a potent

antimicrobial agent due to their high

surface-to-volume ratios compared with their

bulky counterparts. Though each of them has a

different mechanism of biocidal action, a

generally proposed mechanism includes the

disruption of cell membrane metabolism due to

the penetration of nanoparticles and/or release

of metal ions and the effect of photocatalytic,

as reactive oxygen species (ROS) like hydroxyl

(HO·) and superoxide radicals (O2-·)

are generated, which induce oxidative stress to

microorganisms and cause the ultimate

inactivation.

Nanoparticles of silver (Ag), silver compounds

(Ag+), titanium dioxide (TiO2),

zinc oxide (ZnO), and aluminum and aluminum

oxide (Al2O3) have been

incorporated to various filters for

antimicrobial properties. A synergistic

antimicrobial performance is also revealed via

their combination with other biocidal agents,

such as carbon nanotubes.

Apart from antimicrobial air filters,

multifunctional air filters, which

simultaneously remove PM, microorganisms, and

volatile organic compounds (VOCs), have drawn

increasing research attention recently. The

integrated multifunctional air filter provides a

promising solution to address the high-pressure

drop often caused by multiple filters with

different functions used in current air filters.

Feng et al. designed and fabricated hierarchical

Ag/ZnO nanorod-wrapped PTFE nanofibrous membrane

with an excellent dynamic antibacterial property

of ~100% against Escherichia coli (E.

coli), and a formaldehyde degradation rate

of 60%, with slightly increased gas penetration,

taking advantages of the antimicrobial

properties and photocatalytic abilities of both

ZnO and nanosilver.

In another study, Zhao et al. reported a

multifunctional Ag@MWCNTs Al2O3 hybrid

filter, where Ag@MWCNTs with a hierarchical

network-like structure uniformly distributed

around the pores of the Al2O3 filter.

The antimicrobial functionality of Ag

nanoparticles, as well as their catalytic

performance for formaldehyde degradation, were

greatly enhanced when loaded on high surface

area of CNTs. Owing to the synergistic

integration, the Ag@MWCNTs/Al2O3 hybrid

filter demonstrated excellent antimicrobial rate

(>98%) against common indoor microorganisms,

outstanding degradation of formaldehyde (99.99%

at 55°C, and 82.24% at room temperature), and

complete retention for particles with sizes ≤

0.3 μm with a pressure drop of 35.60%

compared with the pristine Al2O3 filter.

Copper nanoparticles are strong microbicides for

a broad spectrum of microorganisms. Very

recently, they have been demonstrated to be

effective against the newly emerged 2019

coronavirus (COVID-19), which is threatening the

whole world. Though copper-polymer

nanocomposites have been explored for

antimicrobial applications, the integration of

copper nanoparticles to filters for personal

protection or air filtration has not been

reported yet. With appropriate technologies to

effectively deposit copper nanoparticles onto

fibrous filter matrix, more advancement for

copper nanoparticles as antimicrobial coating in

air filters is expected.

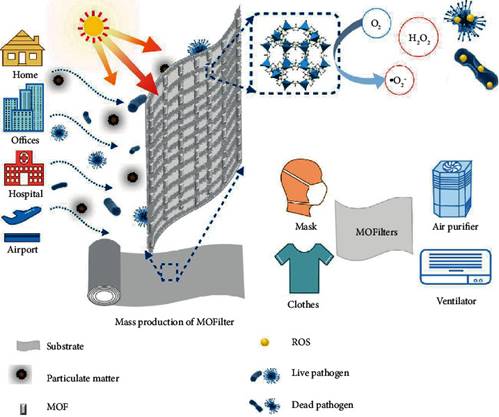

Metal-Organic

Frameworks (MOF)

an emerging new class

of antimicrobials, are superior compared with

metals due to their high surface area, uniform

distribution of metal active sites, and

adjustable porous structures. There has been

rapid progress in recent years on the research

of antimicrobial behavior of MOFs, along with

the antimicrobial application of MOFs and their

composites. The antimicrobial mechanism of MOFs

is mainly accredited to the inherent biocidal

nature from their metal ions and may also be

from the antimicrobial organic ligands.

Ma et al. combined MOFs and cellulose fibre (CF)

via simple in situ generation and established

multifunctional MOFs@CF air filters. The

ZIF-8@CF filter exhibited high filtration

efficiency of 98.36% against 0.3 μm

particles, high gas adsorption ability, and

excellent antibacterial activity against E.

coli under a pressure drop of 134 Pa. Very

recently, inspired by the extremely tunable

photocatalytic properties of MOFs, Li et al.

exploited their photocatalytic biocidal

activities and developed integrated air filters

based on the MOFs. ZIF-8 nanocrystals were

integrated to nonwoven fabrics via hot pressing.

The established MOFilter achieved 96.8% removal

of PM2.5 particles with a

low-pressure drop (64 Pa) at a flow rate of

0.7 m s−1 and bactericidal efficiency

higher than 99.99% over 30 min against aerosols

containing E. coli. The dominant

disinfection behavior of ZIF-8 here was ascribed

to ROS production from photoelectrons trapped at

Zn+ centers within ZIF-8 via ligand

to metal charge transfer (LMCT), rather than Zn2+ releasing.

This work sheds light on the photocatalytic

biocidal action of MOFs and provides valuable

insights for their potential antimicrobial

applications in air disinfection.

Several masks have also integrated more than one

class of antimicrobial agents across multiple

layers. US patent 7845351 disclosed that

treating the outer nonwoven layer with

antimicrobial agents comprising

polyhexamethylene biguanide, citric acid, and N-alkyl

polyglycoside, as well as other known

antimicrobial agents, can deactivate 99.9% of

treated bacteria (MRSA, vancomycin-resistant E.

faecalis, M. catarrhalis, and K.

pneumoniae), fungus C. albicans,

and viruses (rhinovirus 1A, influenza A) within

30 minutes of contact. US patent application

US20110114095A1 disclosed the use of AgNP-impregnated

activated carbon cloth (ACC) as the filtration

layer in a face mask; ACC itself showed

antiviral activity (93%) against MS-2 coliphage

after 6 h incubation, which was enhanced by

impregnation of AgNPs (98%). Incorporation of

the AgNPs/ACC into a mask resulted in >99.88%

virus filtration while having increased air

permeability compared to the FFP3 mask. Some

FDA-cleared examples of antimicrobial mask

include Filigent's BioFriendTM BiomaskTM ,

cobranded with Medline Curad® BiomaskTM (ONT

and OUK), as well as Innonix's RespoKareTM mask

line (OUK child masks), which both use 2 wt%

citric acid on the outermost spun-bound PP

layer, as well as Cu(II) and Zn(II) (1.6 wt%

each) coordinated to sulfonated Rayon in a

second layer before the melt-blown PP filter.

Both antiviral masks inactivated 99.99% of

tested influenza A (H1N1, H2N2, H3N2, H5N1, and

H5N9) and B viruses within 5 minutes. Nexera

Medical's SpectraShieldTM 9500 masks

(ONT) use patented Ag-Cu zeolite (Agion®,

Sciessen LLC) in the outer PET fibre layer (Fosshield®,

Foss Manufacturing); it kills 99.99% of tested

bacteria (S. pyogenes, MRSA, and H.

influenzae) and can also inactivate SARS,

influenza, and filovirus. It has been tested for

continuous use for up to 8 hours.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7429109/

Cummins is in Mask Manufacture for the

Long

Haul

Amy Davis, Vice President of

Cummins Filtration, shares an update on the

company's progress to provide filter media to

mask manufacturers around the globe.

As the world began to grapple

with COVID-19, employees at Cummins were working

on innovative solutions to help supply PPE that

was in high demand. On April 6, Cummins

announced plans to use their filter

technology to supply critical materials for N95

respirator masks, an essential piece of personal

protective equipment for front-line healthcare

workers.

Following the N95

announcement, on April 14, Cummins announced an

additional partnership with 3M, which would

include the utilization of equipment typically

used for producing diesel engine filters to

manufacture high-efficiency particulate filters

for use in 3M’s powered air purifying

respirators (PAPRs).

To date, Cummins has provided

more than 14 tons of its filtration media to

mask manufacturers across the globe, which has

been used to produce more than eight million

masks. Amy Davis, Vice President of Cummins

Filtration, recently shared an update on the

company’s progress to date.

Q: First, can you share more about the

Cummins Filtration business and your core

products?

DAVIS: Our core expertise is designing,

manufacturing and selling air, fuel, hydraulic

and lube filtration, as well as chemical

technology products for diesel and gas-powered

equipment around the world.

Q: How did Cummins Filtration get involved in

supplying media for masks?

DAVIS: The need for masks, especially N95

respirator masks, skyrocketed in March and April

in response to the COVID-19 pandemic. We learned

that many of the world’s leading mask

manufacturers needed the critical materials to

assemble masks and were struggling to meet

demand. We realized that the NanoNet® and

NanoForce® Media technology typically found

in filtration products for diesel engines could

also be used in surgical masks and N95

respirator masks worn by healthcare

professionals to help stop the spread of

COVID-19. Once we made that connection, we began

exploring partnerships to apply the filter

material to masks.

Q: How has Cummins been able to partner with

3M in an additional effort to meet the surge in

demand for PPE due to the COVID-19 outbreak?

DAVIS: We needed to move fast and saw an

opportunity to use our existing workforce at our

Neillsville, Wisconsin facility to meet this

demand. We acquired, commissioned and tested a

new pleater in a matter of weeks and have

already produced more than 41,000 filters for

3M’s PAPRs since mid-April. Internally, we talk

a lot about employee empowerment and decision

making and this project is a testament to our

employees’ ability to adapt quickly to fill an

important supply void in a totally different

market.

Q: What has the response been like from mask

manufacturers?

DAVIS: Demand has been strong – in fact, it’s

getting to the point where demand will exceed

our capacity. Seeing so many organizations

inquire about the media reinforced how critical

the need for masks was globally. We’ve talked

with Universities, health care systems, other

automotive companies and mask manufacturers

large and small about our media. To date, we’ve

supplied 6 tons of the complete composite

multilayer media that can be used in N95 masks,

and we’ve shipped 8 tons of a simpler

polypropylene media that can be used in surgical

masks.

Q: Do you plan on selling media for masks

long-term, or is this a temporary measure to

respond to the COVID-19 pandemic?

DAVIS: We’ve added manufacturing capacity and

capability to our plants and plan on continuing

to supply media for masks as long as there is

demand and a need to protect our communities

from COVID-19.