Coronavirus

Technology Solutions

October 9, 2020

New Officers for Eurovent Air Filters

Eurovent Publishes HVAC Market Report

Suominen has Unique Media for Masks

Screentec Expanding Mask Production

Mask Leakage is Greater for Small Particles in

the Size Range of COVID

Vogmask has Low Leakage Due to the Option for

Five Mask Sizes

Georgia Tech Researchers Design Mask with Low

Leakage

___________________________________________________________________________

New Officers for Eurovent Air Filters

During its meeting on 29 September 2020, the

Eurovent Product Group ‘Air Filters’ (PG-FIL)

elected Dr. Marc Schmidt (Vice President

Technologies Europe, AAF International) as its

new chairman. He is joined by Dr. Thomas Caesar

(Director Global Filter Engineering, Freudenberg

Filtration Technologies), who was re-elected for

his second term as PG-FIL Vice-Chairman.

PG-FIL met in a full-day online session on

Tuesday, 29 September 2020, with a focus on

regulatory updates under Ecodesign and REACH,

and the revision of several Eurovent Air Filter

Recommendations. The group elected Dr. Schmidt

as its new chairman for the next two-year term.

He will succeed Jan Andersson of Camfil, who

served as PG-FIL chairman for many years. Dr.

Caesar was unanimously re-elected as the group’s

vice-chairman, continuing his role for the next

two years.

Dr. Schmidt, new chairman of PG-FIL, stated:

“Correct air filtration is more crucial than

ever for the health and well-being of building

occupants. Under the banner of Eurovent, it is

our duty to convey this message to the market,

to the policymakers, and to the public, and to

raise awareness of the importance of clean and

healthy indoor air. I am humbled that the

Product Group ‘Air Filters’, which represents

manufacturers from all over Europe, has vested

its trust in me to lead the charge on this.”

The next meeting of PG-FIL is scheduled for

March 2021. Given the continued uncertainty

around the public heath situation, the exact

date and location of the meeting will be

determined at a later stage.

Eurovent Publishes HVAC Market Report

Yannick Cotrelle Market Intelligence Manager of

Eurovent commented on the new report assessing

the European HVAC market.

“With one million deaths worldwide, and more

than 33 million people infected in 188

countries, the coronavirus called covid-19 will

have been at the origin of the worst pandemic of

the beginning of this 21st century. The first

wave, which occurred between February and June

for Europe, forced a number of countries to take

restrictive measures (closures of schools,

hotels, restaurants, borders; general lockdown,

etc.) which had a negative impact on the economy

̶but not always as we will see!

The second wave currently underway, which is

fortunately much less deadly than the first

(especially in Western Europe), will have a more

transparent impact on the market, with most

sectors having already started to adapt to this

new post-covid world. It is impossible to

summarize in one sentence or even one page the

effects of the covid-19 crisis on the entire

HVAC&R market, past and future, as they depend

on very different factors. This is why the

ambition of this special covid-19 report is to

provide you with a clear and concise answer to

each question you ask yourself about your

market, thanks to a simplified framework,

organized by type of product, country,

application and project. We hope you will

appreciate reading this prospective study which

marks a new stage in the development of Eurovent

Market Intelligence, always with the aim of

better helping you to find your way in this

uncertain world.”

This survey was conducted in the period from 12

August to 25 September 2020 with 100 HVACR

companies from 19 countries. The survey

concerned eight types of products, that were

united in three groups for the analysis: - HVAC

(Chillers, AHU, Fan Coil Units, Rooftops, VRF);

- Refrigeration (Heat exchangers and Cooling

towers); - Air filters.

The survey was based on primary and secondary

research: 1. Primary research: 1.1. The

questionnaire on the sales results and prospects

in 2020, as well as expectations for the future

(filled in by all the respondents). 1.2. A

profound interview with the respondents for

qualitative clarifications of their market

situation and vision (conducted with 40

respondents). 2. Secondary research: 1.1.

Analysis of the macroeconomic statistics on the

economic development by country. 1.2. Analysis

of the information in press article on

countries' economy in 2020 and forecasts about

their further development, government response

to Covid crisis and the situation in the most

important industries (construction, tourism,

health, etc.).

Forecast methodology The forecast for 2020-2023

was made by product, by country and by

application. The forecast was based on the

following information: 1. 2020 forecast: -

quantitative results on orders cancelled, new

orders received during 1H2020 in comparison to

1H2019 and the size of order book for 2H2020 in

comparison to 2H2019, received from the

questionnaires of the respondents; - results of

market evolution in Q1-Q3 2020 for four products

(chillers, fan coils, AHU, rooftops), based on

the quarterly survey regularly conducted by EMI;

2. 2021-2023 forecast: - expectations of the

respondents for the business restart; - analysis

of the macroeconomic situation by country and by

the industry/application of HVAC products.

Suominen has Unique Media for Masks

Suominen has developed a nonwoven material for

the manufacturing of face mask applications. The

new nonwoven has passed European Standard EN

14683:2019 Type II requirements in terms of

filtration efficiency and pressure drop.

“Our FIBRELLA® Shield nonwoven has

excellent filtration efficiency and pressure

drop values meaning that the material provides

protection while being comfortable and easy to

breathe through. Measured with an applied method

by VTT results indicate that FIBRELLA® Shield

nonwoven’s filtration efficiency is higher than

99% reaching type II requirements but of course

the material can also be used for lighter model

Type I masks or uncertified masks,” says

Category Manager Johanna Sirén.

“FIBRELLA® Shield has received

positive feedback from several user panel tests

about its textile-like softness and being

odorless. The panel results show also that

FIBRELLA® Shield is comfortable to

use even for several hours and it doesn’t build

up moisture during use,” Johanna Sirén

continues.

The standard EN14683:2019 for medical masks is

for end products and the converter has to repeat

the tests to confirm the standard compliancy for

the end product. The end product needs to comply

also with the regional regulations, if any.

Developed in cooperation with VTT, this new

material is the latest addition to the FIBRELLA® family.

FIBRELLA® Shield is already in

production at Suominen’s Nakkila plant.

Currently the plant is capable of producing

material for approximately 15 million masks per

month.

Screentec Expanding Mask Production

The past few months have seen major changes at Screentec’s Oulu-based factory. New production lines and more factory space are just a few of the exciting changes happening. There is a lot of positive news, despite these turbulent times.

Screentec Oy, together with its partners, such as Nord Option, and support from the Finnish ELY-Centre, has invested heavily in new production lines of PPE equipment. The need from the healthcare sector for surgical masks and FFP 3 masks has been great, especially on the Finnish domestic market. The importance of domestic supply chains and manufacturing has never been greater.

Screentec aims to get three new production lines up and running as soon as possible. The first two, one for surgical masks and the other for FFP2 and FFP3 masks are already up and running. There is still work to be done on the 3rd production line and steps have been taken to ensure there is enough floor space for the machines to operate.

Starting next month, their factory will be expanded with over 400m2 of extra space to allow for this new expansion. This also means that Screentec has had to increase its workforce significantly. Over the past few months they have managed to create well over 30 new jobs and their growth will continue in the coming months.

Last month, their quality management system has

undergone an extensive audit and they are proud

to inform you that their ISO 13 485

certification has been renewed for another three

years!

In March, Screentec’s Chief Technology Officier, Mikko Paakkolanvaara, got the idea to start producing the Screentec V3 Visor after seeing that there was a great shortage of domestic PPE in Finland. In just a few weeks’ time Screentec has managed to set up a mass production of these devices and CE mark certification is well underway. Weekly production volumes of the Visor V3 are already in excess of 30 000 units per week and production speed is being ramped-up constantly.

Sadly, Visors aren’t the only piece of PPE in short supply, new measures both in Finland and the rest of the EU mean that there is an unprecedented need for FFP3 masks. These masks protect the user from a minimum of 99% of particles, with a leakage of 2% or less under EU standards. This means they are some of the best pieces of protective gear available to prevent infections from happening. Urgent action is needed to make sure that enough FFP3 masks are available to both healthcare professionals and other people in the near future.

To this end, Screentec struck a deal with five university hospitals across Finland to set up a production line for almost six million FFP3 masks. Production of the masks started in June 2020. It involved significant investments in production equipment and logistics, but Screentec’s CEO Mr. Antti Tauriainen, is confident that the company is able to meet this new challenge: ” With the Visor V3 production, we were able to show that our company is able to quickly set up production lines and deliver on promises. This gave the hospitals the confidence to choose us as their partner for this task.”

Despite the increase in activity at the company, Antti is keeping a level head in this situation: ” The Visor V3 production line enabled us to hire between 18-26 new people, which is a significant increase for us. We would like to keep these people on in the future as well, so we are taking steps to ensure that their employment is sustainable. Our company has been around for over 30 years and we always keep the long run in mind.”

When asked about continued support for the new

PPE products, Antti mentioned that Screentec

intends to keep them as a permanent part of the

company’s product portfolio. Customers can

expect to be able to purchase them for years to

come.

Mask Leakage is Greater for

Small Particles in the Size Range of COVID

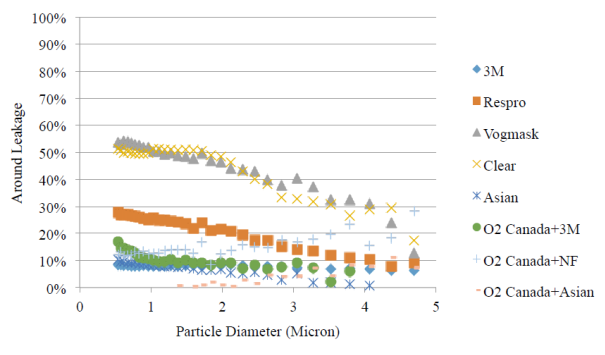

An older study by the University of Waterloo has

an important comparison of dust masks. It shows

that the inward leakage is higher for sub-micron

particles than for larger particles.

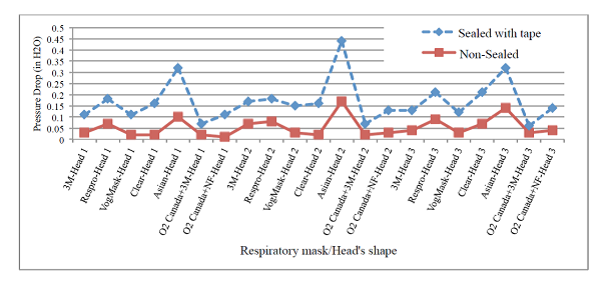

Also the pressure drop across the mask is a

function of leakage.

https://nirvanabeing.com/wp-content/uploads/2019/11/UW-Air-Pollution-Data-Round-1.pdf

Vogmask has Low Leakage Due to the Option for

Five Mask Sizes

This older data in the chart above with one mask

design does not reflect the current Vogmask

products. Vogmask supplies five sizes S - XL.

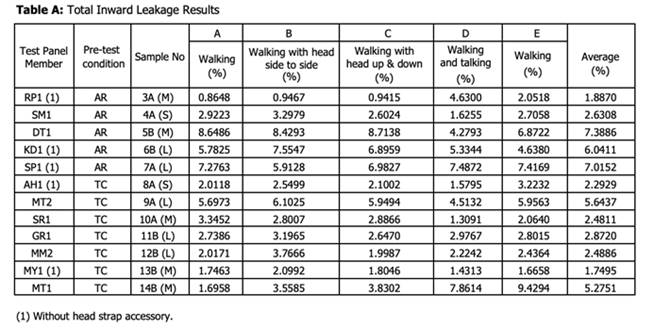

Vogmask is Quantitatively Fit Tested on human

subjects to ensure the filtering efficiency is

retained over a series of motions like walking,

head movements, bending over, talking, etc. Here

is a sample of the fit testing on Test Subjects.

Georgia Tech Researchers Design Mask with Low

Leakage

Imagine a reusable face mask that protects

wearers and those around them from SARS-CoV-2,

is comfortable enough to wear all day, and stays

in place without frequent adjustment. Based on

decades of experience with filtration and

textile materials, Georgia Institute of

Technology researchers have designed a new mask

intended to do just that — and are providing

the plans so

individuals and manufacturers can make it.

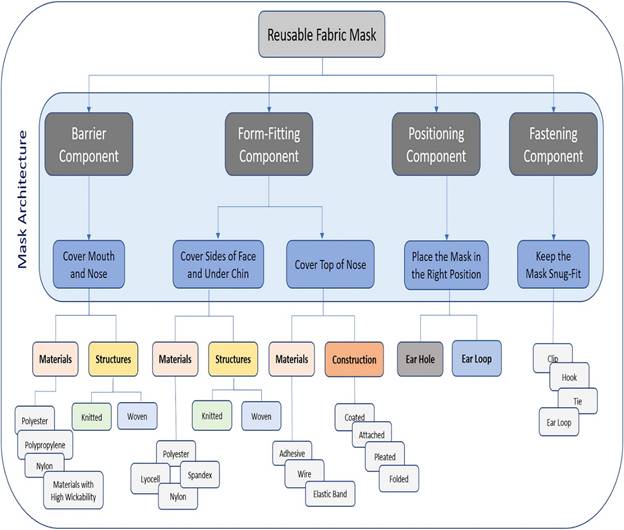

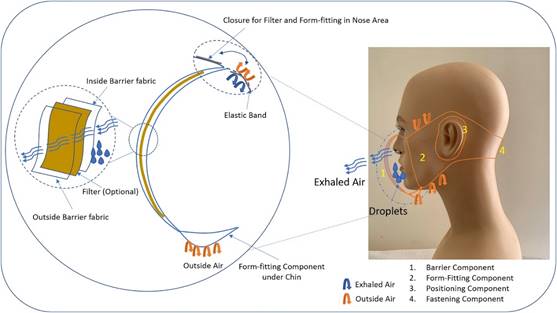

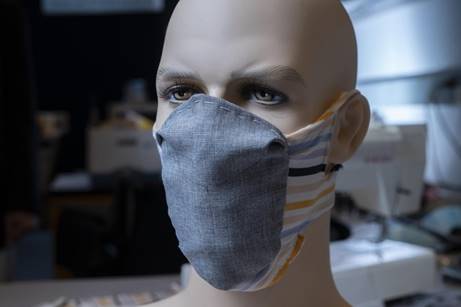

The modular Georgia Tech mask combines a barrier

filtration material with a stretchable fabric to

hold it in place. Prototypes made for testing

use hook and eye fasteners on the back of the

head to keep the masks on and include a pocket

for an optional filter to increase protection.

After 20 washings, the prototypes have not

shrunk or lost their shape.

“If we want to reopen the economy and ask people

to go back to work, we need a mask that is both

comfortable and effective,” said Sundaresan

Jayaraman, the Kolon Professor in Georgia

Tech’s School of Materials Science and

Engineering. “We have taken a science-based

approach to designing a better mask, and we are

very passionate about getting this out so people

can use it to help protect themselves and others

from harm.”

The fundamental flaw in existing reusable cloth

masks is that they — unlike N95 respirators,

which are fitted for individual users — leak air

around the edges, bypassing their filtration

mechanism. That potentially allows virus

particles, both large droplets and smaller

aerosols, to enter the air breathed in by users,

and allows particles from infected persons to

exit the mask.

The leakage problem shows up in complaints about

eyeglasses fogging up as exhaled breath leaks

around the nose, making people less likely to

wear them. The fit problem can also be seen in

constant adjustments made by wearers, who could

potentially contaminate themselves whenever they

touch the masks after touching other surfaces.

To address the leakage challenge, Jayaraman and

principal research scientist Sungmee

Park created a two-part mask that fastens behind

the head like many N95 respirators. The front

part — the barrier component — contains the

filtration material and is contoured to fit

tightly while allowing space ahead of the nose

and mouth to avoid breathing restrictions and

permit unrestricted speech. Made from the kind

of moisture-wicking material used in athletic

clothing, it includes a pocket into which a

filter can be inserted to increase the

filtration efficiency and thereby increase

protection. The washable fabric filter is made

of a blend of Spandex and polyester.

The second part of the mask is fashioned from

stretchable material. The stretchable part,

which has holes for the ears to help position

the mask, holds the front portion in place and

fastens with conventional hook and eyelet

hardware, a mechanism that has been used in

clothing for centuries.

“We want people to be able to get the mask in

the right place every time,” Jayaraman said. “If

you don’t position it correctly and easily, you

are going to have to keep fiddling with it. We

see that all the time on television with people

adjusting their masks and letting them drop

below their noses.”

Beyond controlling air leakage, designing a

better mask involves a tradeoff between

filtration effectiveness and how well users can

breathe. If a mask makes breathing too

difficult, users will simply not use it,

reducing compliance with masking requirements.

Many existing mask designs attempt to increase

filtration effectiveness by boosting the number

of layers, but that may not be as helpful as it

might seem, Park said. “We tested 16 layers of

handkerchief material, and as we increased the

layers, we measured increased breathing

resistance,” she said. “While the breathing

resistance went up, the filtration did not

improve as much as we would have expected.”

“Good filtration efficiency is not enough by

itself,” said Jayaraman. “The combination of

fit, filtration efficiency, and staying in the

right place make for a good mask.”

The stretchable part of the mask is made from

knitted fabric — a Spandex/Lyocell blend — to

allow for stretching around the head and under

the chin. The researchers used a woven elastic

band sewn with pleats to cover the top of the

nose.

The researchers made their mask prototypes from

synthetic materials instead of cotton. Though

cotton is a natural material, it absorbs

moisture and holds it on the face, reducing

breathability, and potentially creating a “petri

dish” for the growth of microbes.

“Masks have become an essential accessory in our

wardrobe and add a social dimension to how we

feel about wearing them,” Park said. So, the

materials chosen for the mask come in a variety

of colors and designs. “Integrating form and

function is key to having a mask that protects

individuals while making them look good and feel

less self-conscious,” Jayaraman said.

The work of Jayaraman and Park didn’t begin with

the Covid-19 pandemic. They received funding 10

years ago from the Centers for Disease Control

and Prevention to study face masks during the

avian influenza outbreak. Since then Jayaraman

has been part of several National Academy of

Medicine initiatives to develop recommendations

for improved respiratory protection.

Covid-19 dramatically increased the importance

of using face masks because of the role played

by asymptomatic and pre-symptomatic exposure

from persons who don’t know they are infected,

Jayaraman said. While the proportion of aerosol

contributions to transmission is still under

study, they likely increase the importance of

formfitting masks that don’t leak.

Jayaraman and Park have published their

recommendations in The Journal of The Textile

Institute and will make the specifications

and patterns for their mask available to

individuals and manufacturers. The necessary

materials can be obtained from retail fabric

stores, and the instructions describe how to

measure for customizing the masks.

“There is so much misinformation about what face

masks can do and cannot do,” Jayaraman said.

“Being scientists and engineers, we want to put

out information backed by science that can help

our community reduce the harm from SARS-CoV-2.”

Link to plans, patterns and specifications for

this mask

The full article can be found on line.

The authors are Sungmee Park and

Sundaresan Jayaraman,. the paper is “From

containment to harm reduction from SARS-CoV-2: a

fabric mask for enhanced effectiveness, comfort,

and compliance.” (The Journal of The Textile

Institute, 2020) https://doi.org/10.1080/00405000.2020.1805971