Coronavirus Technology Solutions

September 29, 2020

ATI Automated Filter Tester Meets New European

Standard

Real-Time Detection of Airborne Biological

Threats

Filter and Mask Production and Project Tracking

System

Ventilation Being Prioritized in Germany but

will it be Properly Directed

ElectrospinTech Gathering Knowledge on Nanofiber

Filtration

Electrospun Media in HEPA Filters

__________________________________________________________________________

ATI Automated Filter Tester Meets New European

Standard

Air Techniques International (ATI), a leader in

the design and manufacture of specialized

testing equipment for HEPA filters, media,

filter cartridges, respirators, and protective

masks, announced

the addition of

European

Standard EN 13274-7:2019 for Paraffin Oil to its

100X Automated Filter Tester lineup. The 100X

automated filter tester with full EN13274-7:2019

compliance has already been delivered to leading

filter manufacturers from ATI’s global

Headquarters in Owings Mills, MD, USA.

EN 13274-7:2019 supersedes the previous standard

(EN 13274-7:2008) and acts as the test method to

determine particle filter penetration for

respiratory protective devices. EN 13274-7

standard is the test method called by EN 149 for

the testing of filtering half masks to protect

against particles (FFP1, FFP2 & FFP3 masks)

which are in high demand during the current

global Covid-19 pandemic.

EN 13274-7:2019 complements the existing set of

global standards that the 100X meets. “Our

customers expressed strong interest in test

equipment that is fully compliant with the new

standard. We quickly developed a version of the

100X that precisely meets the aerosol

concentration and particle size distribution

required by the standard, and we have ramped up

production to ship within 6-8 weeks to meet

strong customer demand” said Gautam Patel,

Global Product Manager.

Service and support for 100X customers using the

new standard is managed through ATI’s Owings

Mills, MD Headquarters and its UK facility.

Also, ATI’s global network of Distribution

partners and Service Centers are ready to

respond when service is needed.

In addition to EN 13274-7:2019, the 100X

Automated Filter Tester product range meets

other major industry standards, such as NIOSH 42

CFR Part 84, GB 2626, ISO 23328, JICOSH/JMOL,

and more. The 100X Automated Filter Tester is

used worldwide in production, quality control,

and R&D applications to test and validate filter

media, cartridges, and respirators. To view a

short video and learn more about the 100X,

https://www.atitest.com/products/100x-automated-filter-tester/

Real-Time Detection of Airborne Biological

Threats

The

ATI Polaron F10+ provides real-time detection of

airborne biological threats and other

aerosolized anomalies. It rapidly and reliably

detects all four classes of biological agents

(spores, toxins, viruses, and bacteria) at low

concentrations, with low false-alarm rates. By

combining state-of-the-art patented polarized

elastic light scattering and laser-induced

fluorescence, the Polaron can detect small

particles with weak fluorescence properties,

down to 0.5 micron sensitivity, while rejecting

commonly occurring non-biologic fluorescing

material that can cause false alarms in legacy

detectors.

Polaron monitors air continuously and provides

early-warning alarms of potential aerosol

threats. It transmits information as a

first-tier “trigger” in a networked system for a

variety of applications:

·

Building protection

·

Mass-transit security

·

Special-event monitoring

·

Force and base protection

Filter and Mask Production and Project Tracking

System

We have initiated

a system to track filter and mask

production.

This will include media and machines as

well as finished filters. We have started to

make entries as shown below. The continually

updated version will be linked to the website

along with the searches by key words and

headlines

Random New Entries Made Today

Some entries to the system will not be covered

with articles in the Alert.

Here are three of them today

|

Date |

Company |

Product |

Specific |

City/State |

Country |

|

20-09-29 |

BYD |

masks |

surgical |

Shenzhen |

China |

|

Quantity |

Start |

Notes |

|||

|

5 million/day |

03-20 |

Large privately

held company

backed by Warren

Buffett |

|||

|

Company |

Product |

Specific |

City/State |

Country |

|

|

20-09-29 |

3M |

mask |

N95 |

|

U.S. |

|

Quantity |

Start |

Notes |

|||

|

50,000,000/mo |

June 2020 |

Up 40% over

March |

|||

|

Date |

Company |

Product |

Specific |

City/State |

Country |

|

20-09-29 |

M+H |

HEPA |

respirator |

|

Ger, U.S |

|

Quantity |

Start |

Notes |

|||

|

3500/day |

March 2020 |

Microglass for

Ford respirator

production |

|||

Ventilation Being Prioritized in Germany but

will it be Properly Directed

Germany is focusing on increasing outside air

ventilation of facilities. The question is

whether this is being done with the knowledge of

the importance of air flow direction. Outside

ventilation is only valuable to the degree it

reduces virus load in the breathing zone of

people. For example if the load is higher but it

is near the floor and not in the breathing zone

the risk is lower than if most of this virus is

redirected to the breathing zone even as it is

eventually discharged outside.

Ventilating rooms has been added to the German

government’s formula for tackling coronavirus,

in refreshing news for the country’s air hygiene

experts who have been calling for it to become

official for months.

The custom is something of a national obsession,

with many Germans habitually opening windows

twice a day, even in winter. Often the

requirement is included as a legally binding

clause in rental agreements, mainly to protect

against mold and bad smells.

But while some people may dismiss the method as

primitive, “it may be one of the cheapest and

most effective ways” of containing the spread of

the virus, Angela Merkel insisted on Tuesday.

The German chancellor explained that the

government’s guidelines to tackle the virus,

encapsulated in the acronym AHA, which stands

for distancing, hygiene and face coverings, will

be extended to become AHACL. The “C” stands for

the government’s coronavirus warning app, and

“L” for Lüften or airing a room.

“Regular impact ventilation in all private and

public rooms can considerably reduce the danger

of infection,” the government’s recommendation

explains.

Impact ventilation, or Stosslüften, which

needs explanation for most people unfamiliar

with Germany except

for experts in air hygiene, involves widely

opening a window in the morning and evening for

at least five minutes to allow the air to

circulate. Even more efficient is Querlüften,

or cross ventilation, whereby all the windows in

a house or apartment are opened letting stale

air flow out and fresh air come in.

In Germany, windows are designed with

sophisticated hinge technology that allows them

to be opened in various directions to enable

varying degrees of Lüften.

Since it has become known that 90% of Covid-19

patients pick up the virus indoors, the practice

has come into its own. With winter on the

doorstep, it will become even more important,

experts insist.

The country’s leading coronavirus expert,

Christian Drosten, who is head virologist at the

Charité hospital in Berlin, has already dedicated

an edition of his hit

pandemic podcast to the importance of Luftverdünnung and Luftbewegung –

air rarefaction and movement – in which he

extols the praises for frequent airing, while

the weekly Die Zeit has published

a 10-page feature on ventilation,

including the science behind it and, especially

how to do it in winter.

Even without coronavirus, Martin Kriegel, an

engineer and air current analyst at the

Technical University in Berlin, told Die Zeit,

“there is clear evidence that air quality in

offices correlates with the number of days

workers are off sick”.

Schools, which have increasingly been viewed as

a testing ground for how society can learn to

live with the disease, have long since adopted

the practice. A recent gathering of the

ministers of education for Germany’s 16

states was dedicated to how to air a classroom.

Five experts, from

fluid mechanics to indoor air hygienists and

aerodynamicists, reinforced the importance of

airing a room every 15 to 20 minutes, for five

minutes in spring and autumn, and three minutes

in winter.

But although the custom is well-established in

Germany, it is also a frequent cause of tension,

which some fear is only likely to increase this

winter the more people practice it. The typical

grumpy German response of someone objecting to

an open window, is erfroren sind schon viele,

erstunken its noch keiner – many people have

frozen to death, but no one has ever died from a

bad smell.

Helen, a 34-year-old primary school teacher from

Cologne, who did not want to give her full name,

said: “A typical scenario in Germany is someone

opening the window in an office or on a train,

say, then the next person comes in and complains

it’s draughty – that’s another German obsession

– and insists on closing it. That’s also why

Germans often wear scarves.”

She has been following the recommendations and

airing her classroom every 20 minutes, she said.

“I do enjoy regularly airing, whether in the

classroom or at home, and now because of the

coronavirus it seems more important than ever.

Though I am concerned how I will manage with the

kids in winter when it’s really cold.”

ElectrospinTech Gathering Knowledge on Nanofiber

Filtration

ElectrospinTech is an online knowledge and

information resource center on electrospinning.

It aims to facilitate the advancement in science

and understanding of the process to foster

greater utilization of nanofibers to create new

materials and products. Information found on

their platform includes upstream basic research

to downstream consumer products.

Electrospinning Mass Production Machine

Providers

|

Company Name |

Country |

Product/Service |

Website |

|

4SPIN by

Contipro |

Czech Republic |

Laboratory Setup

and accessories |

|

|

Elmarco |

Czech Republic |

Supplier of

industrial level

and lab scale

electrospinning

machine |

|

|

MECC Co. Ltd |

Japan |

Supplier of lab

scale and

semi-industrial

level

electrospinning

machine |

|

|

Fuence |

Japan |

Lab scale

electrospinnng

setup and

semi-industrial

level

electrospinning

machine.

Contract

manufacturing of

nanofibers. |

|

|

ANSTCO (Asian

Nanostructures

Technology

Company) |

Iran |

Supplier of

industrial level

and lab scale

electrospinning

machine |

|

|

Fnm Co. (Fanavaran

Nano-Meghyas) |

Iran |

Supplier of

industrial level

and lab scale

electrospinning

machine and

accessories |

|

|

inovenso |

Turkey |

Supplier of

industrial level

and lab scale

electrospinning

machine |

|

|

Yflow |

Spain |

Supplier of lab

scale and

industrial level

electrospinning

machine |

|

|

SPUR |

Czech Republic |

Supplier of

industrial level

setup |

|

|

Bioinicia |

Spain |

Custom

manufacturer of

electrospinning

machine and

accessories.

Basic and

industry setups. |

http://bioinicia.com/, |

|

IME Technologies |

The Netherlands |

Manufacturer of

electrospinning

equipment for

research and

industry |

|

|

Leonardino S.r.l |

Italy |

Electrospinning

equipment for

lab, small and

industrial scale

of manufacturing |

http://leonardino.eu, |

http://electrospintech.com/index.html

Electrospun Media in HEPA Filters

High efficiency particulate air (HEPA) filters

are very important in industrial applications

for keeping a designated environment free of

particulate contaminants such as cleanrooms. In

most countries, HEPA filters need to meet

stringent requirements. United States Department

of Energy (DOE) standard states that a HEPA

filter needs to remove at least 99.97% of

airborne particles 0.3 µm in diameter and other

requirements. The European standard has

different classes of HEPA with specific

requirements. Electrospun filter membrane is

known for its high filtration efficiency and

performance which makes it potentially suitable

for HEPA filter.

The basic determination of a membrane

suitability in filter application is its

particulate rejection according to the size of

the particles and its pressure drop. Such

performance is in turn determined by the

material used and fiber diameter. In one of the

earliest reported studies on the use of

electrospun nanofibers for HEPA filter, Li et al

(2006) used electrospun nylon-6 nanofibers with

diameter of 120 nm coated on

air filter media to test its filtration

efficiency across a range of particles size. For

0.3 µm particles, a filtration efficiency of

about 80% can be achieved with a basis weight of

0.5 g/m2.

A good filtration efficiency is not the only

requirement of HEPA filters. Pressure drop which

is a measure of the resistance to airflow due to

the filter membrane barrier, should be as low as

possible. This is where nanofibers has an

advantage. With smaller fiber profile, slip flow

will be larger and this will facilitate

collision of the particles to the surface of the

fibers. This will also reduce pressure drop as

air molecules faces less resistance when passing

through the membrane.

Matulevicius et al (2014) investigated the

performance of electrospun polyamide 6 (PA6) and

polyamide 6/6 (PA6/6) nanofibers as air filter

membrane. Between the two materials, electrospun

PA6/6 fiber reached a diameter of about 60 nm

while PA6 fiber diameter had a diameter of 200

nm. PA6/6 nanofibers membrane had a filtration

efficiency over 90% with basis weight of 0.46g/m2 while

PA6 nanofibers membrane has a filtration

efficiency of 88% with basis weight of 0.75g/m2 for

300 nm particles. The pressure drop of PA6

nanofiber with its smaller diameter was also

lower at 66.7 Pa but the PA6/6 nanofiber

membrane had a pressure drop of 105 Pa. Although

the materials are different, it is likely that

the much smaller diameter of PA6/6 nanofiber

contributed to the better filtration

performance. With larger diameter fibers, it may

also be possible to obtain good filtration

performance. Nakata et al (2007) showed that

with electrospun poly (ether sulfone) (PES) with

diameter of 1 µm, they can achieve a 98%

filtration rejection of 0.3 µm size particles

and pressure drop of 134 Pa. The basis weight

for this membrane was 30 g/m2. By

varying the electrospinning conditions for PES,

a slightly smaller fiber diameter of 0.9 µm can

be fabricated, but with smaller pore size of 3.2

µm instead of 5.6 µm gives a filtration

rejection of 99.9998% but the pressure drop

increases to 215 Pa.

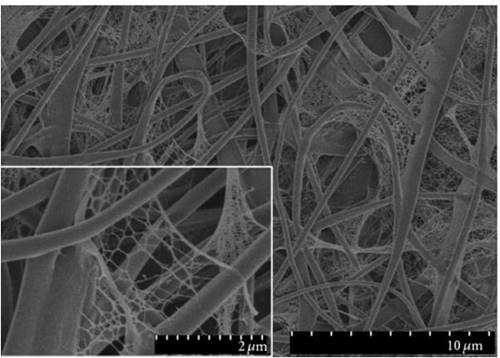

Under certain electrospinning conditions, the

electrospinning process is able to generate

nanonets between nonwoven nanofibers. The

nanonets are made out of random nanofibers but

with much smaller fiber diameter (low tens of

nanometer) and pore size (tens to hundreds of

nanometer) compared to the main fiber network

which typically have diameter in the hundreds of

nanometer and pore size of a few microns. Zhang

et al (2017) showed that such electrospun

structures vastly improves the filtration

efficiency and reduces the pressure drop. To

produce nanofiber/nanonet structure of poly (m-phenylene

isophthalamide) (PMIA NF/N), Zhang et al (2017)

added DTAB to the solution for electrospinning.

This nanofiber/nanonet composed of nanonet with

fibers of diameter of about 20 nm. With just a

basis weight of 0.365 g/m2, it is

able to achieve a removal efficiency of 99.999%

for NaCl particles (300 to 500 nm) and a low air

resistance of 92 Pa. The pore size of the

nanonet was found to be about 200 to 300 nm

which means that it is able to physically trap

particles at 300 nm or higher instead of just

random surface contact adhesion.

|

|