Coronavirus Technology Solutions

September 28, 2020

Air Filter Market will Grow but by How Much ?

Avery Dennison Supplies Improved Components for Masks

NXTNANO Spinning Lines can Produce 60 million m2 of Media Each Year

Donaldson is the Original Nanofiber Air Filter Supplier

Filter Manufacturers Who Also Supply Media

Lydall Partners with XPRIZE

Yanjiang Expands Meltblown Capacity to 18 Tons Per Day

150 Million Rapid Coronavirus Test Kits to be Distributed in Next Few Weeks

Japanese Government Sued Over Mask Choices

______________________________________________________________________________

Air Filter Market will Grow but by How Much ?

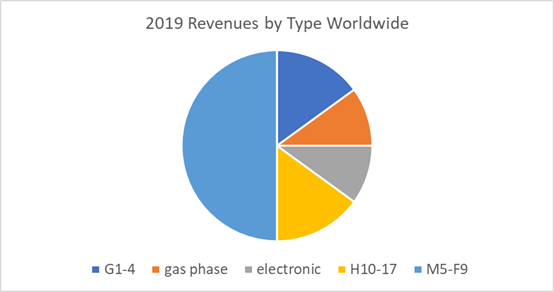

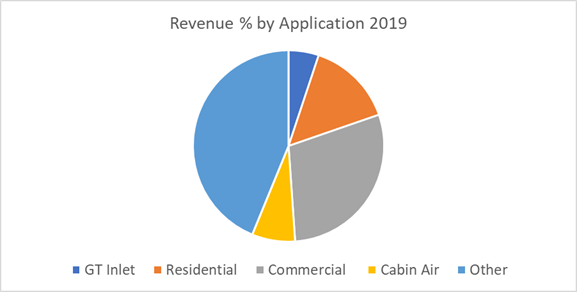

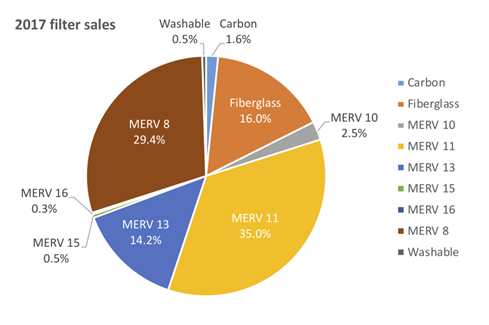

The suppliers of air filters and media are producing at capacity around the world. With the new evidence showing that most COVID transmission is through small aerosols there is the potential for the market to expand at an unprecedented rate in the next year. There are two questions. How big is the potential? Can the filter and media companies meet the increased demand? Most of the demand will be in F9 and H10-17 high efficiency media. This is presently just a small fraction of the total air filter market.

In terms of applications the only one not impacted by COVID is the gas turbine inlet. But even for this application the trend is toward higher efficiency.

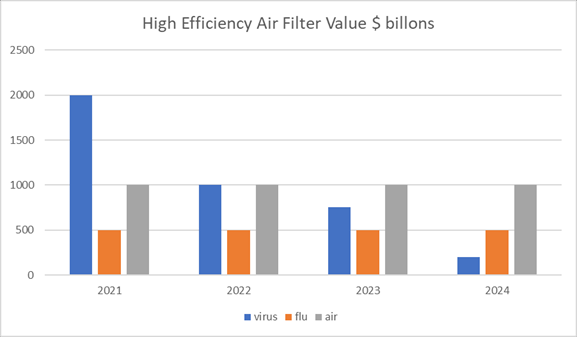

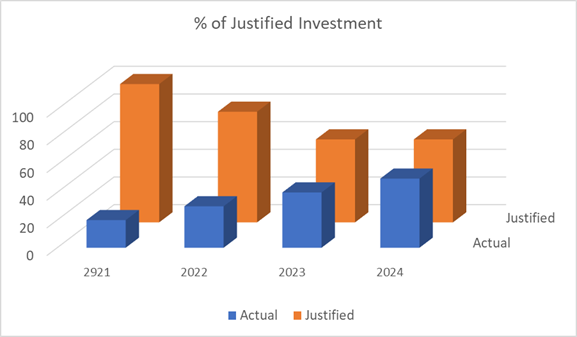

McIlvaine has analyzed the benefit of high efficiency filters. Even though the highest benefit occurs in 2021 when the pandemic is at its peak, there is a substantial value in future years just based on indoor and outdoor pollution and influenza.

In the U.S. in recent years there have been very few high efficiency filters installed.

Another pressure is the very large requirement for high efficiency media for masks.

There is less question about gearing up to increase filter production by 100% or more than there is the filter media. Sine the demand for high efficiency masks will likely soar it will be challenging to produce enough meltblowns just for masks. The question is then whether microglass, nanofibers, versions of spun bond, and membranes can be produced in sufficient quantity to greatly increase the high efficiency filter production.

McIlvaine has been surveying filter manufacturers who in general believe it can be done but that it will be challenging. The biggest obstacle is the risk that a big investment will not be profitable due to a market which will shrink with as the pandemic is brought under control.

Even though there will be justification for higher efficiency filters after the pandemic, this is not sufficient to justify the investment. The likely course of action is that only a portion of the justifiable investment will be made initially.

Many lives could be saved if 100% of the justified investment could be made in 2021. But without government support the investment will be more gradual. It will only approach the amount justified as it is seen that there will be a continuing market.

This opportunity is being continually assessed in Air Filter Market and Supplier Program. Click here to view a video description or Click here for the power point display.

Avery Dennison Supplies Improved Components for Masks

Since the beginning of the health crisis, a global race against the clock has been going on to develop more and better personal protection against the Covid-19 virus. Due to restrictions to manage the pandemic, some industries were forced to temporarily reduce or even stop their production. But often the machinery and equipment is capable of contributing to society and the economy in another way. Some companies are therefore adapting their business so that they can help in the production of personal protective equipment. Avery Dennison is equipped to develop, produce and supply adhesive tapes and foams for face masks and face shields within a very short timeframe and in large quantities. Application examples

● Customers in automotive converting: In the face mask, a foam is provided at the level of the nasal bridge to protect the nose. To attach this foam to the mask, a durable tape from Avery Dennison with strong adhesion strength is applied.

● Customers in general converting: Face masks with a metal nosepiece to better 'shape' the mask and make it fit closer around the nose. Avery Dennison provides the tape that attaches the metal piece to the face mask.

● Customers in automotive supply: To protect the face, facial shields are very frequently used in hospitals. A foam at the top of the shield ensures that the mask fits well and is comfortable to wear. Avery Dennison has a suitable tape with strong adhesion and the required performance for this application

NXTNANO Spinning Lines can Produce 60 million m2 of Media Each Year

NXTNANO’s HYPR spinning lines are roll-to-roll production with an annual capacity for high-efficiency nanofiber air filtration media in excess of 60 million sq. meters. The HYPR spinning process is also very flexible in the types of media that can be processed: Cellulose Blends, Spunbonds, Felts, Wet Laid, Synthetics, Ceramics (to name a few).

Besides enhancing existing media with nanofiber, NXTNANO is uniquely positioned to produce fully stand-alone 100% nanofiber membranes. The membranes are available in basis weights from 2-15 GSM, and deliver consistent, controllable pore sizes.

Common applications for NXTNANO’s air filter media include:

• Gas turbine inlet filters;

• Industrial cartridge filters;

• HVAC pocket & pleated filters;

• Automotive air intake; and

• Face Masks

The nanofiber membranes operate in three distinct categories:

• Micro-venting;

• Micro-filtration; and

• Apparel

In Micro-filtration the nFLUX nanofiber membranes deliver more than a 100% increase in flux for a given pore size compared to a traditional cast membrane of the same pore size. nVENT nanofiber micro-venting media offer a tight pore size distribution while being readily compoundable as hydrophobic/oleophobic, hydrophilic, or even antimicrobial. To further support their nanofiber customers NXTNANO also has in-house slitting of materials across two slitters, or contract pleating of media via two rotary pleaters, and a blade pleater with full mini-pleat capability.

Donaldson is the Original Nanofiber Air Filter Supplier

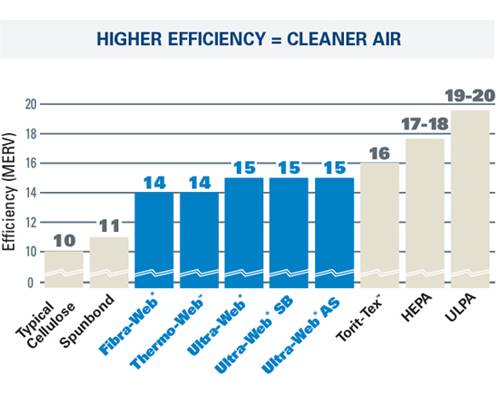

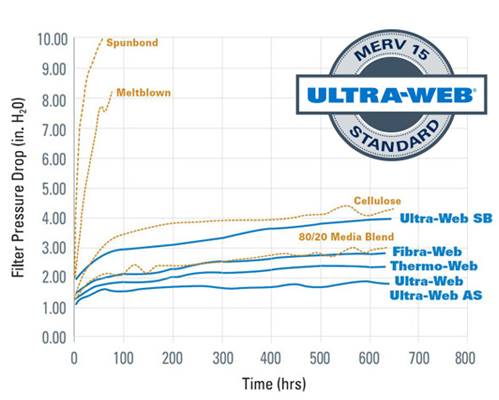

Donaldson Ultraweb using nanofibers has been available for decades. The company also supplies membrane filters. They have not been targeted toward HVAC but with the increased demand for high efficiency should their media be considered? The membrane has a MERV 16 rating (Torit-Tex) whereas the ultraweb has a MERV 15 rating.

The TextraTex PTFE membrane laminated to needled 16 oz. polyester is a high efficiency media used in pulse jet baghouse dust collectors. This material delivers superior dust cake release and high filtration efficiency in applications with demanding emissions standards. This material is strong, with high resistance to acids and alkalis, and good for applications up to 275° F.

In the ultraweb nanofiber applications , the nanofibers can be applied to cellulose or synthetic media. The pressure drop compares favorably to spun bond and meltblown.

In addition to its own media Donaldson spends roughly in the region of $185-200 million on filter media annually. Further, Donaldson reports that it buys its filter media from just two suppliers and works closely with them on the development of proprietary nonwoven processes and products.

Filter Manufacturers Who Also Supply Media

In addition to Donaldson as discussed above other filter manufacturers also make their own media.

3M is one of the larger filtration industry players to manufacture its own nonwovens, rather than buying them from third parties. Acquisitions related to filtration by 3M include that of filter media manufacturer Cuno for $1.3 billion back in 2005. This business was subsequently renamed 3M Purification and manufactures a comprehensive range of mostly microfiltration products for the separation, clarification and purification of fluids and gases for the healthcare, bioprocessing, industrial, food and beverage, electronics and drinking water markets.

3M then acquired Powell Corporation, a manufacturer of spunbonded polyester mats used for membrane supports, in 2007.

With the breakup of Polypore International in February 2015, the company added microporous membrane capability that is highly complementary to a range of valuable medical products within its core nonwoven-based filtration platform.

Pall is a division of Danaher. Sixty percent of sales are generated by consumables made with the company’s proprietary branded filter media, which include membranes produced by chemical film casting, meltblown and wetlaid nonwovens and metal products.

Cummins Filtration, headquartered in Nashville, Tennessee, manufactures media for air, fuel, hydraulic and lube filtration, chemicals and exhaust system technology for engine-powered equipment.

In April of this year, Cummins announced an agreement with 3M to manufacture high-efficiency, three-layer particulate filters for use in 3M facemasks and PAPRs (powered air purifying respirators), in the fight against Covid-19.

Cummins’ NanoNet and NanoForce filter media employ DuPont’s Hybrid Membrane Technology (HMT) and are usually employed in air, fuel and oil filtration products used in heavy-duty diesel engines to prevent long-term engine wear.

By the beginning of July, Cummins had provided more than 14 tons of the filtration media to 3M and mask manufacturers across the globe, employed to produce more than eight million masks.

Parker Hannifin has grown through acquisitions.

Parker-Hannifin’s Filtration and Engineered Materials business now has annual sales of over €4 billion.

Lydall Partners with XPRIZE

Lydall, Inc. announced its partnership with XPRIZE, a nonprofit organization that uses global competitions to crowdsource solutions to some of the world’s biggest challenges. Lydall will supply fine fiber meltblown filtration media, the critical component of N95 respirators and surgical masks to the 25 qualified teams of XPRIZE’s Next-Gen Mask Challenge. Launched in July 2020, this four-month challenge invites young adults around the world to develop the next generation of surgical-grade consumer face masks. In addition to sharing a one-million-dollar prize, the three winning teams will be connected to rapid manufacturing opportunities in the U.S. to bring their designs to life.

Although the material has a variety of applications, in response to COVID-19, Lydall quickly pivoted to meet the explosive demand for meltblown filtration media for N95 respirators, surgical masks and other personal protective equipment (PPE). The company also announced investments in two new production lines in New Hampshire and one in France. The first new production line will be operational by the beginning of 2021, with the other two coming on line in mid-2021, increasing Lydall’s output of meltblown filtration media many times over.

“Innovation is core to who we are, and that means not only challenging ourselves to advance filtration science, but also supporting the next generation of innovators,” said Ashish Diwanji, President of Lydall Performance Materials, who will also serve on the judging panel for the challenge. “We’re honored to use our knowledge and resources to support XPRIZE and the young adults who are passionate about addressing the greatest global health crisis in over a century. I speak on behalf of all my colleagues at Lydall when I say that we can’t wait to see what kinds of solutions the teams come up with.”

Participants in XPRIZE’s Next-Gen Mask Challenge are tasked with designing face masks that offer a level of performance comparable to that of a surgical mask. This means that the mask must block 95 percent of particles while letting in enough air to allow the wearer to breathe comfortably. Lydall’s meltblown filtration media enables mask manufacturers to meet rigorous standards for quality and efficiency set in the U.S. by NIOSH, a division of the CDC, and ASTM. The material is even imbued with an electric charge that attracts particles, keeping them away from the wearer’s nose and mouth.

“We’re thrilled to have found such a strong partner for the XPRIZE Next-Gen Mask Challenge in Lydall,” said Sarah Saenz, XPRIZE Next-Gen Mask Lead. “We are challenging young innovators across the world to shift the perception around mask-wearing behavior by reimagining face masks entirely, but the most important aspect is safety. Lydall is providing the critical filtration media that makes N95 and surgical masks effective, and just as importantly, its team of engineers and material scientists will provide counsel and support to young adults around the world who want to build a better face mask. Their participation will help ensure that real solutions to a very real crisis are made available to our communities.”

Yanjiang Expands Meltblown Capacity to 18 Tons Per Day

Xiamen Yanjiang in reply to the letter of the Shenzhen Stock Exchange said that the company has completed the related work of upgrading the civilian melt blown non-woven production line into a medical meltblown nonwoven production line, and the daily output of medical melt blown non-woven fabric can reach 14 tons. At present, the company is striving to expand production capacity to meet customer demand.

Yanjiang said that the current melt blown non-woven fabric Nissan can reach 14 tons per day , with a monthly capacity of 420 tons. In April, the company received orders of 481 tons, with an order capacity ratio of 114.52%. In April, the number of customer orders was 99, an increase of 27 over March. The company plans to expand its capacity to 16-18 tons/day, and the capacity expansion plan will be completed by the end of April. At present, the personnel needed to expand the production capacity have been recruited, the main equipment of the production line has been put in place, the installation and commissioning of the equipment have already started, and it is expected to be put into trial production in April 30th. The expansion plan is feasible according to the company's existing personnel and equipment.

In the second half of the year, if the epidemic situation is eased, the demand for medical melt blown nonwovens decreases and the company has surplus capacity, the company will continue to accept the order production of civilian melt blown nonwovens. In the first quarter of 2020, the sale of civilian melt blown nonwovens has already confirmed revenue of about 26 million yuan, with a profit of about 17 million yuan and a profit of about 45%.

Yanjiang shares were established in 2000, mainly engaged in the research, production and sale of disposable sanitary products surface materials. In 2019, Yanjiang shares achieved a business income of 1 billion 38 million 112 thousand and 500 yuan, an increase of 35.48% over the same period last year, and the net profit attributable to shareholders of listed companies was 82 million 310 thousand and 700 yuan, an increase of 69.32% over the same period last year.

According to the products, the business income of punched nonwoven business was 426 million 236 thousand yuan, an increase of 6.31% over the same period last year, and the PE membrane business realized a business income of 443 million 651 thousand and 100 yuan, an increase of 60.47% over the same period last year. The net cash flow generated by the company's business activities was 74 million 223 thousand and 100 yuan, an increase of 88.06% over the same period last year.

150 Million Rapid Coronavirus Test Kits to be Distributed in Next Few Weeks

President Trump announced on Monday that the federal government will distribute 150 million rapid, point-of-care coronavirus tests to states over the next few weeks, including to K-12 schools and vulnerable communities like nursing homes and assisted living facilities.

The Trump administration has stressed the importance of reopening schools in allowing parents to return to work and jumpstarting the economy.

Who gets tested is ultimately at the discretion of the governors, but the administration is encouraging schools to use the rapid tests to help restart and maintain in-person teaching.

- The rapid tests, which deliver results in 15 minutes, will come from a previously announced supply of 150 million tests ordered from Abbott Laboratories. Teachers and parents would be able to test their children on a weekly basis.

- 6.5 million tests will go out this week and a total of 100 million tests will be distributed to governors based on state population over the next several weeks, Trump announced.

The rapid tests are less accurate and need confirmation from more sensitive PCR swab tests, which take days for results.

Health officials also fear many of the tests will go unreported, as states could authorize tests outside of a health care setting — leading to underreported state and nationwide case counts.

"As of today, the nation has performed over 111 million tests for the virus causing COVID. On 13 separate days, we have achieved tests of over 1 million per day, and our average test numbers are now approximately 920,000 per day," the administration's testing coordinator Adm. Brett Giroir said Monday before demonstrating how to use a rapid test.

"We are now at an inflection point for testing. We now have available on average 3 million tests per day, not counting pool testing which could multiply that number several-fold. Nearly half of our current tests are rapid point-of-care."

Japanese Government Sued Over Mask Choices

A law professor sued the government Monday demanding it reveal the unit price of washable cloth masks, dubbed "Abenomask," that were distributed for free to all households in Japan amid the coronavirus pandemic, as well as how many were ordered from each contractor.

In the suit filed with the Osaka District Court, Hiroshi Kamiwaki of Kobe Gakuin University claimed it is unreasonable for the government to withhold the information as it prevents discussion of the appropriateness of the policy to distribute the masks, which proved unpopular among the public with some questioning if it was cost-effective.

The initiative by then Prime Minister Shinzo Abe to help contain the spread of the novel coronavirus sparked criticism due to the poor quality of the masks and their slow delivery to the public, with many viewing them as symbolic of the government's inadequate response to the pandemic.

More than 120 million of the washable masks, two per household, were distributed nationwide from April to June, with masks in short supply amid the pandemic. They were dubbed "Abenomask," which means "Abe's mask" in Japanese and is a pun on Abe's signature "Abenomics" economic policy mix.

Abe stepped down as prime minister earlier this month due to health reasons. The project cost the government 26 billion yen ($247 million), with 18.4 billion yen spent on procurement and 7.6 billion yen on delivery.

Kamiwaki, who has published a book on politics and money, requested between April and May that the government disclose documents related to its contracts with the mask producers and invoices for shipments, according to the suit.

The government did supply some documents but they were heavily redacted, with the unit price and size of orders concealed. The government justified withholding the information, saying disclosure could have a negative impact on future price negotiations and reveal sensitive procurement details.

However, the plaintiff said some parts of the documents that were not blacked out showed the unit price of the cloth masks at 143 yen including tax.

The price was cited in a document compiled by the education ministry over distribution of the masks to schools across the country.

According to the plaintiff, the document said, "A team handling the matter within the health ministry notified us that the unit price will be 143 yen, including tax, as a result of negotiations with suppliers."

The education ministry declined to comment on the suit. A source close to the education ministry said the part of the document mentioning the price of 143 yen was not blacked out because it only explains about a negotiation process.

The source said while the education ministry does not disclose the contracted price, the document provided to the plaintiff should not have shown information that could be used to surmise the final price.

Disposable mask prices spiked in Japan earlier this year, but a box of 30 such masks now sells for between 800 to 1,000 yen at major supermarkets and drugstores. Fast Retailing Co. sells packs of three fast-drying Airism washable cloth masks for 1,089 yen including tax at its Uniqlo stores.

The professor at the western Japan university argues that the unit price and order data should not be treated as sensitive information because the government is highly unlikely to order a large number of the unpopular face masks in the future.

At a press conference in Osaka, Kamiwaki said, "The Abe government has erased data deemed inconvenient for its members. I'm worried that the new government of (Prime Minister Yoshihide) Suga could inherit its negative legacy."

Kamiwaki is also seeking 600,000 yen in damages from the government, claiming the redacted documents were disclosed around two months after the scheduled date.