Coronavirus Technology Solutions

September 9, 2020

Hydrocharging is a Better Route to Electrify Meltblowns

Hydrocharged Meltblowns with H 13 Efficiency Better than Glass Fibers

Huadi Supplies HEPA H13 Meltblown Non-woven Air Filter Media and N95 Masks

Welcron Supplying Filter Media to Mask and Air Filter Suppliers in Korea and China

ULPATEK Supplies a Wide Range of Products Including Absolute, EPA, HEPA and ULPA Filters

TBH Supplies Air Purifiers for Dental Practices

N95 Masks can be Recharged

Transformative Wave, eIQ Platform, Allows Buildings to Comply with CDC Ventilation Guidelines

Mobile Fan Filter Units Available from Technical Air Products

______________________________________________________________________________

Hydrocharging is a Better Route to Electrify Meltblowns

Dr. Peter Tsai at the University of Tennessee has developed a new method and apparatus for preparing an electrostatically charged filter media by saturating a nonwoven material with excess liquid and then removing the liquid via suction to generate charges. The result is a material with filtration efficiencies 20 times higher than uncharged material.

In comparison to previous charging techniques, this novel method does not require a wetting agent, the fabric does not need to be pre-charged via corona charging, and the suction process does not need to be repeated multiple times. Further, the excess liquid can not only be easily collected and recycled but it falls off the sheet rather than pooling on it, preventing its interference with the impingement and saturation of other sections of the sheet.

Benefits:

· More efficient: Achieves filtration efficiencies of up to 99.99% on a basis weight of 25 grams per square meter

· Less material: Half the material needed due to higher filtration efficiency, also making it easier to breathe through

· Faster: Eliminates the time-consuming multi-step procedures of previous triboelectrification methods

· Versatile: Works with various nonwoven fabrics including nonconductive thermoplastic fibers (with or without additives), polypropylene fibers, and meltblown or spunbonded fibers

· Patent pending and available for non-exclusive licensing

Hydrocharged Meltblowns with H 13 Efficiency Better than Glass Fibers

The purpose of a Korean study on asbestos protection was to compare the performance efficiency of melt-blown and currently used glass fiber filter media under the same environmental conditions. To evaluate filter efficiency, filter class was determined according to ISO and European standards (EN 1822-1:2009) using an automated filter tester (0.3 μm size), taking into account particle filtration, fractional efficiency for negative pressure devices, and consumption of electrical power. The average fractional efficiency, quality factor (QF), fractional efficiency by dust loading amount, pressure by dust loading amount, and QF by dust loading amount were higher in the case of melt-blown media than in the case of glass fiber filters. The fractional efficiency of hydrocharged melt-blown filters was higher than that of uncharged media. Based on performance efficiency, melt-blown filters are more effective high efficiency particulate air filters than glass fiber media.

When comparing fractional efficiency and pressure drop, the study confirmed that MB filter media performed better than glass fiber filter media for both parameters. In the case of glass fiber H13, the minimum fractional efficiency (99.95%) satisfied the requirements of ISO and European standards but not at the true HEPA level of 99.97%.

Glass fibers are currently used in HEPA filters, as the fine diameters of glass fibers provide increased surface area, leading to better efficiency (Rathey 2006). However, glass fibers have the disadvantage that this superior packing also increases pressure drop. Conversely, synthetic MB fibers made from traditional melt spinning techniques are usually larger in diameter, producing more open filter media with lower pressure drop (Skomra 2010).

Pressure drop is closely associated with energy saving and air circulation of asbestos removal systems. Low pressure drop means that air can pass through the filter easily; when air cannot pass through, pressure drop gradually increases due to the high flow amounts necessary to pass through the filter, requiring high power consumption. Filter resistance to air flow is a measure of the energy requirement and cost associated with using the product. MB filter media are more open and pressure is lower when compared to glass media. Glass fiber media provide greater resistance to the flow of air, and the fan hence consumes greater energy to maintain equivalent airflow rates.

The study confirmed that hydrocharging the MB filter media led to a fractional efficiency as high as 99.98% (H13), higher than that achieved with corona charging. Unlike glass fibers, polymer fibers such as MB fibers can be electrostatically charged (Carlsson 2001). One study reported that hydrocharged filter media had a higher QF than corona-charged filters (Angadjivand et al. 1996). The hydrocharging method is advantageous because it easily provides the required charge to form HEPA filter media. Moreover, this method can be used on a preformed web, thereby avoiding the difficulties in forming charged fibers on a uniform web structure

https://www.tandfonline.com/doi/full/10.1080/02786826.2017.1423274

Huadi Supplies HEPA H13 Meltblown Non-woven Air Filter Media and N95 Masks

Huadi is a Chinese manufacturer of filter media and masks.

HUADI Meltblown Non-woven air filter media is created using melt-blown technology which can use mechanical or charged filtration mechanisms to capture and retain particles. This versatile filter media can be utilized in many different markets including industrial pre-filtration, medical facemasks, respirators, and HVAC systems.

Features include:

Removal of a wide range of contaminants from water (bacteria, viruses, metals, minerals etc.)

Uniform structure

Tear- and puncture-resistance

Chemical resistance

High retention capacities

High air permeability

Excellent abrasion resistance

Flame retardancy

Absorption of fats and oils

High level of flow capacity

High tensile strength

Meltblown PM2.5 KN95 Dust Mask with Valve uses N95 filter material, The mask has a filtration rate of more than 95 percent. Three-dimensional cutting allows the respirator to form a 360-degree three-dimensional breathing space. Folding design is more convenient to carry.

Welcron Supplying Filter Media to Mask and Air Filter Suppliers in Korea and China

Welcron Group started out in 1992 as an industrial textile business. It is now a true group company, combining consumer goods and industrial goods, from industrial textile, functional hygiene products, energy plant, and construction business.

Welcron Group is leading Korea’s economy in many different industries, including Welcron, which is leading the industrial textile market, Welcron Hantec an industrial plant and construction company, Welcron Healthcare which is leading the oriental medicine hygienic product market, Welcron Global Vina which is the overseas production base and the global market base of Welcron Group, a company that specializes in renewable energy through waste recycling.

The company produces mask material as well as a range of air filtration media.

High-Efficiency Filter Material, Air Filter

|

Filter Grade |

Standard Spec. |

MB Weight (g/㎡) |

Pressure Drop (mmAq) |

|

H-10 |

80% |

15 |

0.7 |

|

H-11 |

95% |

20 |

1.2 |

|

H-12 |

99.5% |

20 |

2.5 |

|

H-13 |

99.95% |

30~40 |

3.5 |

|

H-14 |

99.99% |

50 |

6.0 |

Measurement Instrument : TSI 8130, Flow Rate : 32LPM,

Particle Size : 0.3 micron, Test Particle : NaCl

· · HEPA filter is a filter that filters 99.97% of 0.3㎛ fine dust. With electrostatic charging of Melt blowns Welcron produces filters that have the filter efficiency but 1/3 the low-pressure drop compared to existing Glass Fiber.

· · EN-1822 standard: produce H-10~H-14 Grade

· · Eco-friendly materials compared to existing glass fiber

Possesses excellent tearing strength, tensile strength, and shock resistance by manufacturing human-friendly and highly elastic urethane materials into non-woven fabric through melt blown process.

The media can be used continuously for a long time since it has excellent rebound resilience and elasticity recovery. Welcron elastic non-woven fabric is more environment- and human-friendly than PVC materials. It has excellent air permeability.

Mask filter media uses Welcron’s Melt blown. Welcron is currently producing and delivering common masks and core filter layer of industrial dust mask.

Welcron is currently supplying major domestic and Chinese dust mask and common mask manufacturing companies. Dust masks, with low inhalation resistance are currently replacing 3M masks.

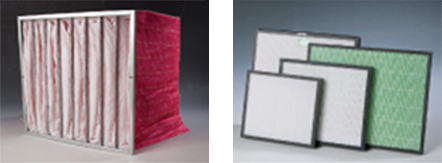

ULPATEK Supplies a Wide Range of Products Including Absolute, EPA, HEPA and ULPA Filters

ULPATEK filter production started in 2008 in Istanbul Hadımköy facilities. Coarse, Medium, Absolute, EPA, HEPA and ULPA filters are manufactured with the most advanced machines in the filtration field according to EN 779 and EN 1822 European standards. ULPATEK has obtained ISO: 9001 quality management certificate from TUV NORD/Germany since its establishment. Products have been exported to 70 different countries so far.

R & D engineers are working on product support, product development and engineering applications and transferring their technical knowledge about filtration and indoor air quality (IAQ) to their customers through training programs and comprehensive resources.

HIGH CAPACITY HEPA FILTER V-MODUL

Filters with the most energy saving and long filter service life, which can be used for face velocities up to 3m/s (air volumes up to 4000m³/h) with the construction allowing maximum filter surface area usage.

TBH Supplies Air Purifiers for Dental Practices

TBH GmbH is an independently owned company located in Straubenhardt (Baden-Württemberg), Germany. It is one of the market leaders in the field of high-quality extraction, and filter technology for industrial and medical applications. the philosophy is to design products, which extract harmful particles from the air, and fully meet international and local standards.

The DF-Series filters Coronaviruses from the air. This protects patients, doctors and medical staff, because filter and extraction systems from this series ensure a safe environment. The series was specifically created for use in dental practices. These systems are easy to use and its filters are simple to change.

N95 Masks can be Recharged

N95 masks are a critical part of the personal protective equipment used by front-line health care workers. These masks achieve 95 percent efficiency at filtering out tiny 0.3-micron particles, while maintaining reasonable breathability, thanks to a layer of fine melt-blown polypropylene fibers incorporating electrical charges to attract particles.

Extended usage and decontamination provoked by severe supply shortages around the globe during the COVID-19 pandemic can easily remove the charges and degrade filtration efficiency.

In the journal Physics of Fluids, from AIP Publishing, researchers from India’s Tata Institute of Fundamental Research and Israel’s Technion-IIT share a method to restore the filtration efficiency of N95 masks to out-of-box levels—as long as the mask is not structurally compromised.

“Today, N95 masks are being worn by health care workers for extended periods,” said co-author Shankar Ghosh. “This gives rise to very humid conditions, and humidity is detrimental to electrostatics.”

During use, all electrostatics-based masks slowly lose their efficiency due to humidity.

“It’s much worse in a place like Mumbai during the Indian monsoon, where ambient humidity levels can reach more than 90 percent,” Ghosh said.

The group’s work exploits that, under high electric fields, the polypropylene conductivity is high, which makes introducing excess charges into the material possible by connecting it to a battery. When the charge source is switched off, the applied electrical field becomes zero, and the conductivity of the polypropylene drops effectively to zero. As a result, the added charge carriers immobilize, and the material remains charged.

The researchers discovered they could toss an N95 into a standard washing machine to clean it, which significantly reduces its filtration efficiency. They could then recharge it by sandwiching it between two electrodes at high voltage to recover its 95 percent efficiency.

“We’ve also shown a proof-of-concept construction of a battery-operated smart mask, where the lost charge gets replenished periodically by plugging the mask into a charging station—akin to how you would charge your smartphone,” Ghosh said.

The group believes its method to keep masks charged will lead to highly energy-efficient smart masks.

“Currents are in microamps, and the power requirement is extremely low, on the order of a milliwatt, so a compact and practical solution may soon be feasible,” said Ghosh.

Beyond this, their method will be useful for a variety of air filtration applications, such as HVAC or industrial filters.

Transformative Wave, eIQ Platform, Allows Buildings to Comply with CDC Ventilation Guidelines

The CDC has issued guidelines for commercial buildings including malls, retail stores, and restaurants to increase the amount of fresh outside air from HVAC systems as a strategy for mitigating the spread of the COVID-19 virus. New York and Connecticut have made compliance with these standards a requirement for certain businesses seeking to reopen indoor operations. Compliance presents an extreme challenge for the majority of businesses who are interested in making their facilities as safe as possible.

Modifications to an HVAC system’s ventilation settings and schedules typically require a technician to visit each individual facility to make manual adjustments to each HVAC system. This represents a significant expense and management nightmare.

“We were faced with the need to increase ventilation rates in order to reopen nineteen of our stores in New York and Connecticut. With Transformative Wave, all we had to do is call and ask them to make it happen,” said Alex Douris, Energy Specialist at H&M. “With our older building automation system, we would have been forced to physically go out to hundreds of HVAC units in order to do what Transformative Wave did in a few hours for us. The cost would have been significant.”

Compliance with CDC guidelines requires operators change three HVAC settings - eliminate demand-controlled ventilation (DCV), increase the minimum amount of outside air, and extend the length of time the HVAC systems operate (up to 24/7). The Enhanced Ventilation Mode addresses all three by allowing users to set multiple ventilation schedules with increased outside air assignments for each period. It is possible to aggressively purge the building with fresh air prior to occupancy and/or ventilate at predetermined levels for longer periods of time.

Transformative Wave’s eIQ Platform is a robust building automation and energy efficiency technology that goes beyond the limitations of conventional control systems. Automating the process of making complex changes in ventilation settings and schedules is unprecedented.

Enhanced Ventilation Mode can be applied globally across all buildings in a customer’s portfolio or only select buildings and individual HVAC units in the portfolio. This flexibility allows operators to navigate variations in local standards, occupancies, or climate realities.

Once the Enhanced Ventilation Mode parameters have been defined, enabling and disabling is accomplished with the “push of a virtual button” in the eIQ Platform user interface.

Automated compliance is simply not within the reach of the majority of facility operators in the retail sectors. It requires direct control over the HVAC system’s outside air dampers, operating schedules, and existing ventilation settings. Transformative Wave’s unique technologies make these kinds of operational changes possible.

Another advantage of this feature is the ability for operators to return systems to normal ventilation settings once the pandemic has passed and a return to pandemic ventilation standards can be easily accomplished should it be necessary due to an isolated or widespread outbreak. This is a mechanism for enterprises to protect themselves now and in the future.

Complying with these COVID-inspired guidelines can have adverse effects on comfort and energy costs. Transformative Wave’s family of products help building operators make pandemic-related ventilation changes with minimal increase in energy expense and impact on indoor comfort.

“COVID has created many new challenges for businesses seeking to reopen. Our goal was to remove the burden of ventilation compliance by adding this ground-breaking feature to our product suite. Given the alternative of manual compliance, automating this process has immense value,” said Danny Miller, President of Transformative Wave. “This is possible due to the deep reach our technologies have into the HVAC assets. We leverage the substantial energy savings we generate and then exploit associated utility subsidies to create an economical path to intelligent buildings. The Enhanced Ventilation Mode feature now adds compliance with these emerging standards in pandemic ventilation management to our toolbox.”

Mobile Fan Filter Units Available from Technical Air Products

For over 25 years, Technical Air Products has manufactured motorized HEPA fan filter units (FFU). FFU’s are individually powered fan units that draw “dirty” air through HEPA filters, to deliver clean air to, or from, a critical environment.

HEPA filtered FFU’s are most widely used to provide clean air in positive pressure rooms. Positive pressure cleanrooms keep contaminated air from surrounding areas out. However, FFU’s can also be reconfigured to exhaust air out of a room, through the HEPA filter, to protect surrounding areas from contaminated air particles in the room. When more air is exhausted out of a room than is supplied to the room, a negative pressure relationship is created, which helps ensure that contaminated air in the room is isolated and does not spread outside of the critical environment.

Typically, positive pressure cleanrooms, or negative pressure isolation rooms, are designed that way from the beginning, and are never used for both. FFU’s are usually installed in the ceiling of a room and can be part of a more extensive HVAC system. However, there are times when customers need to convert standard rooms in their facility into either positive or negative pressure critical environments. This has become even more of a need recently, as the COVID-19 pandemic has forced us all to change the way we operate and live.

With that in mind, Technical Air Products has designed mobile versions of its HEPA fan filter units, providing customers more flexibility to react to ever-changing critical environment needs. Mobile FFU’s can each deliver over 600 cfm of clean air to any room. They are a perfect tool for reducing the amount of airborne contaminants circulating in a room, protecting the health of its occupants. Or, add an optional ducted hood over the HEPA filter and exhaust air out of the room, creating a negative pressure isolation room to keep people in surrounding areas safe from infectious air particles in the room.