Coronavirus Technology Solutions

September 4, 2020

Beijing Residents are Wearing Masks Outdoors Even After Requirement is Lifted

ISO 16890 Rates Filters on a Range of Particle Sizes

Tri-Dim Room Air Purifier has HEPA Filter, UV, and Three Speed Fan

Knorr Brake has Ionizing System for Railcars

Comparison of Filter Efficiencies

U.S. Could Achieve a $320 billion/year Benefit by Upgrading HVAC Just from Air Pollution Reduction Benefits

_____________________________________________________________________________

Beijing Residents are Wearing Masks Outdoors Even After Requirement is Lifted

Health authorities in China’s capital Beijing have removed a requirement for people to wear masks outdoors, further relaxing rules aimed at preventing the spread the novel coronavirus after the city reported 13 consecutive days without new cases.

Despite the relaxed guidelines, a large proportion of people continue to wear masks. Some said the mask made them feel safe, while others said social pressures to wear the masks were also a factor.

“I think I can take off my mask anytime, but I’ll need to see if others accept it. Because I’m afraid that people would be scared if they see me not wearing mask,” one 24-year old Beijing woman surnamed Cao told Reuters.

It’s the second time Beijing’s health authorities have relaxed guidelines on mask wearing in the capital, which has largely returned to normal after two rounds of lockdowns brought it to a standstill.

Beijing’s municipal Centers for Disease Control first said residents could go without masks in outdoor areas in late April, though the rules were swiftly reversed in June after a new outbreak in a large wholesale market in the city’s south.

China has reported no new locally transmitted cases on the mainland for five days after successfully controlling flare ups in the capital, Xinjiang and elsewhere.

Experts say the key to the country’s success in controlling the disease has been the strict enforcement of local rules, including wearing masks, mandatory home quarantine and participating in mass testing.

Authorities reported 22 imported cases in the mainland on Aug. 20, and has closed its borders to most non-Chinese citizens. The country has reported a total of 84,917 cases since the outbreak began.

ISO 16890 Rates Filters on a Range of Particle Sizes

At the beginning of 2017, a new standard for the testing and classification of HVAC air filters came into force. ISO 16890 addresses many of the concerns surrounding the outgoing EN 779 standard and aims to give a more accurate view than ever of a filter's performance in the real world.

ISO 16890 provides a standardized process for classifying air filters used in general ventilation - in other words, it's a new method for grouping HVAC filters depending on their performance.

EN 779 has done much to improve quality standards across the industry and has provided a uniform method for selecting filters. But our understanding of the air around us has grown enormously over the 20 years since its launch, and its limitations are now obvious.

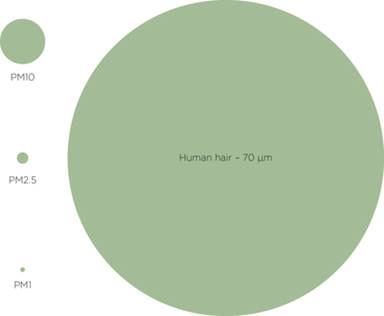

Chief among these limitations is the fact that EN 779 only tests a filter's performance against one particle size - 0.4 µm. Particulate matter (PM) is not uniform in size or shape, so exposing a filter to one particle size in testing is not reflective of the conditions it will face when in operation.

The new ISO 16890 standard differs because it focuses on a filter's ability to capture different size particles in the danger zone - where particulate is too small for our bodies in-built defenses to protect against.

Testing under ISO 16890 exposes a filter to particles from 0.3 µm all the way up to 10 µm. This means that filters are tested in conditions that are much more similar to real life, and you get a product capable of performing as you expect it to.

Here are the new ISO 16890 filter groups?

Based on this testing, filters are classified according to their efficiency at PM10, PM2.5 and PM1 - that is, particulate matter with a diameter less than 10 µm, 2.5 µm and 1 µm respectively.

And these particle sizes are the basis for the four ISO 16890 groups: ePM1, ePM2.5, ePM10 and Coarse. ‘e' in the group name simply stands for efficiency and the number relates to PM size. To qualify in each group, a filter must have 50% efficiency at that PM size. So, a filter classified as ePM1 captured at least half of the PM1 contaminant it was subjected to in testing. Filters achieving an efficiency lower than 50% with PM10 go into the Coarse group.

|

ISO 16890 Filter Group Efficiencies |

|

|

Coarse |

< 50% of PM10 |

|

ePM10 |

≥ 50% of PM10 |

|

ePM2.5 |

≥ 50% of PM2.5 |

|

ePM1 |

≥ 50% of PM1 |

Once tested, filters are awarded an efficiency rating that's rounded to the nearest 5%. So you will see filters described as ePM10 70% and ePM2.5 95%, for example. This simply means that the first filter is 70% efficient at PM10 and the second product is 95% efficient at PM2.5.

ISO 16890 was launched at the beginning of 2017, but most countries have an 18-month transition period where EN 779 will continue to be valid alongside the new standard. This is to give end users, distributors and manufacturers time to adjust to the new system.

Once any transition periods are finished, no. ISO 16890 uses a different grouping method to the G and F classes that we're familiar with under EN 779. A direct comparison between the old filter classes and the new groups is not straightforward as EN 779 examines a fraction of the performance data that ISO 16890 does. Making like-for-like conversions also ignores much of the benefits that ISO 16890 brings.

ISO 16890 is just for general ventilation applications, so the higher efficiency filters classified according to EN 1822 - such as EPA, HEPA and ULPA filters - are not affected by the new standard.

ISO 16890 also only currently impacts those countries adopting the EN 779 standard, so regions using other schemes - such as ASHRAE - will also remain unchanged for the time being. Discussions to introduce ISO 16890 to these markets are underway, with the aim of creating a truly global standard.

Tri-Dim Room Air Purifier has HEPA Filter, UV, and Three Speed Fan

Ebm-papst is supplying the fans for the portable Tri-Kleen 500UV vacuum air filter system according to Mark Pierce, Vice President Sales & Marketing at ebm-papst.

The core components of the air purification system are an MERV 9 prefilter and a cylindrical HEPA (High Efficiency Particulate Air) filter. With help from a micro-glass medium, this high-performance filter guarantees that 99.97 percent of all particles up to 0.3 µm in size are separated.

The effect of filtration is amplified by combining the HEPA filter with a UV lamp, whose light destroys germs, bacteria and viruses.

The RadiCal from ebm-papst generates the air flow for the air pressure required in the treatment room. The Tri-Kleen unit has three speed settings and can be operated in “quiet mode”. An optional flange can be used to connect a flexible duct, which the system utilizes to discharge a higher air flow out of the room than is fed into it.

Nilesh Tharval, manager of advanced technology at Mann+Hummel USA adds: “Our promise to our customers is that we will continuously work on innovative, new products and improve existing ones. In ebm-papst, we have found a partner that shares this attitude. For the next generation of Tri-Kleen air filter systems, we are talking about using energy-efficient EC fans. Although we can’t stop the COVID-19 virus, we have worked together and harnessed our expertise to curtail it on a small scale.

Knorr Brake has Ionizing System for Railcars

Knorr Brake Company, headquartered in Westminster PA, has developed a technology that can be installed in HVAC units on metro, train and light rail cars, and continually cleanse the air.

The company’s technology works in three stages. First, particles in the air pass through a charging grid. Once charged, they’re attracted to a dielectric air filter. Then, the particles are treated with an ultraviolet light placed behind the charging grid in the HVAC unit. Finally, the system ionizes the particles in the air, just before they pass out into the ductwork that flows into the car. The ions travel through the air and attack pollutants in the car and on handrails, poles and seats.

“It’s not like wiping it down with disinfectant, but it helps to neutralize the virus on surfaces in the car,” said Derek Hurst, the company’s director of Rail Services.

The system, which can be retrofitted into existing HVAC units on train cars, helps supplement the cleaning that takes place while trains are out of service, by cleaning the air while the train is in operation.

“The rail industries are doing tons of things between running the trains,” said Tyler Bowie, a Rail Services sales application engineer at the company. “They’re cleaning all the surfaces, they’re spraying everything. But the interesting part is, as soon as one person gets on the train between those cleanings, they could infect the whole train again. So having these technologies applied in the recirculated air brings the greatest safety.”

The engineers in Westminster worked alongside groups in China and Australia to develop the three-part technology. Segments of the system, including the UV light component, were previously in use in train cars in other parts of the world.

“This is the first time that we’ve pulled together the three individual technologies into a single package in this way, which was what makes it novel and why we filed for a patent for it.” Hurst said.

The system is capable of eliminating 99.9% of airborne particulates, bacteria, and viruses, “including PM10, PM2.5, and smaller; plus pollutants such as TVOC, ammonia, toluene, formaldehyde, and acetaldehyde. It also targets viruses and bacteria — including COVID-19, natural bacteria, H1N1 influenza, E. Coli, Staph, H3N2 influenza, plus the fungus that causes black mold,” according to a Knorr Brake Company news release.

It’s crucial to evaluate how quickly the system is able to remove airborne virus particles, said Jelena Srebric, a mechanical engineering professor at the University of Maryland, College Park, who focuses on ventilation technology.

“It’s not possible to eliminate all risk,” she said. “If you are standing next to somebody who has the pathogen and you are not wearing appropriate protection, then there is no system that can protect against that, right? But for a reasonable set-up with people wearing masks and maybe some of them wearing shields and so on, the question is then how quickly this can remove the pathogen from the space.”

Because train cars are small, and therefore the HVAC unit is typically in closer proximity to individuals than in, say, a building, the HVAC system could remove virus particles fairly quickly. But, they could still linger in parts of the car. That’s why personal protective gear remains so important, Srebric said.

After recent lab tests in Texas, the team discovered that after 15 minutes, the system achieves 99.99993% elimination of virus particles. As part of the test, scientists filled a chamber with the MS2 bacteriophage virus, and ran the Knorr Brake Company technology, evaluating its efficacy by taking samples at various time intervals.

The system, which weighs less than ten pounds, takes about two hours to install.

Comparison of Filter Efficiencies

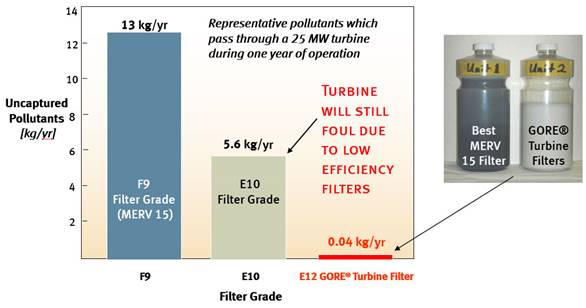

Relative to HVAC gas turbines have the same ambient air sources. McIlvaine has conducted webinars on various gas turbine inlet filter options. W.L. Gore has a membrane which has substantially greater efficiency than E 10 (MERV 16) and much more than the F9 (MERV 15).

The F9 filter emits 325 x more particles by weight than does the E 12. With this same ratio in HVAC filters or masks, the benefits of higher efficiency in COVID prevention are apparent.

U.S. Could Achieve a $320 billion/year Benefit by Upgrading HVAC Just from Air Pollution Reduction Benefits

This is the conclusion of a Lawrence Berkeley National Laboratory study titled “Effectiveness and Cost of Reducing Particle Related Mortality with Particle Filtration

William J. Fisk and Wanyu R. Chan of the Energy Analysis and Environmental Impacts Division Lawrence Berkeley National Laboratory Indoor Environment Group conducted an analysis of the benefits of upgrading home and commercial air filters. This paper was written in 2017 and does not include the benefits of removing the COVID virus. But just the outdoor air pollution protection alone is sufficient to more than justify upgrading to MERV 13 or higher in HVAC and adding room air purifiers with HEPA filters.

This paper evaluates the mortality-related benefits and costs of improvements in particle filtration in U.S. homes and commercial buildings based on models with empirical inputs. The models account for time spent in various environments as well as activity levels and associated breathing rates. The scenarios evaluated include improvements in filter efficiencies in both forced air heating and cooling systems of homes and heating, ventilating, and air conditioning systems of workplaces as well as use of portable air cleaners in homes. The predicted reductions in mortality range from approximately 0.25 to 2.4 per 10,000 population. The largest reductions in mortality were from interventions with continuously operating portable air cleaners in homes because, given our scenarios, these portable air cleaners with HEPA filters most reduced particle exposures. For some interventions, predicted annual mortality-related economic benefits exceed $1000 per person. Economic benefits always exceed costs with benefit-to-cost ratios ranging from approximately 3.9 to 133.

Intervention i8 which modestly increases the efficiency of filters in commercial building HVAC systems from MERV 8 to MERV 11 is predicted to decrease premature mortality by approximately 0.25 per 10000 population, with about 0.5 per 10,000 population predicted for intervention i9 which increases filter efficiency from MERV 8 to MERV 13.

The high benefit -cost ratios for the filtration interventions suggest, at a minimum, that there be routine use of higher efficiency filters in home HAC systems and commercial building HVAC systems and upgrades to the associated minimum filtration efficiency requirements in standards. For example, the commercial building ventilation standard of the American Society of Heating, Refrigerating, and Air Conditioning Engineers [32] has a minimum filter efficiency of MERV 8, with MERV 11 required only where outdoor air particle levels are high. Based on these findings the minimum required filter efficiency should be increased, e.g., to MERV 11 or higher. the findings also suggest that concerned home owners who are able to accommodate the costs may want to continuously operate portable air cleaners with high efficiency filters in their homes, particularly if occupants are elderly or have respiratory or cardiac health conditions that increase their susceptibility to particle-related health effects. In selection of portable air cleaners, costs over time, including energy and filter replacement costs, should be considered as these ongoing costs can exceed the initial purchase price. An extrapolation of the results to the full U.S. population leads to a very large national-level potential mortality reductions and mortality-related economic benefits. The largest benefits are from interventions that use portable air cleaners, these could be employed in nearly all homes and apartments. They result in predicted mortality reduction of approximately 2 per 10,000 population. For the total U.S. population of approximately 320 million, this mortality reduction rate corresponds to 64,000 prevented premature deaths each year. For several of the interventions, the estimated mortality related economic benefits exceed $1000 per person per year, with peak estimates exceeding $2000 per person per year. For the full U.S. population, a $1000 per year per person benefit translates to a potential nationwide annual benefit of $0.32 trillion. This extraordinary potential benefit, together with the predicted high benefit-cost ratios, suggest that much greater attention be placed on improvements in particle filtration.