Coronavirus Technology Solutions

September 1, 2020

EawayFilter Makes HEPA Filters and Fan Filter Units

Tri -Dim Portable Air Cleaner has HEPA and UV Light

Investment in Increased HVAC or Filter Efficiency or Both?

Ceiling High Efficiency Filters with UVGI are Cost Effective for Virus Capture

Trane Recommends Higher Efficiency Filters

Trane Catalytic Air Cleaning System Combines Multiple Technologies

Upgrading Your HVAC System can be Challenging

Freudenberg has Multi Stage System for Indoor Air and Virus Removal

Fruit Extracts Used in Freudenberg Cabin Filters to Inactivate Viruses

Freudenberg’s micronAir proTect Line Filters can Deactivate Almost 100% of Viruses

Freudenberg says Viruses on Surfaces in Vehicles Become Airborne Again

______________________________________________________________________________

EawayFilter Makes HEPA Filters and Fan Filter Units

EawayFilter Co., Ltd makes all kinds of air filters and filter equipment such as pre filter, medium filters, HEPA filters, and Fan Filter Units. For HEPA filters, performance of each filter is checked for airflow rate and pressure drop, and to ensure each HEPA filter is without leakages.

Filters are mainly used for pharmaceutical, electronics, and food & beverage processing, automotive, and paint spray industries. Standard size HEPA and custom sized HEPA filters are available..

To control quality the company tests the raw material glass fiber media by particle counter and pressure drop sense. After confirmation that the filter media meets efficiency, pressure drop and dust holding ability then the HEPA filter begins. After the production, the company tests the filters by DOP and laser particle counter according to EN:1822 standard.

The company has more than 20 years’ experience in the air filter industries, It has over 200 employees and 10 engineers. The company has high tech machines for mini pleated HEPA folding, CNC Shear plate bending, air pressure and air flow test tunnel, and efficiency test equipment.

The company also makes room air purifiers. The design uses 610*610*69 mm HEPA filters, with low resistance and high dust holding glass fiber media.

Fan Filter units in stainless steel frames are available.

Tri -Dim Portable Air Cleaner has HEPA and UV Light

Tri-Dim’s portable air cleaner, TRI-KLEEN 500UV, features a HEPA filter, as well as a UV-C Germicidal Light to increase the effectiveness of air cleaning from pathogens, such as bacteria and viruses. But the TRI-KLEEN 500UV is more than just a HEPA air cleaner with UV protection. It also features an optional flex duct and collar, which can achieve either negative or positive air pressure in a particular space. Closed-off rooms can be continuously cleaned of particles in circulation mode, which significantly improves the air quality.

Investment in Increased HVAC or Filter Efficiency or Both?

Would a MERV 13 filter and higher air flow be better than a MERV 16 filter and lower air flow to reduce the risk of COVID infection in a building? This will be one of the topics in the webinar on September 10.

Dr. Clifton W. Draper is the Corporate Engineering Director at Tri\-Dim. He addressed routes to decrease infection through a balance of increased filter efficiency and HVAC air flow.

“According to the well-used Wells-Riley equation for mathematically modeling the infection risk factors for airborne disease transmission, the probability is inversely correlated (proportional) to the ventilation rate. Ventilation is one of the most important means to control the cross infection by removal or dilution of virus –laden aerosols: exhaled, coughed, sneezed, etc. All air filters have a rated efficiency. Tradeoffs between particulate removal and filter resistance are rationalized under normal conditions with the reduction of electrical energy usage as a major driver by decision makers. However in almost all commercial buildings, room exists in the total system resistance allocation for increasing ventilation rates even in the face of electing to significantly upgrade the filter efficiency; and thus add some air resistance to the system. The bottom line being you should seriously consider upgrading your filter or combined filter efficiencies along with increasing the CFM being moved through those filter banks. Yes your filter upgrade will likely increase their cost. Yes bumping up the fan speed will drive up energy costs for a period of time. Pandemics have beginnings and ends. The increased costs will have a finite duration.”

Ceiling High Efficiency Filters with UVGI are Cost Effective for Virus Capture

The enVerid Air Purifier from enVerid Systems, a provider of indoor air quality solutions, is a filtration product that has been shown to capture 99.99% of viruses, including a surrogate for the COVID-19 virus. It combines a high-efficiency filter with built-in ultraviolet germicidal irradiation (UVGI) technology to capture and inactivate viruses, and is suitable for offices, classrooms, retail stores, and other commercial applications.

The enVerid Air Purifier can be mounted below the ceiling where their visibility provides peace of mind, or out of sight in the ceiling plenum. Each unit comes with a wall-mounted LCD-display controller for monitoring and control. This localized filtration solution offers a way to ensure healthy indoor air quality without the significant expense of upgrading HVAC systems, and the “energy penalty” associated with conditioning higher volumes of outside air. Compared to portable air filters, this ceiling-mounted system saves floor space, avoids clutter, and allows for more flexible placement to minimize noise and optimize air flow.

“Indoor air quality (IAQ) has never been more important to school administrators, building owners, and tenants as they prepare for people to return to school and work,” said Christian Weeks, CEO of enVerid Systems. “Consistent with our company mission to make the world a cleaner, healthier place, we are excited to expand our product offerings with a solution that provides peace of mind for building occupants and owners concerned about COVID-19 airborne transmission in the buildings where we learn, work, and shop.”

Each enVerid Air Purifier quietly pulls air from the occupied space and runs it through a multi-stage series of high-performance filters. Cleaned air is then sent back into the space. Each unit treats up to 1,000 square feet of space, cleaning the entire air volume every 20 minutes. Multiple units can be installed to meet the requirements of any size space.

ASHRAE’s most recent Building Readiness guide recommends high-efficiency filters “in high occupancy or high bioburden (such as the building entry) spaces” in addition to increasing filter MERV levels in existing air handling equipment fans and motors.

Third-party tests conducted by LMS Technologies, a U.S.-based independent air media and filter testing company, showed that the enVerid Air Purifier removes 99.99% of viruses from air passing through the filter. Testing was done using MS-2-bacteriophage, a surrogate for SARS-CoV-2. Viral efficiency testing was performed according to ASTM F2101-19, the standard test method for determining bacterial filter efficiency for medical face mask materials.

Testing by LMS also showed a single pass efficiency of 99.95% for particles whose diameter is equal to 0.3-0.5 μm, the lower end of the size range generally attributed to bioaerosols that can carry viruses. The UVC sterilization lamp installed in the return air box kills bacteria and viruses entering the unit and adsorbed on the filters. The Air Purifier can also be used without the UVC sterilization lamp.

Four hanging brackets are included with the enVerid Air Purifier. Duct connections and ceiling return may be required depending on the installation. The unit requires access to 110V or 220V power and is connected to the controller with an 18-gauge stranded shielded communication wire (not included). Side access is required for filter replacement. The filter display on the control panel shows the number of days until the next high efficiency filter replacement, which is required every six months if the UVC lamps are in use and every 12 months if they are not in use. The washable pre-filter should be cleaned every time the high efficiency filter is changed and replaced every one to two years. The UVC lamp bulbs should be replaced every 9,000 hours and cleaned whenever the high efficiency filter is replaced.

Trane Recommends Higher Efficiency Filters

Ron Cosby, Thermal Systems and Technology Leader at Trane Technologies, says best practice is to consistently run an HVAC system to remove stagnant air from the room and replace it with fresh, clean air. This and other opportunities are included in a Trane® Indoor Air Quality Assessment. The assessment identifies areas of improvement and provides concrete guidance to optimize indoor air quality, including:

· A report with actionable, strategic recommendations to improve indoor air quality

· Guidance on what systems to update or improve to address critical issues

· Options to implement recommendations and a documented list of completed results

There are a variety of different air cleaning technologies ranging from Ultraviolet Germicidal Irradiation (UVGI) to photocatalytic oxidation. However, the quickest and most cost-effective way to enhance air cleaning is by upgrading HVAC filters to ones that more aggressively capture certain microbiological particles.

· Upgrade filters to ones with high MERV ratings. The Minimum Efficiency Reporting Value (MERV) range spans eight to 16. The rating system created by ASHRAE indicates how effectively the filter captures contaminants based on contaminate size. The higher the MERV number, the smaller and finer the particles it can potentially capture. ASHRAE recommends building managers use filters rated MERV13 and above.

· The most effective filters are High Efficiency Particulate Air (HEPA) filters to reduce both larger micro-biologicals and those that adhere to aerosols and small particulates.

· Consider a long-term air cleaning solution. For example, the Trane Catalytic Air Cleaning System (TCACS) neutralizes and significantly reduces certain contaminants in the air using an advanced photocatalytic oxidation process.

More details on the Trane approach are found at https://facilityexecutive.com/2020/08/trane-indoor-air-quality-assessment/

Trane Catalytic Air Cleaning System Combines Multiple Technologies

Air entering the TCACS passes first through a MERV 13 high-efficiency particulate filter, which captures many of the larger biological contaminants and small airborne particles such as mold spores and pollen.

Viruses, odors, VOCs and micro-organisms pass through the filter and into the TCACS’ ultraviolet germicidal irradiation (UVGI) area, where they are exposed to a high-intensity ultraviolet light. This UV radiation penetrates microorganisms such as fungi, bacteria and viruses and damages their DNA bonds, sterilizing them.

As the air is being exposed to UVGI, it’s also passing through a mesh panel coated with titanium dioxide (TiO2). When subjected to ultraviolet photons, TiO2 creates hydroxyl radicals, one of the most powerful oxidizing agents in nature. As air passes through this ultraviolet-powered catalyst, the radicals oxidize gaseous organic compounds, such as odors and VOCs, reducing them to minute amounts of harmless carbon dioxide and water. The radicals and UV light work together to inactivate and decompose organic contaminants.

Upgrading Your HVAC System can be Challenging

According to Sarah E. Maston, PE, BCxP, QCxP, LEED AP, owner of Green Footprint Commissioning Inc., of Hudson, MA: “It’s important to examine the HVAC documents, including the blueprints and other drawings. The as-builts are especially helpful because the installation team created them based on what was installed, where it was installed, and how it was installed. The original specifications are important, but they reflect what was called for, not what was specifically done.”

“What we’ve found is that for a particular size virus particle, if your system has allowed you to go up to a MERV 13 or 14 filter, the efficiency is considerably better at that limit. And that’s kind of the trade off,” says Maston. “Some systems might not be able to handle [a more efficient filter] because it takes a lot more energy to push air through it.”

The use of HEPA (High Efficiency Particulate Air) filters is not usually an option either. There two good reasons for this: 1) the relatively high cost of HEPA filters, and 2) these filters pose considerably more resistance to air flow than MERV filters do.

If the AHU’s blower(s) motor is not sufficient to the task, an increase of static pressure will slow the flow of air, which is counterproductive to the task of catching virus’ in the filtration system. In this regard, air flow is likewise a key component in the IAQ effort and cannot be ignored.

Good air flow will also assist in humidity control. Maston says that if you can maintain a relative humidity of 40% to 60% inside your facility, this will decrease the virus’ ability to infect occupants. If your HVAC system already incorporates makeup air, this also will increase ventilation, thus creating an even more healthy environment.

More details on upgrading are found in this article https://facilityexecutive.com/2020/08/hvac-systems-and-reopening-buildings-amid-covid-19/

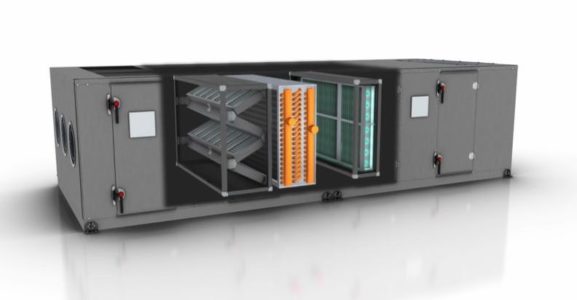

Freudenberg has Multi Stage System for Indoor Air and Virus Removal

Filters of different filter classes are combined in a multi-stage system to ensure the desired indoor air quality. The basis for perfectly matched filter stages and the classification of air filters is the ISO 16890 test standard. Air filters are classified into the corresponding ISO classes based on their separation efficiency of the different particle sizes PM10, PM2.5 and PM1. For HEPA filters (EPA, HEPA and ULPA filter classes), the new ISO 29463 provides orientation based on the European filter standard EN 1822.

Filter stage 1: Pocket filters initially separate most of the larger particles (PM10) such as dust and pollen from the supply and recirculated air. Their low pressure drops make them particularly energy efficient.

Filter stage 2: Almost all PM2,5 particles are filtered in filter stage 2. Cassette filters excel here with their high dust holding capacity and stable separation efficiency.

Filter stage 3: The third stage with HEPA filters is responsible for ensuring sterility and clean room air. A HEPA/ULPA filter of filter class H14 removes more than 99.995 % of the remaining particles, germs and viruses from the air – and thus effectively minimizes the risk of contracting infections indoors.

![[Translate to English (US):] Filter stages and separation efficiencies](clip_image009.jpg)

Fruit Extracts Used in Freudenberg Cabin Filters to Inactivate Viruses

The modern cabin filter is a relatively new innovation. It was first devised and commercialized in 1957 by Germany’s Freudenberg Group. In 1989, Freudenberg began producing its micronAir cabin-air filter for Mercedes-Benz – leading to millions of annual sales across the industry and a market-leading role that the company maintains today.

Volker Braeunling, global technical director of automotive filters at Freudenberg, explained the three essential levels of cabin-air filtration. The first is filtration-collection efficiency, the size of the particulate matter that’s captured. A progressive set of microfiber layers, each finer than the one before, collects the most harmful particles that passengers can breathe. “This microfiber layer is the most functional part,” said Braeunling.

Barry Kellar, Freudenberg’s global vice-president of automotive filters, said that in some automotive applications, pre-filters also are used. For example, vehicles operating on dusty roads might use a pre-filter to capture coarser particles. Because that material can build up fast, these filters are located where they can be easily replaced.

After filtration comes adsorption, a process by which a solid substance collects and contains gas. It often uses carbon to collect harmful odors and gases, thereby removing them from the air. Freudenberg opted for a custom recipe of activated carbon material, fine-tuned to specific adsorption properties.

It’s in the third so-called functional layer that viruses are addressed. Freudenberg’s Braeunling said, “We add a layer that has a specific impregnation of fruit extract to denature proteins, which are more or less also allergens.” In early March, Freudenberg tested the fruit-extract material using multiple third-party labs. “We received excellent results,” said Braeunling. “We tested the H1N1 influenza virus, and the deactivation rate was 99.99%. That means we could really deactivate all the viruses according to this test procedure.”

Braeunling explained that there are two different types of viruses: those with and without a protein-based envelope that protects the virus’s DNA. Freudenberg uses the fruit extract to destroy the virus’s shell, thereby deactivating the virus’s ability to enter the human body and to duplicate. However, filtering for viruses is also dependent on particle-size efficiency. The popular press describes coronavirus as very small, about 120 nanometers.

“But in the ambient air, you don’t see a single coronavirus flying around because these viruses are in the droplets coming from a human being who is sneezing or coughing,” said Braeunling. He explained that the droplets evaporate quickly

A typical cabin-air filter is around 9 inches by 8 inches by 1 inch. Pleating the material can expand the area by about ten-fold. The goal of reliably filtering coronavirus from a vehicle cabin has myriad challenges. The efficiency and adsorption functions, the need for effective and safe anti-allergen additives and the form factor of the filter all must work as a system – one that’s comfortable for passengers using the vehicle’s air conditioning and that can be industrialized by manufacturers. There’s no silver bullet.

More on cabin air filtration including the launch of ICON in China is found at https://advancedfleetmanagementconsulting.com/eng/2020/07/14/vehicle-cabin-air-filters/

Freudenberg’s micronAir proTect Line Filters can Deactivate Almost 100% of Viruses

Recent ISO18184 tests conducted by the Guang Zhou Institute of Microbiology in China have shown that Freudenberg Filtration Technologies’ micronAir proTect line filters can deactivate almost 100% of viruses with its anti-viral filter layer.

To prevent viral airborne aerosols from causing harm they must be directly filtered from the ambient air and then the critical virus load must be deactivated with an anti-viral filter media layer. Closed environments like vehicle interiors pose a higher risk of infection through inhalation.

The micronAir cabin air filters capture aerosol droplets and droplet nuclei within the range of 0.05 μm to 16 μm. The latest Covid-19 studies from the World Health Organization (WHO) show that these aerosols contain the critical virus load as they are emitted during breathing, talking, coughing or sneezing.

Once the filter captures the virus, it is deactivated through an approach based on natural fruit extracts which prevents secondary contamination. The virus interacts with the fruit extract’s acid environment. The reaction causes the rendering or denaturation of the virus’ protein structure, giving a harmless pathogen unable to infect human cells.

Freudenberg says Viruses on Surfaces in Vehicles Become Airborne Again

Contaminated particles inside a vehicle cabin rarely pass directly into the air filtration system. Initially, they are much more likely to settle on and around the air vents or on the upholstery and other surfaces. They remain actively infectious in such places for anything from a few hours to several days. At the same time, even if they are not passed on by touching, they will become airborne again in regular cycles as a result of wind disturbance, changing humidity levels, wiping or simply the vibration of the vehicle.

In terms of air purity, it is vital that the cabin air filters are capable of separating submicron particles. Even if the infected droplets emitted by the vehicle occupants are in the larger size range, the effects of evaporation mean that the droplet sizes that eventually reach the air filter will be much smaller. For this reason, it is preferable to use the vehicle’s fresh air HVAC mode to ensure that the cabin is supplied with plentiful fresh air. This will dilute the particle concentration and reduce stress on the filter as well as rapidly evacuating virus droplets. If recirculation mode is preferred, it is essential to use the most efficient cabin air filter available to minimize the risk of transmitting the infection. In all cases, cabin air filters should currently be changed even more often than usual to ensure maximum filter efficiency and thus protection against viruses.