Coronavirus Technology Solutions

August 26, 2020

NAS Airborne Virus Conference Provided Good Background Information

Valved Masks Should Play a Bigger Role

Ahlstorm-Munksjo has New Medical Fabric to Protect Against Pathogens

American Elite Molding will be Making Meltblowns By Next Month

Branford Castle Partners Purchases Fibrix Filtration

American Airlines will be Applying Long Lasting Decontamination Fluid

____________________________________________________________________________

NAS Airborne Virus Conference Provided Good Background Information

The two day NAS conference on the significance of airborne virus started today. In general it supported the growing evidence that much of the transmission is airborne. Small droplets have higher percentages of virus than do large droplets and there are more small droplets than were originally thought.

The virtual conference included presenters from the U.S. and Australia and participants from around the world. There were hundreds of written questions and some good but brief discussions. The conclusion to be reached from this session is that the focus should be protection from airborne viruses.

The airborne viruses can emanate not only directly but indirectly. One example was the flexing of fabric from clothing or wipes which had been sprayed with virus. Large numbers of particles were released from this movement. Given this statement McIlvaine submitted a written question which was not answered. If the flexing of virus laden fabric generates virus aerosols, what about the flexing of a cloth mask with each breath. In the case of the mask there is turbulent air flow in addition to flexing.

The presenters cited the difficulty in quantifying the virus activity in the lungs. It is easy to access the nasal passages but there are lots of unknowns about virus aerosol formation and movement in the lungs.

Linsey Marr discussed the chemistry of viral droplets and pointed out that surfactants comprise a small portion along with proteins. The McIlvaine question would be what impact the surfactants have on aerosol formation from cough droplets landing on the interior of the cloth mask. As the large droplet starts to evaporate the percentage of surfactants will increase relative to water vapor. Will this potential reduction in surface tension lead to the formation of smaller droplets?

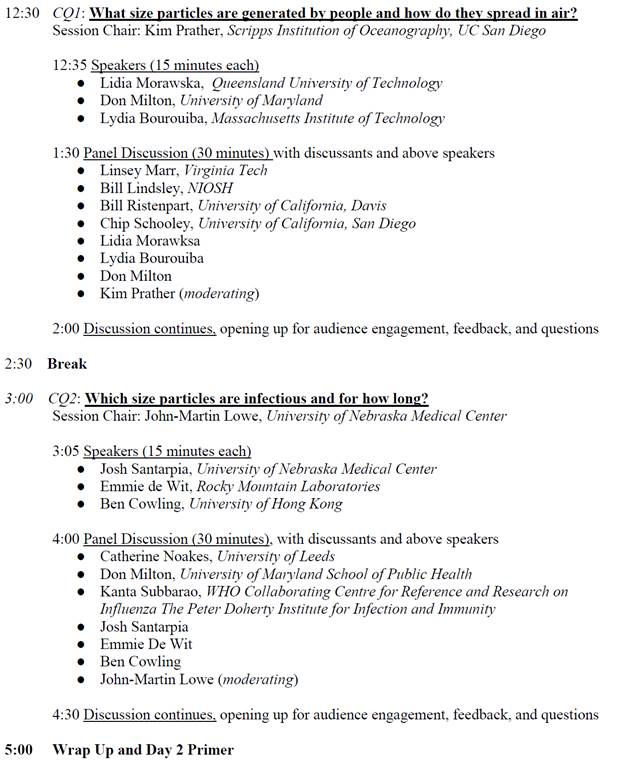

There was some discussion of the rheology on how droplets flow or deform under an applied force such as coughing. This information should be helpful in understanding the rheology of large droplets captured on inefficient mask and filter media. The afternoon speakers today are listed below.

Valved Masks Should Play a Bigger Role

An article in Salon magazine this month points out the advantages of valved masks. It quotes CDC recommending them for healthcare workers not involved in surgery or situations where they are likely to infect others. CDC cites the comfort advantages. The Salon authors point out that over 600 versions of valved masks have been recommended by CDC.

The sudden about shift by CDC seems contradictory and may have been influenced by initiatives by others such as Delta Airlines which has banned valved masks while not banning inefficient non valved masks.

In the NAS workshop the panelists stated that the use of masks and reduction of COVID was not linear. The reduction in COVID would be greater as masks were more widely worn. But the workshop presenters were also emphasizing the larger percentage of aerosol generated COVID. They discussed aerosol generation from surfaces. So there are lots of ways the virus becomes airborne.

The wearing of cloth masks is unlikely to make a big reduction in the amount of COVID. On the other hand if large numbers of people wore efficient masks to protect themselves there would be a substantial reduction.

Linsey Marr in the workshop today used the example of both transmitter and recipient wearing 50% efficient masks. She pointed out that the recipient would inhale only 25% of the load. But let’s take the example where both transmitter and recipient are wearing 95% efficient valved masks. Even though the transmitter emits 100% the recipient only inhales 5% or one fifth the amount in the Marr example. So efficient valved masks are better than inefficient non valved masks.

Many millions of people around the world wear efficient valved masks to protect themselves against indoor and outdoor air pollutants. The masks they buy are comfortable enough that they can be worn for long periods.

The main value cited for inefficient cloth masks is the prevention of cough and sneeze transmission on people nearby. The bigger risk is the airborne viruses which are transmitted over longer distances and for which cloth masks are not a protection.

One compromise solution would be valved masks with a lock position. When an individual is within six feet of others he keeps his mask in the locked position. For most of the day the valve is in an unlocked position where he can be made both safe and comfortable.

Saliva testing is likely to provide inexpensive self-testing. For those who are availing themselves of these daily tests the risk of infecting others when wearing a valved mask is minimal. At the same time the high efficiency is the protection needed against contracting the virus.

The Salon article an be found at

Ahlstorm-Munksjo has New Medical Fabric to Protect Against Pathogens

Ahlstrom-Munksjö announces the launch of TrustShield Biological, a personal protective apparel medical fabric designed to shield against hazardous pathogens.

The TrustShield product portfolio offers a range of medical fabrics designed to provide superior protection in the operating room, clinical and laboratory environments. TrustShield fabrics are laser resistant, protect against chemical permeation, and are highly absorbent. They can be easily converted into medical grade gowns or drapes.

TrustShield Biological is designed for personal protective apparel applications requiring biological protection to prevent penetration of blood and other hazardous fluids that can spread and cause infections. TrustShield Biological is a bi-laminate (two layer) fabric that consists of a polypropylene based nonwoven layer designed for comfort, and polyethylene film layer for protection against biohazards.

“It is important to focus on how we can advance product functionality in our smart fiber-based solutions. This holds true especially for our medical business and the protective fabrics we produce to keep front line workers safe. TrustShield Biological further underscores our mission to deliver high performing medical fabrics that fully protect health care workers and patients globally,” comments Lionel Bonte, vice president, Medical, Ahlstrom-Munksjö.

For decades the medical business has been making fabrics used to construct surgical gowns, drapes, pleated face masks, protective apparel and sterile barrier systems. These high performing medical fabrics are used around the world to protect health care workers and patients against viruses, bacteria and fluids. TrustShield Biological joins Ahlstrom-Munksjö’s high protection portfolio, which includes ViroSēl and PureArmor, Ahlstrom-Munksjö’s next generation breathable viral barrier (BVB) fabrics.

American Elite Molding will be Making Meltblowns By Next Month

American Elite Molding, a manufacturer of cable ties, announces the start-up of a new company to address the dire need for U.S.-manufactured materials for the personal protective equipment market in the U.S. The new company, American Elite Personal Protective Equipment (American Elite PPE), will begin production of meltblown polypropylene, the critical filter medium used in medical grade face masks and gowns, in early September 2020.

The Covid-19 pandemic has highlighted the fact that the supply of materials used to make personal protective equipment comes primarily from offshore manufacturers, and the risks of that have become apparent as widespread delays, shortages, and quality issues have occurred. The key to highly effective masks and gowns is the layer of meltblown polypropylene. This material filters very small particles and organisms efficiently while allowing enough porosity to breathe easily. American Elite PPE is gaining U.S. control of this crucial product by investing in its own manufacturing facility and establishing a U.S.-based supply chain.

American Elite PPE will manufacture meltblown filter material, the critical medium used in medical grade face masks and gowns, using polypropylene sourced from U.S. manufacturers. The filtering material will be made in the company’s Florida location by American workers, using equipment that has been designed, manufactured, and machined in the U.S. with advanced machining techniques used in domestic high tech industries.

"No longer will China control the supply of this vitally important material,” says American Elite Molding founder and CEO Robert Sires. “We are proud to be an American manufacturer that produces more than 1.5 billion cable ties in the United States utilizing American-made raw material and supplies. We have proven ourselves to be highly competitive with manufacturers in China and other offshore locations. Now, through our new company American Elite PPE, we will provide American-made products for the personal protective equipment that our front line healthcare providers, first responders, and citizens are so dependent upon.

“Our production lines are staffed by Americans who are committed to manufacturing the highest quality filter material. We manufacture to tight specifications so our customers can trust that they are getting the protection they need. We believe that during this crisis, it’s vital for the U.S. to secure a reliable, sustainable source of PPE material supply for critical healthcare needs, and for Americans to buy from U.S. businesses to support our economy and our workers. This new initiative delivers on both counts.”

Branford Castle Partners Purchases Fibrix Filtration

Branford Castle Partners, LP, a New York City-based private equity firm, announced that its affiliate has purchased Fibrix Filtration, a leading provider of specialized high loft and pleat media air filtration products. The company sells its products to many of the large, brand name filter manufacturers throughout the United States. Branford is teaming up with existing management including CEO Keith White, who is one of the current owners and who will be investing in the transaction as well. This investment represents the first transaction for Branford Castle Fund II, which had a first close in late 2019.

"Branford's Fund II is off to a fast start, despite the challenging environment, and we are delighted that Fibrix Filtration is the first investment for our second fund. With air filtration an area of increasing concern throughout the world, we look forward to working with Fibrix management to grow the business and develop new products," says senior managing director Laurence Lederer.

Based in Charlotte, NC, Fibrix Filtration has been manufacturing air filtration media products for over 50 years. With four facilities located in North Carolina and Texas, the company's products are pivotal in optimizing the performance of commercial and industrial HVAC systems, leading to enhanced system efficiency, lower energy costs and improved air quality. Fibrix's air filtration media products are designed to meet specific technical standards related to particle capture, pressure drop and dust collection.

"We are excited about the Fibrix opportunity and believe the company is well-positioned to grow through a number of organic initiatives under the direction of its excellent management team," says Branford senior associate, Ceon Francis. "We are especially pleased to work on this investment with Byline Sponsor Finance, a division of Byline Bank, which is providing senior debt financing, and Brookside Mezzanine Partners, which is providing mezzanine debt financing."

Keith White, CEO, further adds, "The team and I are very proud of all that we've accomplished over the last few years at Fibrix. We look forward to working closely with our partners at Branford Castle in the next stage of growth of our business."

American Airlines will be Applying Long Lasting Decontamination Fluid

American Airlines is upgrading its Clean Commitment by adding the electrostatic spraying solution SurfaceWise®2 from Allied BioScience to its multitiered cleaning and safety program in the coming months. The SurfaceWise2 solution is the first-ever long-lasting product to help fight the spread of the novel coronavirus that is approved by the U.S. Environmental Protection Agency (EPA).

“The American Airlines Clean Commitment is our promise that we’re taking bold measures and using the latest products and technology to help ensure our customers’ well-being when they travel with us,” said David Seymour, American’s Chief Operating Officer. “Thanks to rigorous evaluations conducted by the experienced professionals at the EPA, the American Airlines team and Allied BioScience, our multitiered program will become even stronger at safeguarding our customers and team members from virus such as coronavirus and the flu.”

“SurfaceWise2’s long-lasting defense provides a layer of protection against viruses not offered by any other solutions on the market,” said Maha El-Sayed, PhD, Allied BioScience Chief Science Officer. We look forward to also seeing SurfaceWise2 used in offices, schools, gymnasiums and other high-traffic areas to support the nation in safely reopening.”

In the coming months, American will begin using SurfaceWise2 for electrostatic spraying on surfaces inside its aircraft with plans to use the product throughout its entire fleet, including those in its American Eagle regional partners. Other elements of the airline’s multitiered Clean Commitment, include enhanced aircraft cleaning performed before every mainline flight and an even deeper overnight cleaning.

“SurfaceWise2 creates an invisible barrier on surfaces, which physically breaks down and kills virus cells,” said Dr. Charles Gerba, a leading infectious disease expert. “This helps protect passengers and crew members against the transmission of coronavirus via surfaces, particularly on high-touch areas such as seats, armrests, tray tables and overhead bin doors.”