Coronavirus Technology Solutions

July 30, 2020

H&V Offers an Array of Media for Respiratory Protection

Initiative to Make Sure Enough Media is Available to Meet COVID Requirements

Freudenberg will Make Face Masks in Partnership with NC University

Lydall’s Second Quarter Sales Negatively Impacted by COVID

Ahlstrom-Munksjo Sales Down Nearly Seventeen Percent

Computer Modeling of Diamond Princess Shows Transmission Through Small Aerosols

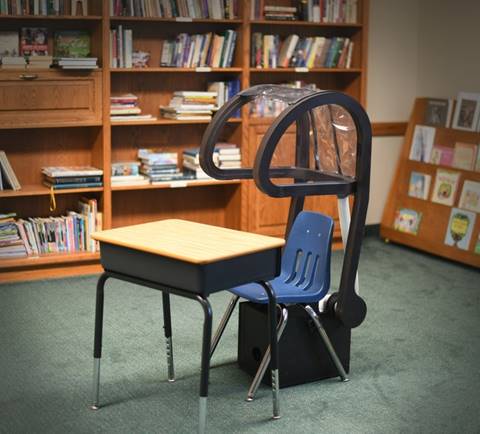

HEPA Filtered Chairs for Schools

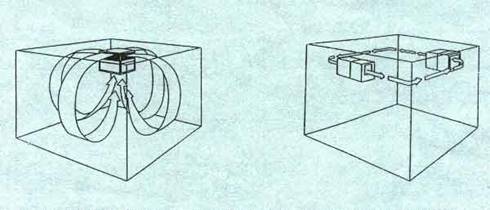

Air Quality Engineering has Unique Air Flow Concept

______________________________________________________________________________

H&V Offers an Array of Media for Respiratory Protection

Hollingsworth + Vose has a range of filter media for masks and respirators to meet different efficiency requirements:

- The new AlphaPerm® media provides 40% lower resistance vs. standard meltblown media and is available to meet NIOS N95 and EU143 and EU159 FFP2 and FFP3 standards after heat aging and paraffin oil loading.

- Meltblown media are among the most widely used respirator filter material in the world. They are manufactured to meet the tightest performance specifications to reliably and consistently meet global regulatory standards.

- The company says that If your goal is to produce the most comfortable mask that is cool and easy to breathe through while still meeting global standards, then Technostat is the right choice for your respirator. Technostat and Technostat composites are our premium media for respirator applications. Media are triboelectrically charged to provide the highest efficiency with the lowest resistance.

- Composites of Technostat and meltblown media are ideal for respirators to meet the NIOSH or EN standard which require liquid particle removal such as NIOSH P95 or P100 classifications.

- As the leading manufacturer of HEPA microfiberglass media, we recommend glass grades for use in full and half mask respirators with pleated cartridges where mechanical filtration media are required for HEPA and sub HEPA performance. H&V says its Perform® glass media deliver the lowest resistance for a specified efficiency.

Initiative to Make Sure Enough Media is Available to Meet COVID Requirements

The research now shows that the solution to the COVID problem lies with efficient filtration in HVAC, room purifiers, and in highly efficient masks. The question is can the media be made available to meet requirements such as N95 quality masks for three billion people while at the same time fulfilling the media needs for HVAC, room purifiers, and all the other filtration applications

It can be assumed that creating enough meltblown capacity by 2021 to supply three billion people with masks will not be possible. However, membranes and other media can be utilized and a strategy can be put in place to make the mask and HVAC filter media available by 2021. This achievement may be as important as having a vaccine.

We will be working with our subscribers to obtain their input as to how the matrix of media can be adjusted to meet all the 2021 requirements. We will seek input from one and all but the subscribers will be the ones to receive the detailed output. Here is a draft of the matrix with numbers which are not meaningful except for some of the totals. In the case of fabric filters and gas turbines we have very detailed forecasts. We have done lots of work on media segmentation in fabric filtration but only some segmentation in commercial and residential air filtration.

The 2021 mask media represents a very large growth from a $ few billion presently. The MERV 8-16 and MERV 17 and higher represent growth rates of 800 % for 2021. So this will be difficult but not impossible to achieve when you consider other nonwoven markets such as diapers and wipes.

|

Filter Media Revenues $ billions 2021 with Proactive COVID Mitigation Program |

|||||||

|

|

Meltblown |

Micro Fiberglass |

Membranes |

Spunbond |

Needlefelt |

Nanofiber |

Total |

|

Masks |

25 |

10 |

15 |

5 |

5 |

10 |

30,000 |

|

HVAC MERV 8-16 |

|

|

|

|

|

|

8,000 |

|

HVAC MERV 17 and higher |

|

|

|

|

|

|

8,000 |

|

HEPA room air purifier |

|

|

|

|

|

|

4,000 |

|

Gas turbine inlet filter |

20 |

70 |

50 |

? |

10 |

15 |

200 |

|

Mobile air intake |

|

|

|

|

|

|

5,000 |

|

Liquid filtration |

|

|

|

|

|

|

15,000 |

|

Fabric filter |

|

100 |

400 |

|

1400 |

100 |

2000 |

McIlvaine has forecasts in the various areas but most are not detailed as to media type. For fabric filters we forecast the media separately from the bags. But for gas turbine inlet filters we show forecasts for finished filters below. We estimate the media at 200 million and the finished filters at $571 million for 2021.

FABRIC FILTER WORLD MARKETS-Media

Expanded Industry Totals

|

Classification: |

|

|

Subject: |

|

|

Continent: |

|

|

World Region: |

|

|

Country: |

|

(Millions)

|

Industry |

2014 |

2015 |

2016 |

2017 |

2018 |

2019 |

2020 |

2021 |

|

Total |

1,570.28 |

1,622.10 |

1,680.27 |

1,740.72 |

1,804.55 |

1,872.46 |

1,940.15 |

2,012.01 |

|

Asphalt |

130.63 |

135.15 |

140.08 |

145.47 |

151.33 |

157.70 |

164.42 |

171.52 |

|

Chemical |

101.97 |

105.89 |

110.14 |

114.76 |

119.76 |

125.18 |

131.05 |

137.43 |

|

Food |

28.42 |

29.38 |

30.43 |

31.55 |

32.76 |

34.05 |

35.42 |

36.89 |

|

Incinerators |

74.24 |

76.55 |

79.03 |

81.72 |

84.61 |

87.69 |

90.99 |

94.51 |

|

Industrial Power |

47.69 |

49.34 |

51.15 |

53.14 |

55.29 |

57.62 |

60.13 |

62.83 |

|

Metals |

129.35 |

133.64 |

138.35 |

143.42 |

148.89 |

154.76 |

161.04 |

167.75 |

|

Mining |

95.04 |

99.46 |

104.35 |

109.64 |

115.35 |

121.50 |

128.10 |

135.16 |

|

Other Industries |

150.49 |

155.57 |

161.09 |

167.02 |

173.38 |

180.18 |

187.43 |

196.75 |

|

Pharmaceutical |

25.61 |

26.42 |

27.31 |

28.28 |

29.34 |

30.50 |

30.50 |

31.81 |

|

Power - Existing |

193.16 |

211.14 |

228.98 |

246.38 |

263.51 |

281.16 |

296.38 |

309.31 |

|

Pulp & Paper |

24.23 |

24.41 |

24.60 |

24.79 |

25.00 |

25.23 |

25.46 |

25.71 |

|

Steel |

188.74 |

184.97 |

184.36 |

184.06 |

184.07 |

184.35 |

184.92 |

185.78 |

|

Stone |

380.71 |

390.20 |

400.40 |

410.47 |

421.28 |

432.55 |

444.31 |

456.57 |

Air Filtration and Purification World Markets Gas Turbine Air Filters

Expanded World Region Totals

|

Industry: |

|

|

Classification: |

|

|

Subject: |

|

|

Continent: |

|

|

Country: |

|

|

World Region |

2014 |

2015 |

2016 |

2017 |

2018 |

2019 |

2020 |

2021 |

|

Total |

406.54 |

426.70 |

449.21 |

472.59 |

500.11 |

525.04 |

548.54 |

571.41 |

|

Africa |

17.54 |

19.33 |

21.11 |

22.90 |

24.68 |

26.47 |

28.25 |

30.04 |

|

CIS |

8.08 |

9.08 |

10.09 |

11.09 |

12.09 |

13.10 |

14.10 |

15.11 |

|

East Asia |

64.50 |

68.70 |

73.03 |

78.54 |

84.51 |

90.38 |

96.24 |

101.50 |

|

Eastern Europe |

3.06 |

3.78 |

4.50 |

5.23 |

5.95 |

6.67 |

7.40 |

8.12 |

|

Middle East |

59.80 |

64.10 |

68.39 |

72.69 |

76.99 |

81.29 |

85.59 |

89.88 |

|

NAFTA |

144.92 |

148.36 |

154.61 |

160.71 |

170.43 |

177.68 |

183.57 |

189.02 |

|

South & Central America |

17.26 |

18.02 |

18.78 |

19.54 |

20.30 |

21.06 |

21.82 |

22.58 |

|

West Asia |

13.03 |

13.72 |

14.41 |

15.10 |

15.79 |

16.48 |

17.17 |

17.86 |

|

Western Europe |

78.35 |

81.62 |

84.29 |

86.80 |

89.37 |

91.91 |

94.41 |

97.30 |

We will keep subscribers updated as we start to populate these charts. Please contact Bob McIlvaine 847 226 2391 or rmcilvaine@mcilvainecompany.com for more details.

Freudenberg will Make Face Masks in Partnership with NC University

Freudenberg Performance Materials has partnered with the Nonwovens Institute at North Carolina State University to manufacture face masks for UNC system universities, North Carolina government organizations and hospitals.

As the fight against coronavirus continues, the need for essential face coverings continues to rise. Together with the Nonwovens Institute at NC State University, Freudenberg Performance Materials will begin production of earloops and N95 masks. The two organizations are aligning their expertise and supply chains to bring PPE to universities and healthcare workers as quickly as possible.

Through this partnership, NC State is supplying Freudenberg Performance Materials with the necessary roll goods needed for production while Freudenberg provides the textile manufacturing expertise and work force needed to install, operate and maintain the four new production lines. “As the leader in the development of the next generation of nonwovens, we knew we could step in and help fill this critical need. By partnering with Freudenberg, we will ensure the reliable completion of millions of protective face coverings to battle the coronavirus using NWI’s novel filter media”, says Behnam Pourdeyhimi, executive director of the Nonwovens Institute. Once fully operational the site will be able to produce more than one million masks a month.

In addition to the face mask lines provided by NC State, Freudenberg is also in the process of installing six additional production lines to manufacture surgical and N95 masks. Not only will the lines help provide essential face coverings, but the addition of the lines has enabled Freudenberg add 50 new positions within the company to operate the lines. “Having the opportunity to make an impact in the fight against the pandemic and to help improve the safety of our community has given new meaning to our business, our operations and the engagement from our employees. We are happy we are able to take advantage of NC State’s capabilities and align them with our own to make this happen,” says Raoul Farer, general manager, Regional Business Unit North America.

Lydall’s Second Quarter Sales Negatively Impacted by COVID

Lydall’s net sales of $146.2 million in the second quarter of 2020 decreased by $74.7 million, or 33.8%, compared to $220.8 million in the second quarter of 2019, primarily due to the effects of COVID-19 related automotive OEM shutdowns and weaker industrial demand.

“I am incredibly proud of Lydall's global employees who delivered extraordinary results while the world was in the midst of the COVID-19 pandemic. In times like these, cash matters most and the team rose to the occasion by generating almost $14 million of cash from operations in the second quarter,” Sara A. Greenstein, president and chief executive officer, says. “Additionally, we quickly pivoted our resources to the production of personal protective equipment for our first responders, medical professionals, military personnel and the general public, which contributed to our adjusted consolidated EBITDA margin of nearly 8% in the quarter. We also announced new strategic investments to accelerate domestic meltblown filtration media capacity supported by a $13.5 million commitment from the U.S. Government.”

Greenstein says the demand for the filtration media produced in Lydall’s Performance Materials segment significantly increased—the company saw a 20% increase in Filtration sales in the second quarter compared to prior year, a trend it expects to continue. “In our Technical Nonwovens segment, we completed a large order for nonwoven material used in medical gowns to support first responders for the New York Department of Health,” adds Ms. Greenstein. “When our automotive customers shuttered their factories late in the first quarter, the Thermal Acoustical Solutions business saw a historic decline in second quarter volumes in North America and Europe. The team responded quickly and decisively to flex our cost structure, and by the end of the second quarter our factories were back to nearly full pre-COVID production to support our automotive customers’ production re-starts.”

Ahlstrom-Munksjo Sales Down Nearly Seventeen Percent

Ahlstrom-Munksjö’s net sales in the second quarter of 2020 decreased by 16.6% to €621.5 million ($729 million) compared to the second quarter of 2019. This was mainly due to lower delivery volumes. In addition, average selling prices decreased, which was partly due to a less favorable product mix. The impact of the pandemic on customer activity varied. Deliveries increased in the health care and life science end-use segments, while they were relatively stable in the consumer goods end-use segments. Deliveries decreased clearly in the home building and furniture, transportation, and industrial end uses.

The decline in net sales in the Filtration & Performance Solutions business area was mainly driven by lower delivery volumes, particularly in the Filtration business. The divestment of the glass fiber reinforcement and fine arts businesses had an impact of about €11 million ($12.9 million) on net sales.

The company reported that demand decreased in filtration materials for transportation applications, while it remained more stable in industrial applications. Demand for abrasives, plasterboard, flooring and wallcoverings weakened particularly in Q2. At the same time, Ahlstrom-Munksjö reported continued good demand for hygiene-related nonwoven materials.

Hans Sohlström, president and CEO, comments: “Within our broad product range of advanced fiber-based solutions, the impact of the coronavirus pandemic on customer activity has varied. Demand remained strong in the healthcare and life science end-use segments, while it remained relatively stable in the consumer goods segment, albeit with some variation depending on end use. The biggest decline was in the home building and furniture, transportation and industrial end-use segments. All in all, the exceptional market environment led to a 10% reduction in our deliveries, which was the main driver behind the decrease in net sales and comparable EBITDA. However, we worked hard on our own actions to reduce variable and fixed costs, and this cushioned the impact of lower volumes.

“I’m also pleased that we were able to drive our business forward during the pandemic. Our in-depth knowledge of fiber-based materials, agile organization and common manufacturing platform enabled us to expand our manufacturing capabilities of face mask fabrics globally to lines normally used for the production of other fiber-based materials. We also took further steps in supplying the electric vehicle battery market by introducing a platform of fiber-based energy storage applications solutions. Our other new value-added solutions include a replaceable filter media for branded outdoor apparel used as face masks.”

Computer Modeling of Diamond Princess Shows Transmission Through Small Aerosols

Researchers from Harvard and IIT analyzed the virus spread on the Diamond Princess and came to the following conclusions.

Mean estimates of the contributions of short-range, long-range, and fomite transmission modes to infected cases aboard the ship across the entire simulation time period were 35%, 35%, and 30%, respectively. Mean estimates of the contributions of large respiratory droplets and small respiratory aerosols were 41% and 59%. Short-range transmission was the dominant mode after passenger quarantine began, albeit due primarily to aerosol transmission, not droplets.

Interpretation: Our results demonstrate that aerosol inhalation was likely the dominant contributor to COVID-19 transmission among passengers aboard the Diamond Princess Cruise Ship. Moreover, close-range and long-range transmission likely contributed similarly to disease progression. The full paper is shown at

https://www.medrxiv.org/content/10.1101/2020.07.13.20153049v1

Based on this paper Benedict Carey and James Glanz of the NY Times interviewed authors and experts and came to the following conclusions.

Wearing good-quality masks — standard surgical masks, or cloth masks with multiple layers rather than just one — will most likely be needed as well, even in well-ventilated spaces where people are keeping their distance.

The smaller droplets are also more likely to penetrate deeply into the respiratory system, down to the lungs. It may take a much smaller viral load — fewer viruses — to cause infection in the lungs than higher up, such as in the throat. This, at least, is the case for other respiratory viruses, like the flu.

Brent Stephens, an engineering professor at the Illinois Institute of Technology in Chicago and a co-author on the paper, said the findings were important in shaping, for example, measures that should be taken as college students return to campus.

The first, he said, should be “really enforcing mask policies.” Another, he said, is to recognize that there is a “huge variability in mask quality,” and material that actually stops small aerosols when someone is breathing, speaking, coughing or sneezing is crucial. Surgical masks are good, he said, but single-ply fabrics often are not.

The value of this model is that it allows for recommendations and guidance to be specific to each unique environment,” said another co-author, Joseph G. Allen, an expert in indoor air quality and an assistant professor at Harvard’s T.H. Chan School of Public Health.

Dr. Allen said those environments ranged from restaurants to dentist offices. In each case, he said, there are low-cost solutions that sharply improve ventilation and filtration — most buildings fall well short of optimal levels — and in turn reduce the risks of airborne infection.

“To me, this is an all-in moment,” Dr. Allen said. “We need better ventilation and better filtration, across the board, in all our buildings.”

https://www.nytimes.com/2020/07/30/health/diamond-princess-coronavirus-aerosol.html?smid=em-share

HEPA Filtered Chairs for Schools

Imagine Fiberglass Products Inc., a Canadian manufacturer of fiber-reinforced plastic products, has created a solution for the classroom that allows kids to safely return to school without the discomfort of wearing a mask for most of the day. The IsoBooth Student system helps to protect eyes, nose, and mouth against exposure to droplet and aerosol viral contaminants, like COVID-19.

The IsoBooth Student assembly attaches to most standard school chairs and is lightweight and easy to use.

"The IsoBooth Student is intended to give kids a protected, safe and comfortable place in the classroom to sit, do their work, listen to lessons and eat their lunch without the distraction and discomfort of wearing a mask," said Imagine Fiberglass President Jim Ashton. "As a parent, it is especially important to me that my kids can get back to school."

The IsoBooth is a patent-pending, engineered solution consisting of a lightweight canopy and blower system that attaches to a standard school chair and can easily be pulled up to the desk by a student. The canopy can be adjusted forward as the student leans forward in a writing position at their desk.

Engineered using advanced Computational Fluid Dynamics modeling, the heart of the IsoBooth is a compact, energy-efficient, air handling system. At the front, a push-pull air curtain can capture and reject airborne droplets and aerosols, while inside, the positive pressure breathing zone is protected and filled with HEPA filtered air, allowing students to work comfortably without mask or eye covering.

"Parents are concerned that their kids are falling behind due to COVID-19 interruptions and that return to the brick-and-mortar school is extremely important. However, we are all genuinely concerned about the safety of the students, teachers, and staff and have been frustrated that there really hasn't been any agreement on a safe plan for return," said Ashton.

Made from durable, lightweight plastics, the IsoBooth is easy to clean and exceptionally durable. Consuming less than 80 watts of power per seat daily, the unit costs literally pennies per day to operate. The cost of the unit itself is comparable to that of one week of childcare.

A similar version of the IsoBooth Student is available for the Office and is easily attached to a standard five-spoke base office chair or stool. The IsoBooth Office unit can be implemented for teachers and staff.

Air Quality Engineering has Unique Air Flow Concept

The flow patterns needed to most efficiently capture dust and those needed to protect workers from viruses are different. But one concept may be useful for both

The diagrams below show how Air Quality Engineering’s unique four-way (360 degree) air recirculation system works. Air movement experts refer to it as the “Coanda Aerodynamic Principle” which is the most efficient way to circulate air.

· The company says it takes advantage of and work with the natural, upward movement of air vs. the old-fashioned, horizontal approach.

· Air cleaners are installed directly overhead in problem areas to isolate and capture smoke BEFORE it disperses.

· It eliminates “Dead Spots”; hence it is more efficient in overall cleaning.

· The more uniform, ceiling-to-floor air circulation saves on heating and cooling. There are NO HEAVY DRAFTS as with the “pass-thru” units.

· In many applications, one of COANDA air cleaners will do a better job than two “pass thru” units.

McIlvaine Company has been writing about Ortner fan filter units which blow clean air down between the cashier and customer in a checkout line. Using this Coanda flow pattern you can visualize four checkout areas in a circle with space in the middle for the return air.