Coronavirus Technology Solutions

July 24, 2020

Interview with Mike Clark of H+V

COVID-19 Protective Barrier Solutions Manufactured in the USA by UltraBoard

Ahlstrom-Munksjö Partners with Sportswear Company to Provide Filter Media for Facemasks

Eagle Filters’ FFP2 and FFP3 Respirator Facemasks Now Made in Finland

Three Options for Higher Efficiency Air Filters

Shopping Center Switches from Two Stage to Camfil Hi -LoES and Reduces Labor Costs

Meltblowns are Ideal for Masks but in Short Supply

Upgrade to MERV 15 Without Increasing Fan Energy

Lots of Technology Solutions for Vehicles

______________________________________________________________________________

Interview with Mike Clark of H+V

Mike Clark provided Bob McIlvaine and Ross Ardell with insights on high efficiency filter media with and without electrostatic charging for a range of applications.

Mike is Division President of High Efficiency and Specialty Filtration. This includes filters with higher than MERV 8 rating. Therefore the high efficiency filter efforts to vanquish COVID are within his group. Mike joined H&V in July 2003 as a member of the New Business Development Group. Prior to his current role, Mike served as Director of Global Market Management—HVAC and Clean Room and as Director, Sales and Marketing of their European HESF business unit.

His experience in cleanrooms provided perspective as he discussed the McIlvaine concept of treating the world as one big cleanroom with internal space which has various cleanliness levels depending on the needs. Since H&V has products in the cleanest semiconductor and pharmaceutical space it can provide the highest levels of filter efficiency.

We asked Mike about the conflicting media demands from a number of COVID applications. Hollingsworth & Vose has, on a rapidly accelerated timeline, developed a new material for non-surgical medical gowns. Its origin stems from a COVID-19 related task force that H&V convened at the start of the pandemic to see how the company could expand production and help meet the shortage of medical grade PPE.

H&V manufactures filtration media for N95 respirators, ventilator filtration media and the materials used in surgical hoods. These are the products directly associated with healthcare. Recently it has been determined that much of the virus is transmitted in small aerosols. This means that air filter media in HVAC systems will be a major weapon in the battle. McIlvaine asked Mike about the comments yesterday in a WFI webinar by Sean O’Reilly of AAF/Flanders who said that their demand for MERV 13 filters was 10 times greater than normal. Finding media has been a big problem for AAF.

Mike says H&V is very focused on the wide range of needs and is thoroughly evaluating demand. He says that a big question for H&V is the long term demand. Mike believes that awareness of the advantages of air quality will insure that there is a big long term market. In fact he was making this prediction as far back as 2019. See the complete Interview on the ThinkNanoWave YouTube Channel: Interview with Mike Clark, Division President at Hollingsworth & Vose, at the FILTECH 2019

The company has manufacturing capabilities around the world. It has manufacturing and R&D facilities in China. Mike believes this Chinese capability is an asset. The company sells based on high quality and performance. McIlvaine indicated why this might distinguish H&V in China due to failures of domestic meltblown manufacturers.

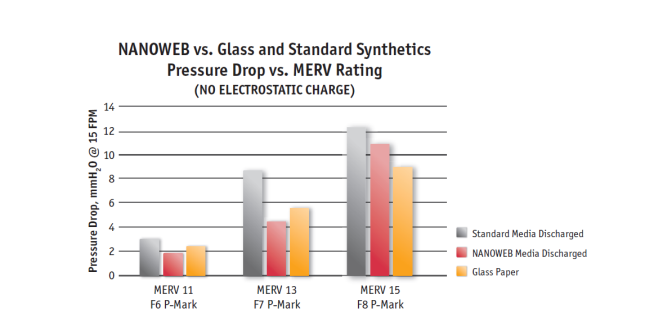

H&V has a range of synthetic and microfiber glass media. Electrostatic charging is an option to improve performance for a relatively long period. For MERV 15 filter media for example Nanoweb and glass paper pressure drop is considerably less than standard media. Since upgrading the filtration efficiency of existing HVAC systems while minimizing any fan or HVAC system will be attractive the higher performance H&V media will have an advantage.

Mike pointed out that H&V has long focused on decreasing total cost of ownership. In the past this has primarily involved reducing energy costs. This same approach can be used in the COVID battle but with the new goal of increasing efficiency at minimal additional energy cost. The interview with Mike can be viewed at https://youtu.be/7ZbONOv84pU

COVID-19 Protective Barrier Solutions Manufactured in the USA by UltraBoard

United Industries UltraBoard, a U.S. based manufacturer of foam core boards, has launched a complete line of COVID-19 preventative barrier aids for schools and other public spaces where social distancing barriers can aid in preventing transmission.

Primarily a manufacturer and supplier for the U.S. Sign Industry, UltraBoard experienced a downturn in their manufacturing due to close parallels with U.S. retail industry performance. "In an effort to sustain business and retain our employees' jobs, we had to pivot our game plan," stated Mark Ferm, CEO of UltraBoard.

OSHA's guide for preparing businesses for COVID-19 has recommended that spaces with medium exposure risk to COVID-19 may install physical barriers or plastic sneeze guards to help aid in the prevention of transmission.

The current health epidemic has rapidly depleted resources in clear plastics and acrylics that are utilized in the manufacture of COVID-19 barriers. Due to high demand acrylic prices have greatly increased within the shield market. UltraBoard's barrier shield solutions offer a more cost-effective approach as they feature an all-plastic foam board frame with rigid film windows. Rendering the UltraBoard Barrier an excellent alternative to acrylic barriers for large deployments and are easily sanitized and reused. The barriers are constructed of UltraBoard's flagship foamboard product, UltraBoard Classic.

UltraBoard's manufacturing plant literally produces tons of foam board annually. Having plenty of supply stock in their warehouse locations, UltraBoard is able to provide a massive-scale solution for supplying schools, gyms, salons, and other public spaces. Utilizing their foam boards and a rigid clear film window, UltraBoard has produced an affordable and easily-deployable COVID-19 preventative aid.

UltraBoard is providing several different types of COVID barriers to appeal to the different spaces where transmission may occur. Currently they are offering three different styles:

- The Barrier Micro for schools, educational institutions and public spaces.

- The 3-window Barrier Trio for schools, educational institutions and public spaces.

- The Barrier MAX panels for large spaces like salons, gyms or museums.

- The Barrier Stand for retail spaces including cash registers or food service.

Ahlstrom-Munksjö Partners with Sportswear Company to Provide Filter Media for Facemasks

Ahlstrom-Munksjö established a partnership with Spanish sports and life style accessories company BUFF to provide filter media for face masks.

The BUFF facemasks are now available in the United States and Canada following a launch in Europe in June. Each BUFF facemask includes five single-use filters in the original packaging. Replacement filters are sold separately in packs of 30 units.

The spread of COVID-19 and the consequent increase in the global demand for facemask components required many companies to rapidly adapt, leverage on their expertise and innovate. Thanks to Ahlstrom-Munksjö’s long-term experience in the manufacturing of filter media and protective medical fabrics, the company has developed a new material suitable for Type II facemask applications. Leveraging on its capabilities and adapting its converting and packaging processes, Ahlstrom-Munksjö has established a partnership with BUFF to supply its replaceable filter media which is included in BUFF’s new range of facemasks.

Tests conducted on these new single-use filters have shown a 98% bacterial filtration efficiency and meet EN14683:2019 Type I & II standards. The new BUFF Filter Mask is lightweight, ergonomic and easily adjustable. Its features make it ideal to be worn also during sport and outdoor activities, protecting the user yet allowing a high level of comfort.

Eagle Filters’ FFP2 and FFP3 Respirator Facemasks Now Made in Finland

Eagle Filters announced its first facemask respirators are now being rolling out from the company’s production facility located in Kotka, Finland, with deliveries to the healthcare industry in the region coming soon.

Eagle Filters´ respirator product range covers respirators that meet both FFP2 and FFP3 class efficiency, with and without a valve.

Eagle’s unique filter material enables highly purified air, while keeping breathing resistance low. The respirators’ sensitive exhale valve reduces moisture and heat buildup inside the respirator for a more comfortable user experience, according to the company.

Three Options for Higher Efficiency Air Filters

Today synthetics are a popular option but this was not true a few years ago. In 2015 Filtration Systems analyzed air filter options. When it came to high-efficiency air filters, anything MERV-11 or higher, there were three prevailing medias (the part that catches particles) available. They are: Coarse Fiber/Synthetic, Airlaid Fine-Fiber, and Wetlaid Fine-Fiber.

Coarse fiber/Synthetic air filter media was becoming more popular because it has low material and production costs; however ASHRAE, Eurovent, and most credible sources admit that it loses the ability to capture particles the longer it is in-service. ASHRAE had a disclaimer on page 3 of their 52.2–2012 air filter testing standard and Eurovent had a discharging step in its standard before particle removal efficiency testing is complete. There have been large gains in the discipline of nano-fibers and synthetic to overcome this efficiency loss problem. Synthetics are an attractive option as explained in the H&V interview in this Alert.

The other two options analyzed by Filtration Systems maintain their efficiency throughout the filter’s life — Airlaid and Wetlaid fine-fibers. Each has their set of benefits and weaknesses so determining which is better for a facility will come down to the environmental conditions, desired performance properties, and to some extent personal preference.

Wetlaid air filter media is made similarly to the process to make paper using glass fibers instead of cellulose fibers and is typically used in compact 4” and 6” deep mini-pleat, V-Bed, Aluminum Separator, and HEPA/ULPA filters. Being able to handle very high temperatures and having particulate removal efficiencies of up to 99.99995% @ Most Penetrating Particle Size (MPPS usually 0.112μ) are the two most significant benefits of wetlaid air filter media. Also more media per square foot can be installed into a filter frame of the same size compared to airlaid media, but this is not just possible but needed because wetlaid media comes with a higher static pressure/resistance to airflow and lower dust holding capacity per square foot compared to airlaid media. A MERV-14 wetlaid air filter media will typically hold between 1.4 and 1.75 grams of ASHRAE dust per square foot of media. This relatively low dust holding capacity is due to the face loading properties of the media. Face loading is when debris is collected on the face of the media and is not able to penetrate into the media before being captured, which is called depth loading.

Airlaid air filter media is made by melting glass pellets and drawing the liquefied glass through a strainer before it is collected at a uniform depth on a belt and dried. This media is only used in deep-pleated and bag/pocket style air filters. Having a lower static pressure/resistance to airflow and higher dust holding capacity per square foot of media are the main advantages of airlaid or “lofted” media. The lofted properties of this media allow depth loading of debris which is what allow the low static pressure and high dust holding properties. Depending on filter style and manufacturer the ASHRAE dust holding capacity of MERV-14 airlaid media ranges between 2.5 and 4.2 grams per square foot — roughly two to two and a half times higher than wetlaid media. Large particles are also handled better by airlaid media, so if the application has a high volume of large debris the lofted media will offer more filter longevity. However, as shown by the limited filter styles airlaid media is available in does have some significant drawbacks; such as having a maximum removal efficiency of 85% on ASHRAE’s Eparticle size range and the depth loading media needs to be held in place. Bag style filters are notorious for “shedding” debris because the pockets shake and the particles that wedged their way into the media are shaken through. Airlaid media is also subject to collapsing when it gets fully saturated with water, when this happens the benefit of having the lofted media goes away and the static pressure raises significantly.

In most HVAC applications either airlaid or wetlaid media will do a sufficient job with airlaid products usually offering a better price-to-life solution. Wetlaid products will give higher filtration efficiencies and with some configurations having 4–5 times more media than airlaid products the filter life and average static pressure will be much lower. With the large amount of options for high efficiency filters comparing and estimating life of different styles across different manufacturers can be nearly impossible but understanding how the filter media is made and the benefits and limitations will help with evaluation.

Shopping Center Switches from Two Stage to Camfil Hi -LoES and Reduces Labor Costs

By switching from a traditional 2-Stage MERV-8 Prefilter and MERV-13 Final filter one of the largest shopping centers in the world was able to save 68% of the labor hours for unloading, changing, and disposing their air filters in their 32 air handlers that provide over 3,000,000 cfm of air. This was accomplished with the Hi-FloES from Camfil, the only high efficiency air filter specifically designed to be operated without a prefilter and not sacrifice filter life, even the boxes are designed with multiple handles to make transporting the filters to the air handler easier. The previous 2-stage systems final filters averaged 12 months between changes and the Hi-FloES was able to go 14 months before reaching final pressure

The Hi-Flo ES incorporates Camfil air laid microfiber glass media that ensures reliable efficiency throughout the life of the filter. Its fine fiber diameter and uniform loft results in a consistent sub-micron particle capture and a low resistance to airflow. This exclusive media is designed to maintain this low resistance to air flow, saving energy, while still holding efficiency throughout the filter life. The Hi-Flo ES will maintain its particle efficiency, regardless of dust loading and/or humidity. A synthetic micro mesh media backing ensures media protection and support in turbulent or varying airflows.

Hi-Flo ES filters are available in four efficiencies: MERV 11, MERV 13, MERV 14 and MERV 15, when evaluated per ASHRAE Standard 52.2

Meltblowns are Ideal for Masks but in Short Supply

From a supply chain perspective, meltblown, has been a key stumbling block in N95 mask availability. “The supply situation is still an ongoing challenge. The demand is unprecedented and will continue to be so for the foreseeable future,” says Per Lindblom, global segment leader for Hollingsworth & Vose’s Respiratory Protection business. “It is relatively easy to add facemask capacity versus adding meltblown capacity due to the complexity of the machines and costs. The increase of mask capacity has so far exceeded the increase of meltblown.”

Meltblown is the ideal material for respirator-type facemasks because it offers high filtration efficiency, with excellent breathability. “Breathability is an important factor to consider,” says Todd Hillam, a senior scientist with Nelson Labs. “Although there may be plenty of materials out there that can offer a high level of filtration efficiency, not all of them are breathable, and if you can’t breathe through them, or they require bypass to breathe, then the material isn’t filtering and they may not be safe to use and will not meet N95 respirator requirements.”

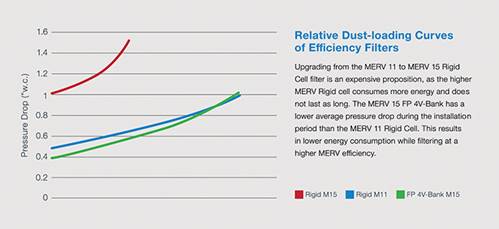

Upgrade to MERV 15 Without Increasing Fan Energy

Michael Bruce of Filtration Group in an article on selecting filters for lowest cost of ownership provided this comparison of an upgrade from MERV 11 rigid filter to a V bank design with little increase in pressure drop.

The full article is displayed at https://www.filtnews.com/simplify-your-hvac-investment-with-a-total-cost-of-ownership-analysis/

Lots of Technology Solutions for Vehicles

Car companies are investigating ways to virus-proof their vehicles to win customers concerned about infectious diseases once the coronavirus pandemic fades.

Ideas under consideration include blasting car interiors with ultraviolet light, using foggers to spray disinfectants, having upgraded air filtration systems and employing antimicrobial materials.

One-third of vehicle shoppers recently told Cox Automotive they are more likely to consider air quality features for their next vehicle than before COVID-19.

“Safety is definitely top of mind for car shoppers," said Vanesa Ton, Cox senior industry intelligence manager. "Not only are they expecting sanitization and social distancing protocols in place at the dealerships, they also want features in their cars to protect them such as air quality/purifier options."

In a sweeping five-country survey, 80% of respondents in the U.S., China, Japan, Germany and Italy told consultant IHS Markit they’d be willing to pay for systems to disinfect their vehicles.

“People want their vehicles to sterilize themselves,” said IHS supplier technology expert David Trippany.

A Michigan tech company has begun making UVC lights to sterilize the inside of ambulances, police cars and other emergency vehicles. UVA light is a component of the natural sunlight we're exposed to daily. Shorter wavelength UVC is more toxic, but normally screened out by the Earth's atmosphere. It can be produced by artificial lights and arc welders.

We’ve been working on UVC light to clean and disinfect vehicles for some time,” said John Major, director of marketing for GHSP, in Grand Haven, Michigan.

GHSP’s grēnlite system is in use on vehicles in Grand Rapids, Boston and in North Carolina.

“COVID-19 has moved this to the forefront,” said Todd Fletemier, technology vice president of interior supplier Faurecia. “We must combine the quick development and evaluation processes we’ve learned from the medical community with the auto industry’s needs for safety and durability.”

There’s a definite need for the systems in mass transit and ride-hailing vehicles. Demand for personal vehicles isn’t clear, but automakers are watching.

“Recent events have directed us to investigate additional technologies for improving cabin air for our heating and air-conditioning systems. We're also looking at antimicrobial materials and easily-cleanable surfaces for our interiors,” a Fiat Chrysler spokesperson said.

“COVID-19 will prompt more focus on air filtration and, perhaps, on more segregated climate zones in the cockpit, features there was already movement toward. But more extreme measures, like antibacterial touch surfaces, will be poorly rewarded in the long term if they mean less visually attractive or durable interiors,” said Eric Noble of product development consultant The Carlab.

UV light can’t be used when people are in the vehicle, but its sterilizing effect is cumulative, meaning “you don’t have to kill 100% at once," GHSP's Major said. "Short bursts every time the vehicle is empty work. You do a full cleaning between shifts or at the end of the day and maintain it with short doses throughout the day.”

The lights can be integrated into headliners or existing lighting systems, he said. Irradiating air in the climate control system’s ducts is another possibility.

Motion sensors and thermometers can determine the vehicle is empty and ready for irradiation, said Fletemier of Faurecia, which is looking at UVA and UVC sterilization.

Fogging systems that spray hydrogen peroxide or another disinfectant into the cabin air are another candidate, and another system that would require occupant detection for safety, Fletemier said.

Supplier Magna is evaluating an ozone-generating system it used to disinfect personal protective equipment for automotive use.

“We hope to leverage this Magna technology to sanitize ride-sharing vehicles and other future mobility applications,” Scott Mitchell, Magna’s global director of new technology and innovation, told the SAE International’s publication Autonomous Vehicle Engineering.

“It’s still too early to say how we’d go about implementing a sanitizing method for a vehicle interior, we have lots of options on the table that are under review,” Mitchell said.

Supplier Lear makes antimicrobial leather and fabrics that resist viruses, bacteria, mold and fungus. "We are seeing increased interest from our customers on surface materials that repel microorganisms,” Lear Chief Technology Officer John Absmeier said.