Coronavirus Technology Solutions

July 23, 2020

Interview with Lloyd Armbrust on Efficient Masks

WFI Webinar Today Covered Masks and Filters for COVID

Building Owners Receiving Poor and Outdated Advice on Filters

UV-C is Effective and Can be Safe

Portland Middle School Installed High Efficiency Filters Because of Local Air Pollution

Chicago Area Commercial Building Owners Prioritizing COVID Mitigation

___________________________________________________________________

Interview with Lloyd Armbrust on Efficient Masks

In this recorded interview Lloyd describes his production and software background and his determination to help address the COVID problem. He has set up a mask manufacturing facility in Austin and is gearing up to produce up to 1.6 Bllion highly efficient masks per year. He already has seven manufacturing lines in place and believes that within a few months he could expand to meet the goal. He uses equipment which has short lead times such as Chinese Folders. Much of the other equipment is domestically made and readily available.

He has his own meltblown manufacturing capability and is producing the three layer SMS media and has his own electrostatic charging system. He is able to achieve a high level of breathability while meeting the BFE requirements. The electrostatic charge can last up to 24 hours. For this reason he believes that inexpensive disposable masks are the best solution. These masks might be made available for as low as $ 0.15 each.

In a show of support for domestic manufacturing, Armbrust American received over 1.46 million orders in the first week after opening its Austin, Texas mask factory in early June.

"American's always come together in a time of crisis, and I knew there would be strong demand to buy USA-made products, but honestly, I wasn't expecting the overwhelming support and positivity we have received ," said Lloyd.

Lloyd was previously the Founder and CEO of OwnLocal, a company that automates production for 3,500 newspapers worldwide.

P

Production highlights

· Medical-grade N95, Surgical and protective face masks designed, developed and produced end-to-end in America (Austin, TX).

· Each fully-automated assembly line can eventually produce 120 masks per minute but is presently running at 90 masks per minute

· Vertically integrated factory takes raw US-Made Polypropylene and transforms it into surgical and N95 masks.

· Sterile production facility

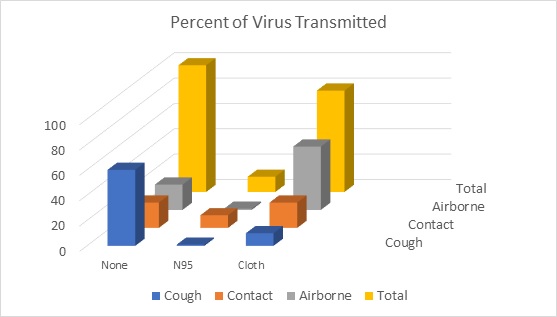

Lloyd indicated that enough highly efficient masks can be delivered quickly so that each of the 250 million Americans who are in public places each day can be protected. The importance of this is displayed in the following graph which shows that efficient mask will eliminate 84% of the COVID transmission whereas inefficient masks can only eliminate 20%.

If 250 million Americans require 300 masks per year each = 75 billion masks per year. At $0.20/mask the total cost would be only $15 billion per year. This is a small cost compared to the losses generated by COVID.

Lloyd is continuing to innovate and is evaluating a cast membrane fabric with high efficiency and breathability.

The full interview with Lloyd can be seen at https://youtu.be/4qN1rdBJAF4

WFI Webinar Today Covered Masks and Filters for COVID

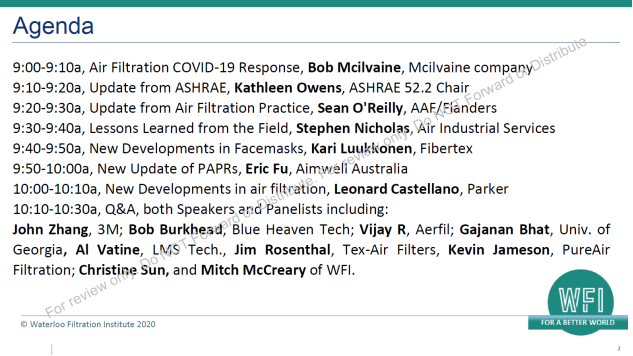

An informative webinar today addressed the challenges and opportunities. Sean O’Reilly of AAF Flanders addressed the shortage of MERV 13 filter media whereas Bob McIlvaine predicted that the need for high filtration media will soar beyond the present high demand levels. Here was the Agenda

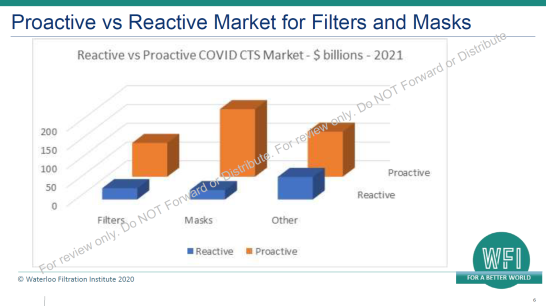

Whereas some of the proactive solutions in the form of MERV 13 filters are already underway a truly proactive filtration industry can be the major force in vanquishing COVID.

The industry will have to gear up to the huge demand requirement. There are many challenges and considerable investment needed. One optimist is the CEO of Ambrust American. Lloyd Armbrust stated in his McIlvaine interview covered in the previous article the increased demand for masks can be met within months by using innovative technology.

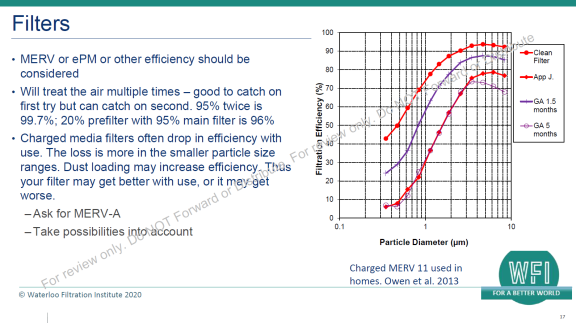

Kathleen Owens points out that if the air is treated more frequently than new contaminants are generated the removal efficiency will be a function of the number of passes. Also where there are pre filters the total efficiency combines both this and the final filter. The loss in efficiency of charged media over time is a concern.

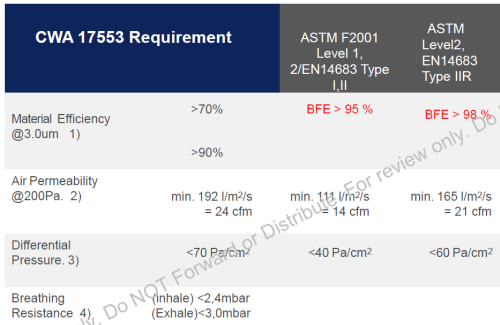

Kari Luukkonen discussed the new EU initiative to provide standards for masks won in public with either 70% or 90% efficiency on 3 micron particles. Differential pressure would be somewhat higher than with surgical masks.

Building Owners Receiving Poor and Outdated Advice on Filters

Propmodo is a publication for building management which recently gave questionable advice. “One of the earliest coronavirus studies published by the CDC showed that a single droplet from a diner at a 1,500 square foot restaurant in Guangzhou, China infected nine customers, dispersed by the building’s HVAC system. Several outbreak investigations have shown that COVID-19 transmission can be particularly dangerous in ventilated indoor spaces such as offices and factories. The role HVAC ventilation plays in transmission, like much of the virus itself, is still being discovered. While experts debate the details about ventilation’s role all urge caution. Caution is not an option when there is the need to act. There is enough evidence about the prevalence of airborne virus that it is time to act The American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) has put together an Epidemic Task Force to provide guidance.

“The main way (air conditioning) can contribute to spreading coronavirus is by creating strong air currents that can move the droplets…and contribute to increased risk,” Chair of the ASHRAE Epidemic Task Force William Bahnfleth told USA Today. This is also how you remove the virus cloud from the air. Without good ventilation you have the situations such as found in bars which were sources of superspreading.

The current state of most of the nation’s HVAC systems leaves us woefully unprepared. At best, most HVAC systems in commercial buildings can only control ventilation by increasing the outdoor air ventilation rate. Even then, there’s no understanding of how much outside air is enough to diffuse virus particles. Improving filtration is hardly an option. Why not? In fact it is the solution. Most of America’s commercial and residential building’s use a Minimum Efficiency Reporting Value (MERV) on their air filters somewhere between six and eight, which are not capable of filtering out the tiny aerosol droplets containing the virus. Simply installing better filters restricts airflow to the system by forcing the air through smaller pores, which most systems wouldn’t be able to handle, causing a total failure or extreme inefficiency. Upgrading is always possible and not necessary. Opening windows seems to be the only practical advice property managers can follow. This will make air flow unpredictable and could have negative consequences.

UV-C is Effective and Can be Safe

“UV-C Technology is a well-proven, extremely safe technology that is underused and often misunderstood,” Dr. Edward Nardell, a professor at Harvard Medical School, told NPR. “No one doubts the efficacy of germicidal UV in killing small microorganisms and pathogens. I think the bigger controversy, if there is any, is misperceptions around safety.”

Public perception has shifted against UV over the decades, as UV light strong enough to disinfect has been proven to damage the eyes and skin. Nardell says those risks can be avoided if the appropriate guidelines are followed, like keeping all devices out of sight. Just like with any ultraviolet technology, from teeth whiteners to tanning beds, proper precautions must be taken. The biggest issue may be the market for the UV-C products itself. After dealing with skewed public perception for decades, the industry is limited in scope. The global market for UV-C light barely reaches one billion annually, so it may struggle with the expected rise in demand generated by the pandemic, according to the researchers in Spain.

Portland Middle School Installed High Efficiency Filters Because of Local Air Pollution

The air outside the school was deemed so polluted, Portland Public Schools spent millions two years ago to install a state-of-the-art HVAC system.

"A distinct feature of Harriet Tubman Middle School is that there are these advanced air cleaning systems that remove air pollution," explained Elliot Gall.

Gall was part of a team of researchers from Portland State University helping the district come up with the lung-saving system.

Its purpose is to remove the tiny particles coming from vehicle exhaust.

"They removed 95% or more of the particles or aerosols that were present in air that passed through that filter," Gall said. "So the system is quite effective at removing those particles from air."

It's a system some experts say every school needs, especially now.

One of the ways the COVID-19 virus spreads is by aerosol transmission. Aerosols are the tiny droplets which stay suspended in the air after an infected person coughs or speaks. Those particles are actually quite a bit larger than some of the particles coming from car exhaust.

That means that the HVAC system at Harriet Tubman is also able to filter out airborne diseases including the COVID-19 virus.

"Air cleaning certainly plays a role when we think about bringing buildings back on line and bringing people back into buildings," Gall said.

It's a fix with a cost in the millions, but it's an investment that should have healthy returns for our schools and those who learn and work inside them.

"It's certainly not a silver bullet to making buildings safe," said Gall. "But it's one tool we should be thinking about."

Chicago Area Commercial Building Owners Prioritizing COVID Mitigation

There is great concern,” said Sean McCrady of Underwriters Laboratories, a global safety certification company based in Northbrook. “We get questions over and over about how to navigate this.”

“What we tell people is, you can’t put a force field around your property,” said McCrady, the national service line manager for indoor environmental quality. “You have to know what you can control and what you can’t.”

Efforts to stop the spread of COVID-19 primarily have focused on cleaning hands and surfaces, wearing masks and maintaining six feet of distance to prevent exposure to large droplets from an infected person’s mouth or nose.

Unlike large droplets, which fall to the ground within a few feet, scientists believe smaller droplets can linger in the air and within indoor ventilation systems.

More than 200 scientists earlier this month signed an open letter warning that public health agencies such as the WHO and U.S. Centers for Disease Control were ignoring the potential risk of the virus spreading through air circulating indoors.

The WHO responded by updating its guidance to acknowledge the possibility of airborne transmission of COVID-19.

“I think improving ventilation and improving air cleaning is one of the few lines of defense that we have,” said Brent Stephens, an engineering professor and chair of Illinois Institute of Technology’s Department of Civil Engineering, who signed the open letter.

“I don’t think we really have a good sense of how important it is,” said Stephens, who specializes in air quality in buildings. “We’re still learning.”

There are several ways to improve air flow and quality, but many virus-fighting technologies are relatively new and difficult to research, experts say.

Costly changes to HVAC systems also can create a false sense of security, said Raj Gupta, executive chairman of ESD, a Chicago-based engineering firm.

Gupta said companies first should focus on three primary goals before addressing air quality: keeping sick people out of their space; enforcing distancing and mask-wearing; and emphasizing cleaning and hygiene.

“It’s important to realize that if we want to throw money at filters and everything, it’s not going to matter if we don’t do those first three things,” Gupta said. “People should not rely on it as a quick fix.”

Ways to improve air quality include humidity control, boosting the amount of outside air flowing into buildings, improving ventilation in areas such as bathrooms and cafeterias, and upgrading air filters to capture smaller particles.

There also are technologies such as ultraviolet light in air ducts, and filtration systems such as bipolar ionization and non-thermal plasma to help capture contaminants.

“It’s a bit of a wild west landscape out there when it comes to air cleaning,” said IIT’s Stephens. “You don’t know whether you’re buying snake oil or what. “It’s buyer beware for building engineers. They need to do their due diligence.”

That includes evaluating the cost, said Sudesh Saraf of architecture firm Wight & Co., who leads the firm’s engineering group that focuses on mechanical, electrical and plumbing systems.

Wight recently invested about $45,000 to add bipolar ionization systems and other improvements in its Darien and downtown Chicago offices, Saraf said.

The firm’s clients include several schools and municipal buildings, as well as private-sector clients. All of them are trying to weather the financial impacts of the pandemic.

“This thing has hit our clients at a time when they can ill afford it, from a money standpoint,” Saraf said.

Riverside Investment & Development, a developer of some of Chicago’s highest-rent office towers, said it has received far more questions about air quality from tenants and prospective tenants in recent months than it ever did before the pandemic.

One tenant submitted six pages of questions, according to Riverside. In response to COVID-19, the firm is making more than $1 million in upgrades to air flow in the trophy office tower at 150 N. Riverside Plaza, a building completed in 2017.

Riverside also is bolstering its ventilation systems at the nearly completed Bank of America Tower at 110 N. Wacker Drive on the Chicago River, and in the recently begun BMO Tower next to Union Station, according to CEO John O’Donnell.

The developer is working with ESD and a spinoff of the company, smart-building technology firm Cohesion, to improve air flow and quality and limit high-touch areas. Using an app, tenants at 150 N. Riverside soon will be able to view measurements of pollutants in the building. The app will show readouts for several aspects of air quality, ranging from specific toxins in the air to ventilation and humidity levels, within a particular floor or room.

“In the post-COVID world, transparency is going to be key,” ESD’s Gupta said.

Cohesion expects its growth to come in part from increased demand for technology in buildings because of COVID-19. The firm recently announced $6.5 million in seed funding from investors including Hyde Park Angels, Citadel founder and CEO Ken Griffin and GCM Grosvenor CEO and Chairman Michael Sacks.

Cohesion in May conducted a study of more than 1,300 workers throughout the country, mostly in office buildings.

After working from home, 65% of respondents said they wanted to return to their office sooner rather than later, while just 8% hoped to continue remote working indefinitely. Only 20% of the workers surveyed said they thought regularly about air quality or the overall health of people in their building before the pandemic, but more than 80% said they expected to do so in the future.

Protecting and reassuring office tenants will be one of the biggest tests for office landlords since the 2001 terrorist attacks stoked fears of working in skyscrapers and led to extensive security measures, said Chicago real estate veteran Bob Wislow.

“This is a really big challenge, just like Sept. 11 was a challenge for tall buildings,” Wislow said. “We learned how to secure and manage those buildings in a way that regained the trust of the public.

“As an industry, we have to work our tails off to regain everyone’s confidence during a pandemic. And I think the real estate industry is doing that.”

Wislow is chairman of Parkside Realty, developer of the 12-story Fulton East office building in the Fulton Market district.

The building, which has yet to sign tenants, will be completed in August after making changes in response to the pandemic, including adding non-thermal plasma air cleaning units throughout the property, Wislow said. In such systems, ions attach themselves to pathogens, making them larger and easier to capture and kill.

Other changes included adding elevators that can be operated by foot, rather than by touching buttons with hands.

Wislow also is an owner of the space leased to the Chicago French Market within Ogilvie Transportation Center, where two wall-mounted non-thermal plasma units have been installed.

Another boutique office building, the 20-story structure at 145 S. Wells St., which opened last year, is being upgraded with an ionization and air purification system in response to the pandemic, according to developer Moceri + Roszak.

The firm is installing the same system into the 26-story Parkline Chicago condo and apartment tower, which will open next year near Millennium Park, according to principal Tom Roszak.

“The healthy building idea is going to be prevalent for everybody,” Roszak said. “I think you have to have this.”

Air cleaning also is likely to be emphasized in other types of real estate, such as hotels and retail.

James McHugh Construction Co. expects to see more hotel projects designed with outside air flowing directly into each unit, said McHugh executive vice president John Sheridan. “Post-COVID, you’ll see more and more developers pay that extra dollar per square foot to bring air directly to the unit,” he said.

The extra duct work could add hundreds of thousands of dollars to the cost of a high-rise, but such expenses may be part of doing business in 2020 and beyond.

“A lot of it is just giving people comfort that you’re doing everything you can,” said Riverside’s O’Donnell. “This particular virus will go away, but there may be mutations or other pandemics. I think this will continue to be on people’s minds, and we’re committed to keep adapting.”