Coronavirus Technology Solutions

July 20, 2020

COVID Antibodies Peak and Then Decrease

High Efficiency Filters Not Widely Used in Residences

Research Shows That Thicker Filters with MERV 13 and Higher Efficiency are Best for Indoor Air Quality Improvement

Mask Webinar August 20 will Focus on All the Issues

Respiratory Droplets from a Cough or Sneeze Travel Farther and Last Longer in Humid or Cold Climates than in Hot and Dry Ones

Drager Mask Order for UK will Generate Revenues of €100 Million

Mondi will Produce Meltblowns and Masks in Germany

DuPont will Supply Millions of Hooded Coveralls to COVID Frontline Workers in Europe

Nanhai Nanxin Wufangbu is Using Maag’s extrex6 Pressure Booster Melt Pump in its Production of Nonwovens for Face Masks

United will Maximize HEPA Filtered Air During Boarding

______________________________________________________________________________

COVID Antibodies Peak and Then Decrease

Researchers from King’s College London, Guy’s and St. Thomas’ Hospital Trust, and the University of Kent examined patients with confirmed Covid-19 infections and found that protective antibodies peaked 23 days after the onset of symptoms, on average, “and then decrease[d] 2- to 23-fold during an 18-65 day follow up period … highlighting the transient nature” of Covid-19 immunity. Those who got sicker in the first place generally had stronger immune responses, the authors found, noting that while antibody counts faded “over a 2–3 month period,” those with stronger responses “would likely have sufficient” antibody levels “to be protected from clinical illness for some time if re-exposed to SARS-CoV-2.”

High Efficiency Filters Not Widely Used in Residences

Since MERV 11 filters remove few viruses it is significant to learn that at least in 2018 they commanded the largest share of sales for one large retailer.

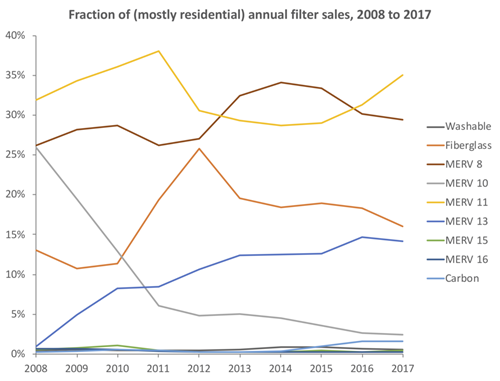

Brent Stephens of IIT was preparing analyses of the distribution of filters by efficiency, Rich Scott from Discount Filters, a major online retailer of HVAC filters, volunteered to provide some sales data. Rich and his team provided a database of over 6 million filters they have sold to (mostly) residential customers from 2008 to 2017.

You can see MERV 13 has been steadily on the rise since 2008, while the fraction of MERV 8, 11, and fiberglass (i.e. low MERV, probably less than MERV 4) filters are all fairly steady over time, albeit with some year to year variation. MERV 10 filters have been decreasing but the retailer says that has less to do with the filters themselves and more to do with production and marketing (in other words, the retailer has moved away from MERV 10 in favor of some of the other filters). Washable, MERV 16, and activated carbon filter sales were steadily low throughout the period.

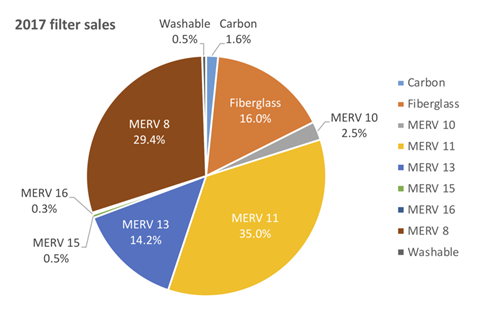

Last, let’s look at a snapshot of these same data in 2017, the most recent full year of sales in the data set.

In 2017, for this particular retailer, MERV 11 filters made up the largest share of sales at about 35%, followed by MERV 8 at about 29% of sales. Fiberglass filters were third at around 16% followed by MERV 13 filters at about 14% of sales. In fact, fewer than 15% of filters sold were MERV 13 or higher. These data suggest that at least for shoppers on this major online retail site, not that many people are using high efficiency filters in U.S. residences!

Research Shows That Thicker Filters with MERV 13 and Higher Efficiency are Best for Indoor Air Quality Improvement

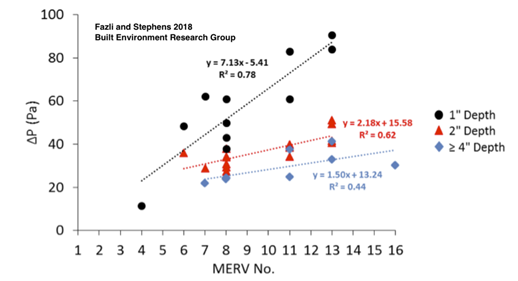

Brent Stephens of ITT has been conducting measurements of filter pressure drop, air handler flow rates (in a nominal 1000 CFM air handler with a PSC blower), and in-situ filtration efficiency for fine and ultrafine particles for a large number of commercially available filters with various manufacturer-reported ratings (e.g., MERV = minimum efficiency reporting value, FPR = filter performance rating, and MPR = micro-particle performance rating) and various depths (e.g., 1-inch, 2-inch, 4-inch, and 5-inch). Brent has now tested about 50 filters, 36 of which have had a MERV rating reported by the manufacturer. The goal was to provide data on pressure drop and MERV to help justify the proposed Title 24 changes in California. The figure below shows filter pressure drop measurements made with each of these 36 filters plotted against the manufacturer-reported MERV rating for each filter. Note that all pressure drops are measured with new (clean) filters.

From this work, previous work, and the work of several others Brent concludes the following about higher efficiency residential filters:

· PM2.5 is probably the most important indoor pollutant to control to mitigate long-term (chronic) adverse health outcomes associated with indoor pollutant exposure

· Only MERV 13 filters and above are explicitly required to have a single pass removal efficiency of at least 50% for particles smaller than 1 µm (according to ASHRAE Standard 52.2)

· Targeting removal of particles 0.3-1 µm generally increases PM2.5 removal efficiency, more so than targeting removal of 1-3 µm or 3-10 µm particles

· Therefore, MERV 13 makes sense from a public health perspective

· MERV 13 filters can have high pressure drops, particularly in the narrower 1-inch depth variety

· The energy consequences of high filter pressure drops are probably smaller than most people think, but they can still cause increased fan energy consumption in residential systems with ECM fan motors that increase fan power to maintain the same airflow rate and can cause longer system runtimes (and thus higher energy consumption) in residential systems with PSC fan motors that respond to increased pressure drop by reducing air handler flow rates and thus capacity

· Thicker depth filters — including at minimum 2-inch filters — tend to have lower pressure drops than 1-inch filters within a given MERV category

· Therefore, if one is to move to MERV 13, one should strive to accommodate deeper bed filters that should have fewer pressure drop issues

For these reasons, the data generally support the move to require MERV 13 and minimum 2-inch depth filters.

Relative to COVID it would seem that thick MERV 16 filters could be installed without increasing fan pressure drop

Mask Webinar August 20 will Focus on All the Issues

The next mask and other PPE webinar is scheduled for 10:AM CDT August 20, 2020. To register Click here

This webinar will be a high level discussion and debate relative to the issues affecting mask selection. It will expand on the previous webinars and interviews which you can see below. It will also reference the articles in the Alerts. Even if you are not a subscriber you can at least see the titles Search All Alerts by Keyword (80 articles on masks as of July 18).

|

Mask Performance |

How efficient are various masks at capturing virus particles? Do cloth masks simply become aerosol generators after stopping large cough droplets? |

|

Virus Parameters |

How big are aerosols when released initially versus after evaporation or release from surfaces? How long are viruses active and are they revived in the lungs? How many virus particles are released? What Is the minimum viral load? Do inefficient masks capture cough droplets and become aerosol generators? |

|

Mask Media Types |

Electrostatically charged meltblowns vs nanofibers and other media |

|

Mask Media Availability |

What is the availability of meltblown media worldwide as well as in specific countries? What is the availability of alternative high efficiency media? What will it take to produce 500 million masks per day? |

|

Mask Physics |

What is the importance of fit? What is the comfort and breathability for various alternatives? What about the expanded media area with respirators and or pleats? |

|

Mask Cleaning |

What are ways to decontaminate meltblowns without losing electrostatic effect? How many cleanings are possible? How are nanofiber masks cleaned and how many wearings can be achieved at acceptable performance levels? |

|

Mask Cost |

What is the cost per wearing for various mask types? |

|

COVID Nationalism |

What are the implications for adequate availability of masks in each country versus restrictive policies of some countries? |

|

Educate Public |

Mask differences for COVID protection are as great as are butcher knives and scalpels for surgery? How is this best communicated? |

|

Long Term Market |

When will the market peak? Does the use of decontamination eliminate the need for excess mask production facilities? Will the fear of viruses plus the realization of air pollution protection create a permanent market? Will vaccines provide only temporary immunity? |

You can view the previous mask webinars and interviews Click here for more information

Respiratory Droplets from a Cough or Sneeze Travel Farther and Last Longer in Humid or Cold Climates than in Hot and Dry Ones

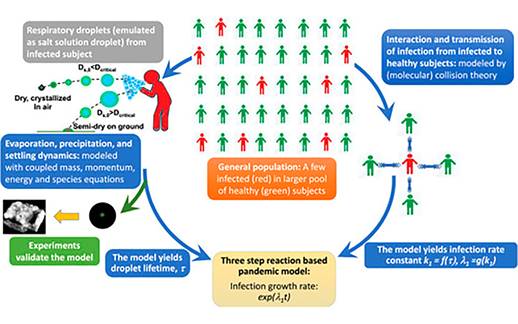

Respiratory droplets from a cough or sneeze travel farther and last longer in humid, cold climates than in hot, dry ones, according to a study on droplet physics by an international team of engineers. The researchers incorporated this understanding of the impact of environmental factors on droplet spread into a new mathematical model that can be used to predict the early spread of respiratory viruses including COVID-19, and the role of respiratory droplets in that spread.

The team developed this new model to better understand the role that droplet clouds play in the spread of respiratory viruses. Their model is the first to be based on a fundamental approach taken to study chemical reactions called collision rate theory, which looks at the interaction and collision rates of a droplet cloud exhaled by an infected person with healthy people. Their work connects population-scale human interaction with their micro-scale droplet physics results on how far and fast droplets spread, and how long they last.

Their results were published June 30 in the journal Physics of Fluids.

“The basic fundamental form of a chemical reaction is two molecules are colliding. How frequently they’re colliding will give you how fast the reaction progresses,” said Abhishek Saha, a professor of mechanical engineering at the University of California San Diego, and one of the authors of the paper. “It’s exactly the same here; how frequently healthy people are coming in contact with an infected droplet cloud can be a measure of how fast the disease can spread.”

They found that, depending on weather conditions, some respiratory droplets travel between 8 feet and 13 feet away from their source before evaporating, without even accounting for wind. This means that without masks, six feet of social distance may not be enough to keep one person’s exhalated particles from reaching someone else.

Drager Mask Order for UK will Generate Revenues of €100 Million

In connection with the COVID 19 pandemic, Dräger has received an order from the British government to deliver respiratory protection masks (FFP3). The delivery of the order will start in 2020 and will stretch until the end of 2021. The expected net sales are roughly €100 million.

For this purpose a mask production facility will be set up in the UK, in the Blyth area of Northumberland. There, Dräger has had a development and production site for respiratory protection technology for firefighters and industry for over 50 years.

This is in addition to the existing production network in Sweden and South Africa and the recently decided new production sites in France and the US. The investment in the expansion of production capacities across all five production sites will require a mid-double-digit million euro amount in the 2020 financial year.

Rainer Klug, Chief Officer of Safety Division at Dräger: "We are very pleased about the major order from the British government. It gives us the opportunity to expand our international production network for FFP masks."

"With this additional production unit, Dräger will increase volumes quickly and flexibly," Klug said. "Our international production network enables us to react very quickly and specifically to national or local requirements on the one hand, and to cover international requirements in a closely networked and flexible manner on the other. Dräger thus operates a highly responsive manufacturing system for certified FFP respiratory protection masks, with a product design originating from our own development in Germany."

Mondi will Produce Meltblowns and Masks in Germany

Mondi, global supplier of packaging and paper, is set to build new production lines in its plant in Gronau, Germany, to produce melt-blown nonwoven fabric and surgical face masks.

This move is part of Mondi's efforts to mitigate the spread of COVID-19 and respond to increased demand by health authorities, businesses and consumers for face masks.

Mondi Gronau has a proven track record of producing and handling films, laminates, nonwovens and elastic ear laminates for hygiene products. This knowledge will be applied to the entire value chain of face mask production.

Jürgen Schneider, Managing Director of Mondi Personal Care Components (PCC), said: "We are well-positioned for the increased production of face masks and melt-blown nonwoven fabric in Gronau. Our people have the needed know-how and expertise on working with these materials and the technology required. The in-house production capability of all substantial components positions us to build up a long-term competitive local supply."

Once up and running, we will be able to produce more than one million face masks per day. The production lines will produce melt-blown nonwoven fabric and surgical masks.

Given the shortage of melt-blown fabric in the market place, Mondi's plant in Gronau will offer approximately 50% of its production to other face mask manufacturers in Europe.

DuPont will Supply Millions of Hooded Coveralls to COVID Frontline Workers in Europe

DuPont, has signed a contract with the European Commission and EU countries, opening the door for countries to place orders for the delivery of millions of Tyvek® hooded coveralls to COVID-19 frontline workers across Europe. The contract allows for over 4.9 million coveralls over the next 12 months to be delivered to key workers.

One of the products offered is Tyvek 500 Xpert, category III, Type 5-B and 6-B coverall, which is designed to protect wearers against biohazards as well as liquid and particulate threats. Featuring stitched external seams, elasticated wrists, ankles, and face, it is ideally suited to protect workers in healthcare and other frontline occupations from contamination by droplets, while also providing optimal ease of movement and comfortable wear. Alternatively, if the delivery of the products is time-critical, instead of Tyvek 500 Xpert, member states can also opt to receive another type of DuPont Tyvek garment that offers similar performance and may be more readily available.

In total, the contract entitles the participating countries to order more than 8 million garments over a period of 12 months from DuPont, if demand persists and production processes allow. Since being signed in early May, the contract currently allows procurement from Austria, Belgium, Cyprus, Germany, Estonia, Greece, Croatia, Hungary, Latvia, Malta, Romania, Sweden, Slovenia, and Slovakia.

Since March, DuPont has increased its production volume and shortened its supply chain to optimize the manufacturing capacity in response to the global crisis. It has also donated 50,000 Tyvek® coveralls to help protect healthcare workers in some of the worst affected countries in Europe. The company has many years of experience in supplying protective garments during viral outbreaks, and some of its Tyvek® and Tychem® hooded coveralls have been successfully used by frontline workers during past epidemics, including Ebola and Bird Flu.

“It is vital that healthcare workers have access to PPE that they can rely on so that they can turn their full attention to the task in hand,” said Albrecht Gerland, Product Manager for DuPont Personal Protection in Europe. ”We are proud to play a part in the ongoing battle against COVID-19. As we manufacture both the fabric as well as the actual coveralls, we are well-placed to quickly respond to the current demand without disrupting the supply to our existing customers. This contract will bring our proven DuPont Tyvek technology to those most in need, and we will continue to work tirelessly to meet the European Commission’s requirements in this evolving situation.

Nanhai Nanxin Wufangbu is Using Maag’s extrex6 Pressure Booster Melt Pump in its Production of Nonwovens for Face Masks

The market for gear pumps for nonwovens will increase greatly due to the need for masks and other PPE to mitigate COVID. The installation of the extrex6 allows the fabric specialist to meet demands for high quality and produce the material more economically because the gear pump makes the processing of thermoplastic polymers more efficient. The low compression gearing of the new Maag gear pump extrex6 allows transfer, pressure-boosting and dosing applications at high pressure and with low shear stress.

The company says that in the production of nonwovens, this means a 10% higher specific flow volume relative to other pump solutions and 25% better wear resistance and sealing capability of the drive shaft seal. The cooling surface of the seal is double that of conventional pump designs. The temperature rise through the pump is 40% less, and the pulsations at the melt pump discharge are minimized with an energy saving of 12%.

The pump’s design makes it virtually maintenance-free design and its high levels of accuracy deliver benefits in long-term operation.

United will Maximize HEPA Filtered Air During Boarding

United Airlines is taking additional steps to purify the air on its planes to protect passengers from Covid-19. United “will now maximize air flow volume for all mainline aircraft high-efficiency particulate air filtration systems during the entire boarding and deplaning process,” the Chicago carrier said in a statement. “In combination with the HEPA filters, the air conditioning and pressurization system onboard United's mainline aircraft recirculates the air every two to three minutes and removes 99.97% of particles, including viruses and bacteria during both ground and air operations.” United said that makes the air on its planes “significantly” cleaner than is typical in restaurants, grocery stores, schools or “even some hospitals.” The system is due to start operating July 27. "The quality of the air, ... a strict mask policy and regularly disinfected [surfaces] are the building blocks towards preventing the spread of Covid-19 on an airplane,” said United Chief Executive Scott Kirby.