Coronavirus Technology Solutions

July 13, 2020

A Proactive

Filtration

Industry can

Vanquish COVID

and Boost

Revenues by

Hundreds of

Billions of

Dollars

Carrier White

Paper is a Guide

to Air

Conditioning and

Ventilation to

Combat COVID

Ambrust American has Delivery Problems

Microwave can

Sterilize N95

Masks

Lots of

Decontamination

Investigations

Lysol Approved

as a

Disinfectant for

COVID

Wipes Demand

Still Exceeds

Supply

OZ Health

Contracts with

Oerlikon for

Spunbond and

Meltblown Plant

U.S. Coronavirus

Deaths Rising

and Large

Numbers are

Predicted

The Relationship

Between Viral

Load and Air

Transmission

__________________________________________________________________________

A Proactive

Filtration

Industry can

Vanquish COVID

and Boost

Revenues by

Hundreds of

Billions of

Dollars

Even though

COVID travels as

small aerosols

it is not

invincible. It

is just a matter

of choosing the

right weapons.

The filtration

industry has

developed and is

improving these

weapons. If the

filtration

industry is

proactive these

weapons will be

available in the

quantity and

time frame

needed. The

evidence

continues to

mount that

asymptomatic

individuals

transmit the

virus just by

talking or

breathing. What

is needed is to

treat the COVID

space as one big

cleanroom or one

big air

pollution stack.

Semiconductor

cleanrooms and

waste to energy

plants remove

99.99 % of

particles in the

virus size

range.

If every

transmitter and

every recipient

wore a mask as

efficient as a

cleanroom or air

pollution filter

there would not

be a problem.

Back in the

1960s the major

air pollution

source was

foundry cupolas.

There were no

national

regulations. In

fact there was

no EPA. But

States passed

regulations to

prevent the

emission of the

large particles

that fell on

nearby cars and

destroyed the

paint. So an

inefficient

device called a

multi tube

cyclone was

mandated.

It worked

well.

The big

particles were

captured and the

small particles

were invisible

and

blown

down wind

into the

next State.

A cloth face

mask is the

equivalent of

the multi tube

cyclone. It is

efficient on 100

micron particles

but captures

little below 10

microns. Today

every foundry

cupola has

efficient

filters with

nonwovens or

membranes with

efficiencies

exceeding an N95

mask. By wearing

no masks or

inefficient

masks we are

blowing the

virus downwind.

Another

challenge in

operating a

foundry cupola

is fumes which

may escape

through the

charging door.

This is solved

by good

engineering

which assures a

flow of inward

air at a

velocity

sufficient to

overcome

turbulence

within the

cupola. Air

velocity and

direction are

also important

in the

transmission of

COVID.

We used foundry

cupolas as an

example. But the

challenges in a

semiconductor or

pharmaceutical

cleanroom are

much greater and

have been met

with very robust

technology

solutions. Now

is the time for

the filtration

industry to use

its capability

and take a

proactive stance

to solve the

COVID problem.

The rewards will

be immense. The

difference

between a

reactive and

proactive

program is

hundreds of

billions of

dollars of

revenue in 2021.

With a proactive

program the air

filter and room

air purifier

sales will

increase by $60

billion per

year. Mask and

respirator sales

will increase by

over $155

billion per

year.

Disinfection,

wipes,

monitoring, and

anti-microbial

coating

revenues will

increase by over

$60 billion per

year.

In the reactive

program the

decisions are

made by

governments and

researchers. In

a proactive

program the

filtration

industry becomes

a full partner

and leader. The

position by

governments that

efficient masks

were not needed

by the public

represents a

failure by the

filtration

industry to

communicate the

basic knowledge

which it has.

This basic

knowledge has

led from the

simplistic

concept of one

large

semiconductor or

pharmaceutical

cleanroom with

all the air of

the same purity

to a concept of

many

progressively

cleaner rooms

within the main

room.

The new

classifications

are more complex

and deal with

particles of

various sizes.

The older

classification

suffices as an

illustration. It

is based on

particles 0.5

micron and

larger.

Relatively clean

ambient air is

rated at class

500,000 or

500,000

particles in

each cubic foot

of air. When a

few HEPA filters

are added you

can achieve

class 100,000.

Many

semiconductor

operators opt

for lots of

class 10,000

space with class

1 space for the

most critical

operations.

Pharmaceutical

manufacturers

opt for class

10,000 general

space with class

100 space for

vial filling

operations.

Isolators

with class 1

rating are used

for the most

critical

operations. The

COVID battle

plan can use the

same concept.

The world is one

big cleanroom in

a pyramid of

smaller spaces.

Each local space

has its own more

restrictive

efficiency

criteria and

then the

individual

represents the

smallest

cleanroom within

the pyramid.

Class 500,000:

Let’s

start with the

class 500,000

cleanroom or

ambient air. The

problem is that

the ambient air

at traffic

intersections in

the cleanest

cities and the

air throughout

many cities

and even

the rural areas

in many

countries

contains many

millions of 0.5

micron particles

per cubic foot.

This is why

Germany is

supplying

ambient air

filtration

systems at some

traffic

intersections.

This is why in

India, China,

and many other

countries

efficient masks

are worn by many

citizens.

Small air

pollution

particles are

not stopped by

cloth masks. So

there is already

a large market

for efficient

masks in many

countries. The

masks which stop

small dust

particles will

also capture the

small virus

particles. In

fact research in

the Lombardy

region in Italy

as well as other

studies show

that the virus

can be attached

to air pollution

particles.

The need to

protect against

the air

pollutants will

be there long

after a vaccine

to prevent COVID

is made

available and

will be there

until the next

virus comes

along. This

means that the

filtration

industry has the

promise of a

large and

continuing

revenue stream

in the Class

500,000 space.

The individual

is the

ultimate

cleanroom within

a cleanroom. He

can change the

cleanroom class

in the air

around him with

a mask. When he

is far from

others, he may

be safe with no

mask and willing

to breathe in

the 500,000

particles with

every cubic foot

inhaled.

Class 100,000:

Many industries

making small

parts operate in

class 100,000

cleanrooms. Food

processing

plants strive to

keep general

space at this

cleanliness

level. Pork

processing

plants have

found that the

shelf life of

their product is

increased by

more than one

week if they

have cleaner air

in the

production

facilities. The

combination of

improved HVAC

and filtration

combined with

the use of

efficient masks

would eliminate

much of the

virus

transmission

presently

occurring in

these

facilities.

Partitions

without air

control can make

matters worse

not better.

The general

space in

hospitals should

be at least

class 100,000.

Hospital

acquired

infections

result in

millions of

deaths per year.

Visitors

account

for some of this

transmission.

PathO3Gen

Solutions found

that their foot

sanitizer used

by all those

entering a

hospital makes a

big difference.

Train stations,

airline

terminals,

nursing homes,

apartment

complexes,

office buildings

and other areas

of congregation

should be kept

in this class

range. The air

in many office

buildings

contains VOCs

generated from

plastic

furniture, floor

coverings etc.

Efficient masks

are needed in

these areas but

in addition

relatively pure

air should be

provided.

An N30 mask will

insure

maintenance of a

class 100,000

atmosphere but

in situations

where people

congregate the

individual

should convert

his inhaled air

to class 100

with an N95

mask.

Class 10,000:

There

have been

initiatives to

eliminate

pharmaceutical

and

semiconductor

class 10,000

space.

Since

people generate

the

contamination,

the concept was

to use isolators

and robotics and

keep people out

of the

production

space. In

practice some

human

intervention is

necessary and no

matter how well

sealed a class l

cleanroom is it

helps if it is

surrounded by

relatively clean

air.

This principle

can be applied

to COVID. Luxury

hotels are

willing

to spend lots of

money to make

their

accommodations

safe. In

addition to

requiring guests

to wear masks it

can create

general space

with class

100,000 air

purity.

Elevators, gyms,

and restrooms

can be designed

as

class

10,000 space.

In the case of

an individual

you have a

twostep process

Step 1 is

filtering out

viruses being

transmitted.

Step 2 is

filtering out

viruses being

inhaled.

Step 1 can be

the filter in an

HVAC system or

it can be a

mask. In each

case the amount

of virus inhaled

is a function of

the combined

efficiency

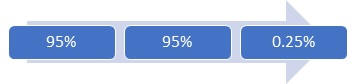

For example if

the transmitter

and recipient

each have N95

masks then the

virus inhaled by

the recipient is

only 0.25

percent.

Compare

this to the N30

mask where the

combination

results in the

recipient

inhaling 49

percent of the

virus.

A MERV

13 filter in an

HVAC system can

provide a 30

percent

reduction in

viruses or

equivalent to an

N30 Mask. So if

you have a

building with

MERV 13 filters

providing 10 or

more air changes

per hour to each

space and if

each transmitter

and recipient

wears N30 masks

the virus

level is

reduced

in three steps.

Seventy percent

is reduced in

the first step

another 21

percent reduced

in the second

step and another

15 percent in

the third step

leaving 35

percent of the

virus to be

inhaled.

Let’s take the

example of a

hotel elevator

with a HEPA

filter

delivering class

10,000 air. The

transmitter

rides to his

floor but is

wearing an N30

mask

So the

elevator air

contains only 70

percent of the

virus from the

transmitter. The

elevator HVAC

system removes

95 percent of

the virus

leaving only 3.5

percent in the

elevator when

the recipient

enters. He is

wearing an N30

mask so he

inhales only 1.2

percent of the

potential

transmission.

If a HEPA filter

is installed in

a robust HVAC

system and

laminar air flow

prevents the

transmitter from

directly

exhaling to the

recipient then

99 percent of

the virus is

captured even if

the recipient

has no mask. In

reality it is

prohibitively

expensive to

create a space

with the ceiling

covered with

HEPA filters

discharging at

100 fpm and air

return systems

below a

perforated

floor. So some

air will flow

from transmitter

to recipient

without being

first filtered.

So the recipient

will be

contaminated by

the general

viral load plus

any virus

from a

transmitter

circumventing

the HVAC system.

Class 1000 to

Class 1: Drug

preparation

areas of

hospitals are

often designed

for class 1000

but with class

100 enclosures

around actual

filling

operations.

Isolation rooms

in hospitals are

designed to be

class 100 but

also to be under

negative

pressure.

The decision to

invest in a

class 10 or

class 1 space is

a function of

risks to

products or

people. When

applying

this to

COVID it is a

consideration of

risk to the

general

population as

opposed to the

risks to a

specific

individual. N30

masks may be

sufficient to

reduce the

number of cases

in the general

population. But

if the new cases

are 100 today

and 99 tomorrow

it is not

positive news

for the 99. If

by wearing N95

masks the new

cases drop from

100 to 5 this is

very positive

for 95

individuals.

The weapons to

fight COVID are

reduced levels

of virus in the

local space plus

reduction from

individual

transmitters and

efficient

elimination of

viruses by the

inhaling

recipient. Every

cleanroom

operator would

prefer to

operate in a

class 1 space

but the cost

exceeds the

value in most

cases. So there

is always a

risk. Whether it

is

pharmaceutical

products, chips,

or individuals

the risk and

rewards need to

be analyzed and

the proper level

of investment

made.

Information on Coronavirus Technology Solutions is found at: http://home.mcilvainecompany.com/index.php/markets/air/82ai-coronavirus-market-intelligence

Information on

relevant market

reports is found

at

www.mcilvainecompany.com

and then

click on

markets.

Carrier White

Paper is a Guide

to Air

Conditioning and

Ventilation to

Combat COVID

Carrier has published a white paper

relative to

COVID and

air

conditioning. It

reviews

the Chinese

restaurant

incident which

has been covered

in previous

Alerts. It makes

the point that

air distribution

was the culprit

and not the use

of AC. It

cites no

trace of virus

on the AC

duct. On

the other hand

other studies

show deposits in

HVAC systems. In

fact Carrier has

anti-microbial

coatings

for duct

interiors. Also

since Carrier is

now offering

HEPA filtered

room air

purifiers for

schools and

other gathering

places, the

value of high

efficiency

filtration is

communicated.

Here is a

summary and link

to the white

paper.

ASHRAE guidelines point to an upper limit

of air velocity

in the occupied

space of 40 fpm.

To achieve this

condition, the

air needs to be

properly blown

by the HVAC

system into the

room, and

properly

distributed in

the occupied

space.

A generation of research and experience

has proven that

when properly

maintained and

operated,

heating,

ventilation and

air-conditioning

systems (HVAC)

can reduce the

spread of

viruses. These

critical

building systems

not only provide

thermal comfort

but, according

to the American

Society of

Heating,

Refrigerating

and Air

Conditioning

Engineers

(ASHRAE), may

also improve

resistance to

infection.

HVAC systems work in a built environment

to supply

comfortable,

clean,

recaptured air,

mix in healthy

levels of fresh

air, and contain

or exhaust

contaminants.

Air delivery

systems can

reduce the

transmission of

viruses through

inline

filtration,

something HVAC

professionals

are capable of

assessing.

Air-conditioning

systems are also

critical in

maintaining

healthy humidity

levels.

“Maintaining a

RH (relative

humidity)

between 40% and

60% indoors may

help to limit

the spread and

survival of

SARS-CoV-2

within the BE,”

the ASM

suggests, “while

minimizing the

risk of mold

growth and

maintaining

hydrated and

intact mucosal

barriers of

human

occupants.” The

Centers for

Disease Control

(CDC) echoes

these findings,

saying that

employers can

decrease the

spread of

COVID-19 by

maintaining a

healthy work

environment.

“Consider

improving and

engineering

controls using

the building

ventilation

system,” the CDC

suggests,

including

increased

ventilation

rates and

increased

percentage of

outdoor air

circulating

through the

system. Well

before COVID-19,

the Healthy

Building

Movement had

begun to measure

and improve air

quality in the

built

environment to

improve

productivity and

health. Of the

nine foundations

for a healthy

building, five

relate to HVAC,

including air

quality,

ventilation,

thermal health,

moisture, dust

and pests.

“There’s just no

reason anymore

to economize on

airflow and

filtration,”

Harvard Business

School’s John

Macomber says.

“It’s a cheap

way to help

people be

healthier.

To ensure the proper indoor air purity, a

good HVAC system

should include

some or all of

the following:

1. (Demand Controlled) Ventilation: When

outside air is

not provided via

separate

devices, the

HVAC system

should provide

outside air

based on the

size/use of the

space. Where

possible, the

HVAC system

should include a

sensor for

carbon dioxide

or other

pollutants to

calculate and

correct in real

time the amount

of ventilation

needed. It is

important to be

aware that the

increase of the

ventilation rate

may cause an

increase of

load, and the

HVAC unit, if

not properly

sized, may not

be able to

provide

sufficient

cooling

capacity. In

such situations,

it may be

appropriate to

consider Direct

Outdoor Air

Supply (DOAS)

units, which are

specifically

designed for

large amounts of

outside air.

2.

Filtration:

Filters are

rated on their

ability to

capture and

retain particles

of different

sizes. The

industry

standard is a

Minimum

Efficiency

Reporting Value

(MERV) rating.

Filters with

MERV >13 have a

significant

ability to

capture

particulate

matter (PM) and

smaller

particles. HEPA

filters are even

more efficient

and are able to

capture bacteria

and viruses.

Note that there

are important

tradeoffs to

consider: the

higher the

filtration

requirements,

the greater the

air pressure

drop and the

size of the

filter. For this

reason, the air

management

system of the

HVAC needs to be

carefully sized

based on the

filtration

requirements.

3. Other Indoor Air Quality Devices:

Numerous

technologies are

available to

reduce the

presence of

contaminants.

Ultraviolet

lights,

ultraviolet

photocatalytic

oxidation,

ionization,

plasma,

electrostatic

active, active

carbon and other

components can

be installed to

specifically

target volatile

organic

compounds (VOC),

bacteria and

viruses. Some of

these options

can be available

as integral

parts of the

HVAC system.

https://www.shareddocs.com/hvac/docs/1001/Public/02/COVID-19-WHITE-PAPER.pdf

Ambrust American has Delivery Problems

Friday, we reported on the big Texas

school order for

the company. The

company has also

offered masks to

the public but

had

delivery

problems.

Lloyd Armbrust,

the founder

said, “ we set

up a website

really fast, and

we just made so

many mistakes.”

Armbrust tells

KXAN there were

logistical and

technical

problems that

led to shipping

delays. That’s

in addition to

the large number

of orders the

company received

for masks.

Armbrust says

he set an order

limit of one

purchase per

customer, but

not on the total

volume of orders

received. The

company received

1.6 million

orders in the

week after the

KXAN

story

aired.

In a sense,

Armbrust

American began

suffering from

its own success.

“I didn’t

really

appreciate the

amount of effort

that it takes

for something to

arrive magically

on my doorstep,”

he said.

Bonnie Bryce

was one of the

customers who

watched the

story, and

ordered 50 masks

from the

company.

“I’m 67 years

old and I had

heart surgery in

February,” she

told us over the

phone Tuesday.

“So my

cardiologist

advised me to be

diligent about

wearing a mask.”

After placing

her order on May

20, she received

a confirmation

email, but

nothing after

that.

Many customers

have found

themselves in a

similar

situation. KXAN

received a

number of

concerns from

people, asking

about the

company and when

they would get

their masks.

Still more

people reached

out to Armbrust

American

directly. We

found a number

of negative

reviews and

posts about the

delays on social

media.

“I thought

maybe he got

overwhelmed a

little bit,”

said Bryce.

After our

interview

Tuesday,

Armbrust

informed us that

Bryce’s order

was shipped,

with a few extra

masks thrown in.

Ultimately,

millions of

masks had been

sitting in the

factory the

entire time.

The company’s

automated

machines can

make 100 masks a

minute. The

delays instead

came with

packing, sealing

and shipping.

Armbrust

explained that

automated

machines cannot

seal and pack

the masks

without bending

them. Therefore,

people have to

do it.

He says it

used to take 10

minutes to box

up 50 masks, but

the company is

now able to do

it in 30

seconds.

Armbrust says

the original

promise was to

ship the masks

to customers one

week after

they’d placed

the order.

He realized

quickly he

wouldn’t be able

to make that

deadline, due to

the huge demand.

He says he sent

a video out to customers explaining

the situation

late last month

but believes

many people

didn’t get the

message.

“I think the

lesson is, when

you start a

company, you

need to make

sure you have

your supply

chain ironed out

before you go on

television,”

said Bryce.

Armbrust

agrees.

“I’d say the

biggest thing I

learned was

setting the

proper

expectations for

people, and to

really

understand the

entire picture,”

he said.

The company is

trying to catch

up now. Armbrust

says he is

prioritizing

orders for

healthcare

workers and

people more

vulnerable to

COVID-19, which

is caused by the

coronavirus.

He added that

all orders out

of Texas would

be shipped out

this week, but

also understands

if people cancel

their order.

Over the last

couple of weeks,

the only option

has been to

pre-order masks,

while the

company catches

up. Those orders

were to go out

starting July 1.

Microwave can

Sterilize N95

Masks

A recent

study from

the American

Society for

Microbiology

offers a new

decontamination

tool that is

much more

accessible and

affordable: a

microwave. Researcher James E. Kirby, MD, from the Beth

Israel Deaconess

Medical Center

of Harvard says

the study’s

findings are

crucial to the

many health care

centers that

lack the

high-capacity

sterilization

systems of large

hospitals.

“We knew there was a critical shortage of personal

protective gear

and N95 masks,

and we knew

there was a need

for a solution,”

he says.

The team of eight researchers set out to provide

an easy

disinfection

method to

different health

care settings

including

“outpatient

practices,

frontline

providers, and

remote clinical

settings.”

“The goal of this work was to identify a widely

accessible,

microwave-generated

steam

decontamination

method,” the

article says.

“To this effect,

we utilized only

common household

items.”

The materials include water, a glass container,

mesh, a rubber

band, and a

1,100- or

1,150-watt

microwave. The

researchers

filled the

container with

60 milliliters

of water, then

secured the mesh

material over

the top of it

with a rubber

band. They then

placed the N95

mask on the mesh

and microwaved

it for 3

minutes. This

effectively

killed all

viruses,

including

coronavirus,

they say.

“It’s simple, but sometimes very simple things

work well,”

Kirby says.

The researchers found that this sterilization

method could be

repeated 20

times on a

single N95 mask

without

damage. Even

though the type

of mask they

used had a metal

piece, they

didn’t have an

issue with it

heating or

sparking during

the 20 cycles of

testing, Kirby

said.

Though the study was done with health care

settings in

mind, Kirby

doesn’t see the

harm in trying

the same method

at home.

A recent USA

Today opinion

piece by

ICU specialists

Pierre Kory, MD,

and Paul H.

Mayo, MD,

reinforces the

importance of

N95s as

coronavirus

rates increase.

Their stance is

grounded on

emerging

evidence showing

that coronavirus

may be

transmitted via

aerosol

droplets.

“The only mask that can prevent aerosol-size

droplet

inhalation is an

N95,” the

authors say.

Due to the shortage of N95s available to health

care workers,

many people are

wearing cloth

masks, which can

be

decontaminated

in the washer.

But more people

may turn to N95

masks as more

research emerges

about the pandemic’s transmission.

Lots of

Decontamination

Investigations

Bloomberg has

summarized a

number of

investigations

into mask

decontamination.

Richard Peltier,

an aerosol

chemist and

associate

professor at the

University of

Massachusetts-Amherst,

is researching

the

effectiveness of

different

decontamination

methods and how

many cycles a

mask can go

through before

its filtering

abilities drop

below the N95

respirator’s

required

threshold. The

research is

funded by the

National Science

Foundation.

To meet the

government’s N95

designation, a

mask must filter

out at least 95%

of particles

that are 300

nanometers or

larger—enough to

trap a single

coronavirus.

Peltier said he

first started

looking at

whether a

decontaminated

N95 mask

continued to be

effective at the

request of a

local hospital

that was

considering

exposing masks

to a

gas—vaporized

hydrogen

peroxide—a

process often

used to

sterilize

medical

equipment.

Using a device

that measures

whether an N95

mask is

filtering out

the microscopic

particles,

Peltier said he

confirmed the

mask was still

functioning

after one

decontamination

cycle.

That led to the

NSF project

where Peltier

evaluated masks

that had gone

through the

vaporized

hydrogen

peroxide process

or several other

decontamination

methods through

up to 10 cycles.

The study is

undergoing peer

review, Peltier

said, and he

can’t yet

discuss his

conclusions.

However, he did

say some

sterilization

methods did

lower masks’

effectiveness

below the N95

threshold.

Companies

manufacturing

N95 respirators

and performing

the

decontamination

work also have

been looking at

the

effectiveness of

N95 masks after

multiple

sterilizations.

Dr. Nikki

McCullough, a

health and

occupational

safety leader in

3M’s Personal

Safety Division,

said 3M has

evaluated some

of its masks

after

decontamination

to determine

through how many

cycles a mask

stays effective.

3M has approved

masks going

through up to 20

cycles. The

limits are

updated

regularly in a bulletin 3M

publishes.

McCullough

cautioned that

other factors

must be

considered on

whether a mask

is still

protective. “The

number of cycles

that a

particular

respirator will

withstand will

depend on how

many times it

has been donned,

stored and

duration and

conditions of

use,” she said.

If a user can’t

get the mask to

form a proper

seal on the

user’s face, the

mask shouldn’t

be worn,

McCullough said.

The Centers for

Disease Control

and Prevention

published guidance for

the maximum

number of times

N95 masks can be

sterilized using

a wide range of

methods from

steam heat

generated inside

a microwave oven

to exposing the

masks to

ultraviolet

light.

The largest

decontamination

effort is

overseen by

Battelle

Memorial

Institute, an

Ohio nonprofit

company.

Will Richter, a

microbiologist

and principal

research

scientist with

Battelle, said

the company has

decontaminated

about 1.2

million N95

masks at centers

across the

nation.

In April,

Battelle was

awarded a

contract from

the Defense

Department,

worth up to $415

million, to open

and operate 60

decontamination

centers that

would sterilize

respirators sent

by health-care

providers.

Richter said

Battelle found

that 20

different models

of N95 mask, and

10 foreign-made

masks, remain

effective

through 20

cycles. The

company has also

cooperated with

3M and the CDC’s

National

Institute for

Occupational

Safety and

Health to

evaluate the

Battelle system.

Battelle’s

systems use

vaporized

hydrogen

peroxide. Each

system can

sterilize about

5,000 masks at a

time in a

process that

takes about 24

hours, Richter

said.

While the CDC

has approved

Battelle’s

methods for up

to 20

sterilization

cycles, Richter

said, the

company has its

own quality

controls. Masks

that are

stained, often

from makeup, or

otherwise appear

soiled, aren’t

processed. Also

pulled out are

masks with

apparent

material flaws

such as broken

straps.

After a batch of

masks has been

decontaminated

and “air washed”

to allow

residual gas to

dissipate,

workers use gas

detectors to

determine if the

amount of

hydrogen

peroxide gas is

below the OSHA

permissible

exposure limit,

Richter said.

The OSHA limit

is 1.0 parts per

million, but

Battelle

enforces a

stricter limit,

0.8 parts per

million.

Of the 1.2

million masks

Battelle has

processed and

returned, the

company has

received

complaints about

fewer than 0.5%

of the masks,

Richter said.

https://news.bloomberglaw.com/safety/decontaminating-covid-19-masks-raises-safety-efficacy-concerns

Lysol Approved

as a

Disinfectant for

COVID

Lysol is the

first surface

disinfectant

approved by the

Environmental

Protection

Agency to wipe

out the

coronavirus.

Two versions of

the common

household

disinfectant

spray were lab

tested by the

agency, which

found they could

kill the virus

on surfaces, the

EPA

announced. Lysol

Disinfectant

Spray, priced

at $4.18 at

Walmart,

and Lysol

Disinfectant Max

Cover Mist, priced

at $5.48,

can kill the

virus in under 2

minutes, the

agency found.

"The EPA's

approval

recognizes that

using Lysol

Disinfectant

Spray can help

to prevent the

spread of

COVID-19 on

hard, non-porous

surfaces," said

Rahul

Kadyan, executive

vice president

of hygiene for

Lysol's parent

company Reckitt

Benckiser in a

statement.

"In the face of

the pandemic,

Lysol continues

to work with a

wide range of

scientific and

health experts

to educate the

public on the

importance of

hygiene.

In March, the

EPA released a lengthy list of

household

cleaners that

were expected to

be effective

against

coronavirus

because they

have been tested

and proven to

work against

similar viruses.

The news sent

the products

flying off

shelves, leading

to shortages at

many local

grocery stores.

Many

supermarkets

still limit the

number of

cleaning

supplies people

can buy to cut

down on

hoarding. Supply

chain experts

previously told

USA TODAY that manufacturers like Lysol and Clorox weren't ready for

a flood of

Americans

suddenly

shopping for

disinfectant.

Wipes Demand

Still Exceeds

Supply

“This is

unprecedented

demand in modern

times for

products like

disinfecting

wipes,” says

Brian Sansoni,

senior vice

president,

Communications,

Outreach &

Membership for The

American

Cleaning

Institute (ACI),

a U.S.-based

trade

association for

the cleaning

products

industry.

“Manufacturers

have been

working around

the clock as

they are able to

get as many

workers in

there—working

safely as well,

as the safety of

the workforce is

paramount.”

Based on reports

and analysis

from

manufacturers,

the ACI

estimates that

consumers will

begin to see a

more regular

supply of

products like

disinfectant

wipes in

mid-summer.

Major

manufacturers of

disinfectants

and disinfectant

wipes weren’t

quite prepared

for such high

demand this time

of year.

On The

Clorox Company’s

earnings call

last month,

chairman and CEO

Benno Dorer

reported that

the company had

all-time record

shipments of

Clorox

disinfecting

wipes, cleanup

disinfecting

spray,

disinfecting

bathroom cleaner

and Scentiva

products. Demand

for some

disinfectant

products spiked

more than 500%.

“Demand has been

clearly

unprecedented,”

he said.

Dorer told

analysts that

the company has

been able to

increase

production of

disinfecting

products by 40%.

It’s now

focusing on

fewer SKUs;

production of

its line of

Clorox

compostable

cleaning wipes

is on hold for

now in order to

prioritize

disinfecting

wipes.

Clorox has also

activated

third-party

suppliers to

help it cope

with the surge

in demand. “We

continue to find

new ways to

increase our

capacity,” he

added.

In terms of

availability,

Dorer told

Yahoo! Finance

last month that

there will be

substantial

improvements in

supply this

summer. “It’s

going to be

touch and go

until then,

unfortunately.

But help is on

the way, and I

think things

should ease up

in the next few

months

To alleviate

shortages caused

by consumer

stockpiling,

wipes

manufacturers

have been

working as

quickly and

safely as

possible to

crank up

capacity.

“Companies

certainly ramped

up production to

meet the demand,

while retailers

have been

seeking to

normalize the

supply situation

by restricting

purchases per

customer,” says

Svetlana

Uduslivaia, head

of Home and Tech

Americas at

Euromonitor

International.

“As stay-at-home

restrictions

ease and some of

the at-home

consumption

normalizes,

coupled with

ramped up

production, the

situation will

likely normalize

in retail.”

OZ Health

Contracts with

Oerlikon for

Spunbond and

Meltblown Plant

OZ Health Plus

will establish

Australia’s

first

manufacturing

plant to make

the critical

fine plastic

material used in

most protective

face masks. OZ

Health Plus has

purchased a

plant of the

Swiss-based

technology

company Oerlikon to

establish a

Queensland-based

production plant

for spunbond and

meltblown

nonwovens. These

fabrics are

essential for

Australia’s face

mask

manufacturers,

who currently

produce about

500 million

medical and

industrial masks

per year.

However the

fabrics have to

be imported from

overseas and

access to these

materials has

been severely

disrupted during

the COVID-19

pandemic.

Oerlikon’s

German-based

business unit

Oerlikon

Nonwoven has now

executed legal

and commercial

arrangements to

supply the

specialized

machinery which

can manufacture

the nonwoven

material

locally. The

same machinery

is used to make

almost all face

masks material

manufactured in

Europe. The

world-leading

Oerlikon

Nonwoven

meltblown plant

will commence

operations in

April next year,

with a second

stage planned

for late 2021.

The Oerlikon

Nonwoven plant

can produce

meltblown

fabrics for 500

million masks

per year, along

with other

medical and

non-medical

grade products,

filtration

products,

sanitary items,

antiseptic wipes

and more. Rainer

Straub, head of

Oerlikon

Nonwoven, says:

“We are very

proud that we

can now for the

first time

supply our

Oerlikon

Nonwoven

meltblown

technology to

Australia. Due

to the short

delivery time,

we hope to make

our contribution

to the

Australian

population and

their safe

supply of

high-quality

protective masks

as soon as

possible.”

OZ Health Plus

director Darren

Fooks says:

“Australia has

access to raw

polypropylene

feedstock but

lacks the plant

to convert that

raw material to

specialized

spunbond and

meltblown

fabrics. These

fabrics are

essential for

local mask

manufacturing.

The Australian-

based Oerlikon

Nonwoven plant

will fill the

production chain

gap for

Australia by

producing the

fabrics we need

for mask

production and

many other

products – it

will reduce

Australia’s

protective mask

supply chain

from thousands

of kilometers,

to tens of

kilometers.”

“Our decision in

favor of

Oerlikon

Nonwoven was a

given once we

had analyzed the

material

samples. It was

a matter of

course for us

that the

Business Unit of

the Oerlikon

Manmade Fibers

segment could

supply

high-quality

machines and

systems,” adds

Fooks.

OZ Health Plus’

new facilities

will take up

15,000 m2 of

manufacturing

space and will

employ 100

full-time roles

once the second

stage of the

project is

complete. OZ

Health Plus

continues to

work with both

Queensland and

Federal

Government

stakeholders and

values their

support in

bringing this

vital capability

to Queensland.

U.S. Coronavirus

Deaths Rising

and Large

Numbers are

Predicted

A long-expected

upturn in U.S.

coronavirus

deaths has

begun, driven by

fatalities in

states in the

South and West,

according to

data on the

pandemic.

The number of

deaths per day

from the virus

had been falling

for months, and

even remained

down as states

like Florida and

Texas saw

explosions in

cases and

hospitalizations

— and reported

daily U.S.

infections broke

records several

times in recent

days.

Scientists

warned it

wouldn’t last. A

coronavirus

death, when it

occurs,

typically comes

several weeks

after a person

is first

infected. And

experts

predicted states

that saw

increases in

cases and

hospitalizations

would, at some

point, see

deaths rise too.

Now that’s

happening.

“It’s

consistently

picking up. And

it’s picking up

at the time

you’d expect it

to,” said

William Hanage,

a Harvard

University

infectious

diseases

researcher.

According to an

Associated Press

analysis of data

from Johns

Hopkins

University, the

seven-day

rolling average

for daily

reported deaths

in the U.S. has

increased from

578 two weeks

ago to 664 on

July 10 — still

well below the

heights hit in

April. Daily

reported deaths

increased in 27

states over that

time period, but

the majority of

those states are

averaging under

15 new deaths

per day. A

smaller group of

states has been

driving the

nationwide

increase in

deaths.

California is

averaging 91

reported deaths

per day while

Texas is close

behind with 66,

but Florida,

Arizona,

Illinois, New

Jersey and South

Carolina also

saw sizable

rises. New

Jersey’s recent

jump is thought

to be partially

attributable to

its less

frequent

reporting of

probable deaths.

The virus has

killed more than

130,000 people

in the U.S. and

more than a

half-million

worldwide,

according to

Johns Hopkins

University,

though the true

numbers are

believed to be

higher.

Deaths first

began mounting

in the U.S. in

March. About two

dozen deaths

were being

reported daily

in the middle of

that month. By

late in the

month, hundreds

were being

reported each

day, and in

April thousands.

Most happened in

New York, New

Jersey and

elsewhere in the

Northeast.

Deaths were so

high there

because it was a

new virus

tearing through

a densely

populated area,

and it quickly

swept through

vulnerable

groups of people

in nursing homes

and other

places, said

Perry Halkitis,

the dean of the

Rutgers

University

School of Public

Health in New

Jersey.

Many of the

infections

occurred before

government

officials

imposed

stay-at-home

orders and other

social-distancing

measures. The

daily death toll

started falling

in mid-April —

and continued to

fall until about

a week ago.

Researchers now

expect deaths to

rise for at

least some

weeks, but some

think the count

probably will

not go up as

dramatically as

it did in the

spring — for

several reasons.

First, testing

was extremely

limited early in

the pandemic,

and it’s become

clear that

unrecognized

infections were

spreading on

subways, in

nursing homes

and in other

public places

before anyone

knew exactly

what was going

on. Now testing

is more

widespread, and

the magnitude of

outbreaks is

becoming better

understood.

Second, many

people’s health

behaviors have

changed, with

mask-wearing

becoming more

common in some

places. Although

there is no

vaccine yet,

hospitals are

also getting

better at

treating

patients.

Another factor,

tragically, is

that deadly new

viruses often

tear through

vulnerable

populations

first, such as

the elderly and

people already

weakened by

other health

conditions. That

means that, in

the Northeast at

least, “many of

the vulnerable

people have

already died,”

Halkitis said.

Now, the U.S. is

likely in for “a

much longer,

slower burn,”

Hanage, the

Harvard

researcher,

said. “We’re not

going to see as

many deaths (as

in the spring).

But we’re going

to see a total

number of

deaths, which is

going to be

large.”

The Relationship

Between Viral

Load and Air

Transmission

According to MIT

one of the

biggest

questions we

still have about

covid-19 is how

much of a viral

load is needed

to cause

infection. The

answer changes

if we think it

is aerosols that

we need to worry

about. Smaller

particles won’t

carry as large a

viral load as

bigger ones, but

because they can

linger in the

air for much

longer, it may

not

matter—they’ll

build up in

larger

concentrations

and get

distributed more

widely the

longer an

infected person

is around to

expel

aerosolized

virus.

The more people

you have coming

in and out of an

indoor space,

the more likely

it is that

someone who is

infected will

show up. The

longer those

infected

individuals

spend in that

space, the

higher the

concentration of

virus in the air

over time. This

is particularly

bad news for

spaces where

people

congregate for

hours on end,

like

restaurants,

bars, offices,

classrooms, and

churches.

Airborne

transmission

doesn’t

necessarily mean

these places

must stay closed

(although that

would be ideal).

But wiping down

surfaces with

disinfectant,

and having

everyone wear

masks, won’t be

enough. To

safely reopen,

these spots will

not just need to

reduce the

number of people

allowed inside

at any given

moment; they

will also need

to reduce the

amount of time

those people

spend there.

Increasing

social

distancing

beyond six feet

would also help

keep people

safer.

Ventilation

needs to be a

higher priority

too. This is

going to be a

big problem for

older buildings

that usually

have worse

ventilation

systems, and

areas with a lot

of those might

need to remain

closed for much

longer. The

impact of asymptomatic spread (transmission

by people who

don’t feel ill)

and superspreaders only

compounds the

problem even

further. But research conducted by the US

Department of

Homeland

Security has

shown that in

the presence of

UV light,

aerosolized

particles of the

size the Tulane

researchers

studied would

disappear in

less than a

minute. A number of businesses have

begun deploying

UV-armed robots

to disinfect

hospital rooms,

shopping malls,

stores, public

transit

stations, and

more.

For many places,

considerable

delays in

economic

reopening might

ultimately be

the price of

getting the

virus under

control.

Otherwise the

kind of thing

that happened

when a single

open bar in

Michigan led

to an outbreak

of more than 170

new cases could

become

commonplace.

This article in

the MIT

Review also

documents the

evidence that

the virus is

airborne and

points out that

inefficient

masks which are

not tight

fitting are not

going to prevent

transmission of

these small

aerosols.

The

authors

therefore

recommend

distancing and

other

non-filtration

initiatives.

McIlvaine

asks the

question why

doesn’t everyone

just wear a mask

which will

capture these

small particles?