Coronavirus Technology Solutions

July 10, 2020

Interview with

Nathaniel Nance

on Holistic

Solution for

COVID

Armbrust

American will

Supply Millions

of Masks to

Texas School

Teachers

Precise Tooling

has Mobile

Transparent

Partition for

Schools

H&V has New

Material for

Medical Gowns

PPE is Again in

Short Supply in

the U.S

Carrier Now has

a 1500 CFM Room

Purifier for

Schools

__________________________________________________________________________

Interview with

Nathaniel Nance

on Holistic

Solution for

COVID

Nathaniel Nance

is now AAF

Flanders

Vice President

of Global

R&D-HVAC

Nathaniel has

been with AAF

Flanders since

2008.

Prior to joining

AAF Flanders, he

held various

positions in

media

manufacturing

companies,

including

product

engineering,

process

engineering, and

research and

development for

microglass and

synthetic media.

Nathaniel holds

a M.S. in

Industrial

Engineering from

Auburn

University.

Nathaniel was

interviewed by

Bob McIlvaine

and Ross Ardell

from the

McIlvaine

Company.

Nathaniel

espouses a

holistic concept

which encourages

collaboration

among filtration

experts,

universities,

HVAC companies,

contractors,

regulators and

local

governments to

mitigate COVID

and improve the

air we breathe.

He points out

that a glass of

dirty air and a

glass of clean

air look the

same. What we do

not see are the

range of

pollutants which

exist. COVID

adds to the

challenge. There

are good, better

and best filter

options at every

efficiency

level. The best

have the lowest

energy

consumption and

longest life.

Membranes have

efficiency and

strength

advantages over

micro fiber

glass. He calls

for a city wide

filtration

concept to

harness the

local winds. As

part of Daikin,

the largest air

conditioning

company in the

world, AAF

Flanders is in a

unique position

to provide

holistic

answers.

The early part

of discussion

focused on

comments

Nathaniel made

in an IFN

article.

Nathaniel

states that the

key to any

drivers of

change in this

industry should

be a mindset

change of the

entire industry.

The industry is

currently

disjointed

between

filtration

experts,

universities,

HVAC companies,

contractors,

regulators and

local

governments.

The future of

filtration that

will evolve from

this is these

groups coming

together to

design, develop,

and deliver real

solutions.

Bob McIlvaine

added to this

analysis by

commenting that

it is time for

the filter and

HVAC companies

to take the

lead. The

universities and

regulators have

done their best

but without the

knowledge about

fine particles

and air flow

some highly

questionable

recommendations

on masks and

partitions are

being offered.

Nathaniel says

the entire world

is coming

together in this

time of crisis

to develop

innovative

solutions in the

face of critical

shortages of

crucial

materials from

facemasks to

gowns to gloves.

These are

collaborative

filtration

solutions for

focused areas,

and this will be

expanded to a

broader scope of

the filtration

world. The what,

how, when, and

why of what

makes a filter a

filter will be

reevaluated.

Nathaniel points

out that Daikin

is uniquely

capable as the

world’s largest

air conditioning

company as well

as with its

leading position

in HVAC,

industrial and

cleanroom air

filtration.

Nathaniel

believes these

changes to

collaborations

will lead to

broader focused

solutions. This

will be

everything from

passive and

on-demand

filtration in

hospitals and

commercial

buildings, where

levels of

filtration are

selected and

monitored in

real time, to

better

filtration in

the home for

split systems,

AHUs (Air

Handling Units),

and room air

cleaners. All

these will be

held to a

standard that

confirms

performance of

the system for

the application,

not just a

component-level

qualification.

This will

require

technology

development to

see the problem

and monitor the

solution from

sensors and

filter design

changes, to

system revamps

that allow the

consumer to

select the level

of filtration

desired or

required.

The indication

of this change

will be the

increased

reliance and

public agreement

on age old

principles

sorely forgotten

and cast aside,

such as proper

gasketing to

seal the system,

solution by

dilution,

charged

principles vs.

mechanical

filtration, and

what is the true

performance in

the real system.

The products

that will come

from this

exercise will

range from

simple to

complex, but

what is clear is

the future is

bright for the

filtration

industry.

For instance, a

system that has

technology

integration to

the point where

the fans,

humidity, UV,

recirculation,

and filters are

adjusted to a

virus capture

mode where

maximum airflow

and filtration

is reached until

biosensors

within the

system determine

the

predetermined

air quality is

reached. Filters

that can change

performance on

demand to

provide energy

savings in clean

environments and

critical

protection.

Diagrams of fan

filter units

above a cashier

and checkout

line were

displayed as

Nathaniel

emphasized the

importance of

controlled air

flow and

filtration.

AAF has good,

better, and best

filters for each

efficiency

range. The best

have the lowest

energy and

longest life.

Gas phase

filters use

activated carbon

or potassium

permanganate.

AAF believes in

barrier

filtration and

does not offer

ionizers.

A whole

connected city

filtration

system can work

in unison to

push the virus

out of the city

or prevent the

contaminant from

even entering

the area.

Nathaniel points

to the potential

of directing the

air flow through

a city rather

than relying on

whatever

turbulence and

other conditions

occur without

planning and

design. The

details on an

ambient air

purifier to be

located at

traffic

intersections

was briefly

reviewed

“The hope of the

industry says

Nathaniel is

that the world

comes through

this crisis with

a better

understanding of

how using

filtration can

protect and

enhance the

lives of the

global

population. We

as an industry

raise the bar

and continue to

exceed the

expectations of

the world’s

customers to

breathe clean

air.”

To view this

YouTube

recording click

here: https://youtu.be/3nqNhOwBHuQ

Armbrust

American will

Supply Millions

of Masks to

Texas School

Teachers

Armbrust

American scored

a big win in its

mission to

address PPE

shortages with

quality,

American-made

masks with the

announcement

that it has

signed a

contract to

supply millions

of masks to Texas's more

than 320,000

public school

teachers.

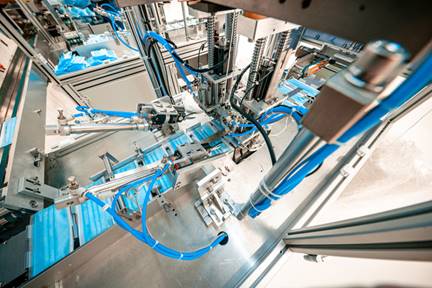

Armbrust

American's

Austin-TX area

medical mask

production

facility

The lack of

domestic

manufacturing

has forced

essential

organizations

like public

schools to rely

on a global

supply chain for

PPE at much

higher costs

during a time of

unprecedented

demand. And with

the vast

majority of

surgical masks

being

manufactured out

of China,

state

governments have

the added burden

of determining

if those masks

meet adequate

quality and

safety

standards.

Combined with

recent reports that

non-medical

masks from China are

being repackaged

and sent to

essential

workers, having

trusted

American-made

PPE has never

been more

important.

"It's taken

almost two

months, but I'm

happy to share

that our masks

have passed

everything

needed for ASTM

Type-II

certification

with bacterial

and particulate

filtration at

99%," said Armbrust

American founder

and CEO Lloyd

Armbrust.

"Our mission is

to supply our

fellow citizens

with superior

quality

equipment, made

right here in Texas.

No one should

have to worry if

the mask they're

wearing will

keep them safe,

especially the

people doing the

important work

of educating our

children."

Armbrust

American's Austin factory

is currently

ramping to

produce 1.2

million masks

per day, with

plans to scale

production to

billions

annually if

needed. The

company

represents an

important first

step in

returning

strategic

manufacturing to

the U.S., thus

ensuring that

American heroes

on the front

lines have

proper defenses

needed during

this pandemic

and beyond.

Nelson

Laboratories,

LLC performed

several

procedures to

evaluate how

Armbrust's

surgical face

masks would

stand up against

fluid

penetration,

bacterial

filtration,

particle

filtration,

flammability,

and sensitivity.

All test method

acceptance

criteria were

met, and testing

was performed in

compliance with

the FDA's Good

Laboratory

Practices (GLP)

regulations.

Precise Tooling

has Mobile

Transparent

Partition for

Schools

Specialty

manufacturer

Precise Tooling

Solutions has

introduced ViralBarrier,

an effective and

affordable

mobile barrier

designed to

prevent

transmission of

the coronavirus

that causes

Covid-19.

ViralBarrier is

adaptable to

virtually any

school setting

from college

through

kindergarten.

Designed with

input from

seasoned

instructors, it

creates safe

social

distancing

whether

standing,

sitting in a

chair or even

sitting on the

floor. And, it's

easily sanitized

with a

non-abrasive

disinfecting

agent.

ViralBarrier was

designed with

input from

instructors.

It's durable,

easy to maneuver

and very

affordable.

ViralBarrier is

adaptable to any

school setting -

in the

classroom,

learning labs,

library,

administrative

areas, and

cafeteria. It

creates safe

social distance

whether

standing,

sitting in a

chair or sitting

on the floor.

"We are proud to

bring this

unique ViralBarrier to

schools so they

can get back to

doing what they

do best, which

is educating our

next generation

of leaders,"

said Don

Dumoulin,

CEO / Owner. "We

hope to help

keep

instructors,

students and

staff healthy as

schools reopen

in a few weeks."

Benefits

include:

- Fully mobile, easy to move with one hand

- Shatterproof polycarbonate is clear as polished glass

- Hooded swivel-casters with brakes for easy repositioning

- Optional mid-level shelf for digital devices and instructional aids

- Fully assembled when delivered – no tools or fasteners required

Privately held

Precise Tooling

currently

employs 40+

craftsmen at its

state-of-the-art

manufacturing

facility

outside Columbus,

IN.

H&V has New

Material for

Medical Gowns

Looking to help

meet the

critical need

for Personal

Protective

Equipment for

healthcare

workers during

the COVID-19

pandemic, global

manufacturer

Hollingsworth &

Vose has, on a

rapidly

accelerated

timeline,

developed a new

material for

non-surgical

medical gowns.

Using standard

construction

methods, this

new material can

be converted

into medical

gowns for

healthcare

workers in

hospitals,

nursing homes

and other

medical

facilities. The

material meets

stringent

testing

including the

AATCC 42 impact

penetration and

AATCC 127

hydrostatic

pressure tests.

Its origin stems

from a COVID-19

related task

force that H&V

convened at the

start of the

pandemic to see

how the company

could expand

production and

help meet the

shortage of

medical grade

PPE. H&V works

across

industries,

including in

medical,

automotive,

energy, power

generation, and

air quality.

“H&V had already

been

manufacturing

critical

materials used

in the fight

against

COVID-19,

including

filtration media

for N95

respirators,

ventilator

filtration media

and the

materials used

in surgical

hoods, so it

made sense for

us to see how

else we might be

able to meet the

needs of

healthcare

workers on the

frontlines,”

Jeff Crane,

Segment Leader

at H&V.

“Accelerating

our research and

development

process,

partnering with

companies that

provide third

party testing

and pulling

expertise from

different

industries we

serve allowed us

to quickly

develop this new

material in just

a matter of

weeks and begin

supplying it to

gown

manufacturers

that are facing

shortages due to

the pandemic,”

added Crane.

Customers for

the new material

include a mix of

existing H&V

customers as

well as new

customers who

are helping to

meet demand for

medical gowns.

H&V is

manufacturing

the material

entirely from

its

manufacturing

facility in

Easton, New

York.

“We will

continue putting

our expertise in

the

manufacturing of

advanced

materials to use

for a wide range

of applications

while also doing

everything we

can to help

those who are

out there in

hospitals,

clinics, nursing

homes and

elsewhere taking

care of others,”

commented

Crane.

As a global

manufacturer of

advanced

materials for

filtration and

battery

separator

materials, H&V

provides

products that

are critical to

responding to

the COVID-19

(the coronavirus)

emergency.

H&V is at the

front end of the

supply chain for

several critical

healthcare

related

materials,

including

filtration media

for N95

respirators,

ventilator

filtration

media, materials

used in the

production of

medical gowns &

surgical hoods,

and consumables

for COVID-19

test systems.

H&V also

supplies

products into

other air

filtration

applications in

medical,

industrial,

residential and

transportation

settings. H&V

battery

separator

materials are

being used in

batteries which

support

life-critical

medical

equipment and

first responder

vehicles, as

well as

emergency backup

power for

telecommunications,

hospitals and

data center

infrastructure.

This power is

critical for

hospitals,

governments, and

financial

institutions.

The company has

manufacturing

capabilities

around the

world.

It has

manufacturing

facilities in

China and a

Chinese website.

H&V will

exhibit at the

Filtration &

Separation Expo,

Shanghai, China,

December 9, 2020

- December 11,

2020.

McIlvaine

visited their

stand at this

show in 2004

when the plant

in Suzhou China

had just been

completed. This

could be one of

the first

international

filtration shows

to take place

since FILTXPO in

Chicago in

January.

On the

other hand will

China give

permission for

U.S. citizens to

participate in

this show?

In 2011 H&V set

up a

global

technology

center in China.

It provides

advanced global

testing and

development of

fibrous media

and elements

used within

filtration,

separation,

battery

separator and

other industrial

specialty

markets.

“Setting up a

production, R&D,

and test center

in Suzhou is a

commitment to

our market

development

strategy in

China and the

Asia Pacific

region,” said

Hollingsworth &

Vose CEO Val

Hollingsworth.

Because of its

global reach and

level of

participation in

products to

battle COVID the

company can be a

leader in a

proactive

collaboration as

suggested by the

McIlvaine

Company.

Here

are articles on

H&V which can be

accessed in

previous Alerts

McIlvaine

Coronavirus

Market Alert

... PM

Develops

Technology to

Help Meltblown

Fabrics Maintain

Electrical

Charge Midwest

Textiles,

Hollingsworth & Vose Partner

to Develop

Homemade

Facemask Kit

Bondex Ramps up

Production of

Material for PPE

& ...

Terms matched: 1

- Score: 22

- 18 May 2020

- URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-05-18/Alert_202005018.html

McIlvaine

Coronavirus

Market Alert

... Near

Zero Airplanes

are Relatively

Safe with the

Following

Guidelines

Midwest

Textiles,

Hollingsworth & Vose Partner

to Develop

Homemade

Facemask Kit

Bondex Ramps up

Production of

Material for PPE

& ...

Terms matched: 1

- Score: 16

- 10 Jun 2020

- URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-06-10/Alert_20200610.html

McIlvaine

Coronavirus

Market Alert

... Paul

Marold,

president of

Lydall, and Val

Hollingsworth,

CEO of

Hollingsworth & Vose.

Bob McIlvaine

was also a

speaker. Details

are found at

https:/ ...

Terms matched: 1

- Score: 6

- 12 May 2020

- URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-05-06/Alert_20200506.html

McIlvaine

Coronavirus

Market Alert

... isolation

gowns. H&V

Continues to

Expand Capacity

to Mitigate

COVID

Hollingsworth & Vose,

has shifted its

focus beyond its

traditional

markets like

medical,

automotive and

filtration ...

Terms matched: 1

- Score: 6

- 25 Jun 2020

- URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-06-24/Alert_20200624.html

McIlvaine

Coronavirus

Market Alert

... DOD

The Department

of Defense has

signed a $2.2

million contract

with

Hollingsworth

and Vose to

produce 27.5

million N95

ventilator

filters and 3.1

million N95

respirators per

month starting ...

Terms matched: 1

- Score: 5

- 1 Jul 2020

- URL:

http://www.mcilvainecompany.com/coronavirus/subscriber/Alerts/2020-06-30/Alert_20200630.html

PPE is Again in

Short Supply in

the U.S

Unlike the

crisis that

caught a handful

of big city

hospitals off

guard in March

and April, the

soaring demand

for protective

gear is now

affecting a

broad range of

medical

facilities

across the

country, a

problem public

health experts

and major

medical

associations say

could have been

avoided if the

federal

government had

embraced a more

aggressive

approach toward

procuring and

distributing

critical

supplies in the

early days of

the pandemic.

Doctors at

Memorial City

Medical Center

in Houston who

treat Covid-19

patients have

been told to

reuse single-use

N95 respirator

masks for up to

15 days before

throwing them

out. The

country’s

largest

organization of

registered

nurses found in

a survey

of its members

in late June

that

85 percent had

been forced to

reuse disposable

N95 masks while

treating

coronavirus

patients. In

Florida, some

hospitals are

handing out only

loose fitting

surgical masks

to workers

treating newly

admitted

patients who may

be asymptomatic

carriers.

The inability to

find personal

protective

equipment, known

as P.P.E., is

starting to

impede other

critical areas

of medicine too.

Neurologists,

cardiologists

and cancer

specialists

around the

country have

been unable to

reopen their

offices in

recent weeks,

leaving many

patients without

care, according

to the American

Medical

Association and

other doctor

groups.

The crisis has

reinvigorated

calls for

President Trump

to invoke the

Defense

Production Act

and order

American

manufacturers to

step in and

help. The

presumptive

Democratic

presidential

nominee, former

Vice President

Joseph R. Biden

Jr., said this

week that he would

use that law to

boost domestic

protection of

medical gear if

elected.

Carrier Now has

a 1500 CFM Room

Purifier for

Schools

As schools make

plans and take

precautions for

reopening in the

fall, Carrier today

announced the

launch of its OptiClean™ 1500-cfm

Dual-Mode Air

Scrubber &

Negative Air

Machine, ideal

for helping to

maintain clean

and healthy

indoor air

quality in

classrooms,

cafeterias,

libraries,

gymnasiums,

restrooms and

more. The new

unit joins the

existing

OptiClean

500-cfm unit,

which was

launched in

April to help

create

infectious

isolation rooms

in hospitals

treating

COVID-19

patients and is

now used in

hospitals and

dental offices

and is ideally

suited for

individual

classroom use.

The new model

draws air from

inside larger

spaces, removes

many

contaminants and

discharges

cleaner,

filtered air.

Carrier is a

part of Carrier

Global

Corporation, a

leading global

provider of

innovative

heating,

ventilating and

air-conditioning

(HVAC),

refrigeration,

fire, security

and building

automation

technologies.

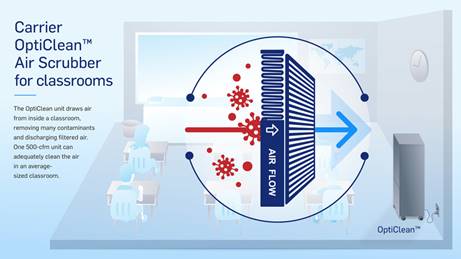

The Carrier

OptiClean unit

draws air from

inside a

classroom,

removing many

contaminants and

discharging

filtered air.

One 500-cfm unit

can adequately

clean the air in

an average-sized

classroom.

The Carrier

OptiClean air

scrubber is

ideal for

maintaining

clean and

healthy indoor

air quality in

K-12 schools.

The 1500-cfm

unit is perfect

for larger

spaces including

libraries, gyms

or cafeterias.

"Schools and

school districts

around the

country are

making very

difficult

decisions about

how to

adequately

prepare to

reopen in the

fall while

keeping their

students and

teachers safe,"

said Chris

Nelson,

Carrier's HVAC

President. "Our

new OptiClean

technology will

provide one

piece of the

puzzle to help

protect the

health of

students and

teachers when

they return to

school. The new

units can be

plugged into a

standard wall

outlet in any

room where

students and

teachers

congregate

during the

school day to

help reduce

contaminants

like the

coronavirus,

improve indoor

air quality, and

slow the spread

of disease."

Like the 500-cfm

unit, the new

OptiClean

1500-cfm unit

plugs into a

standard wall

outlet and uses

a greater than

99.97%

efficient,

long-life HEPA

filter to

significantly

reduce the

presence of

coronavirus and

other

contaminants in

the air.

OptiClean units

exceed the ASHRAE® school

reopening

recommendation*

that portable

electric HEPA

machines be

introduced into

each classroom

and provide a

minimum of two

air changes per

hour.

The Carrier

OptiClean units

are portable,

taking only

about

three-square

feet of floor

space when

oriented

vertically, and

can also be

operated

horizontally,

allowing for

convenient,

unobstructed

placement in

classrooms,

cafeterias,

libraries or

gymnasiums. One

500-cfm unit can

adequately clean

the air in an

average-sized

classroom; the

new 1500-cfm

unit is designed

for larger

spaces. In both

cases, multiple

units can be

used for more

expansive

spaces.

OptiClean is one

of a number of

solutions

offered through Carrier's

Healthy

Buildings

Program that

can aid school

districts in

enhancing indoor

air quality.

Other product

features and

upgrades include

filters with

high MERV

ratings; UV

lights; Agion® anti-microbial

coating, which

can be applied

to protect

against

bacterial

growth;

economizers; and

a Humidi-MiZer® dehumidification

system.