Coronavirus Technology Solutions

June 15, 2020

Eaton Pursuing Face Shield Supply - First with

3D Printing and Later Injection Molding

Eaton Touchless Tool Reduces Virus Spread

Eaton Provides Power Equipment for Expanded

Triage Capability

Eaton Provides Power Equipment to New Hospitals

in Wuhan

N95 Masks will

Remove Coronavirus Particles

Parker Hannifin Offers Range of Filters for HVAC

Parker Hannifin has Multiple Media for

Face Masks

IDEX Provides Dosing Pumps, Clamps, Degassers

and Other Products to Hospitals

Masks are More Important Than Social Distancing

Because of Airborne Aerosols

Chinese Melt Blown and Mask Capacity Reduced as

Low Quality Producers Eliminated

_____________________________________________________________________________

Eaton Pursuing Face Shield Supply - First with

3D Printing and Later Injection Molding

Additive manufacturing opens up new

opportunities to combine novel materials,

designs and process innovations at a much faster

pace than traditional manufacturing. It enables

engineers with quick and cost-effective design

iterations to dramatically reduce development

time. And now more than ever, time is of the

essence.

Eaton says :”What matters most is the ability of

the healthcare system to respond to the crisis

at hand. We’re leveraging our expertise in

additive manufacturing to deliver real-time

solutions.

For example, we’re designing and 3D printing

medical supplies to meet the needs of our

customers and the world. By working closely with

healthcare providers, we’ve developed face

shields that can be sanitized and reused for a

period of time. We’re donating initial supplies

to hospitals in Cleveland, New York City and

beyond.

We’re also pursuing options to transition the

production of face shields to more traditional

manufacturing methods because the current demand

for these critical assets far exceeds the supply

available from 3D printing. We’re looking at

injection molding processes in collaboration

with a variety of manufacturing facilities to

help provide protection for front-line

healthcare workers.

Eaton Touchless Tool Reduces Virus Spread

Hospitals need immediate access to tools that

help reduce the potential for front line

healthcare providers to be exposed to the new

virus. Power management company Eaton

activated its additive manufacturing

expertise to rapidly develop a touchless tool

that helps medical workers avoid contact with

surfaces and slow the spread of the novel

coronavirus. University Hospitals in Northeast

Ohio collaborated on the design and development

of the new Eaton tool.

“The entire community here is indebted to

innovative organizations like Eaton, who are

flexing their technological muscles and making a

difference in these challenging times,” said

Brian Rothstein, MD, pediatric neurosurgeon at

University Hospitals.

A recent study indicates that one of the best

defenses of healthcare workers is through

barrier protection from surfaces that become

contaminated

(Journal

of the American Medical Association,

March 2020). Eaton’s four-inch touchless tool

resembles a plastic wrench and is intended to

help medical workers grab door handles, turn

faucets and push buttons on phones and other

devices without touching surfaces.

“We’re looking for ways that we can apply our

design engineering and manufacturing expertise

to help address the critical needs in the

healthcare industry, and our teams are making it

happen,” said Michael Regelski, senior vice

president and chief technology officer,

Electrical Sector at Eaton. “As this tool and

our face shields demonstrate, we’re able to use

our additive manufacturing, or 3D printing

capabilities, along with a healthy dose of

innovation to compress product development

timelines and rapidly deliver solutions for

healthcare workers on the front line.”

Eaton provided the first batch of touchless

tools to University Hospitals, where doctors,

nurses, emergency medical technicians (EMTs) and

other healthcare workers are using the device.

The tool enables University Hospitals to help

address concerns associated with contracting the

new coronavirus from contaminated surfaces and

reduces the number of times healthcare workers

need to change protective equipment.

“To help fill critical needs of our healthcare

workers during this crisis, we moved from

concept to production in a few short days,” said

Srinivas Garimella, global head of the Additive

Manufacturing Center of Excellence at Eaton.

“This kind of speed and adaptability reaffirms

the power of additive manufacturing, and I am

proud of our teams across the company who

stepped up to help local communities.”

Eaton Provides Power Equipment for Expanded

Triage Capability

While the world continues to react to the

COVID-19 pandemic, healthcare providers are

working with their local communities to expand

treatment capacity and provide exceptional care

for all patients. Power management company Eaton

answered the call when Southside Hospital in Bay

Shore on Long Island – part of Northwell Health,

New York’s largest healthcare provider –

recently extended its triage capabilities with

an emergency hospital tent and called upon a

local partner to provide the critical equipment

needed to keep the facility up and running. The

low-voltage power distribution solutions

provided by Eaton will help enable reliable,

always-on power for the continuous delivery of

patient care in the temporary emergency

facility.

“The rapid completion of our Southside Hospital

facility expansion would not have been possible

without Eaton and our local partners coming

together on short notice to deliver essential

equipment,” said Kurt Jahrsdoerfer, Director of

Engineering, Northwell Health.

“The collaboration between our partners and

others in our community will help bring

essential care to patients during this

pandemic,” said Steven McCormack, Manager of

Plant Operations, Northwell Health.

Electrical distributor WESCO International

received an urgent call from local electrical

contractor Gordon L. Seaman, Inc. for two

switchboards to distribute critical power to the

triage tent facility being constructed at

Southside Hospital. WESCO contacted the Eaton

satellite in Westhampton, New Jersey, knowing

that electrical solutions of that size and

complexity could be built quickly by the

satellite plant. Time was of the essence,

so Eaton quickly activated a network of sites

across Baltimore; Denver; El Paso, Texas; and

Sumter, South Carolina, to coordinate materials

and accelerate production. Ultimately, the New

Jersey satellite was able to deliver

switchboards on site in one week, a fraction of

the standard turnaround time for such complex

equipment.

“When you’re in a situation like this and

working amid a global pandemic, you need a

partner you can really trust,” said Donald Schug,

senior sales representative, WESCO

International. “Eaton’s proven record of

delivering above and beyond expectations as well

as their presence in the local community gave me

the confidence that they would deliver what I

needed at the speed this project required, and

that’s exactly what they did.”

With the Eaton switchboards providing continuous

power for the triage tents, hospital staff can

diagnose and treat non-COVID patients while

maximizing the main facility’s ability to treat

COVID patients.

“The COVID-19 pandemic is driving close

collaboration between healthcare providers and

their communities to ensure all patients receive

the care they need,” said Justin Carron, global

healthcare segment manager, Eaton. “I’m proud of

the fast action and coordination our team and

partners exhibited that enabled the delivery of

essential switchboard technology to the team at

Southside Hospital. As this pandemic continues,

we remain committed to working with partners in

these communities to solve challenges and

deliver electrical solutions that meet their

needs for safe, reliable power.

Eaton Provides Power Equipment to New Hospitals

in Wuhan

China completed construction of two new field

hospitals in Wuhan in just ten days. Power

management company Eaton and its partner

electrical contractors and distributors were

part of the construction project at the new

Huoshenshan and Leishenshan Hospitals that

delivered an additional 2,500 hospital beds to

the front line of this global health emergency.

Eaton solutions are powering the hospitals,

enabling medical teams to diagnose, treat and

monitor more patients.

“Working in the field complicates access to a

steady and reliable power supply, which can be a

matter of life and death when critical medical

equipment is involved,” said Howard Liu,

president of Eaton’s Electrical Sector –

Asia-Pacific region. “Eaton is committed to

providing high-performance solutions to everyday

heroes on the frontlines – on typical days and

in moments of crisis.”

The highly complicated effort to design, build

and construct two hospitals in short order

required consistent quality power. Eaton

mobilized its emergency response teams in China

to help.

An urgent request came to Eaton from the

regional utility, Wuhan Power Supply Bureau.

Both Huoshenshan and Leishenshan Hospitals

needed help connecting to utility power. In a

matter of days, Eaton and its partner helped

connect the main power supply at both hospitals

and provided the medium-voltage cable

accessories supporting intelligent and reliable

power distribution.

Eaton and its local partner, Wuhan Chaote

Network Technology Co., Ltd, worked overnight to

install, deploy and start up power at the

Huoshenshan Hospital. Eaton also provided three

units of uninterruptible power supplies (UPS)

and 112 sets of batteries. This equipment is

enabling healthcare digitalization, the

equipment analyzing blood tests and monitoring

patients, as well as supporting emergency

backup.

Inside of 24 hours’ notice, Eaton delivered the

circuit protection supporting critical CT

equipment onsite at the Huoshenshan Hospital.

This diagnostic equipment is critical to rapid

response and treatment of symptoms. Eaton power

management solutions are protecting these

sophisticated diagnostic imaging machines from

downtime and enabling reliable, efficient power.

N95 Masks will Remove Coronavirus Particles

A good comparison of masks was updated June 2

and is linked below. It confirms that

respirators with high efficiency at 0.3 micron

particle size (N95/FFP2 or better)

can in theory filter particles

down to the size of the coronavirus (which is

around 0.1 microns). What that doesn’t tell us

is how much protection respirators will provide

against coronavirus when in use – we will need

to wait for future studies to confirm.

A

recent paper

shows that the coronavirus ranges from between

0.06 and 0.14 microns in size. Note that the

paper refers to the coronavirus particle as

2019-nCoV, which was its

old name. The virus is

currently called SARS-CoV-2, and the

illness it presents in people is called

Covid-19.

Respirators are measured by their efficiency at filtering particles of 0.3 microns and bigger (noting that the coronavirus is smaller than that).

The reason for the focus on 0.3 microns is because it is the “most penetrating particle size” (MPPS). Particles above this size move in ways we might anticipate and will get trapped in a filter with gaps smaller than the particle size. Particles smaller than 0.3 microns exhibit what’s called Brownian motion – which makes them easier to filter. Brownian motion refers to a phenomenon whereby the particle’s mass is small enough that it no longer travels unimpeded through the air. Instead it interacts with the molecules in the air (nitrogen, oxygen, etc.), causing it to pinball between them, moving in an erratic pattern.

According to researchers this point between

“normal” motion and Brownian motion is the

hardest particle size for filters to capture.

What we can take away from this, is that high

filter efficiency at 0.3 micron size will

generally translate to high filter efficiency

below this size also.

https://fastlifehacks.com/n95-vs-ffp/

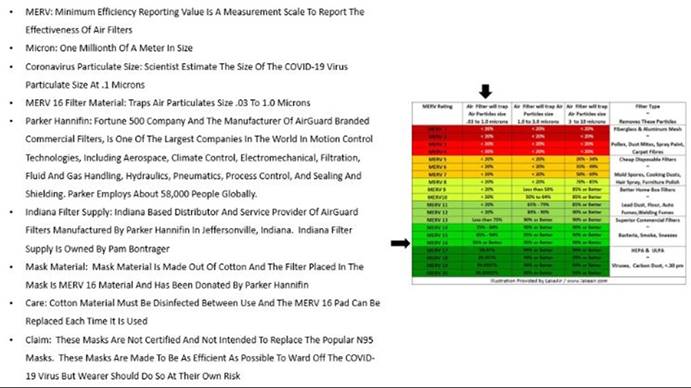

Parker Hannifin Offers Range of Filters for HVAC

For today’s HVAC applications where air

cleanliness is critical, Parker offers an

extensive line of High-Efficiency Particulate

Air (HEPA) and Ultra-Low Particulate Air (ULPA)

filters designed to trap microscopic airborne

particles and contaminants from an air stream to

produce a safe environment and prevent

cross-contamination of manufacturing processes.

Parker says its filter solutions outperform

similar products on the market and are an

effective way to reduce energy use and support

sustainability efforts.

While the

Sub-HEPA, HEPA, and ULPA filters serve

the same function, they vary by efficiency and

performance. The distinction between the filter

types can be unclear given the range of testing

methods. HEPA filters have a minimum efficiency

of 99.97% at 0.3 microns, whereas ULPA filters

have an efficiency rating of 99.999% at 0.12

microns or higher. This does not mean that ULPA

filters are better than HEPA filters when taking

air flow and other variables into account. In

fact, HEPA filters cost less and have a lower

resistance to air flow and have a longer service

life than ULPA filters. Efficiency selection

will be to meet the needs of the user and

application, as specific conditions and

operation may demand either HEPA or ULPA.

Parker HVAC Filtration’s two new energy-saving

filter products, the Parker LoadTECH 4 in and 12

in filters are both MERV 14-rated for high

efficiency and feature gold synthetic media with

a design which captures dust at a higher

capacity than similar models.

The advanced filter systems use Parker’s E-pleat technology,

which moulds filtration media into a series of

pre-formed channels that direct the air smoothly

through the filter, allowing for even loading,

minimum resistance, and complete media

utilization. The advanced media used in the

filters also resists tearing, damage, moisture,

and microbial growth.

Parker Hannifin has Multiple Media for Face

Masks

The company supplied media normally used in air

filters to Indiana Filter to donate to local

prisons who experienced high rates of COVID the

specifics were

Parker Hannifin acquired Clarcor’s some years

ago. Clarcor in turn had previously purchased a

supplier of face mask media and face masks. So

the company does have multiple ways to

participate in the face mask market.

IDEX Provides Dosing Pumps, Clamps, Degassers

and Other Products to Hospitals

As the magnitude of the coronavirus (COVID-19)

outbreak in Wuhan, China became clear, the

Chinese government mobilized its resources and

set out to build two new hospitals in less than

two weeks. To help make it happen Chinese

government suppliers reached out to IDEX China

for several mission-critical components.

Even though businesses were already closed for

the Lunar New Year holiday and many employees

had begun traveling to visit family for the

holiday break, the great teams of IDEX assembled

and shipped a variety of orders for coronavirus

response.

The IDEX efforts have included:

-

Pulsafeeder SPO donating LB

series and LCC4 dosing pumps to

the Red Cross of Yangzhou to

disinfect waste water in the new

hospitals;

-

BAND-IT supplying clamps for

1,300 new ambulances and other

vehicles for emergency medical

transport;

-

Gast delivering pumps for

ventilation in the hospitals;

and

-

IDEX Health & Science provided

degassers, tubing and

connections for blood chemistry

analyzers, and tubing and

connections for

Chemiluminescence Immunoassay

Analyzers.

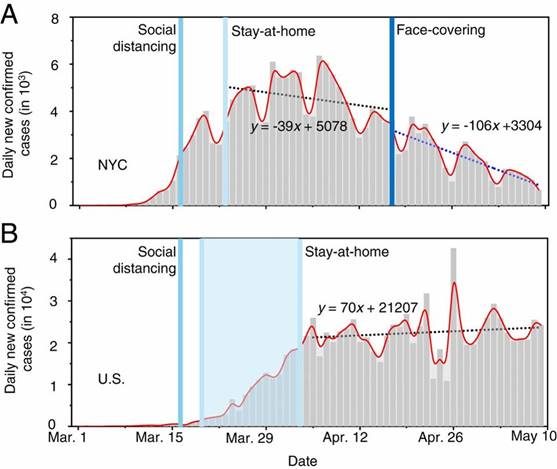

Masks are More Important Than Social Distancing

Because of Airborne Aerosols

As states reopen amid the ongoing Covid-19

pandemic, many are documenting still-rising

levels of new cases. This is partly, or largely,

due to bad pandemic-time behavior—that is, not

wearing masks and not social-distancing. Even in

New York, which has done so well in reducing its

numbers, people are getting weary and a

little sloppy with protections. A new study out

in the journal Proceedings of the National

Academy of Sciences finds that among all

the strategies for reducing transmission,

wearing face masks may be the central

variable that determines the spread of the

virus.

“Our analysis reveals that the difference with

and without mandated face covering represents

the determinant in shaping the trends of the

pandemic,” the team, from Texas A&M University,

the University of Texas at Austin, California

Institute of Technology, and the University of

California San Diego, write in their new paper.

They analyzed the various mitigation measures

put in place in the three major centers of the

outbreak—Wuhan, Italy, and New York City—from

January 23 to May 9, 2020. The team also looked

at the slopes of the curves representing the

number of new cases, and how they changed after

each measure was mandated.

For instance, in NYC, the stay-at-home and

social distancing orders didn’t do a lot: the

curve really started to change after masks were

mandatory. (See the figure below.) Compare that

to the U.S. overall, which never put in place a

face-covering policy.

Daily new confirmed infections in (A) NYC and

(B) the United States. The dotted lines

represent ... [+]

ZHANG

ET AL 2020, COURTESY PNAS

And in Wuhan, the response was not only swift,

but multiple measures—namely, social distancing,

lockdown, and face coverings—were put in place simultaneously.

In the U.S., it was slower, and importantly,

sequential, making it much less effective.

“[T]he response to the pandemic was generally

slow in the western world, and implementation of

the intervention measures occurred only

consecutively,” the authors write. “Clearly, the

responsiveness of the mitigation measures

governed the evolution, scope, and magnitude of

the pandemic globally.”

The team also looked at how the virus, in

droplets and aerosols, travels in the air; how

fast it travels; the weather conditions in the

respective geographic locations; the “dose” and

effectiveness of how it infects the respiratory

system; and other variables. "Our results

clearly show that airborne transmission via

respiratory aerosols represents the dominant

route for the spread of COVID-19," said study

author Renyi Zhang in a statement.

When paired with the data on how the curve

changed in response to the mitigation methods,

this all makes sense—the takeaway being that

face masks are likely the major

determinant of how the infection spreads or

slows.

"Our study establishes very clearly that using a

face mask is not only useful to prevent infected

coughing droplets from reaching uninfected

persons

but is also crucial for these uninfected persons

to avoid breathing the minute atmospheric

particles (aerosols) that infected people emit

when talking and that can remain in the

atmosphere tens of minutes and can travel tens

of feet,"

said study author Mario Molina in a statement.

Indeed, a study

last month in

the same journal showed that just talking loudly

in a room released droplets that lingered in the

air for eight to 14 minutes. The new study also

echoes the update made

by the CDC recently, stating that while

transmission by infected surfaces

(e.g., touching a doorknob that a sick person

coughed on) was possible, it’s not the main

route of infection—air is.

Interestingly, the team also calculated how many

people were likely spared from infection by

wearing face coverings. "By analyzing the

pandemic trends without face-covering using the

statistical method and by projecting the trend,

we calculated that over 66,000 infections were

prevented by using a face mask in little over a

month in New York City,” said Zhang. In Italy

the number was 78,000. “We conclude that wearing

a face mask in public corresponds to the most

effective means to prevent inter-human

transmission. This inexpensive practice, in

conjunction with social distancing and other

procedures, is the most likely opportunity to

stop the COVID-19 pandemic."

As states continue to reopen and many see steady

rises in infection rates, they should heed the

message in the findings of studies like this

one.

Finally, the researchers make the important

point that science must be the foundation upon

which pandemic policy is based. It’s unfortunate

that we live in a time where this point has to

be made, and repeated, but here we are. They

write that “sound science should be effectively

communicated to policy makers and should

constitute the prime foundation in

decision-making amid this pandemic. Implementing

policies without a scientific basis could lead

to catastrophic consequences, particularly in

light of attempts to reopen the economy in many

countries.”

Chinese Melt Blown and Mask Capacity Reduced as

Low Quality Producers Eliminated

In the first five months of the year, 70,802 new

companies registered to make or trade face masks

in China, a 1,256 per cent rise from a year

earlier.

Meanwhile, 7,296 new companies registered to

make or trade

meltblown fabric,

the vital component, an increase of 2,277

percent from a year earlier, according to

Tianyancha, a company registration information

website.

But the frenzy started to cool a little in May,

with the number of new registrations for masks

and meltblown dropping by 70.84 percent and 57.6

percent respectively from April’s peak.

In May, exports

of medical equipment

and supplies rose

89 per cent from a year earlier, with new

pockets of demand popping up as the virus raged

elsewhere in the world, even as many European

and Asian nations appeared to have things under

control.

The situation has changed substantially in the

last month. Many speculative

manufacturers

have been forced to quit the industry due to

changing export rules, tighter licensing

requirements and weaker demand for inferior

quality products.

Industry sources said that the bulk of the

bumper overseas shipments are now going to

established mask-making companies, with

opportunities drying up for those fly-by-night

operators

who were looking to turn a quick buck.

Huang Wensheng is the general manger of Shandong

Jofo Nonwoven, and has been making meltblown and

nonwoven fabrics in his eastern Chinese factory

for more than a decade.

Huang said about half of the mask factories in

his area have closed down, mainly those that

sprang up after the virus was brought under

control in China, but which he said delivered

low quality products.

He blamed falling overseas demand for inferior

masks for the closures, but also Beijing’s

crackdown on the export of non-licensed supplies

amid staunch criticism from governments around

the world. Huang added that for established

manufacturers, business is still “quite good”.

“At the beginning of the outbreak, people would

buy whatever masks were available, but as the

situation improved and fewer people are wearing

masks now, people have more choice, these

unqualified manufacturers are of course being

knocked out [of the market],” Huang said.

Chinese customs authorities imposed more

rigorous checks on mask

exports to

ensure quality control, as the world’s largest

manufacturer faced complaints from some overseas

governments and hospitals over shoddy medical

supplies.

At the height of China’s mask-making mania, the

little-known city of Yangzhong became known as

“the home of meltblown”, with almost 1,000 new

firms registering to make or trade the fabric in

the city of just 340,000, as of April 10,

according to local government statistics.

But now, hundreds of meltblown mills have

closed, with the local sector’s exodus – from

component sellers, to raw material providers, to

even the technicians who helped to debug the

machines – just as dramatic as the mad rush to

enter earlier in the year.

For the best quality output suppliers could

charge up to 400,000 yuan per tonne, but for the

lower-end offcuts, just 1,000 yuan.

On April 15, the

Yangzhong government cracked down on the chaotic

meltblown market, banning 867 companies from

producing the fabric.