Coronavirus Technology Solutions

June 5, 2020

More on Precipitators for Virus Capture

Johns Manville Producing Gown and Face Mask

Media for COVID Mitigation

Facemask

Line Capable

of

Producing Up

to

One Million

Disposable Surgical Masks

per day with a

Lower-Cost Design

A Rapid One-Step Test for COVID-19:

Anti-SARS-CoV-2 Rapid Test

Mettler Toledo Rainin Striving to Assure Stable

Supply of Research Supplies and Calibration

Services

Mask Policy Webinar June 18

HEPA Filters for Indian Government Buildings

CDC Recommends HEPA Filters to Capture Viruses

in Buildings

Disinfection Tunnel for Sports Stadiums

____________________________________________________________________________

More on

Precipitators for Virus Capture

In the Alert yesterday we reported on the

Washington University efforts to evaluate ESPs

for coronavirus capture.

Here is more information from the

research.

A new device called a soft x-ray electrostatic

precipitator protected immunocompromised mice

from airborne pathogenic bacteria, viruses,

ultrafine particles, and allergens, according to

a paper published online ahead of print in the

journal Applied and Environmental

Microbiology. This device, known for short

as a SXC ESP, is highly versatile, with multiple

potential uses, and Washington University is

working on licensing the technology.

"Small particles are difficult to remove, and

our device overcomes that barrier," says Pratim

Biswas of Washington University, St. Louis. The

device not only captures particles with a high

level of efficiency that has never before been

achieved; it also inactivates them. Even

bioterror agents are blocked and completely

inactivated, says Biswas.

The range of potential uses includes indoor

protection of susceptible populations, such as

people with respiratory illness or

inhalation-induced allergies, and young

children; protection of buildings from

bio-terror attack; protection of individuals in

hospital surgical theaters, for example, during

open organ surgery; protection in clean rooms

for semiconductor

fabrication;

removal of ultrafine

particles in

power plants; and capture of diesel exhaust

particulates, says Biswas.

The device could be used in homes, with a cost

similar to that of high efficiency air cleaners,

says Biswas. "But it would be much easier to

operate, and much more effective," he adds. It

could be added into stand-alone indoor air

cleaners, or incorporated into HVAC systems in

homes, offices, and even in aircraft cabins. In

the study, the device exceeded standards for

high efficiency particulate air filters, which

must be capable of removing particles larger

than 0.3 micrometers with 99.97 percent

efficiency.

The SXC ESP works by placing a charge on the

particles—"which it does very effectively," says

Biswas—and then using an electrical field to

trap the particles. The SXC unit then also

completely inactivates biological

particles,

by irradiating them, and photoionizing them—as

UV light does, only more energetically.

Johns Manville

Producing Gown and Face Mask Media for COVID

Mitigation

“There is a desperate need in North America and

in Europe for medical gowns,” said John Vasuta,

President of Johns Manville’s Engineered

Products business. “Our teams are working

quickly to create solutions and manufacture a

new coated polyester spunbond nonwoven fabric.

We are going through unprecedented times – so

every step to support health care workers and

others on the front lines helps right now.”

This is the second move by Johns Manville to

quickly develop and launch a product that can

improve the safety of people in potential direct

contact with the COVID-19 virus. In April,

production started in Richland, Mississippi, of

nonwoven media for the manufacturing of face

masks.

“Given the urgent need for action,” Vasuta said,

“we quickly decided to build on our own

capabilities and develop a coated product to

supply the domestic medical gown manufacturing

industry.”

The new polyester spunbond nonwoven is designed

for the production of Level 3 medical gowns.

“The fabric offers superior liquid barrier

performance compared to materials used for Level

1 and Level 2 medical gowns, while also

providing comfort and stitch-strength,” said

Souvik Nandi, Director Nonwovens Technology at

Johns Manville Engineered Products.

The JM plant in Spartanburg employs 100 people

and produces a variety of polyester nonwoven

products for the use in mainly filtration,

roofing and specialty applications using JM’s

proprietary spunbond technology. Johns Manville

operates a multitude of polyester spunbond lines

across the globe with a distinct customer and

market focus.

The new fabric is formally known as Evalith ®

017/120H3 and is a coated continuous filament,

calendared polyester nonwoven. It meets the

requirements for a Level 3 medical gown as

established by ANSI/AAMI PB70:2012 Liquid

barrier performance and classification of

protective apparel and drapes intended for use

in health care facilities. Per this standard,

the material was tested to AATCC 42-2017 Water

Resistance: Impact Penetration Test and AATCC

127-2017 Water Resistance: Hydrostatic Pressure

Test. Additionally, Evalith 017/120H3 has been

tested to and meets the flammability standard

per 16 CFR Part 1610 Class 1, according to the

U.S. Food and Drug Administration policy and

guidance.

Johns Manville’s (JM) filtration products plant

in Richland, Mississippi started production of

nonwoven filtration media for use in face masks

in April 2020. JM’s Engineered Products business

decided to build on its existing capabilities

and help meet market demand due to shortages in

the US and Europe in relation to the coronavirus

pandemic.

“Johns Manville is in a unique position to serve

a market that is fulfilling a great need across

the world,” said Mary Rhinehart, president and

chief executive officer (CEO) of JM. “Our

high-performance nonwoven material is designed

to provide high levels of filtration for various

types of face masks. We are proud of our teams

in Richland and throughout JM for finding new

ways to support the communities and people who

are on the front lines of this global crisis.”

JM says its media meets or exceeds Level 1 BFE

95% (Bacterial Filtration Efficiency) and VFE

(Viral Filtration Efficiency) requirements.

These results were verified by a Food and Drug

Administration (FDA) registered laboratory.

Facemask Line Capable of Producing Up to One

Million Disposable Surgical Masks per day with a

Lower-Cost Design

The W+D/BICMA hygiene group of Winkler+Dünnebier

has developed a fully automatic, high-speed

facemask converting line for the production of

high-quality disposable face masks. This new

converting line will be able to produce masks

for surgical-grade applications. It is capable

of producing 800 facemasks per minute, but with

a lower cost mask ear loop design.

AUXILIUM FM Facemask Converting Line.

The new AUXILIUM FM has a speed of up to 150

m/min (492 ft/min) and is able to produce up to

1 million high quality face masks per day.

Adding to the manufacturing throughput

efficiency is a unique lower-cost mask design

capability for an expensive component of the

mask, which maximizes the capabilities of lowest

cost per piece mass production. There are also

different options available for mask stacking

and automation, which make this mask machine

best suited for Industry 4.0 manufacturing.

The new mask line produces and laminates three

fabrics (spunbond, meltblown, thermo-bonded

nonwovens and others). It utilizes W+D/BICMA’s

technology in automatic unwinding and splicing

for nonwoven webs, cutting and positioning

devices for the metal nose bar, and heat and

ultrasonic edge welding.

A Rapid One-Step Test for COVID-19:

Anti-SARS-CoV-2 Rapid Test

Anti-SARS-CoV-2 Rapid Test available from Hardy

Diagnostics

is a rapid, one-step lateral flow assay

intended for the presumptive qualitative

detection of IgM and IgG antibodies to the

SARS-CoV-2 virus in patients suspected of a

COVID-19 infection.

By using a patient’s finger prick blood, serum,

or plasma specimen, the Anti-SARS-CoV-2 Rapid

Test offers a turnaround time of only 15

minutes. This simple to use test requires no

equipment or special expertise or training to

implement.

Mettler Toledo Rainin Striving to Assure Stable

Supply of Research Supplies and Calibration

Services

Rainin

employees are working around the clock to assure

a stable supply of research supplies (pipettes,

tips, and calibration services) for customers

and healthcare agencies worldwide who are

working to contain, treat and eliminate the SARS

CoV-2 virus.

Rainin pipettes and tips are used daily by

hospitals, clinical laboratories, companies and

universities who are on the front lines fighting

the COVID-19 disease and performing critical

research for vaccines and therapies.

The

Oakland, California, manufacturing facility is

operating around the clock to maintain a larger

than normal inventory of essential pipettes and

tips.

All four Rainin U.S. calibration service centers

and onsite technicians are fully operational and

ready to serve the

calibration needs.

Mask Policy Webinar

June 18

In

the last few weeks public policy has changed

considerably as people are now advised to wear

masks when in public. In fact they are required

to do so in many countries and cities in the

U.S. However there is no effort to advise or

require the use of high efficiency masks which

would prevent inhalation of virus aerosols.

Since there is considerable new research to

indicate that aerosols travel some distance and

are a transmission route, the subject of mask

selection becomes of utmost importance.

We

are moving forward in preparation for the mask

policy webinar which will be held on January 18

at 10:AM CDT to discuss and debate the

proposition:

Mask

selection should be based on wearer needs first

and then on needs of those at risk.

Since COVID is now known to pass through

surgical masks, the wearer will not be

completely protected unless he has an N95 or

better. Does this mean everyone should wear an

N95 mask all the time?

A way to answer this question logically

is through a measurement tool for all harm and

good.

Bob McIlvaine explained a common metric to

measure all harm and good in the April 2 webinar.

A McIlvaine study for one of the largest

healthcare companies on single use vs reusable

surgical gowns is equally applicable to masks.

The study includes a common metric to measure

all harm and good and to also consider the

future value discount and tribal values. Every

alternative can be measured in Quality Enhanced

Life Days. This includes the discomfort of

wearing a mask vs the benefits. It includes the

possible selection of Far UV to reduce infection

now even if it increases the chance of skin

cancer many years into the future. It provides a

clear method for determining who gets the

ventilator and who does not. The tribal value

consideration takes into account such questions

as should 3M be required to ship masks, they

produce in other countries back to the U.S. It

provides a method of determining when and if the

risks of resuming the normal work schedule are

justified. It is simple and straightforward

because it is simply the aggregation of the

wishes of the majority.

This proposition to prioritize the wearer needs

is in conflict with certain ordinances which

prohibit masks with valves. For example Korean

high schoolers wore masks without valves in a

1000 meter

endurance test and two died. Should they

have worn masks with valves, risked COVID, or

should tests not be conducted?

The general premise that all individuals if

protected by highly efficient masks could lead

near normal lives would be of high importance to

world economic recovery. The support or

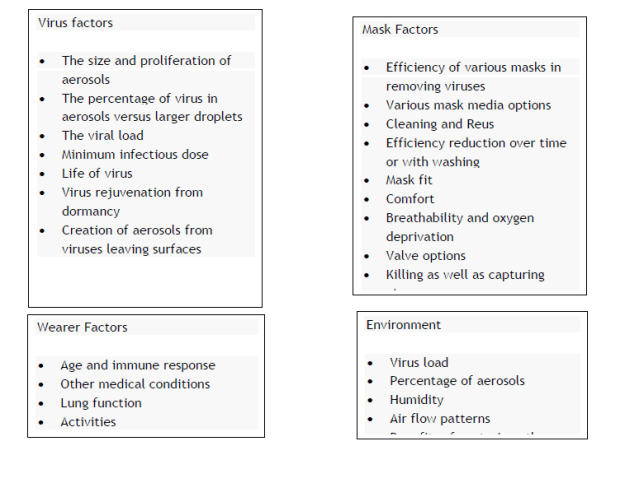

rejection of this proposition rests on

determination of the following factors.

Analysis of each of these factors is in a

background

document found at

http://home.mcilvainecompany.com/index.php/2-uncategorised/1574-coronavirus-webinars

This background includes a number of webinars on

mask selection which can be viewed.

It also includes a review of each of the

mask selection factors under the link

Mask

Policy Review

We

will be updating the factor analysis

continually. In the last few weeks more

has been learned about decontamination options.

One company claims that the antimicrobial layer

in the mask will inactivate the virus. Therefore

if three masks are rotated with a 24 hour

interval to insure deactivation then this will

be sufficient. A number of companies are now

offering washable masks. Decontamination with

H2O2 and other chemical treatment is also

proving successful.

With all these options the factors are

performance vs cleaning cycle and cost.

We

encourage readers and participants to submit

their views. These insights should address the

factors and what is already said about them in

the background document. The session will be in

a discussion format with each of the factors

reviewed as warranted.

To

register for the webinar Click

here

Send your comments to Bob McIlvaine rmcilvaine@mcilvainecompany.com 847

226 2391.

HEPA Filters for Indian Government Buildings

Citing the dangers of air borne transmission of

COVID-19, former MP and BJP leader Vijay

Sankeshwar has urged the union and state

governments to make mandatory installation of

HEPA filters for air conditioners in government

buildings at both the national and state level.

Read more at:

https://www.deccanherald.com/state/karnataka-districts/covid-19-bjp-leader-asks-govt-to-install-hepa-filters-for-acs-in-parliament-vidhan-soudha-845997.html

CDC Recommends HEPA Filters to Capture Viruses

in Buildings

The Center for Disease Control (CDC) recently

released guidance to building owners that would

eliminate much of the shared office space

alignments we have seen over recent years in

many buildings. https://www.cdc.gov/coronavirus/2019-ncov/php/building-water-system.html

Among other steps, the CDC suggested that:

1. Desks – should be placed 6 feet apart

if possible, and if not, employers ought to use

plastic shields to separate desks.

2. Common Areas – there should be no

seating in the common areas of the building and

the tenant suits and amenities such as

refrigerators, microwaves, multiple-serve coffee

pots and water coolers, should be eliminated to

enable better social distancing and less high

touch areas. Multi Serve Coffee service should

be replaced by single-serve items.

3. Air Flow – Open windows are

recommended for fresh air, but if that is not

possible, office building management should

consider increasing air filtration or having the

HVAC systems draw in as much outdoor air as

possible, as much as 100%. MERV 13 filters or

HEPA filters provide a means to capture up to

99% of air borne viruses.

4. Office Interiors – Cleaning frequently

touched surfaces, including keyboards,

telephones, handrails and doorknobs (the CDC

lists cleaning products that are good for

inactivating viruses). https://www.cdc.gov/coronavirus/2019-ncov/community/disinfecting-building-facility.html

5. Workers – the CDC suggests that

workers should also undergo temperature checks,

wear masks and wash their hands often. The

agency stresses the importance of letting all

workers affected by the changes know what is

going on, including management and other staff,

but also relief employees, janitorial staff and

maintenance crews.

Additional information can be found in the

Building Owners and Managers Association (BOMA)

guide entitled “Getting Back to Work-Preparing

Buildings for Reentry,” https://boma.informz.net/BOMA/data/images/Getting%20Back%20To%20Work%20Preparing%20Buildings%20for%20Re%20Entry.pdf

Disinfection Tunnel for Sports Stadiums

Researchers at Bar-Ilan University have

partnered with Karmiel-based company RD Pack to

develop an innovative “disinfection tunnel,” a

new solution which they say could enable large

crowds to gather safely during the coronavirus crisis.

The walk-through tunnel sprays a patented tap

water-based, environmentally-friendly

disinfectant developed at Bar-Ilan University

using electrochemical technology, which has been

proven to powerfully eliminate bacteria and

viruses, including microbes from the coronavirus

family.

Designed to safely disinfect hundreds or

thousands of individuals gathering daily at

locations including stadiums, hospitals and

schools, the tunnel is equipped with an

automated aerosol spray system, which quickly

disinfects individuals, clothes and potentially

contaminated belongings.

The system will be tested at the VIP entrance to

Jaffa’s Bloomfield Stadium, home to soccer teams

Maccabi Tel Aviv, Hapoel Tel Aviv and Bnei

Yehuda, until the end of the current season.

Prior to entering the disinfection tunnel, all

attendees must have their temperature checked

and wear a mask.

“This disinfectant substance is extremely

effective, 100 times more so than a regular

disinfectant, and the advantage is that the

substance is also unstable,” said Dr. Izaak

Cohen, who developed and patented the

disinfectant with Dr. Eran Avraham and Prof.

Doron Aurbach of Bar-Ilan University’s

Department of Chemistry and Institute of

Nanotechnology and Advanced Materials. “Due to

the substance being unstable, it is more

friendly to the environment. Other disinfectants

are more stable and remain on you and can cause

all sorts of burns. The more stable they are,

the less friendly they are to both you and the

environment.”

Bar-Ilan

University researchers Dr. Eran Avraham (front)

and Dr. Izaak Cohen (back) walk through a

disinfection tunnel at Bloomfield Stadium

(Credit: Yoni Reif)

RD Pack, specialists in the development and

construction of automated industrial machines,

has acquired the technology for the water-based

disinfection process and is currently applying

it in so-called disinfection tunnels and other

automated solutions, including the disinfection

of rooms and other spaces.