Coronavirus Technology Solutions

June 3, 2020

The World is One Large Coronavirus Cleanroom

Market

How Long Does the COVID Remain a Threat on

Surfaces?

Study on Hamsters Confirms Efficacy of Face

Masks

Contec Expands Supply of Sporicidin Disinfectant

Silicon Based Membrane for Masks has Efficiency

and Other Advantages

Black & Veatch Develops Boarding Pass to Screen

Employees for COVID Aspects

Short-waved UVC Irradiation is Highly Effective

for Inactivating SARS-CoV-2 Viruses

Antimicrobial Door Handle Cover Available from

Teknomek

Cherwell Laboratories Optimistic About Viable

Air Monitors

Redditch Medical

has New Hand Hygiene Product

Sweden With No Lockdown Has Had Too Many Deaths

230,000 Healthcare Workers have Contracted COVID

Fibre Extrusion Technology Says There May Be

Better Answers Than Polypropylene for Meltblowns

______________________________________________________________________________

The World is One Large Coronavirus Cleanroom

Market

We live in a world where the coronavirus plays a

major role now and for the foreseeable future.

What we are finding is that this virus

can travel in small droplets released by the

lungs or on small particles of which there is no

shortage. We breath in and exhale millions of

tiny particles every hour. With this new finding

we need to turn to the cleanroom experts who

have been focused on eliminating small particles

from the air for 60 years.

These experts and the products and services they

offer provide an essential resource for

mitigating the virus. McIlvaine is assisting by

providing the suppliers with forecasts of the

market opportunities in the broader vision of

the world as one big coronavirus clean room

market.

World Cleanroom Markets

forecasts the revenues of rooms, components,

masks and other consumables for all industries

including biopharmaceuticals and hospitals.

http://home.mcilvainecompany.com/index.php/markets/other/n6f-world-cleanroom-markets

Cleanroom Technology Solutions

with daily alerts and webinars analyzes the

masks, filters, and various other hardware and

consumables which will allow a safe return to

near normal life and work.

http://home.mcilvainecompany.com/index.php/markets/air/82ai-coronavirus-market-intelligence

Coronavirus Pharmaceutical Solutions

tracks the progress to develop vaccines,

therapeutics, and diagnostics.

Bi-weekly Alerts are accompanied by

detailed profiles of the developers and contract

manufacturers who make mitigation possible.

June 3 Alert, Gilead

All three of these services are being offered as

a package and included with the World

Cleanroom Markets report at no extra charge.

A supplier needs all three of these services to

fully understand the opportunities and

challenges created by COVID.

A cleanroom is defined in the ISO standard

14644-1 as:

“A room in which the concentration of airborne

particles is controlled, and which is

constructed and used in a manner to minimize the

introduction, generation, and retention of

particles inside the room and in which other

relevant parameters, e.g. temperature, humidity,

and pressure, are controlled as necessary”

6.2 million people have contracted COVID 19 in

the last six months.

380,000 have died. With a problem of this

magnitude caused in large part by an airborne

virus we have to be thinking of the world as one

big facility which needs to adopt cleanroom

technology. The same strategy can be applied as

would be applied to a pharmaceutical complex.

In a pharmaceutical facility there is likely to

be a progression of clean spaces.

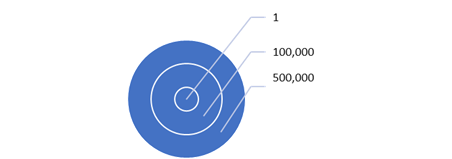

Ambient air in a typical city contains 500,000

or less particles 0.3 microns in diameter in

each cubic foot. It also contains millions of

smaller particles. An individual inhales the air

with the particles and then exhales the CO2 and

sends the particles back into the environment. A

super spreader can be generating thousands of

virus aerosols per minute. Some will be in small

droplets caused by lung splashes. They

may

travel hundreds of yards. Those which attach to

small particles can drift over a whole region

e.g. Lombardy, Italy.

There is no knowledge as to what

percentage is inactivated by distance traveled

and what percentage is just dormant and ready to

be revived in lung moisture.

There is research which indicates that the

disease can be transmitted by as few as 10 virus

particles. On the other hand experts say that

most is contracted through contact with large

numbers of particles. As long as some of the

COVID transmission is through aerosols there

will be no fool proof way to prevent COVID

transmission. A mitigation program has to

therefore accept some risk and minimize the

transmission as much as is economically

possible.

This is the same strategy used in a

pharmaceutical facility. Many pharmaceutical

operations take place in space where the number

of 0.3 micron particles is limited to 100 or

less. Within that space there may be isolators

where there is less than one 0.3 micron particle

per cubic foot. When one leaves a less clean

space and enters a cleaner area there are

possibly air showers, garment changing and other

procedures.

The decision on how clean to make each space is

a function of risk and cost. The same principle

applies to dealing with COVID. The protection

effort needed on a crowded subway is much

greater than a sparsely inhabited park.

Suppliers have products to address varying

levels of risk and reduction.

An advantage of the packaging of the three

services is to determine the impact of one on

the others. The massive effort to create

vaccines, therapeutics, and diagnostics for

COVID means that there will be reduced cleanroom

revenues for cancer and other

biopharmaceuticals.

For more details on this package contact Bob

McIlvaine at 847 226 2391 or email him at 847

226 2391.

How Long Does the COVID Remain a Threat on

Surfaces?

CWS has posted information on coronavirus

tenacity at

https://www.cws.com/en-IE/news/how-long-does-coronavirus-survive-surfaces-2020-05-28.

Currently, nobody knows exactly how long

SARS CoV-2 - as the virus is correctly named -

"survives" on surfaces or, better, how long SARS

CoV-2 remains infectious on a surface. This

depends on its tenacity. This refers to

biological toughness or resistance to

environmental influences.

However, the question of how long the virus

remains active is very important, especially at

this time, and in the cleanroom. It can only be

answered by conducting experiments. There could

be the following possibilities:

-

"Genetic" detection: Comparable

to the corona test on patients,

a sample ("smear") from the

surface is used to measure how

much of the virus’ genetic

information, known as RNA, can

be detected. This allows us to

know whether the virus is or was

present. However, the result

does not tell us anything about

whether the virus is actually

still infectious.

-

Biological cell detection: The

sample, including the virus, is

added to a cell culture. The

virus infects the cells, causing

them to change or die. These

changes can be viewed with a

microscope. If different

dilutions – known as titre

levels - of the virus sample are

added to the cells, quantitative

information on the infectious

potential is obtained. If the

surface is examined at different

time intervals, information can

be obtained on how long the

virus can remain infectious.

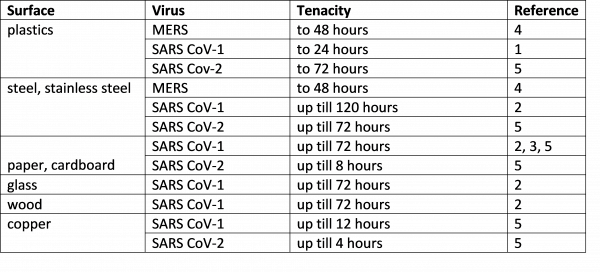

In fact, there is little data on the tenacity of

SARS CoV-2. For the closely related

coronaviruses SARS CoV-1 (causative agent of the

pandemic 2002/03) and MERS (Middle East

Respiratory Syndrome, causative agent of the

epidemic on the Arabian Peninsula in 2012), a

tenacity of up to 120 hours could be

demonstrated in experiments.

The data for the various coronaviruses differ

greatly. With regard to the environmental

conditions, however, it is clear for all

viruses: the tenacity decreases

-

with increasing ambient

temperature

-

with rising humidity

-

with low "load", i.e. number of

viruses/unit area

The table summarizes the "survival times", i.e.

the tenacity determined for different surfaces.

References: 1) CHAN et al. 2011; 2) DUAN et al.

2003; 3) LAI et al. 2003; 4) VAN DOREMALEN et

al. 2013; 5) VAN DOREMALEN et al. 2020

In summary, this means that:

The data unanimously show a high tenacity for

the SARS CoV-2 virus, particularly on plastic

and stainless steel surfaces. In principle,

effective barriers already exist against the

penetration of viruses into cleanrooms. However,

the high "survival times" of SARS CoV 2 demand

and justify further measures for surface

disinfection in the cleanroom itself as well as

in the access area, so that the distribution of

the virus across contaminated surfaces can be

limited. This applies in particular to surfaces

that are frequently contacted, such as door

handles, switches, door surfaces or seating.

Since CoV-2 is an enveloped virus, "limited

virucidal" disinfectants are suitable for

additional disinfection measures. These are

based on ethyl alcohol and/or isopropyl alcohol,

are easy to use and reliably inactivate SARS

CoV-2.

The source of this information was profi-con

GmbH and reinraum-akademie

info@reinraum-akademie.de.

Study on Hamsters Confirms Efficacy of Face

Masks

A study by University of Hongkong researchers

demonstrated that airborne transmission was a

major mode of transmission and that facemasks

were efficient in minimizing the transmission

The researchers

used a

well-established golden Syrian hamster

SARS-CoV-2 model. They

placed

SARS-CoV-2-challenged index hamsters and naïve

hamsters into closed system units each

comprising two different cages separated by a

polyvinyl chloride air porous partition with

unidirectional airflow within the isolator. The

effect of a surgical mask partition placed in

between the cages was investigated. Besides

clinical scoring, hamster specimens were tested

for viral load, histopathology, and viral

nucleocapsid antigen expression.

Non-contact transmission was found in 66.7%

(10/15) of exposed naïve hamsters. Surgical mask

partition for challenged index or naïve hamsters

significantly reduced transmission to 25% (6/24,

P=0.018). Surgical mask partition for

challenged index hamsters significantly reduced

transmission to only 16.7% (2/12,

P=0.019) of exposed naïve hamsters.

Unlike the severe COVID-19 manifestations of

challenged hamsters, infected naïve hamsters had

lower clinical scores, milder histopathological

changes, and lower viral nucleocapsid antigen

expression in respiratory tract tissues.

The conclusion was that SARS-CoV-2 could be

transmitted by respiratory droplets or airborne

droplet nuclei in the hamster model. Such

transmission could be reduced by surgical mask

usage, especially when masks were worn by

infected individuals.

https://academic.oup.com/cid/advance-article/doi/10.1093/cid/ciaa644/5848814?searchresult=1

Contec Expands Supply of Sporicidin Disinfectant

The demand for antibacterial cleaning supplies

continues to climb in response to the COVID-19

pandemic, and healthcare institutions are

looking for effective alternatives to

traditional solutions. To fill this need, Contec,

the critical cleaning products and cleanroom

supplies provider, is scaling up production of

its Sporicidin brand disinfectant, most often

used for mold and water damage remediation, and

turned to diversified global manufacturer and

materials science expert Milliken & Company to

help produce mass quantities.

Since 1978, Sporicidin brand disinfectant

products have been used for infection and

contamination control by hospitals, medical and

dental offices, veterinary clinics, and

restoration professionals.

The EPA-registered intermediate-level

disinfectant cleans, disinfects and deodorizes,

and it provides 100% kill of pathogenic

vegetative organisms, including MRSA, VRE and

Avian Influenza A Virus (H9N2 and H1N1) with

continuous residual activity for up to six

months.

Compatible with plastics, wood, glass and

metals, alcohol-free Sporicidin brand

disinfectant is non-staining, non-abrasive and

non-corrosive. Notably, the disinfectant carries

a Category IV EPA toxicity rating the lowest

toxicity rating given to antimicrobials.

"Milliken immediately came to mind when we

decided to bring on a new manufacturing

partner," said Jack McBride, Contec CEO.

"Milliken is a trusted, key community player

with the mass production, quality systems and

speed-to-market capabilities needed to help us

provide critical cleaning solutions to

healthcare facilities without delay."

Sporicidin production at Milliken began on

Tuesday, 12 May, after a record ramp-up of only

four weeks. Typical similar partnerships require

three to six months to arrange.

"Companies are adapting their core competencies

to meet the global challenges brought on by

COVID-19," said Halsey Cook, President and CEO

of Milliken. "Partnering with Contec was a

natural fit and gave Milliken the opportunity to

quickly reconfigure our manufacturing

capabilities and rapidly solve problems for our

customers and communities."

Milliken quickly undertook an intensive

technical process to manufacture Sporicidin

brand disinfectant on behalf of Contec, Inc.

Enabled by its research, development and

manufacturing expertise, Milliken completed all

EPA requirements and implemented training and

protocols to safely produce a quality

disinfectant.

Sporicidin brand disinfectant is available in

ready-to-use 32 oz (0.65L) spray bottles,

1-gallon (3.8L) containers and pre-saturated

wipes.

Silicon Based Membrane for Masks has Efficiency

and Other Advantages

Researchers funded by King Abdullah University

of Science and Technology

have developed a membrane that can be attached

to a regular N95 mask and replaced when needed.

The filter has a smaller pore size than normal

N95 masks, potentially blocking more virus

particles.

N95 masks filter about 85% of particles smaller

than 300 nm, according to published research.

SARS-CoV-2 (the coronavirus that causes

COVID-19) is in the size range of 65–125 nm, so

some virus particles could slip through these

coverings. Also, because of shortages, many

health care workers have had to wear the same

N95 mask repeatedly, even though they are

intended for a single use. To help overcome

these problems, Muhammad Mustafa Hussain and

colleagues wanted to develop a membrane that

more efficiently filters particles the size of

SARS-CoV-2 and could be replaced on an N95 mask

after every use.

To make the membrane, the researchers first

developed a silicon-based, porous template using

lithography and chemical etching. They placed

the template over a polyimide film and used a

process called reactive ion etching to make

pores in the membrane, with sizes ranging from

5–55 nm. Then, they peeled off the membrane,

which could be attached to an N95 mask. To

ensure that the nanoporous membrane was

breathable, the researchers measured the airflow

rate through the pores. They found that for

pores tinier than 60 nm (in other words, smaller

than SARS-CoV-2), the pores needed to be placed

a maximum of 330 nm from each other to achieve

good breathability. The hydrophobic membrane

also cleans itself because droplets slide off

it, preventing the pores from getting clogged

with viruses and other particles.

https://pubs.acs.org/doi/full/10.1021/acsnano.0c03976

Black & Veatch Develops Boarding Pass to Screen

Employees for COVID Aspects

As return-to-work programs kick off across the

United States, Black & Veatch announced the

launch of COVOPERATE, an innovative new

workforce management application powered by

Field2Base that can help employers navigate the

complex challenge of safely and productively

restoring operations impacted by the COVID-19

pandemic.

Part of a comprehensive safety suite augmented

by on-site, physical screening resources,

COVOPERATE is a flexible, scalable cloud-based

application that tracks and manages

professionals’ critical health data. COVOPERATE

relies on a series of screening questions and

health declarations paired with in-person

temperature checks and other safety protocols to

generate an easily trackable “boarding pass” to

assist in evaluating if professionals are clear

to return to work or require additional

verification.

“Black & Veatch worked closely with Field2Base

to design an easy to use ‘boarding pass’ type of

solution for businesses, schools and commercial

groups looking to minimize risk in their return

to work programs,” said John Chevrette,

president of Black & Veatch Management

Consulting. “By collecting specific health data

determined by each organization, COVOPERATE

quickly evaluates an individual’s return to work

status and shares it with on-site resources that

can determine appropriate site access.”

By digitizing information and securely managing

the data in a secure, HIPAA-compliant and

audited platform hosted by Field2Base,

COVOPERATE helps organizations ranging from

commercial and industrial businesses to

education, government and financial organization

settings to assist in establishing enhanced

safety site access programs. In addition, the

data provided by COVOPERATE can also assist in

management of complex, daily labor workflows by

providing location validation and a real-time

view into available staffing resources.

Based in North Carolina, Field2Base is a

software company that specializes in developing

field service automation and mobile form

solutions. The company will manage the

collection and processing of professionals’

health data and provide technical support for

COVOPERATE at the organization level.

The application is currently in market testing

with select large enterprise companies across

the U.S. and will support access management for

millions of workers. Black & Veatch will also

begin to use COVOPERATE to help foster the

long-term safe return of its professionals.

“We are thrilled to work with Black & Veatch and

to rely on their engineering leadership and

combine our mobile technology expertise to

design COVOPERATE,” said Ed White, CEO and

Chairman, Field2Base. “Helping organizations get

back to work safely and productively will be

critical as we continue to navigate the global

impacts of COVID-19.”

A global leader in critical infrastructure

services, Black & Veatch has introduced several

solutions that support business activities and

return-to-work efforts impacted by COVID-19,

including BV Safe Contact, a

cloud-hosted geospatial tracking tool designed

to help keep field services and construction

crews working on critical infrastructure

projects safe, and the Rapid Modular Health

System (RaMHS), which provides testing and

screening capabilities outside of traditional

healthcare or business security settings.

Short-waved UVC Irradiation is Highly Effective

for Inactivating SARS-CoV-2 Viruses

UV specialist company Dr Hönle has shown that

energy-rich short-waved

UVC irradiation is highly effective for

inactivating SARS-CoV-2 viruses. The tests

were conducted at the Institute for Medical

Virology of the University Hospital Frankfurt.

The results showed coronavirus can be killed

reliably within seconds using Hönle UV units. An

inactivation rate of 99.99% (log4) was confirmed

in the laboratory.

The tests were carried out applying different UV

technologies and showed a clear result: Whether

the disinfection units were equipped with UVC

discharge lamps or UV-LED, inactivation rate and

inactivation time remained constant and

reproducible.

The results concluded that the risk of infection

with COVID-19 is reliably and efficiently

minimized by disinfecting ambient air and

surfaces with UVC irradiation. Hönle used these

results for their latest product series

STERICUBE and STERIAIR, consisting of UVC

cabinets, UVC chambers and UVC hand lamps for

germ inactivation.

Antimicrobial Door Handle Cover Available from

Teknomek

Hygienic furniture specialist Teknomek has

launched easy fit antimicrobial door handle

covers to help businesses manage transference

risks throughout a pharma facility. The product

helps prevent cross-contamination from one user

to the next in under 30 seconds.

Sue Springett, Commercial Manager at Teknomek,

said: "Our sanitizing door handles that release

viricidal gel have unsurprisingly been in great

demand over the course of the COVID-19 pandemic.

While it makes sense to install these at high

risk areas such as the entrance to a cleanroom

or washrooms, the need for antimicrobial

management extends beyond these key areas."

"The new antimicrobial door handle covers are a

quick fit solution adding an additional layer of

protection and reassurance to staff," Springett

added. "Most importantly, they help reinforce

the importance of hygiene culture from the

moment a person arrives at the building, at a

time when this has never been more important."

The hygienic handle covers feature a silver ion

antibacterial coating that kills 99.9% of

bacteria, including e-coli, salmonella,

H1N1 and MRSA.

No tools or experience are required to install

the door hand covers, which can be fitted in

under a minute.

Cherwell Laboratories Optimistic About Viable

Air Monitors

The company, together with Development Bank of

Wales, took a minority holding in Pinpoint

Scientific last September.

“Pinpoint is developing an exciting range of

viable air monitors for the pharmaceutical

industry. The ImpactAir range of air monitors

will directly address the need for continuous

monitoring within Grade A environments as per

the revised Annex 1,” said Managing Director

Andy Whittard.

For the Cherwell boss, growing demands around

environmental monitoring within pharma will

continue in 2020. “We see the ImpactAir product,

alongside our range of prepared media, as being

a key offering.

Redditch Medical has New Hand Hygiene Product

Redditch Medical has launched its hand hygiene

range in a time of greatest need. As the

Coronavirus pandemic continues to effect daily

life with an imminent release from "lock down"

expected and an expected increase in PPE and

Infection Prevention required Reddtich Medical

is prepared to support.

With two formulations in the range a hand rub (InSpec

HR) and a hand gel (InSpec HG). The hand rub is

manufactured according to the World Health

Organization formula and is available in a

convenient personal spray bottle. The Hand Gel

is specially formulated to provide fully

viricidal efficacy and excellent skin

compatibility with provitamin B5, aloe vera and

glycerol designed to protect the skin during

use.

With the development of this new range Redditch

Medical has added further investment into the

InSpec brand with new premises and filling

lines.

Sweden With No Lockdown Has Had Too Many Deaths

Sweden's controversial decision not to impose a

strict lockdown in response to the Covid-19

pandemic led to too many deaths, the man behind

the policy, Anders Tegnell, has acknowledged.

Sweden has seen a far higher mortality rate than

its nearest neighbors and its nationals are

being barred from crossing their borders.

Dr Tegnell told Swedish radio more should have

been done early on.

"There is quite obviously a potential for

improvement in what we have done."

Sweden has counted 4,542 deaths and 40,803

infections in a population of 10 million, while

Denmark, Norway and Finland have imposed

lockdowns and seen far lower rates.

Denmark has seen 580 deaths; Norway has had 237

deaths and Finland 321. Sweden reported a

further 74 deaths on Wednesday.

230,000 Healthcare Workers have Contracted COVID

More than 230,000 health workers around the

world have contracted the novel coronavirus

since the start of the global pandemic, while

over 600 nurses have died from it, according to

a new analysis by the International Council of

Nurses.

The figures show that an average of 7% of all

COVID-19 cases worldwide are among health care

workers.

The International Council of Nurses, which

represents more than 130 national nursing

associations with 20 million members worldwide,

said the analysis is based on data from its

associations, official figures and media reports

from a limited number of countries," since

"there is no systemic and standardized record"

of the global number of nurses and health care

workers who have tested positive for COVID-19 or

succumbed to the disease.

Fibre Extrusion Technology Says There May Be

Better Answers Than Polypropylene for Meltblowns

Fibre Extrusion Technology (FET), a UK-based

specialist in process solutions and equipment

for the manmade yarns and fiber extrusion

industry, has received unprecedented inquiries

about its nonwoven meltblowing systems since the

onset of the coronavirus crisis.

“We’re currently running trials, preparing

samples and defining specifications for

companies in Germany and Italy, as well as the

UK, and we could already have sold the lab line

we have here many times over,” said Managing

Director Richard Slack. “It’s primarily designed

for R&D and pilot scale applications, but trials

have proven it to be suitable for the low volume

production of critical meltblown face mask

materials. Some of the customers to whom we’ve

supplied similar lines have already pivoted

their production to this, which has generated

further interest.

“We feel, however, that we are ideally placed to

offer services to nonwoven companies who may be

exploring alternatives to polypropylene in

meltblown, due to our experience in working with

such a wide range of fiber types.”

FET’s meltblown system was originally developed

for companies looking to process high melt

viscosity medical grade resorbable polymers such

as polyglycolic acid (PGA), polylactic acid

(PLA) and polyhydroxl btyrate (PGH), mainly for

use in implantable products and other medical

devices.

The key applications for these fibers are in

hernia repair patches, staple reinforcement

buttresses, artificial skin, adhesion barriers

periodontal and ringival repair materials and

those for tendon and ligament repair.

“Our meltblowing system provides medical

companies and others dealing in such fibers with

a simpler processing route than other techniques

such as needle punching and a wide range of

structural and mechanical properties is

obtainable from batch production,” Slack said.

“There are also numerous options for

post-processing of the webs, by calendaring,

point bonding or lamination.”

Performance polymers such as TPU polyurethanes

and TPE thermoplastic elastomers are also

processed by a number of leading sportswear

companies on FET meltblown systems, while

engineering polymers such as ABS and PEEK, as

well as polycarbonate and halogenated polymers,

are other possible raw materials.

It is in the area of sustainable resins,

however, that FET believes much more can be

achieved.

Meltblown polypropylene nonwovens are the

critical component of the face masks needed for

Covid-19 frontline workers and their scarcity on

the open market has in part been the reason for

the reported shortages around the world.

An estimated 40 million face masks and other

disposable nonwoven-based PPE items are

currently estimated to be being consumed each

day, amounting to a daily 15,000-ton mountain of

waste — much of which must be incinerated.

“We’ve done a lot of work with sustainable

polyamides and polyesters, as well as with PHAs

and a range of of PLAs,” Slack says. “In the

longer term, there has to be a more sustainable

option than polypropylene in these products and

the opportunity to explore potential

alternatives — drawing on the know-how from the

extensive body of tests and trials we’ve carried

out in the past, as well as the machines run

commercially by our customers — is something I

believe makes us pretty unique in the services

we can offer nonwovens manufacturers.

Conventional meltblown and spunbonded systems

are usually designed for high capacity systems

and are not suitable for product development, he

adds.

“They consume high quantities of materials and

as a consequence are not suitable for

development work with high value materials or

for niche applications. They also rely on

specially formulated low viscosity polymers

which is a further limitation which does not

apply to us.

In processing finer filaments, FET has achieved

structures with average mean filament diameters

of 1.68 microns and 58% of between 0.5 to 1.5

microns, in web thicknesses of 37 microns with

bulk density of 98 mg/ml and porosity of around

92%.

FET’s system is designed for the processing of

pure polymer with no need for processing aids or

additives.

“A wide range of structural and mechanical

properties are obtainable, with numerous options

for post-processing of the web, such as by

calendaring, point bonding or lamination,”

Richard Slack concludes. “More effective and

sustainable PPE solutions could well be achieved

through further product development.”

NXTNano has Nanofiber Media Available for Face

Masks

A recent independent test by a mask supplier

showed high efficiency for media made by NXT

Nano. The company currently has some capacity

available for manufacturing N95 rated face mask

material. However they released this statement

“Please understand this situation is fluid, and

that as COVID-19 continues we expect this

capacity to fill”.

Materials are nanofiber coated PET in ranges

from 29 to 70 GSM depending on the needs of

individual manufacturing lines.

“As we continue to see very strong demand in nanofiber air filtration medias as well as our apparel, medical, and microfiltration business segments, we felt it was critical to keep capacity ahead of demand so our customers can continue to count on the fast order turns they have become accustomed to,” says director of sales Andrew McDowell.